Zinc-rich powder coating as well as preparation method and application thereof

A powder coating, zinc-rich technology, used in conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as VOC emission and environmental pollution, and achieve high powder application rate, good flexibility, and reduce electrostatic shielding effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

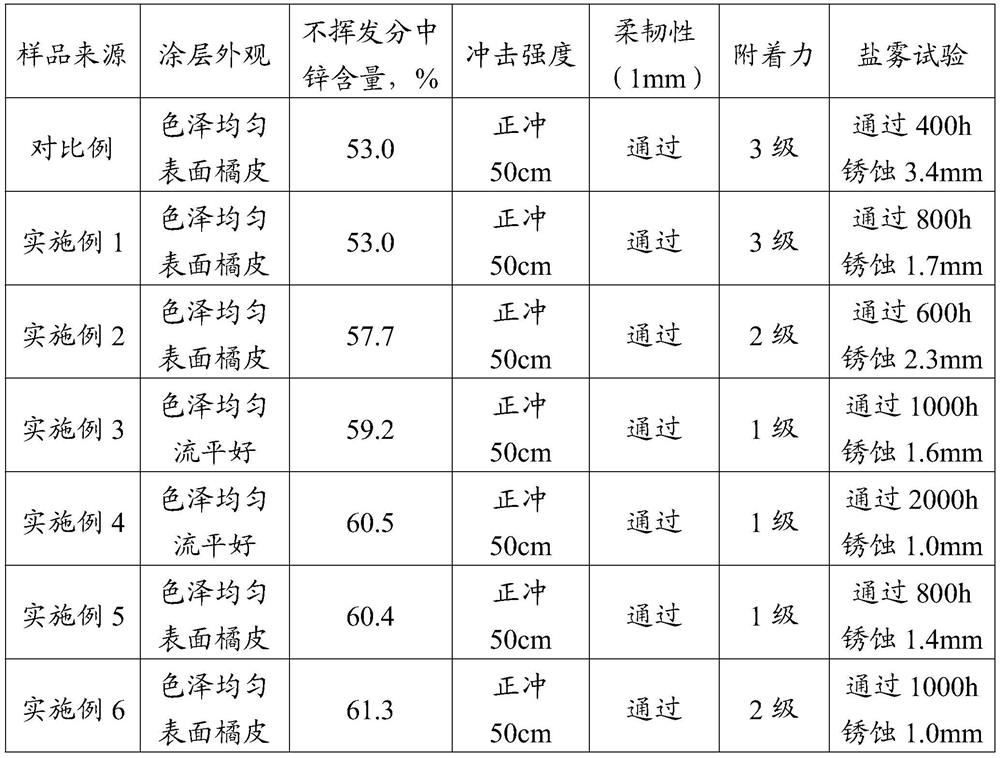

Examples

preparation example Construction

[0034] The invention provides a preparation method of the zinc-rich powder coating, comprising the following steps:

[0035] The preparation raw materials of the zinc-rich powder coating are mixed, followed by extrusion molding, grinding and screening in order to obtain the zinc-rich powder coating.

[0036] The invention mixes the preparation raw materials of the zinc-rich powder coating to obtain the mixed raw materials. In the present invention, the mixing is preferably carried out under stirring conditions. In the present invention, there is no special limitation on the rotation speed and time of the stirring, as long as the raw materials can be fully mixed. In an embodiment of the present invention, the mixing is specifically carried out in a mixing tank.

[0037] After the mixing, the present invention extrudes the obtained mixed raw materials to obtain molding materials. In the present invention, the extrusion molding temperature is preferably 70-90°C, more preferably...

Embodiment 1

[0054] In terms of parts by mass, the raw materials for the preparation of zinc-rich powder coatings in the present embodiment are as follows:

[0055] 37.7 parts of bisphenol A epoxy resin, 0.85 parts of curing agent, 0.5 parts of catalyst, 60 parts of zinc powder, 0.05 parts of conductive powder, 0.4 parts of butyl acrylate leveling agent, 0.4 parts of degassing agent, and 0.1 part of charging agent; Wherein, the bisphenol A epoxy resin is specifically GESR904H epoxy resin, the epoxy equivalent is 850-900g / eq, and the softening point is 100-112°C; the curing agent is specifically Epikure P101 curing agent; the catalyst It is dimethylimidazole; the particle size of the zinc powder is 500 mesh; the conductive powder is specifically BC-XG230 conductive powder; the butyl acrylate leveling agent is specifically BYK-368P leveling agent; Specifically, it is AS90 charge enhancer.

[0056] The preparation method of zinc-rich powder coating in the present embodiment is as follows:

...

Embodiment 2

[0065] In terms of parts by mass, the raw materials for the preparation of zinc-rich powder coatings in the present embodiment are as follows:

[0066] 32 parts of bisphenol A epoxy resin, 0.5 parts of curing agent, 0.3 parts of catalyst, 65 parts of zinc powder, 0.1 part of conductive powder, 1.2 parts of butyl acrylate leveling agent, 0.4 parts of degassing agent, and 0.5 parts of charging agent; Wherein, the butyl acrylate leveling agent is specifically 988 leveling agent, and the types of other preparation raw materials are the same as in Example 1.

[0067] The zinc-rich powder coating was prepared according to the method of Example 1.

[0068] Construction was carried out according to the method of Example 1 to obtain a steel specimen with a zinc-rich coating attached to the surface, and the thickness of the zinc-rich coating was 90-120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com