Preparation method of organically modified graphene with core-shell structure, anticorrosive powder coating and preparation method of anticorrosive powder coating

A technology of core-shell structure and powder coatings, which is applied in anti-corrosion coatings, polyester coatings, dyeing polymer organic compound treatment, etc., can solve the problem of reducing the mechanical properties of graphene powder coating anti-corrosion agents, graphene cannot be tiled, and does not take into account Graphene secondary arrangement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

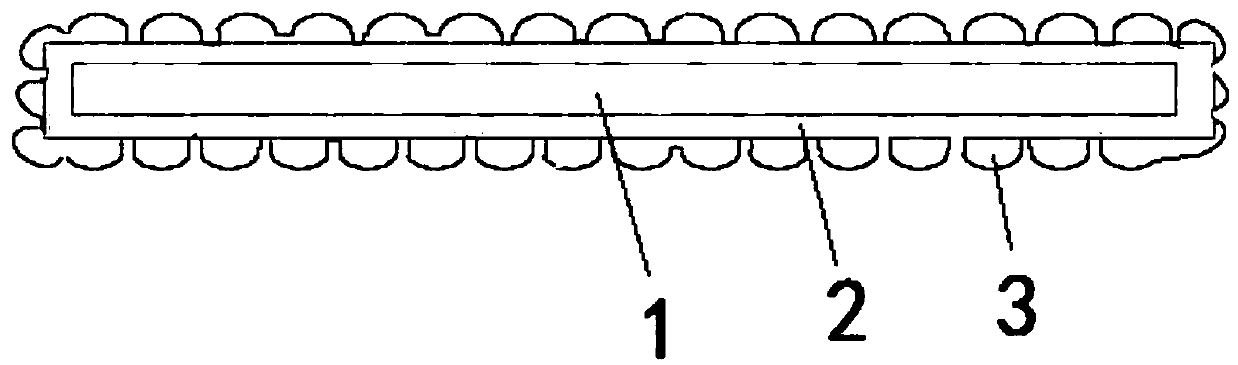

Image

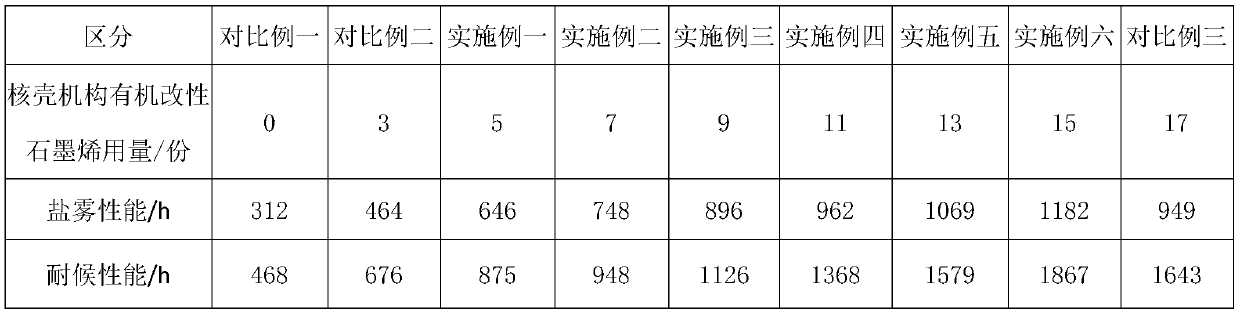

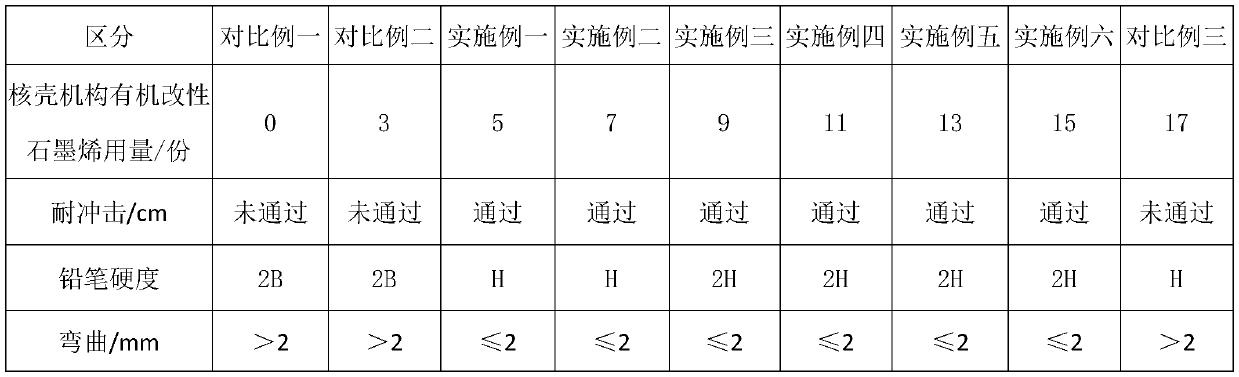

Examples

Embodiment 1

[0043] A kind of anticorrosion powder coating, the mass fraction of the component that it comprises and each component are as follows:

[0044] Polyester resin: 50 parts,

[0045] Curing agent: 3.8 parts;

[0046] Organically modified graphene with core-shell structure: 5 parts;

[0047] Titanium dioxide: 15 parts;

[0048] Barium sulfate: 22.2 parts;

[0049] Benzoin: 2 parts;

[0050] Brightener: 2 parts;

[0051] Leveling agent: 2 parts.

[0052] Specifically, the polyester resin is an unsaturated polyester resin, which is a film former; the curing agent chemically reacts with the terminal acid groups of the polyester, thereby improving the physical and chemical properties of the coating; the barium sulfate acts as a The use of fillers reduces costs and increases certain physical and chemical properties; the benzoin is used as a defoamer; the brightener is used as an anti-interference agent; the titanium dioxide is used as a pigment to improve the hiding power of the ...

Embodiment 2

[0068] A kind of anticorrosion powder coating, the mass fraction of the component that it comprises and each component are as follows:

