Dust-proof and anti-fouling powder coating, preparation method and application thereof and dust-proof and anti-fouling product

A powder coating, dustproof technology, applied in powder coatings, antifouling/underwater coatings, conductive coatings, etc. Easy to stick to dust and other problems, to achieve excellent dust-proof, anti-static, anti-fouling and easy-to-clean performance, eliminate unsafe factors, and reduce the effect of electrostatic shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In a second aspect, the present invention provides a method for preparing a dust-proof and anti-fouling powder coating, the method comprising: mixing a matrix resin, a filler, a general additive, a conductive polymer, an antistatic additive and a pigment, and then mixing the resulting mixture Sequentially carry out extrusion molding treatment, tabletting treatment, cooling treatment, crushing treatment and grinding treatment.

[0034] In the method of the present invention, for the specific selection and dosage of the matrix resin, filler, general additives, conductive polymer, antistatic additives and pigments, refer to the corresponding content above, and will not be repeated here.

[0035] In the method of the present invention, in order to further improve the dust-proof, antistatic, anti-fouling and easy-cleaning performance of the prepared powder coating, preferably, matrix resin, filler, general auxiliary agent, conductive polymer, antistatic auxiliary agent and pi...

Embodiment 1

[0065] This example is used to illustrate the epoxy polyester dustproof and antifouling powder coating and its preparation method.

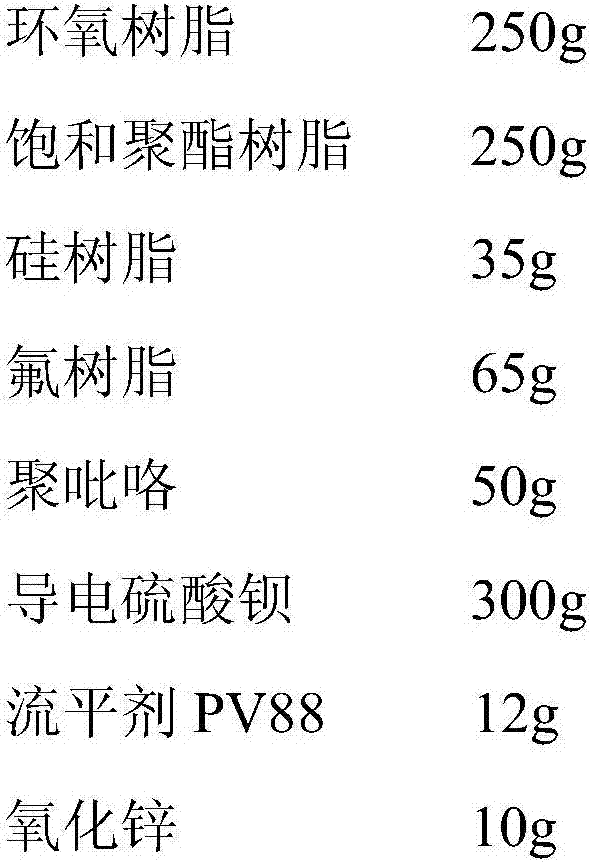

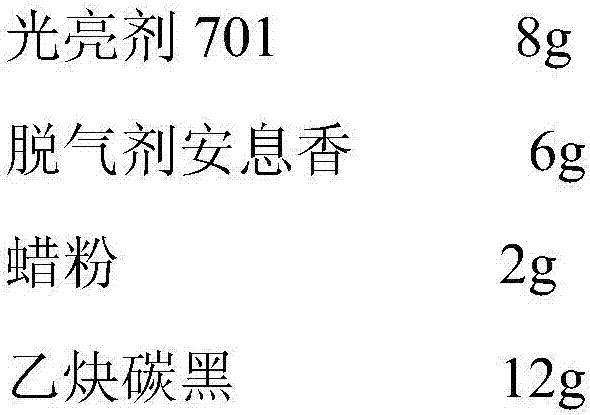

[0066] (1) Accurately weigh each material according to the following proportions:

