Patents

Literature

75results about How to "Reduce static buildup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

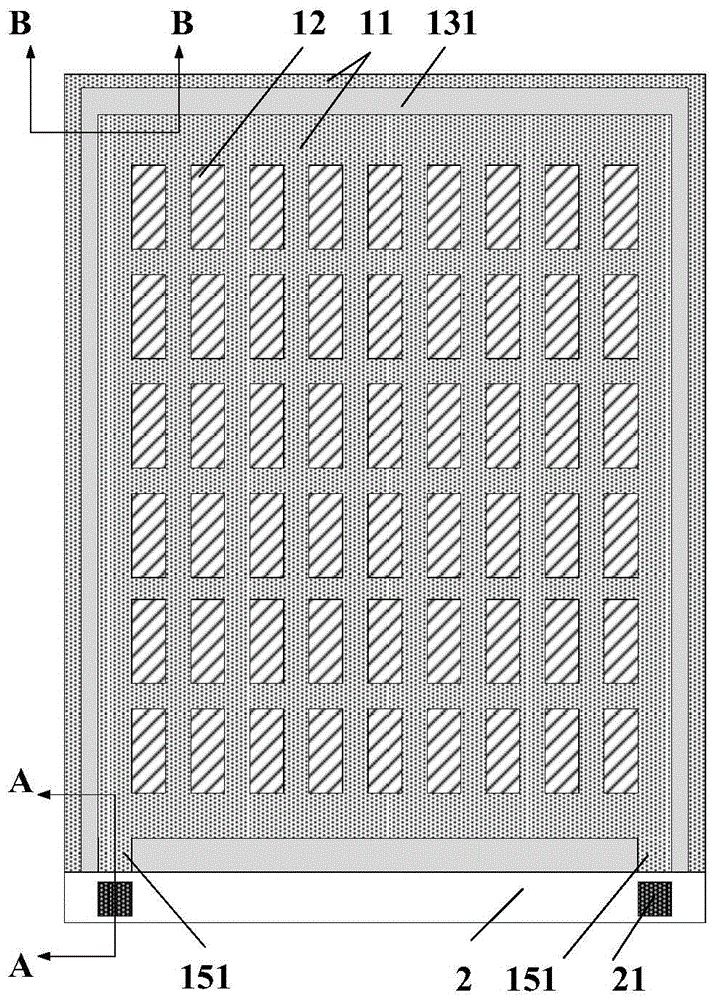

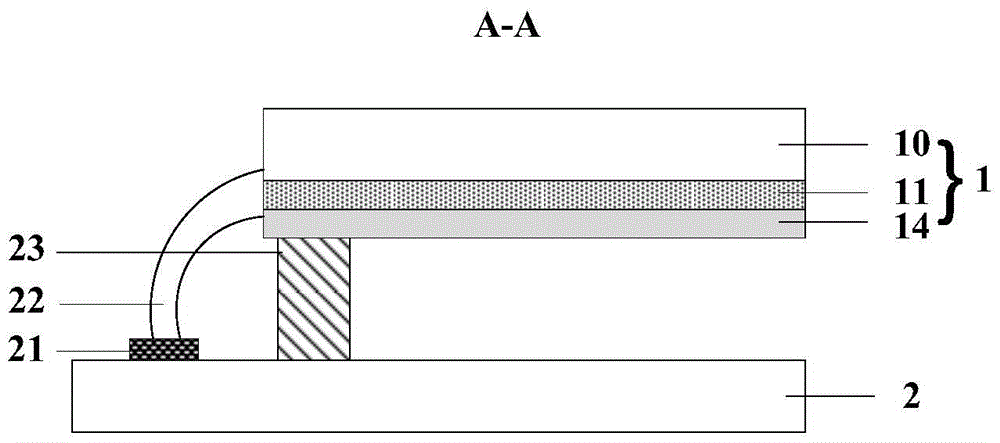

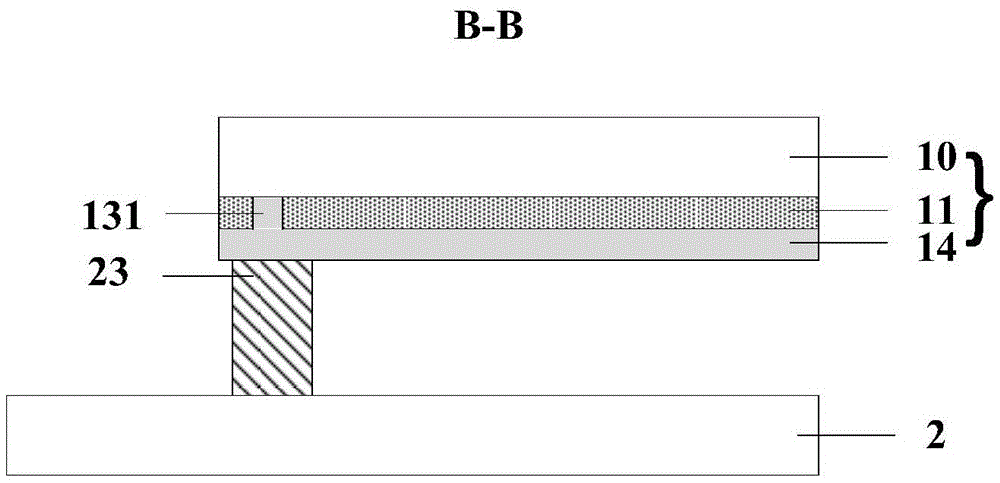

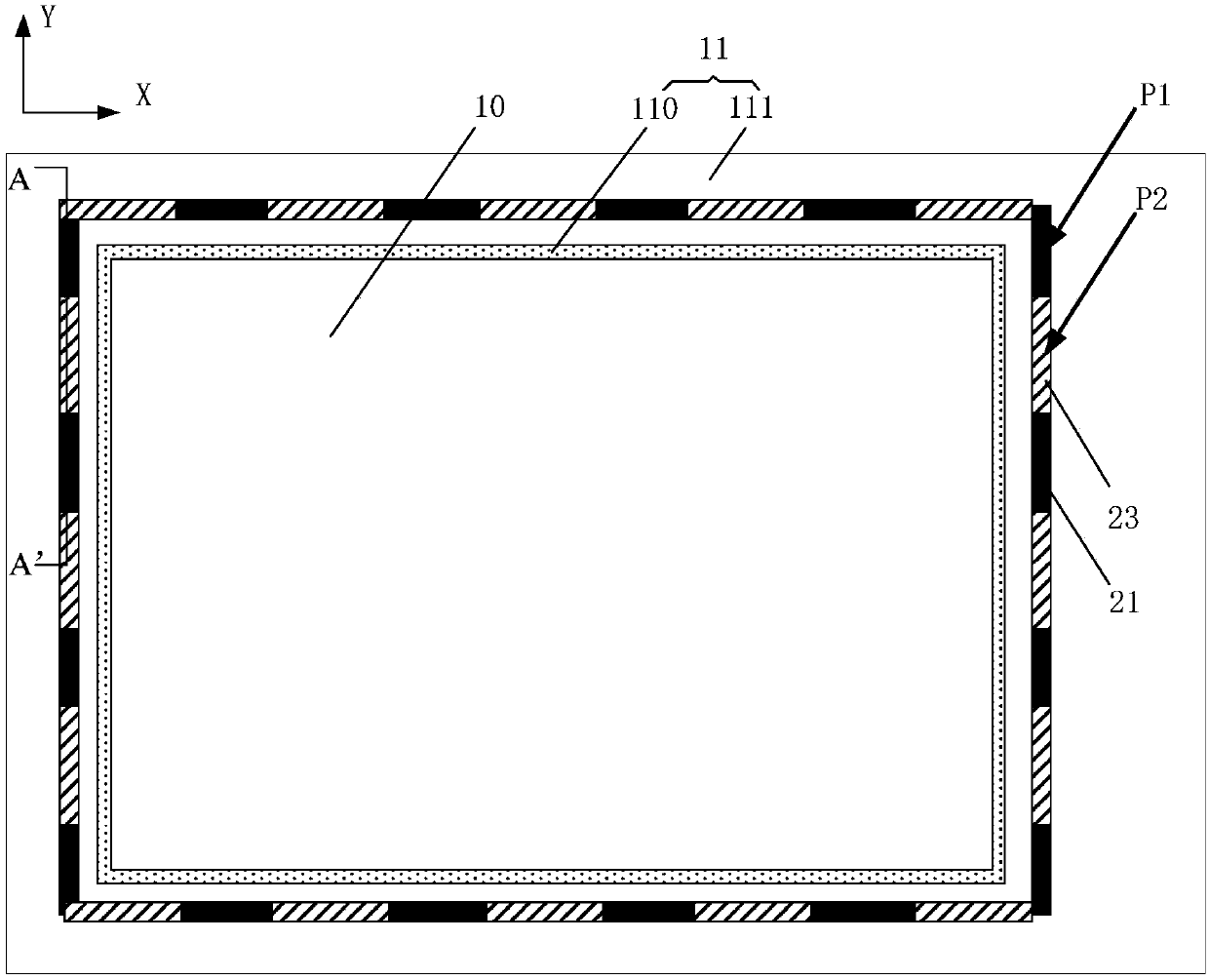

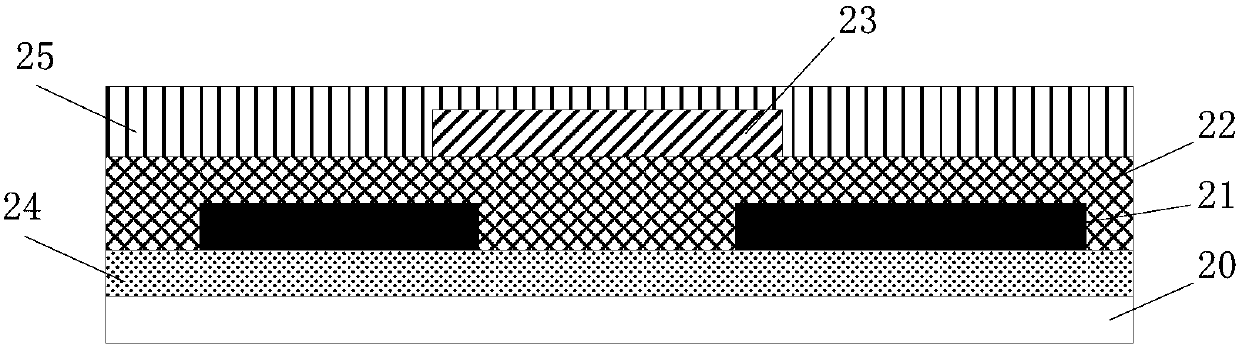

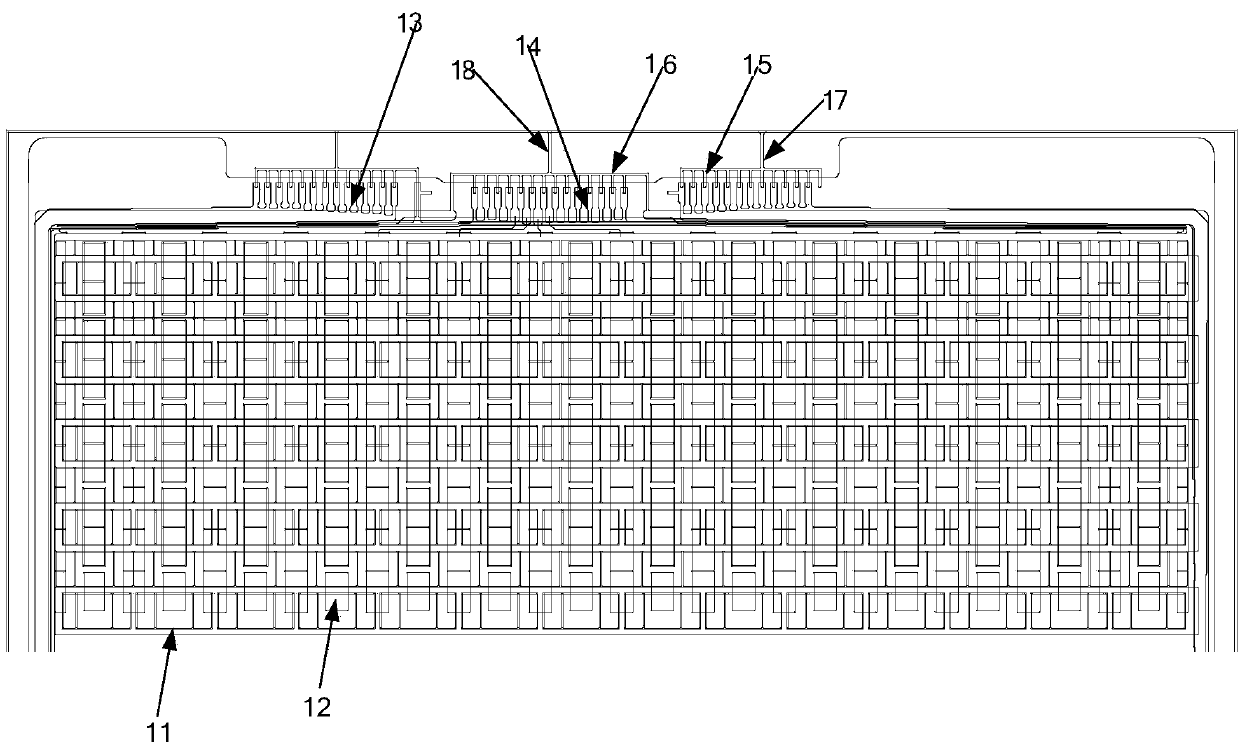

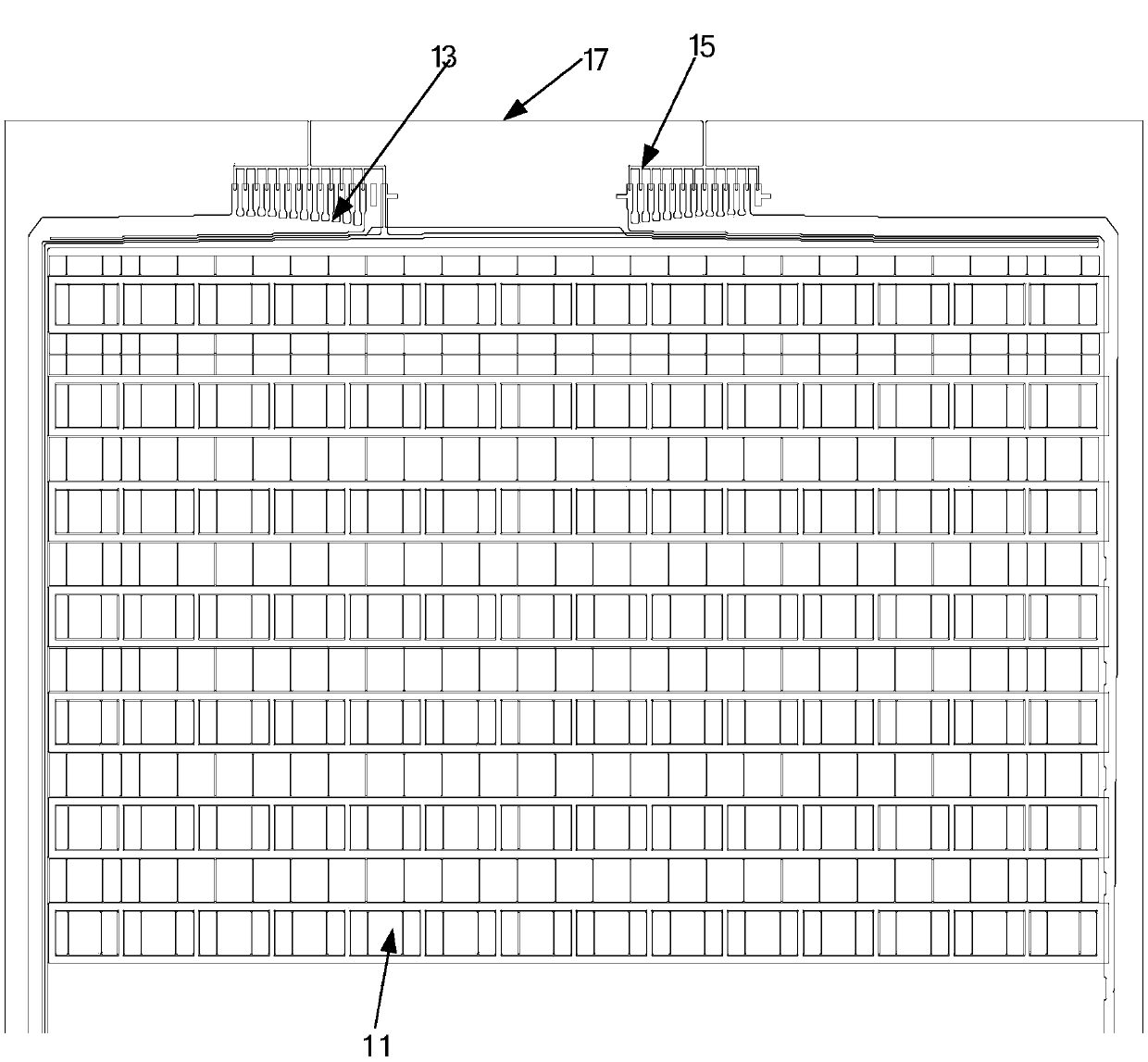

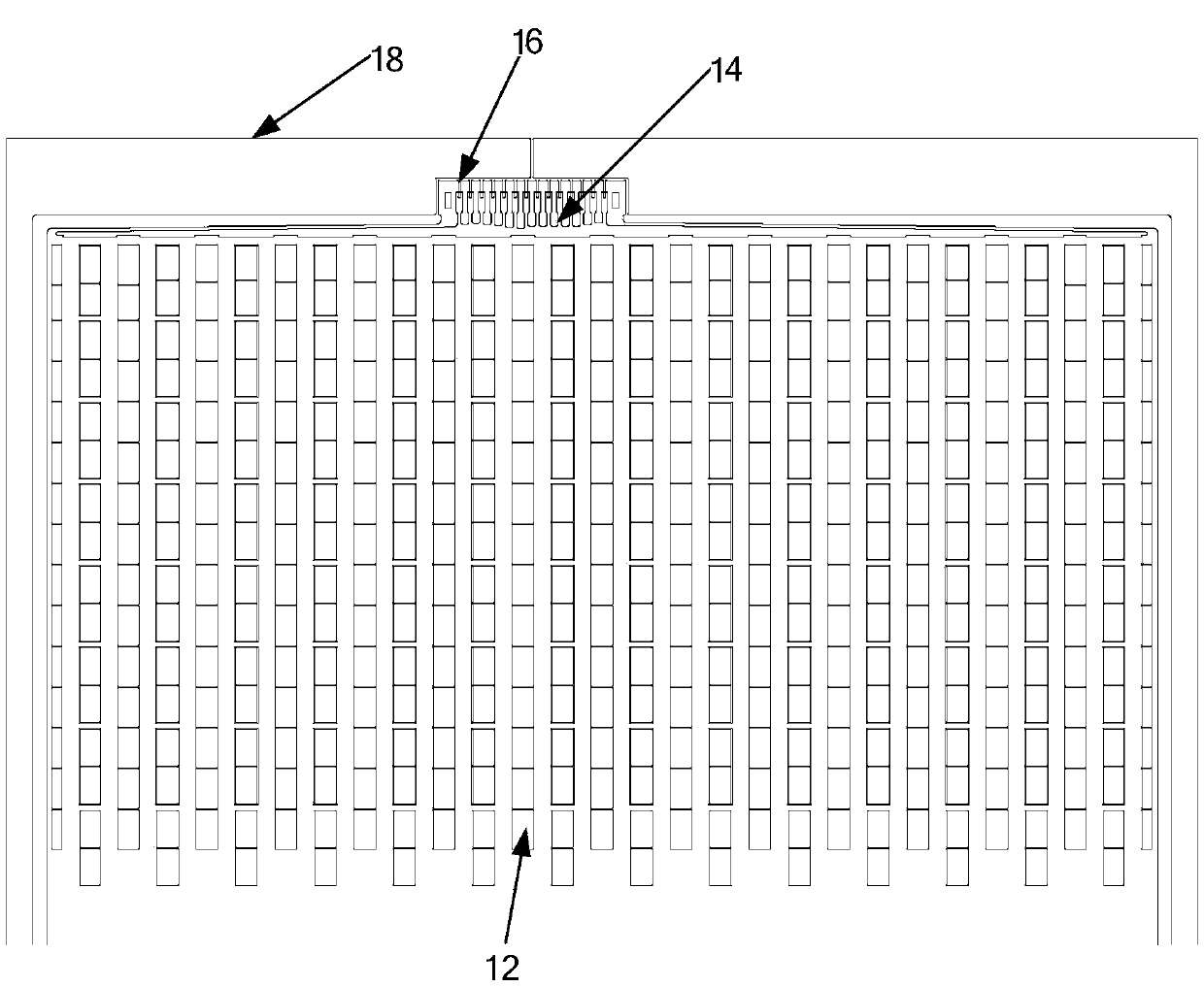

