A kind of preparation method of glass fiber reinforced polycarbonate thermoplastic resin composite material for rapier loom

A technology of thermoplastic resin and polycarbonate, which is applied in the field of textile machinery parts, can solve the problems of low impact strength, short service life, easy cracking, etc., achieve good thermal deformation temperature, good wear resistance, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of glass fiber reinforced polycarbonate thermoplastic resin composite material prepares the preparation method of rapier loom rapier, and its steps are as follows,

[0022] (1) Extruding the dried polycarbonate thermoplastic resin through a single-screw extruder to obtain a molten material; the drying treatment is blast drying at 120° C. for 5 hours;

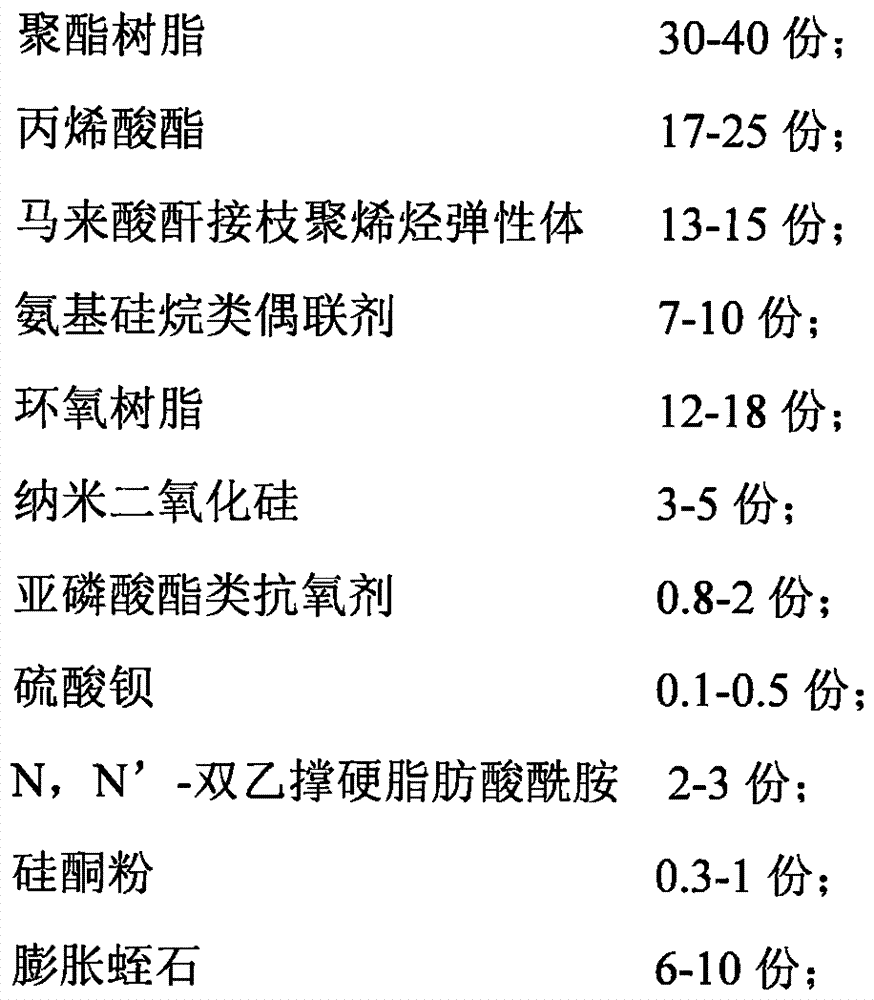

[0023] (2) impregnating the surface of glass fiber strands with a sizing agent, and obtaining modified glass fiber chopped strands through wire drawing, chopping and drying; wherein, the sizing agent is composed of the following raw materials in parts by weight:

[0024]

[0025]

[0026] (3) The polycarbonate melt obtained in step (1) is blended with the glass fiber chopped strands after the coating modification treatment through a twin-screw extruder, and the weight ratio of the glass fiber and polycarbonate 10:90; then granulated to obtain glass fiber reinforced polycarbonate thermoplastic resin pellets, w...