[0067]

[0068]

[0069] (2) Put epoxy resin, saturated polyester resin, silicone resin, fluororesin and conductive polymer polypyrrole in a mixer, mix for 3 minutes at 600rpm, melt and extrude through a reciprocating single-screw extruder, and tablet , air cooling and crushing, wherein the temperature of the clinker section of the reciprocating single-screw extruder is 110°C;

[0070] (3) Stir conductive barium sulfate, leveling agent PV88, zinc oxide, brightener 701, benzoin, wax powder and acetylene carbon black in a stirring tank for 3 minutes at 600rpm, then pour the material obtained in step (2) into In the stirring tank, stir at 600rpm for 2 minutes, and discharge; extrude the mixed material with a twin-screw extruder, tablet, air-cool, and crush to ...

Embodiment 2

[0072] This example is used to illustrate pure polyester weather-resistant dust-proof and anti-fouling powder coating and its preparation method.

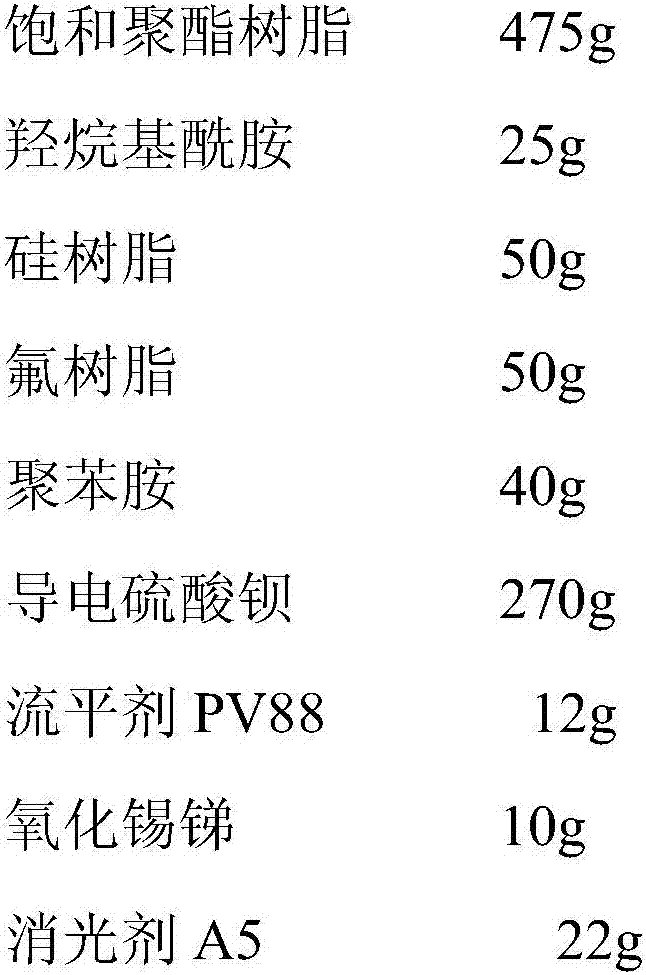

[0073] (1) Accurately weigh each material according to the following proportions:

[0074]

[0075]

[0076] (2) Saturated polyester resin, hydroxyalkylamide, silicone resin, fluororesin and conductive polymer polyaniline were placed in a mixer, mixed for 3 minutes at 600rpm, melted and extruded through a reciprocating single-screw extruder, and pressed flakes, air-cooled, crushed, wherein the temperature of the clinker section of the reciprocating single-screw extruder is 110°C;

[0077] (3) Stir the conductive barium sulfate, leveling agent PV88, tin antimony oxide, matting agent A5, wax powder and conductive graphite in the stirring tank for 3 minutes at 600rpm, and then pour the material obtained in step (2) into the stirring tank In the middle, stir at 600rpm for 2 minutes, and discharge; the mixed material is extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com