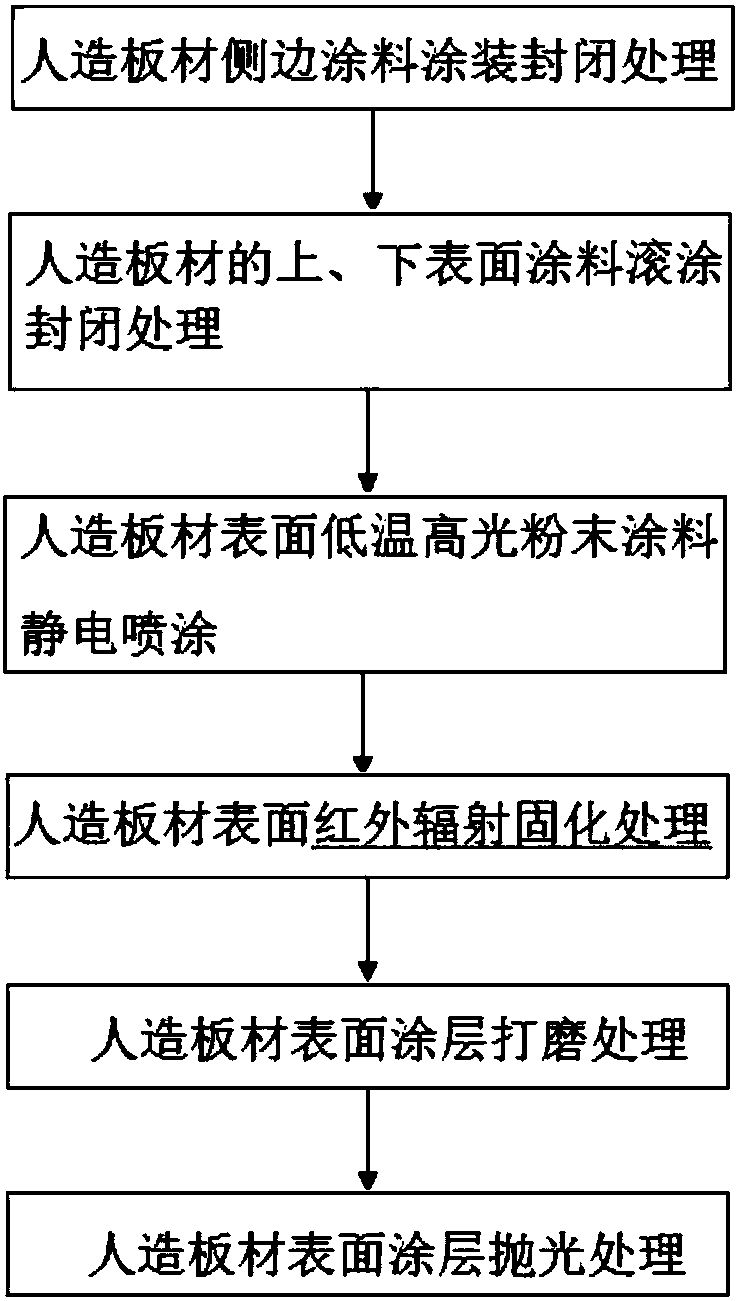

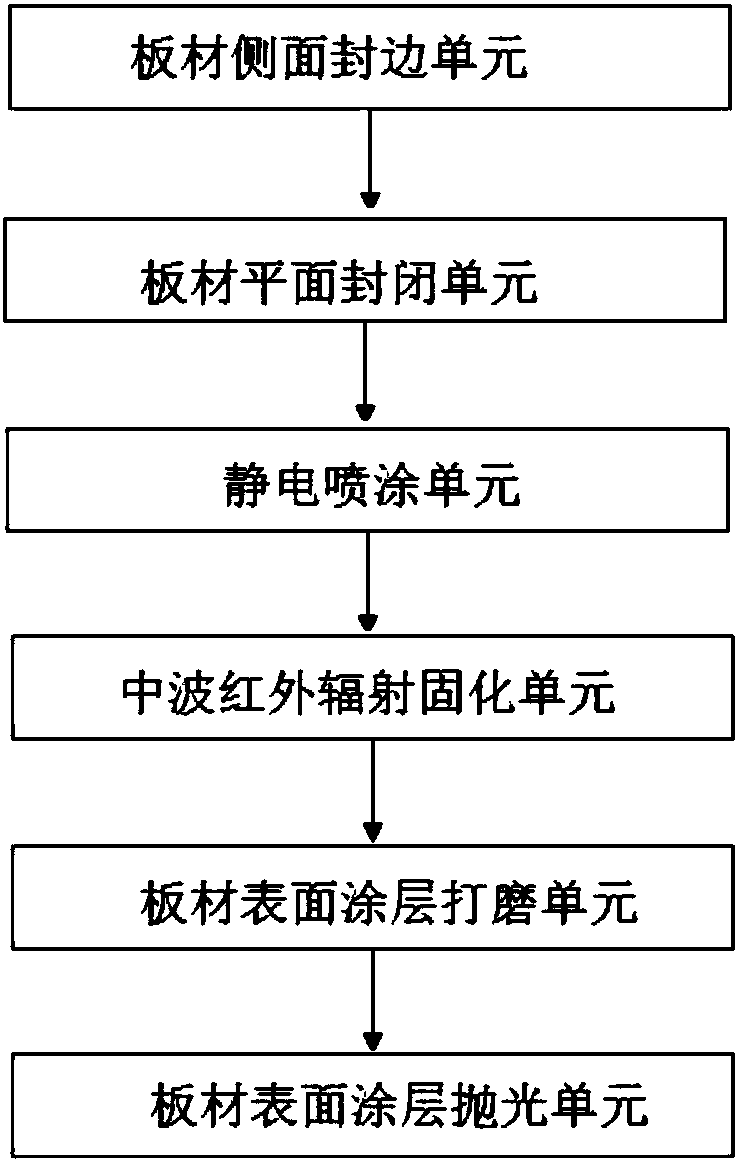

Production technology and equipment for forming specular highlight decorative effect on surfaces of artificial boards by means of powder coating

A production process, powder coating technology, used in powder coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of lack, the coating topcoat contains sand grains, and the curing time is short, and achieve low viscosity performance. , The effect of improving yield and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A commercially available medium density fiberboard is selected, its moisture content is determined to be 6%, and the medium density fiberboard is cut into various required shapes according to requirements. For the straight side of the cut MDF, first use 150-grit sandpaper to automatically polish, then automatically chamfer the upper and lower sides, and then use the roller coating process for sealing treatment. The UV radiation curing coating used includes the following weights Percentage of components: Epoxy acrylate prepolymer 75% (Shanghai allnex resin EB3708), reactive monomer diluent 15% (Shanghai allnex resin DPGDA), UV photoinitiator 3% (Tianjin Jiuri JRCure-1104 ), leveling agent 2% (German BYK BYK-333), filler 5% (Sibelco silica powder). Next, the ultraviolet light curing device is used for irradiation. The ultraviolet light curing light source used is a high-pressure mercury lamp with an output power greater than 80w / cm. The thickness of the edge-sealing coati...

Embodiment 2

[0060] Select a commercially available particleboard, measure its moisture content to 10%, and cut the particleboard into various required shapes according to requirements. For the straight side of the cut particleboard, first use 150 mesh sandpaper to automatically polish, then automatically chamfer the upper and lower sides, and then use the roller coating process for sealing treatment. The ultraviolet radiation curing coating used includes the following weight percentages: Components: Epoxy Acrylate Prepolymer 70% (Shanghai Allnex Resin EB3708), Reactive Monomer Diluent 15% (Shanghai Allnex Resin DPGDA), UV Photoinitiator 5% (Tianjin Jiuri JRCure-1104), Leveling agent 5% (German BYK BYK-333), filler 5% (Sibelco silica powder). Next, use a UV curing device to irradiate. The UV curing light source used is a high-pressure mercury lamp with an output power greater than 80w / cm. Repeat the roller coating irradiation operation twice so that the thickness of the edge-sealed coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com