Accurate arc-shaped plate single-side paint spraying device

A curved board and curved technology, which is applied in the field of precision curved board single-side painting device, can solve the problems of uneven dyeing and spraying, inability to adapt to curved boards, etc., and achieve the effects of avoiding inclination, easy operation, and auxiliary correction of boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

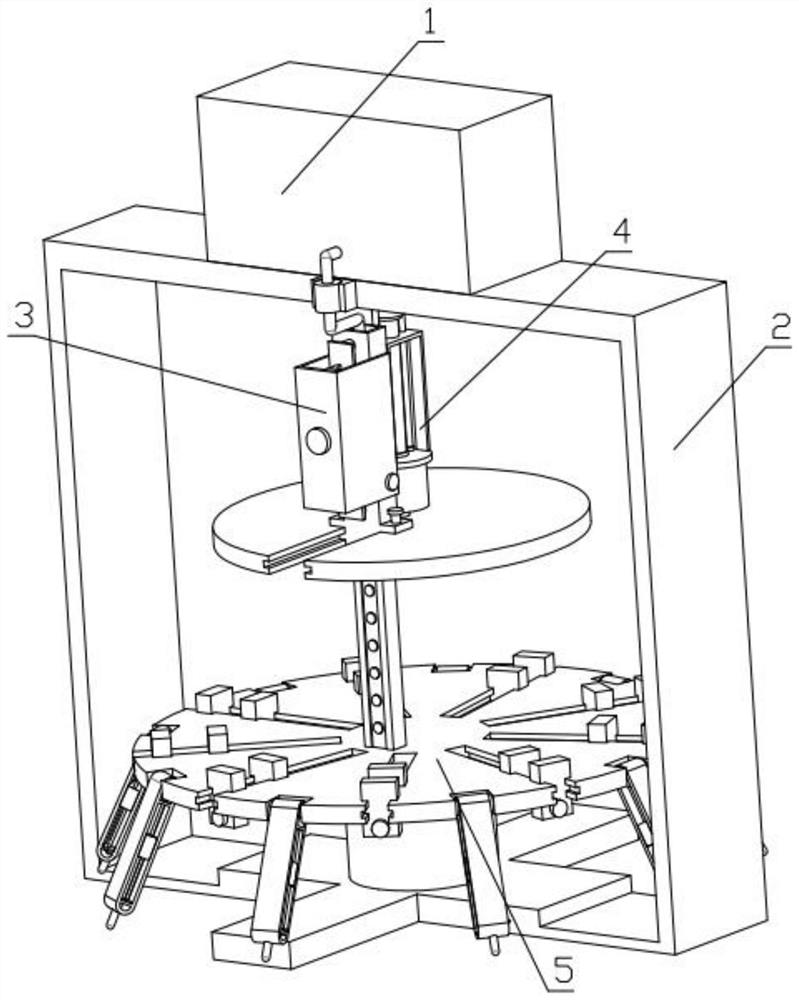

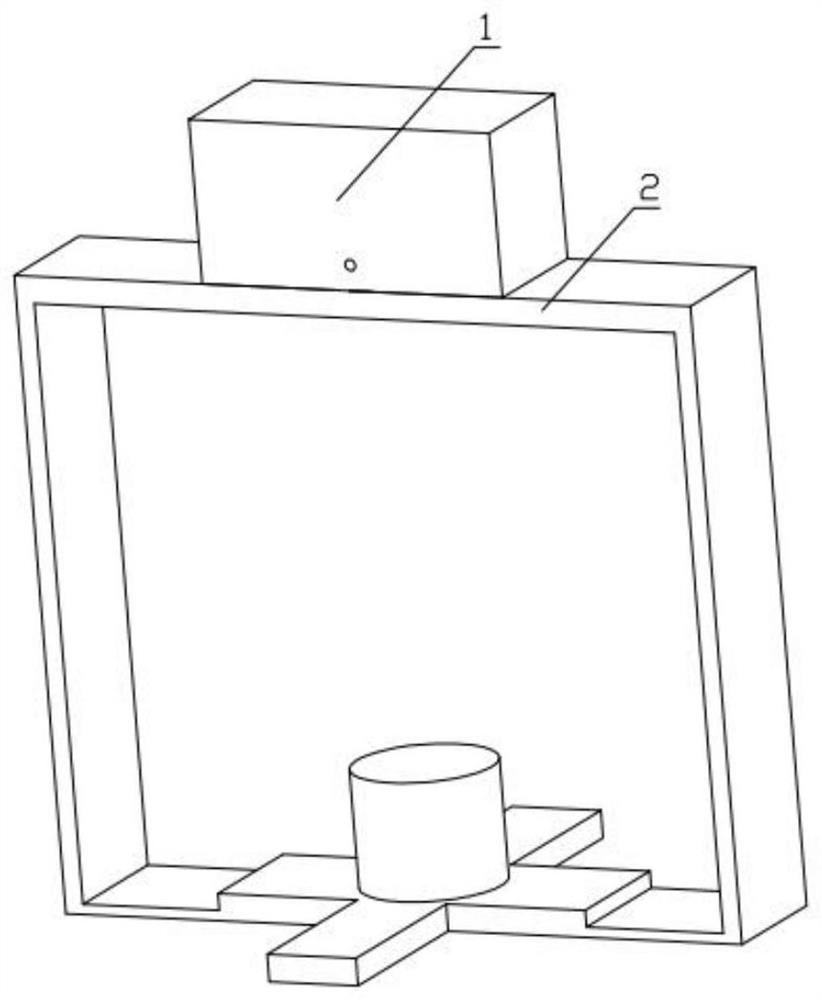

[0038] Combine below Figure 1-14 Describe this embodiment, a precise arc-shaped plate single-side painting device, including a material box 1, an installation frame 2, a spraying mechanism 3, an auxiliary displacement mechanism 4 and an arc-shaped plate positioning mechanism 5, and the material box 1 is fixedly installed on the On the installation frame 2, the arc-shaped plate positioning mechanism 5 is fixedly installed on the installation frame 2, the auxiliary displacement mechanism 4 is fixedly installed on the installation frame 2, the spraying mechanism 3 is slidably installed on the auxiliary displacement mechanism 4, the material box 1 and the spraying mechanism 3 Fixed connection.

