Improved wheel powder spraying line and technology

A powder spraying and wheel technology, which is applied in spray booths, spraying devices, liquid spraying equipment, etc., can solve the problems of long switching time of process materials, affecting product quality, and large space occupation, so as to reduce equipment investment and shorten recycling pipelines , The effect of the system occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

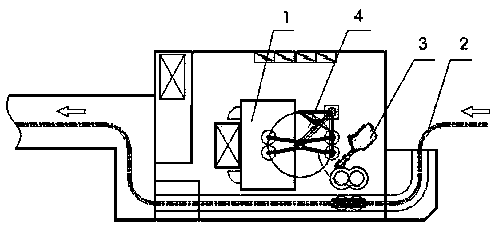

[0016] A wheel powder spraying line, including a powder spraying room 1, a conveying line 2, the conveying line 2 is arranged outside the powder spraying room 1, a robot 3 and a turntable 4 are arranged between the powder spraying room 1 and the conveying line 2, and the robot 1 grabs wheels , The turntable 4 sends the wheels to the powder spraying room 1 and turns the wheels after powder spraying out of the powder spraying room 1.

[0017]

[0018] A wheel powder spraying process, the process flow is: workpiece parameter storage-workpiece identification-entering the powder spraying isolation room-workpiece moving away from the conveyor line-workpiece transferred to the powder spraying room-workpiece spraying-flying powder is recycled into the supply The powder equipment is recycled-the powder spraying is completed-the workpiece is transferred out-the workpiece is transferred to the workpiece cleaning station-the workpiece assembly position is powder cleaning-the turntable powder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com