[0069] Polyester resin: 50 parts,

[0070] Curing agent: 3.8 parts;

[0071] Organically modified graphene with core-shell structure: 7 parts;

[0072] Titanium dioxide: 15 parts;

[0073] Barium sulfate: 22.2 parts;

[0074] Benzoin: 2 parts;

[0075] Brightener: 2 parts;

[0076] Leveling agent: 2 parts.

[0077] Specifically, the polyester resin is an unsaturated polyester resin, which is a film former; the curing agent chemically reacts with the terminal acid groups of the polyester, thereby improving the physical and chemical properties of the coating; the barium sulfate acts as a The use of fillers reduces costs and increases certain physical and chemical properties; the benzoin is used as a defoamer; the brightener is used as an anti-interference agent; the titanium dioxide is used as a pigment to improve the hiding power of the ...

Embodiment 3

[0093] A kind of anticorrosion powder coating, the mass fraction of the component that it comprises and each component are as follows:

[0094] Polyester resin: 50 parts,

[0095] Curing agent: 3.8 parts;

[0096] Organically modified graphene with core-shell structure: 9 parts;

[0097] Titanium dioxide: 15 parts;

[0098] Barium sulfate: 22.2 parts;

[0099] Benzoin: 2 parts;

[0100] Brightener: 2 parts;

[0101] Leveling agent: 2 parts.

[0102] Specifically, the polyester resin is an unsaturated polyester resin, which is a film former; the curing agent chemically reacts with the terminal acid groups of the polyester, thereby improving the physical and chemical properties of the coating; the barium sulfate acts as a The use of fillers reduces costs and increases certain physical and chemical properties; the benzoin is used as a defoamer; the brightener is used as an anti-interference agent; the titanium dioxide is used as a pigment to improve the hiding power of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com