Method for recycling gallium from indissolvable gallium compounds and gallium recycled by virtue of method

A compound, insoluble technology, applied in the field of gallium recovery, can solve the problems of difficult separation, consumption of large oxides, harsh conditions, etc., to achieve the effect of simple process flow, improved leaching rate, and less time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

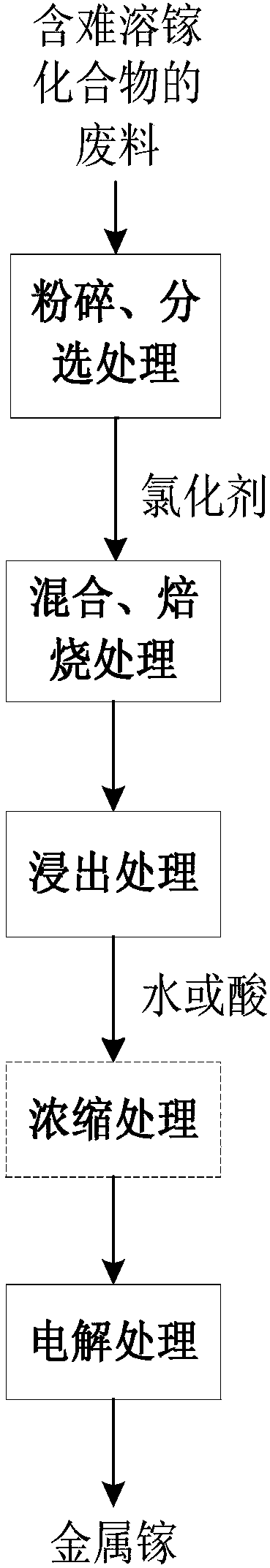

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for recovering gallium from waste materials containing insoluble gallium compounds, the method comprising the following steps:

[0057] (1) Take 100g of powder produced when the MOCVD method is used to produce gallium nitride, wherein the gallium content is 75wt%, and the main form of gallium is GaN, and then 200g of ammonium chloride is mixed with the powder, at a speed of 200r / min Ball milling treatment for 30 minutes, and then roasting treatment, the roasting treatment temperature is 300 ° C, and the roasting treatment time is 2 hours;

[0058] (2) leaching the roasted product of step (1) with deionized water, the leaching temperature is 50° C., leaching for 60 min at a rotating speed of 300 r / min, and filtering to obtain a gallium-rich solution, which is passed through an inductively coupled plasma emission spectrometer ( ICP-OES) test, the gallium-rich solution contains 24.98g / L gallium, the gallium-rich solution is kept at a const...

Embodiment 2

[0061] This embodiment provides a method for reclaiming gallium from waste materials containing insoluble gallium compounds, the process flow diagram of the method is as follows figure 1 shown, including the following steps:

[0062] (1) Take 100g of waste LED lamp bead chips as the waste material containing indium gallium nitride, wherein the gallium content is 6.05wt%, after the waste material is crushed, it is sieved through a sieve with a sieve diameter of 0.149mm, and after soaking in water Filtrate to obtain the powder containing indium gallium nitride, then take 200g of magnesium chloride and mix it with the powder, rod mill for 40min at a speed of 300r / min, and then perform roasting treatment, the roasting treatment temperature is 400°C, and the roasting treatment time is 1.5 h;

[0063] (2) The product roasted in step (1) is leached with 0.5mol / L hydrochloric acid, the leaching temperature is 60°C, and the leaching is performed at a speed of 300r / min for 60min, filte...

Embodiment 3

[0066] This embodiment provides a method for reclaiming gallium from waste materials containing insoluble gallium compounds. The method is referred to the method in Example 1, the difference is only that the chlorination agent used in step (1) is sodium chloride and Potassium chloride, the mass ratio of gallium nitride powder to chlorinating agent is 1:5.

[0067] In this example, 73.90 g of gallium metal was obtained by electrolysis, with a yield of 98.53% and a purity of 99.9 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com