Special anticorrosive powder coating for high-decorativeness pure polyester aluminum section and preparation method of powder coating

A polyester aluminum profile, powder coating technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., to improve the poor leveling of the paint film, improve the appearance smoothness of the paint film, and improve the effect of particle problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

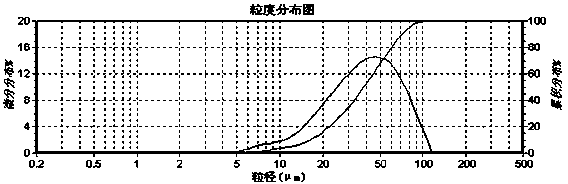

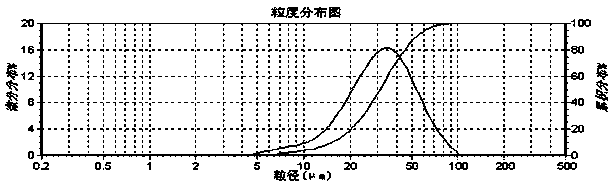

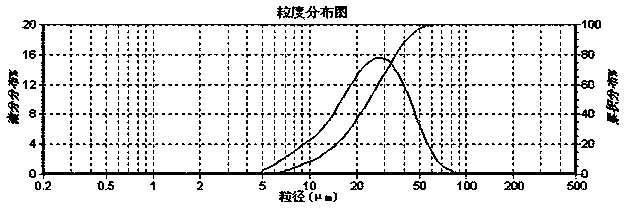

Image

Examples

Embodiment 1

[0034] The ratio of raw materials is as follows: 44kg of carboxyl-terminated polyester resin A, 4kg of carboxyl-terminated polyester resin C, 3.8kg of triglycidyl isocyanurate, 18.5kg of titanium dioxide, 27kg of ultrafine barium sulfate, 0.8kg of charging agent, dry powder 0.5kg of flow aid, 0.6kg of benzophenone ketone, 1.2kg of polyacrylate and 0.6kg of acrylate copolymer; among them, the acid value of carboxyl-terminated polyester resin A is 32-38mgKOH / g, and the softening point is 115-120°C The glass transition temperature is 57-60°C; the acid value of carboxyl-terminated polyester resin C is 30-35mgKOH / g, the softening point is 105-120°C, and the glass transition temperature is 55-60°C.

[0035] The epoxy value of triglycidyl isocyanurate is 0.9257-0.96, the epoxy equivalent is 100 / g, and the average equivalent E is 105. The average particle size of ultra-fine barium sulfate is 1.09, the whiteness is ≥90, and the oil absorption is 16, of which BaSO 4 The content is 97.6...

Embodiment 2

[0041] The ratio of raw materials is as follows: 43.2kg of carboxyl-terminated polyester resin A, 4.5kg of carboxyl-terminated polyester resin C, 3.6kg of triglycidyl isocyanurate, 18.3kg of titanium dioxide, 26.3kg of ultrafine barium sulfate, and 0.49 kg of charging agent kg, dry powder flow aid 0.29kg, benzoethanol ketone 0.49kg, polyacrylate 1.17kg and acrylate copolymer 0.49kg; among them, the acid value of carboxyl-terminated polyester resin A is 32-38mgKOH / g, and the softening point is 115 -120°C glass transition temperature 57-60°C; acid value of carboxyl-terminated polyester resin C 30-35mgKOH / g, softening point 105-120°C glass transition temperature 55-60°C.

[0042] The epoxy value of triglycidyl isocyanurate is 0.9257-0.96, the epoxy equivalent is 100 / g, and the average equivalent E is 105. Ultrafine barium sulfate D has an average particle size of 1.09, whiteness ≥ 90, and oil absorption of 16, of which BaSO 4The content is 97.65%.

[0043] The preparation proce...

Embodiment 3

[0048] The ratio of raw materials is as follows: 43.5kg of carboxyl-terminated polyester resin A, 4.5kg of carboxyl-terminated polyester resin C, 3.5kg of triglycidyl isocyanurate, 18.3kg of titanium dioxide, 26.5kg of ultrafine barium sulfate, and 0.6 kg, 0.4kg of dry powder flow aid, 0.55kg of benzophenone ketone, 1.0kg of polyacrylate and 0.55kg of acrylic copolymer; among them, the acid value of carboxyl-terminated polyester resin A is 32-38mgKOH / g, and the softening point is 115 -120°C glass transition temperature 57-60°C; acid value of carboxyl-terminated polyester resin C 30-35mgKOH / g, softening point 105-120°C glass transition temperature 55-60°C.

[0049] The epoxy value of triglycidyl isocyanurate is 0.9257-0.96, the epoxy equivalent is 100 / g, and the average equivalent E is 105. The average particle size of ultra-fine barium sulfate is 7.16, the whiteness is 91.5, and the oil absorption is 11, of which BaSO 4 The content is 97.15%.

[0050] The preparation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com