Boiler flue gas desulfurization and denitrification device

A technology for desulfurization and denitrification and boiler flue gas, which is applied in the direction of combination device, transportation and packaging, separation method, etc., can solve the problems that the flue gas desulfurization and denitrification cannot achieve the washing effect, and cannot spray a large area of the washing liquid, and achieves good results. , strong practicability, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

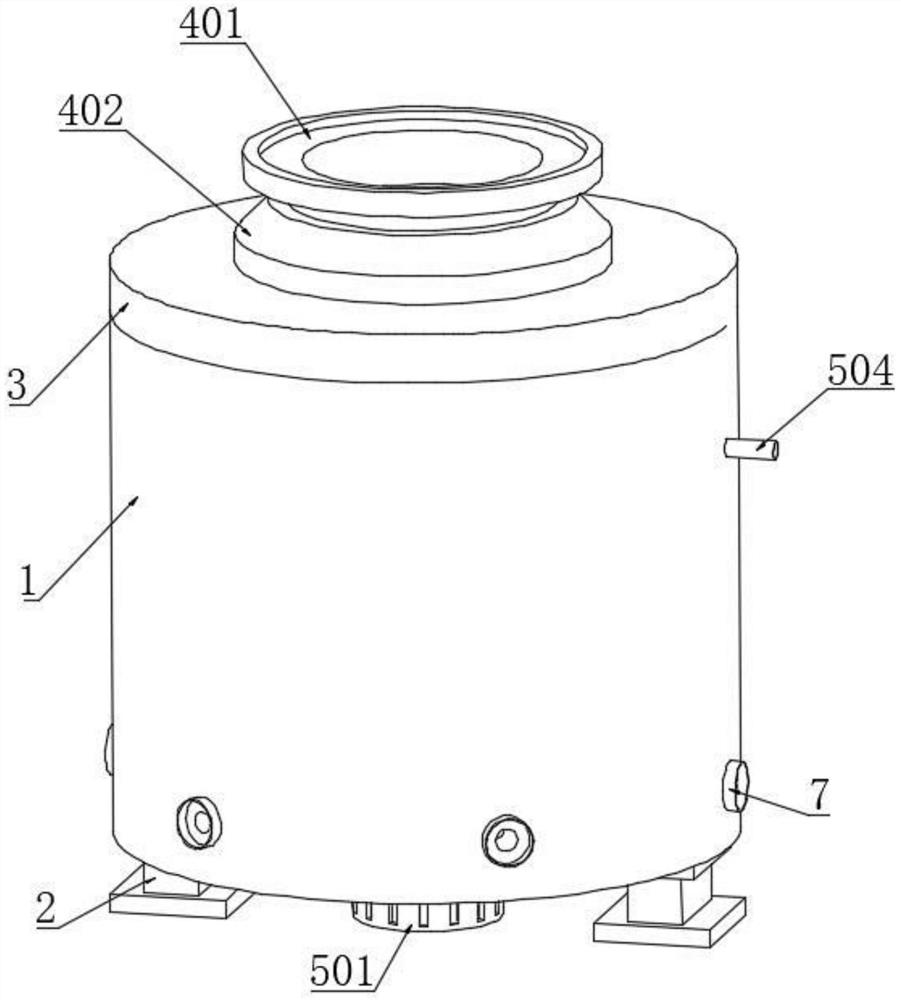

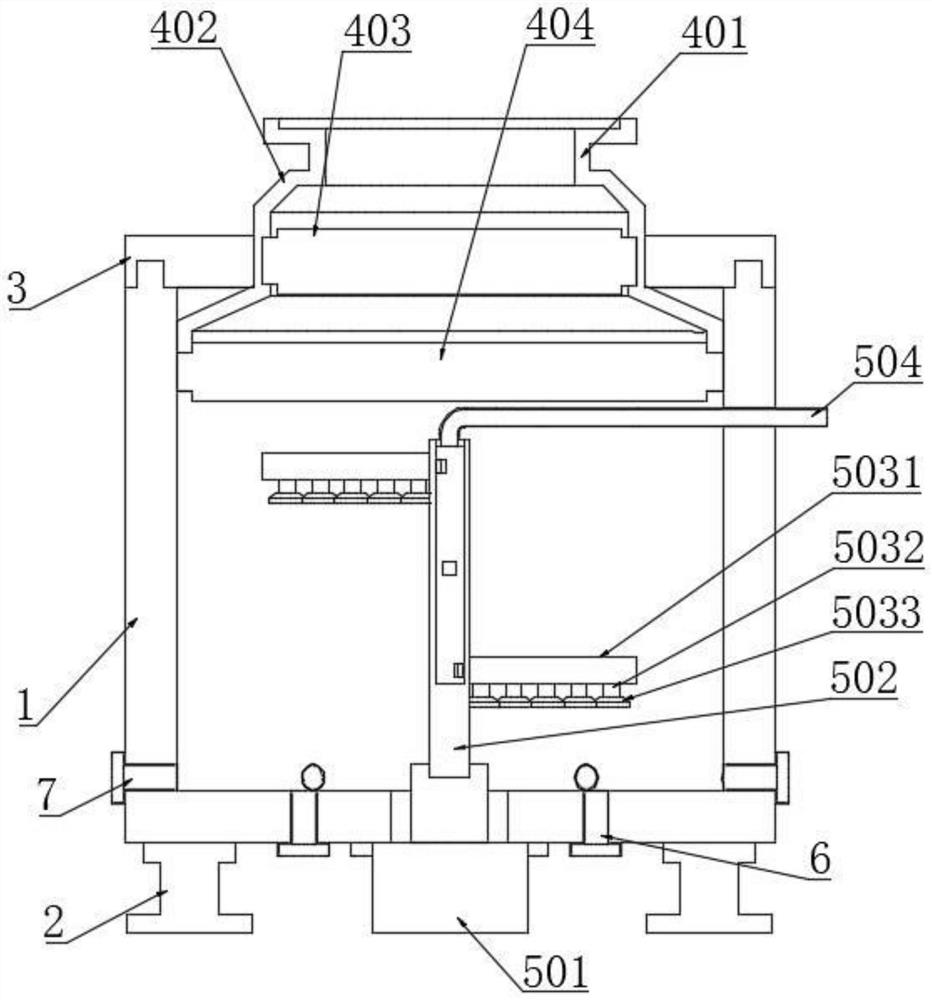

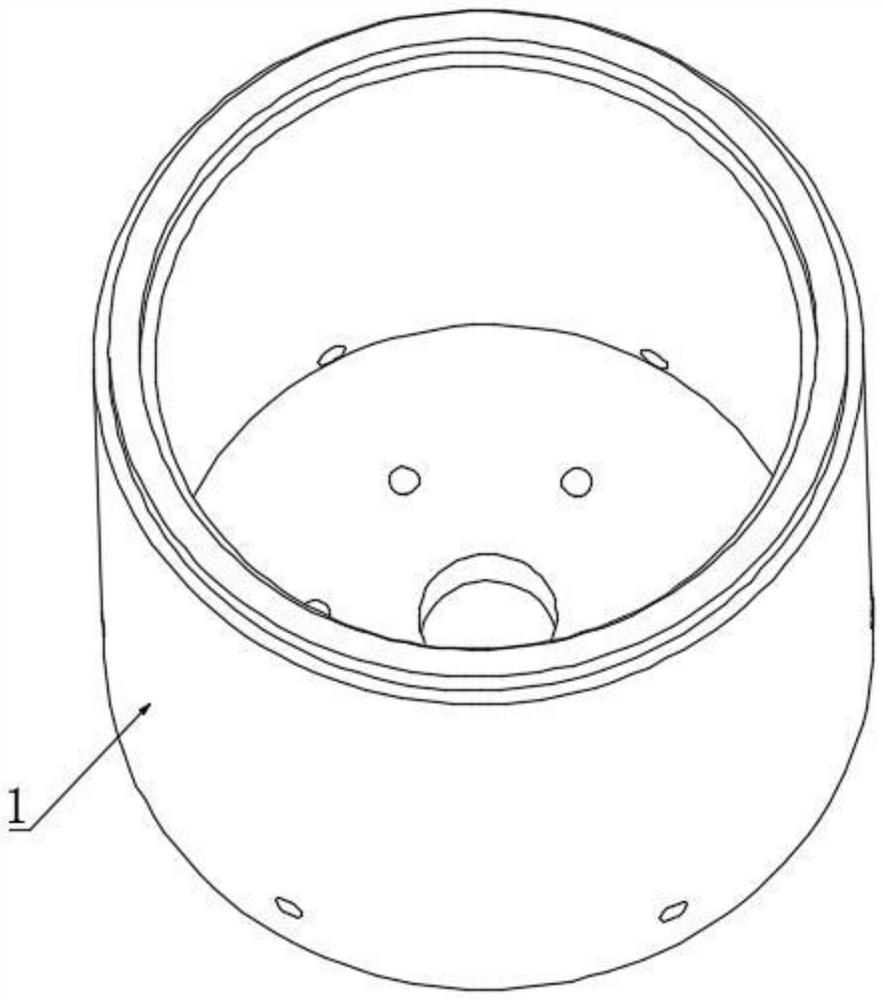

[0038] see Figure 1-7 , a boiler flue gas desulfurization and denitrification device, comprising a cylinder body 1, and also comprising:

[0039] Top cover 3: The top cover 3 is detachably installed on the upper end face of the cylinder body 1; the internal sealing effect of the cylinder body 1 can be ensured by setting the top cover 3, and under the action of the top cover 3, the installation stability of the entire filter mechanism 4 can be ensured Therefore, it will not affect the actual filtering effect and the quality of filtering, with strong practicability and good use effect.

[0040] Filter mechanism 4: The filter mechanism 4 is installed inside the top cover 3, and the lower end of the filter mechanism 4 extends to the inside of the cylinder body 1; by setting the filter mechanism 4, the purpose of filtering the gas for desulfurization and denitrification can be achieved, which effectively improves the device practicability and use effect.

[0041] Spraying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com