specific Embodiment approach 2

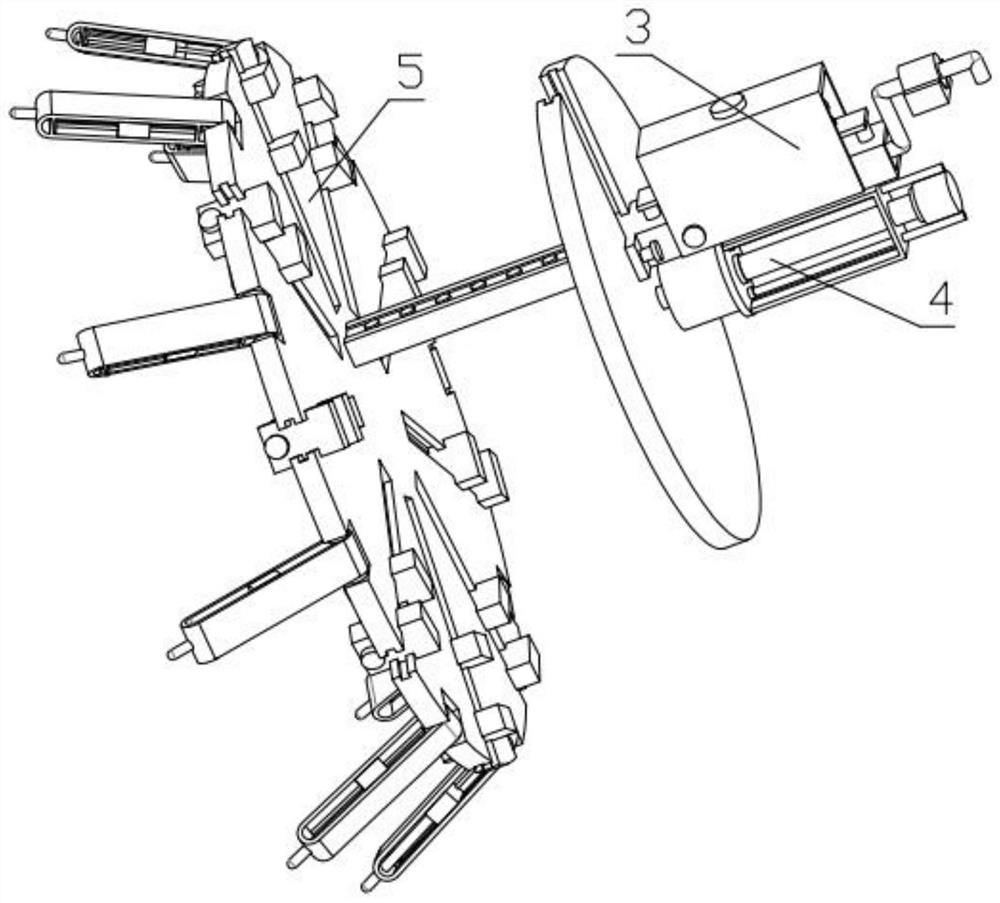

[0040] Combine below Figure 1-14Describe this embodiment, this embodiment will further explain the first embodiment, the spraying mechanism 3 includes a feed pipe 3-1, a material pump 3-2, a pump base 3-3, a discharge pipe 3-4, a sliding square Cylinder 3-5, pull plate 3-6, pull rod 3-7, shell 3-8, side set screw 3-9, bottom set screw 3-10, spray barrel 3-11, nozzle 3-12, rubber column 3-13, support spring 3-14, one end of the feeding pipe 3-1 is fixedly installed on the discharge port of the material box 1, and the other end of the feeding pipe 3-1 is fixedly installed on the material pump 3-2, and the material pump 3-2 is fixedly installed on the pump base 3-3, the pump base 3-3 is fixedly installed on the installation frame 2, the discharge pipe 3-4 is fixedly installed on the material pump 3-2, and the other part of the discharge pipe 3-4 One end is fixedly installed on the spray tube 3-11, and a plurality of spray heads 3-12 are evenly installed on the spray tube 3-11, ...

specific Embodiment approach 3

[0042] Combine below Figure 1-14 Describe the present embodiment, this embodiment will further explain the second embodiment, the auxiliary displacement mechanism 4 includes a motor 4-1, a limit rod 4-2, a threaded rod 4-3, a U-shaped plate 4-4, Connecting circular plate 4-5, motor two 4-6, rotating disk 4-7, motor one 4-1 is fixedly installed on the installation frame 2, limit rod 4-2 is fixedly installed on the installation frame 2, motor one 4 The output end of -1 is fixedly installed with threaded rod 4-3, threaded rod 4-3 is threadedly connected with U-shaped plate 4-4, U-shaped plate 4-4 is slidably installed on the limit rod 4-2, U-shaped plate 4 -4 is fixedly connected with the connection circular plate 4-5, the motor two 4-6 is fixedly installed on the connection circular plate 4-5, the output end of the motor two 4-6 is fixedly installed with a rotating disk 4-7, and a sliding square cylinder 3 -5 is slidably installed in the groove provided on the rotating disc 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com