PA/ABS alloy powder coating and preparation method thereof

A technology of alloy powder and coating, which is applied in the direction of powder coating, polyamide coating, coating, etc., can solve the problems affecting the application of polyamide resin powder coating, low notch impact toughness, notch sensitivity, etc., achieve excellent powder coating rate, improve Notched impact toughness, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0029] The present invention will be described in detail below in conjunction with examples.

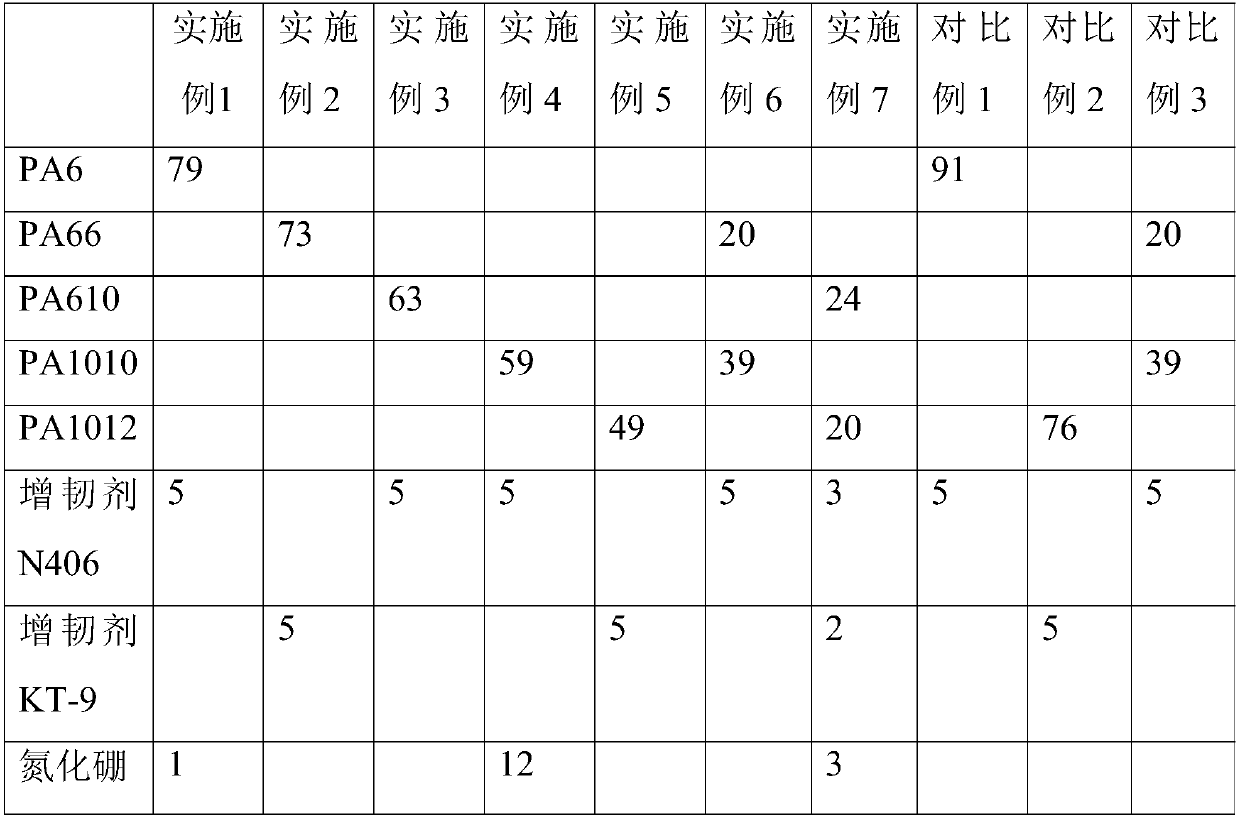

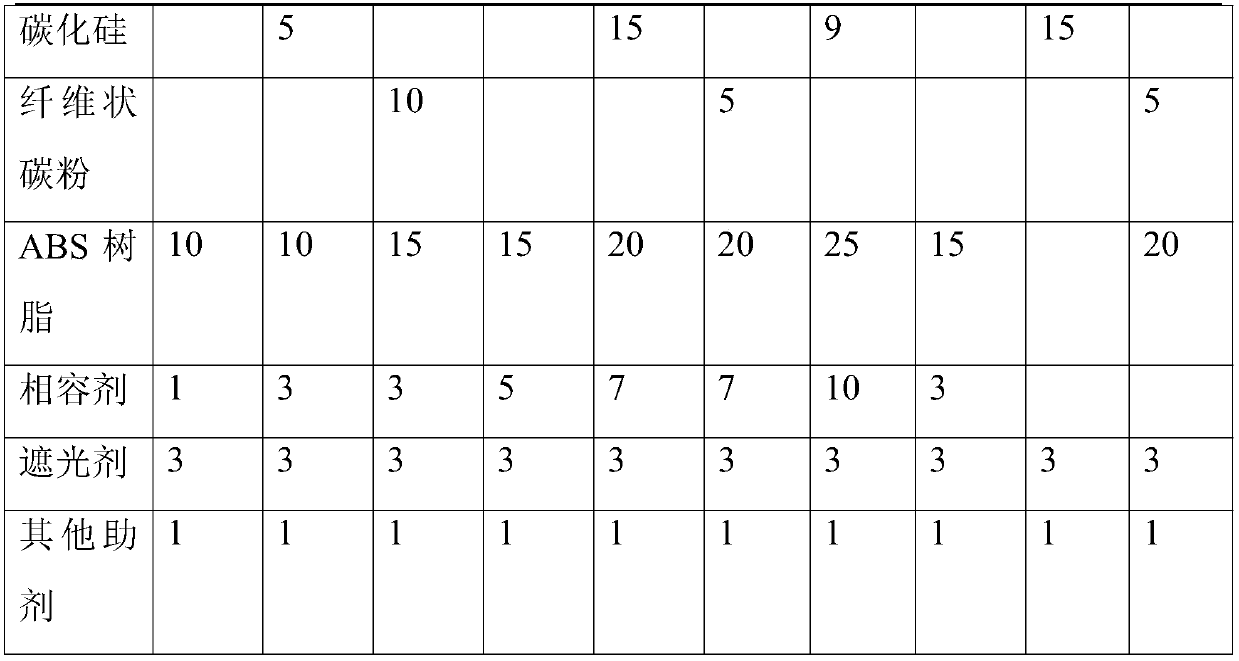

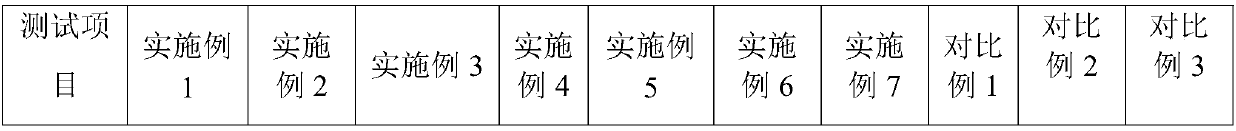

[0030] Examples 1-7 and Comparative Examples 1-3 include the composition and content of raw materials in Table 1 below. The unit in the table is Kg.

[0031] The opacifying agent is selected titanium dioxide, R902, American DuPont Company.

[0032] The auxiliary agent is antioxidant, RIANOX 1098 Tianjin Lianlong;

[0033] Boron nitride, hexagonal crystal, average particle size 50nm;

[0034] Silicon carbide, α-silicon carbide crystal form, average particle size 50nm;

[0035] Fibrous car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com