Embodiment 2

[0029] A kind of glass fiber reinforced polycarbonate thermoplastic resin composite material prepares the preparation method of rapier loom rapier, it is characterized in that, its steps are as follows,

[0030] (1) extruding the dried polycarbonate thermoplastic resin through a single-screw extruder to obtain a molten material; the drying treatment is blast drying at 140° C. for 3 hours;

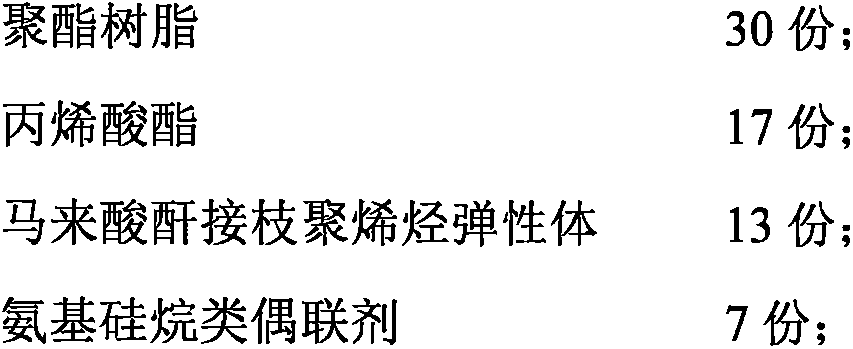

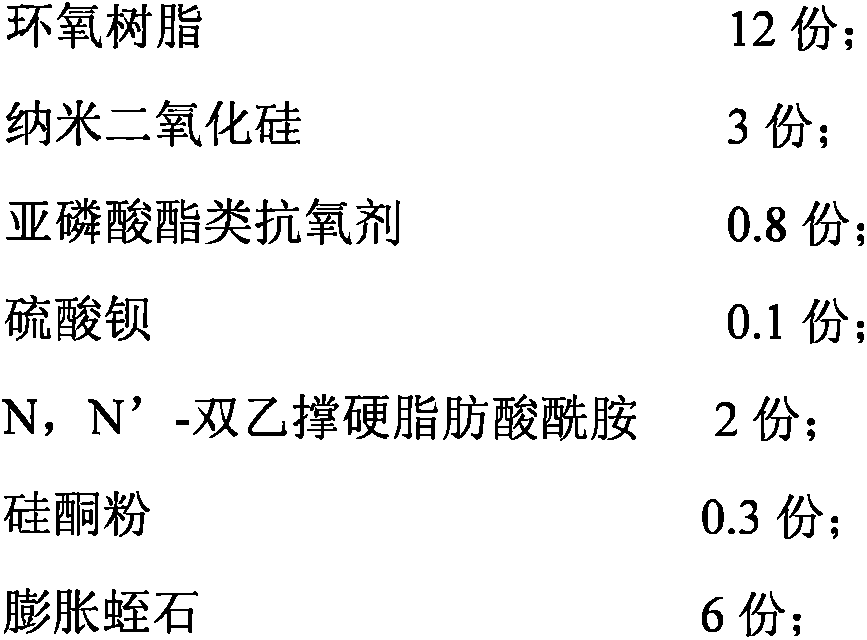

[0031] (2) impregnating the surface of glass fiber strands with a sizing agent, and obtaining modified glass fiber chopped strands through wire drawing, chopping and drying; wherein, the sizing agent is composed of the following raw materials in parts by weight:

[0032]

[0033]

[0034] (3) The polycarbonate melt obtained in step (1) is blended with the glass fiber chopped strands after the coating modification treatment through a twin-screw extruder, and the weight ratio of the glass fiber and polycarbonate 18:82; then granulated to obtain glass fiber reinforced polycarbonate therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com