Graphene transparent powder coating for tribo gun to spray MDF plate

A powder coating and graphene technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problem of missing carbon atoms in graphene, and achieve the effect of cost reduction and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

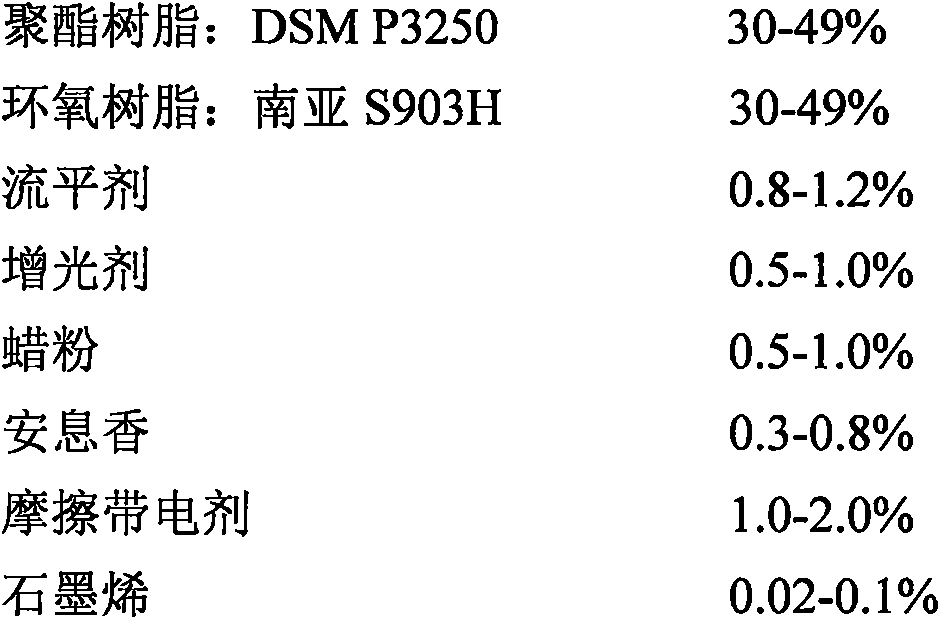

[0028] A kind of graphene transparent powder coating of friction gun spraying MDF board is made from the raw material of following percentage by weight:

[0029] Polyester resin / epoxy resin=5:5

[0030]

[0031] Preparation process: The above raw materials are weighed, mixed, extruded, crushed, ground, graded and sieved according to the weight percentage of each component to obtain a transparent powder coating, and the MDF is friction sprayed, and put into an infrared oven at 150°C for 15 minutes to cure , Form a coating of 80-100μm, just take out the MDF.

Embodiment 2

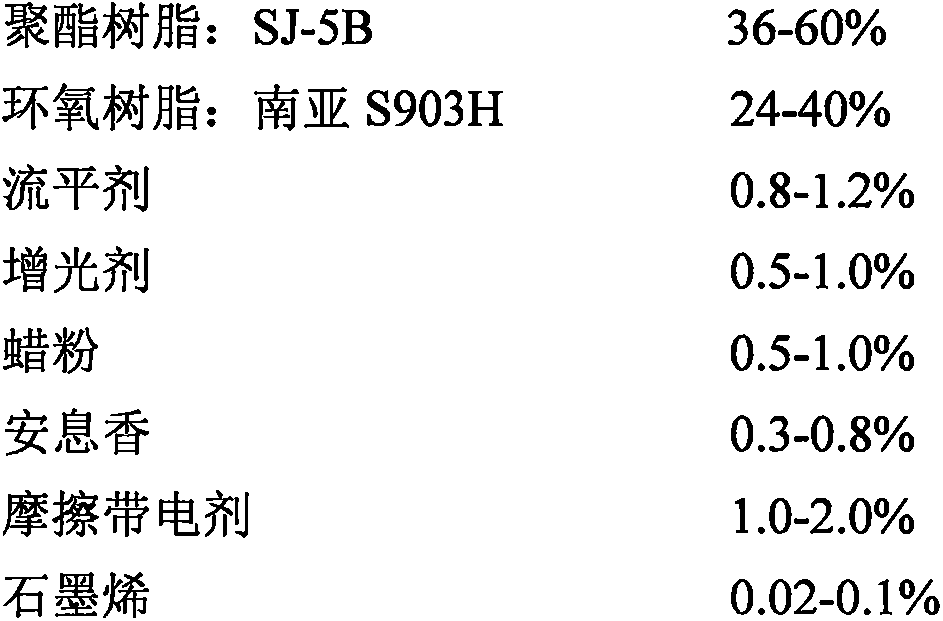

[0033] The graphene transparent powder coating that friction gun spraying described in the present embodiment is sprayed on MDF is made by following component and component weight percent:

[0034] Polyester resin / epoxy resin=5:5

[0035]

[0036]

[0037] The preparation process is the same as in Example 1.

Embodiment 3

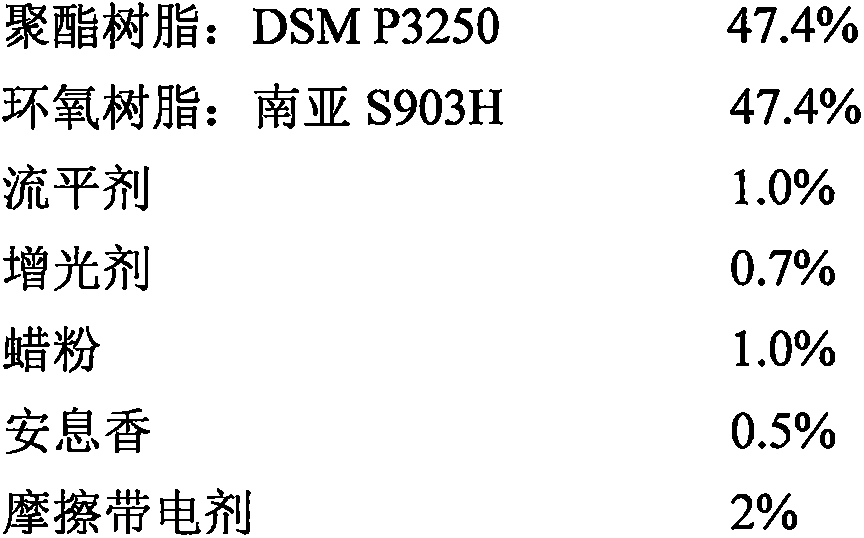

[0039] The graphene transparent powder coating that friction gun spraying described in the present embodiment is sprayed on MDF is made by following component and component weight percent:

[0040] Polyester resin / epoxy resin=5:5

[0041]

[0042] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com