Robot for construction site construction management

A technology for construction management and construction sites, applied in construction, chemical instruments and methods, and the use of liquid separating agents, etc., can solve problems such as hazards and large dust, and achieve the effects of reducing physical damage and suppressing the content of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

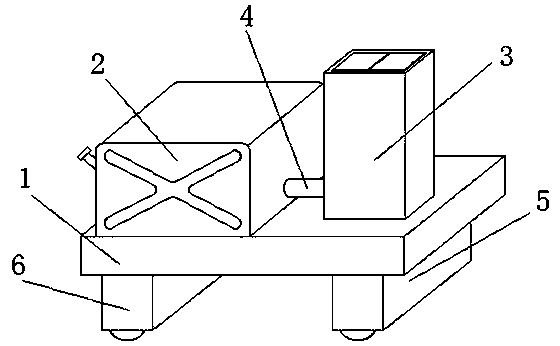

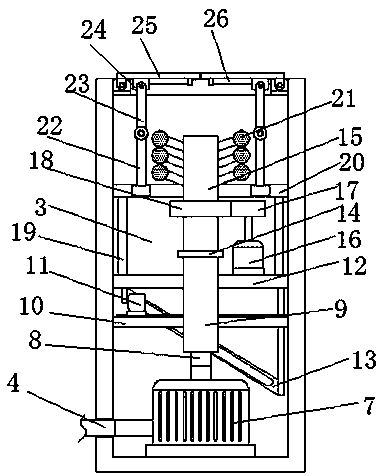

[0030] refer to Figure 1-6 In this embodiment, a robot for construction management on a construction site is proposed, which includes a base 1, a mounting cover 5 and a driving cover 6 are respectively fixedly installed on the bottom of the base 1, and two first wheels 33 are connected symmetrically in the mounting cover 5 , and the bottom ends of the two first wheels 33 all extend to the bottom of the installation cover 5, and the drive cover 6 is connected with two second wheels 45 for symmetrical rotation, and the bottom ends of the two second wheels 45 all extend to the drive cover 6, a water tank 2 and an installation box 3 are fixedly installed on the top of the base 1 respectively, and the installation box 3 is located on one side of the water tank 2, and a water pump 7 is fixedly installed on the inner wall of the bottom of the installation box 3, and the suction end of the water pump 7 is fixedly installed There is a connecting pipe 4, one end of the connecting pipe ...

Embodiment 2

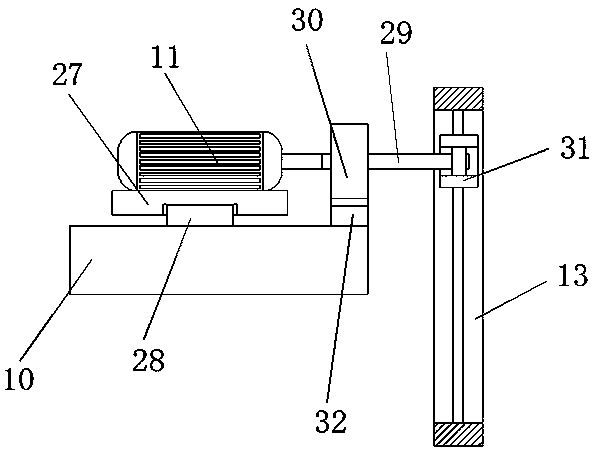

[0033] In this embodiment, a lifting plate 12 is fixedly installed on the moving tube 9, and the lifting plate 12 is slidably connected with the inner wall of the installation box 3. The bottom of the lifting plate 12 is fixedly installed with a connecting ring 13 that is arranged obliquely, and the connecting ring 13 is mounted on the box. The inwall of 3 is slidably connected with drive motor 11 positioned at lift plate 12 below, and the output shaft of drive motor 11 is connected with link ring 13 transmission, utilizes the inclined installation of link ring 13, can facilitate lift plate 12 longitudinal movement.

[0034] In this embodiment, the installation beam 10 located below the lifting plate 12 is fixedly installed on the inner wall of the installation box 3, and the drive motor 11 is slidably installed on the top of the installation beam 10, and a rotating shaft 29 is fixedly installed on the output shaft of the drive motor 11. The inner wall of connecting ring 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com