Spraying component and leachate reflux system for dry anaerobic fermentation formed by spraying component

A technology of leachate and components, applied in the field of sprinkler heads, can solve problems such as easy blockage of sprinkler heads, and achieve the effects of diversion and dispersion, equipment cost saving, and uniformity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

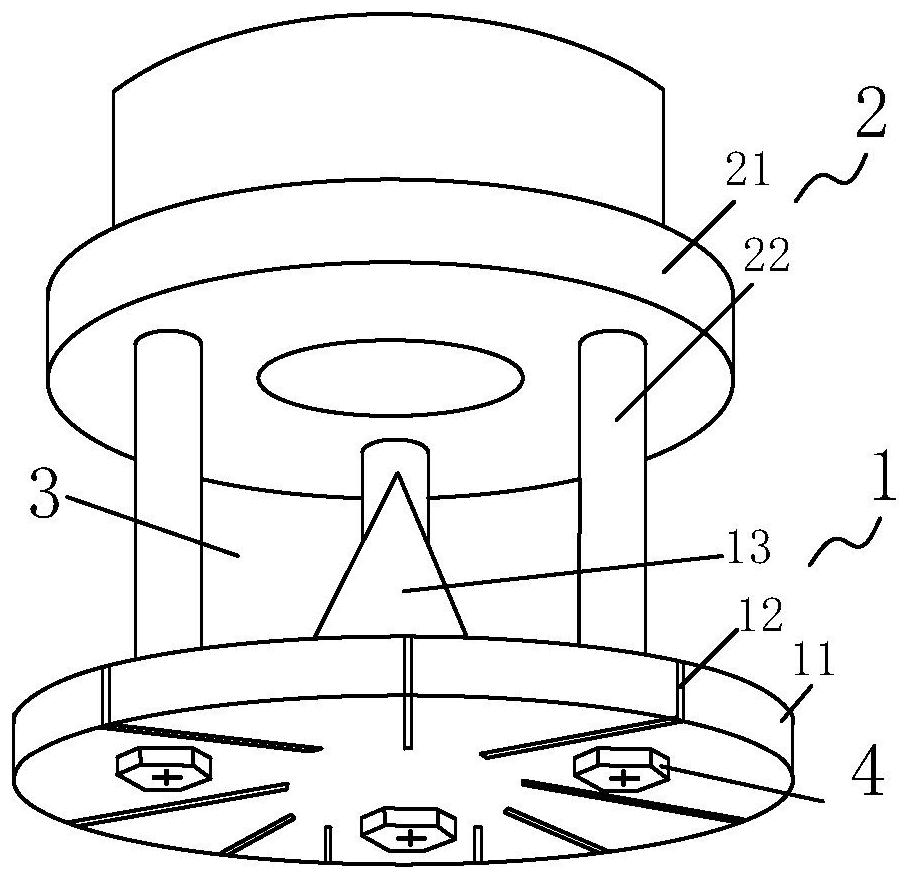

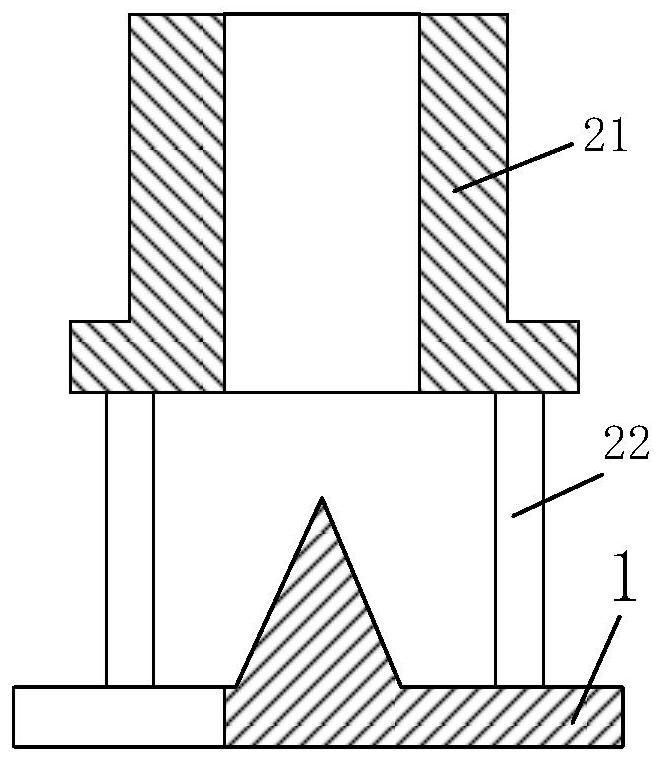

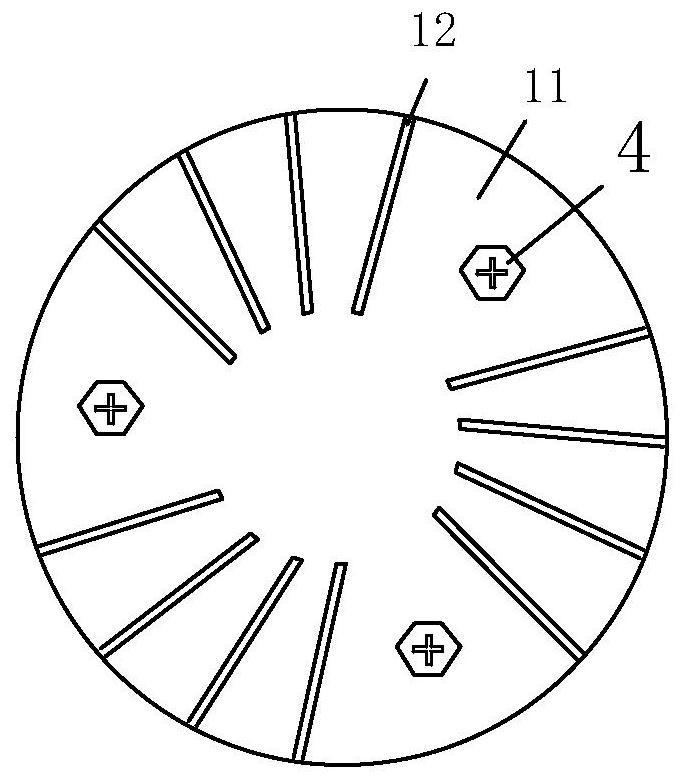

[0049] A sprinkler unit such as Figure 1-Figure 3 As shown, it includes a spray plate 1 and a connecting piece 2, wherein the spraying plate 1 includes a plate body 11 and a dispersion water channel 12 passing through the plate body 11; the connecting piece 2 is used to connect the plate body 11 to the water outlet; the connection The part 2 is provided with a large particle discharge port 3 located between the disc body 11 and the water outlet.

[0050] Through the optimal setting of the above-mentioned disc body and dispersed water channel structure, the liquid discharged from the water outlet can be effectively shunted, and then the purpose of liquid spraying can be realized; at the same time, the connecting piece can not only effectively realize the connection between the disc body and the water outlet, Moreover, the large particle discharge port provided on it can also discharge the large solid particles through the large particle discharge port when there are large soli...

Embodiment 2

[0059] A leachate reflux system for dry anaerobic fermentation, comprising a reflux system body, the water outlet of the reflux system body is provided with the spraying part described in Example 1. In this setting mode, the filter structure in the backflow system body, such as the filter tank, can be effectively omitted, and the leachate from dry anaerobic fermentation can be directly pumped into the spraying part through the pump to save filtration equipment costs while improving cycle efficiency.

[0060] Specifically, the return system body includes: a spray pipeline 5 , the spray components described in Embodiment 1, an outlet pipeline 6 and a return pump 8 . Wherein, one end of the spray pipeline 5 extends into the anaerobic fermentation tank 4, and the spray component is installed on the water outlet of the spray pipeline 5; Connected, and then effectively pump the leachate drawn out of the lead-out line 6 into the spray line 5, and then spray back into the anaerobic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com