Powder coating with good weather resistance and method for preparing powder coating

A powder coating and weather resistance technology, applied in the field of coatings, can solve the problems of inability to effectively improve labor productivity, prolong production cycle, long curing time, etc., to improve storage stability, improve powder rate, and short curing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

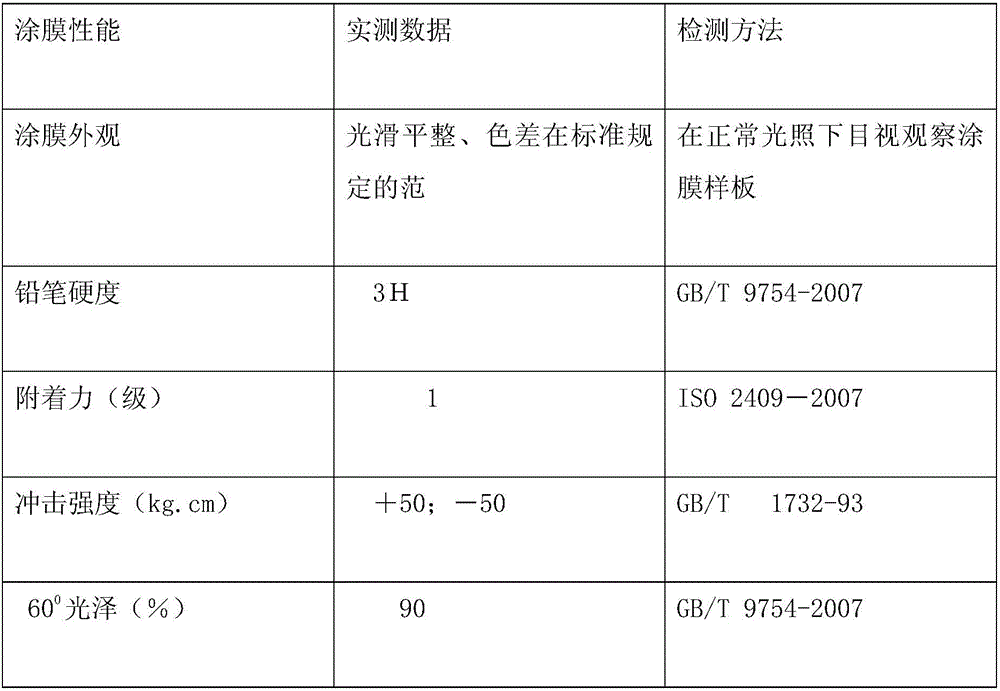

Image

Examples

Embodiment Construction

[0022] A powder coating with good weather resistance, prepared from the following components by weight (kg): epoxy resin 56, acrylic resin 25, diethyl glutaric anhydride 3, imidazole 1.5, chlorinated rubber 5, hindered amines Light stabilizer 0.2, benzotriazole light stabilizer 0.3, tetrabutylamine-bis[methyl-phthalic disulfide] complex copper 0.4, sepiolite powder 14, short fiber 4, carbon black 13, mica powder 3, Diethylene glycol butyl ether 1, precipitated barium sulfate 13, castor oil 3, aluminum powder 3, benzoin 0.6, 2,6-tertiary butyl-4-methylphenol 0.4, didodecyl alcohol ester 0.2, modified Auxiliary 4,

[0023]Among them, the modified auxiliary agent is made of the following components by weight (kg): polyvinyl alcohol superfine powder 25, zinc borate 1.5, aluminum powder C6, magnesium oxide 3-4, castor oil 3, boron nitride 1.5, gas phase two Silicon oxide 5, xylene 35, alkoxy diol 4, alkoxy triol 4, dimethylolpropionic acid 5, polysiloxane 3, p-toluenesulfonic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com