A paint automatic mixing and spraying device

An automatic stirring and spraying device technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of spraying equipment blockage, paint solidification, uneven paint spraying, etc., and achieve the effect of avoiding solidification and improving spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

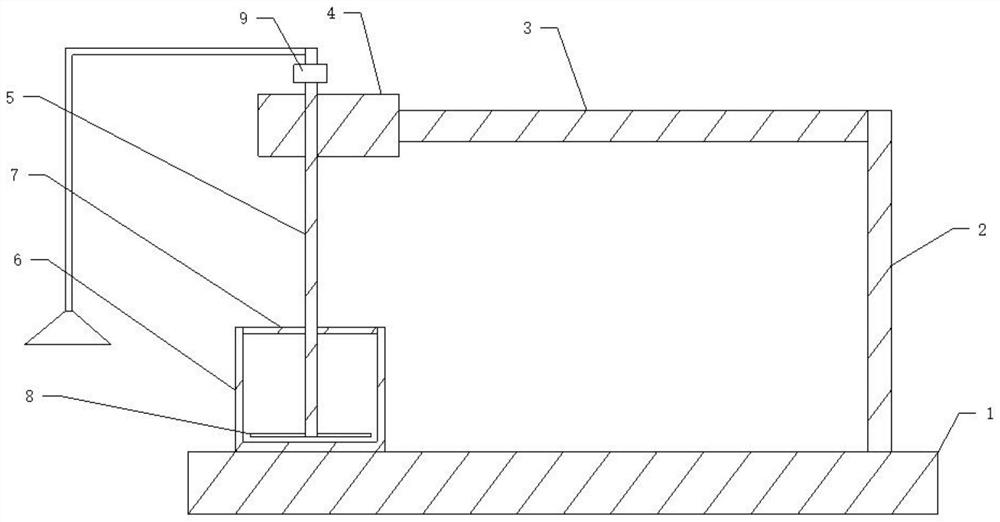

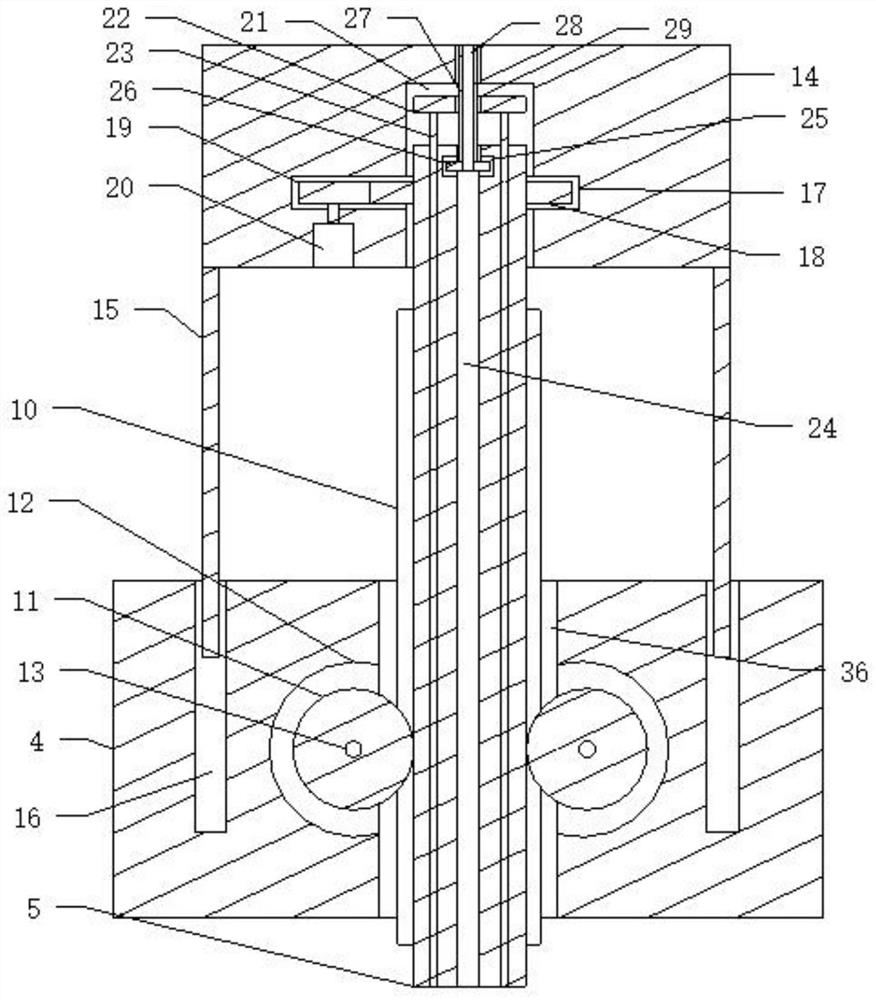

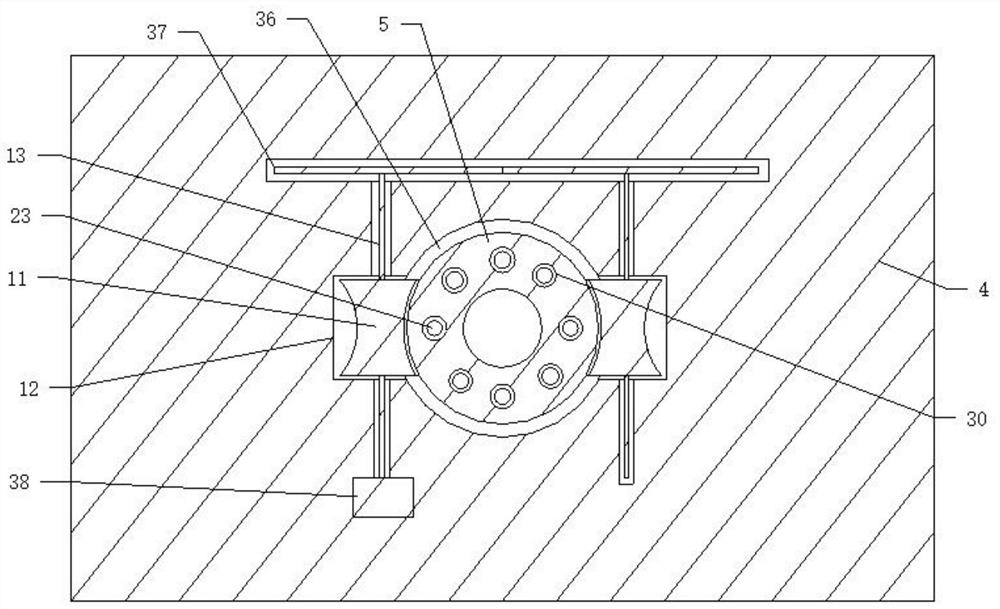

[0027] Such as Figure 1 to Figure 6As shown, a kind of automatic paint stirring and spraying device includes a fixed base 1, the fixed base 1 is provided with a paint bucket 6, the described paint bucket 6 is provided with a sealing cover 7, and the described fixed base 1 is provided with A first support 2, a second support 3 is connected to the first support 2, a first control module 4 is connected to the end of the second support 3, and a first control module 4 is provided with a Sliding lifting shaft 5, the first control module 4 is provided with a second motor 38 to control the sliding of the lifting shaft 5, the lifting shaft 5 slides in the paint bucket 6 after passing through the sealing cover 7, so The lifting shaft 5 is provided with a swinging stirring support 8, and the other end of the lifting shaft 5 is provided with a third control module 14 that slides on the first control module 4, and the lifting shaft 5 is positioned on the first control module 4. The third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com