Color film substrate, display panel and display device

InactiveCN105607332ANo problems with mechanical damageAvoid enteringNon-linear opticsColor filmDisplay device

The invention belongs to the technical field of display, and particularly relates to a color film substrate, a display panel and a display device, wherein the color film substrate comprises a conducting layer positioned at the color film side of the color film substrate; an isolation belt used for isolating external static electricity is arranged on the periphery of the conducting layer; a notch is formed in the isolation belt; extending parts used for outputting static electricity are arranged on the inner side conducting layer on the inner sides of the isolation belt; the extending parts extend to the edge of the color film substrate through the notch. According to the color film substrate, the display panel and the display device, the conducting layer and the isolation belt are arranged at the color film side of the color film substrate, so that the problem in the prior art of static electricity accumulation due to external static electricity's entry into the display device through an ITO thin film prone to mechanical damage is effectively solved.

Owner:BOE TECH GRP CO LTD +1

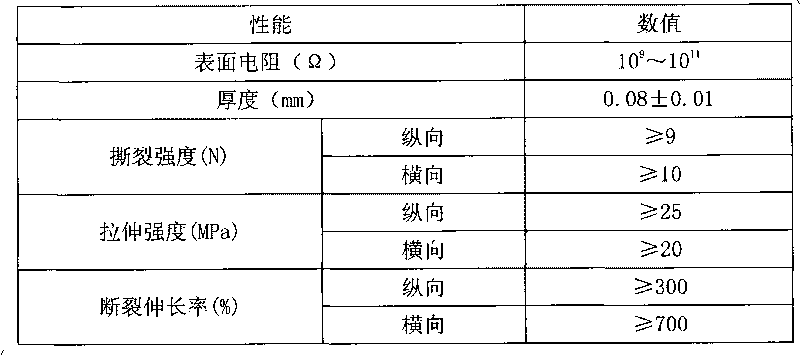

Anti-electrostatic degradable film material and preparation method thereof

The invention discloses an anti-electrostatic degradable film material and a preparation method thereof. The film material is prepared from the following raw materials: LDPE, LLDPE, starch-based degradable plastic materials and anti-electrostatic master batch. The preparation method comprises the following steps: uniformly mixing the raw materials at a high speed; and obtaining a product by extruding, swelling and stretching. The anti-electrostatic degradable film material has good anti-electrostatic effect, is degradable and does not pollute the environment; and the preparation method of the anti-electrostatic degradable film material has simple process and low cost and can prepare finished products with good quality.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

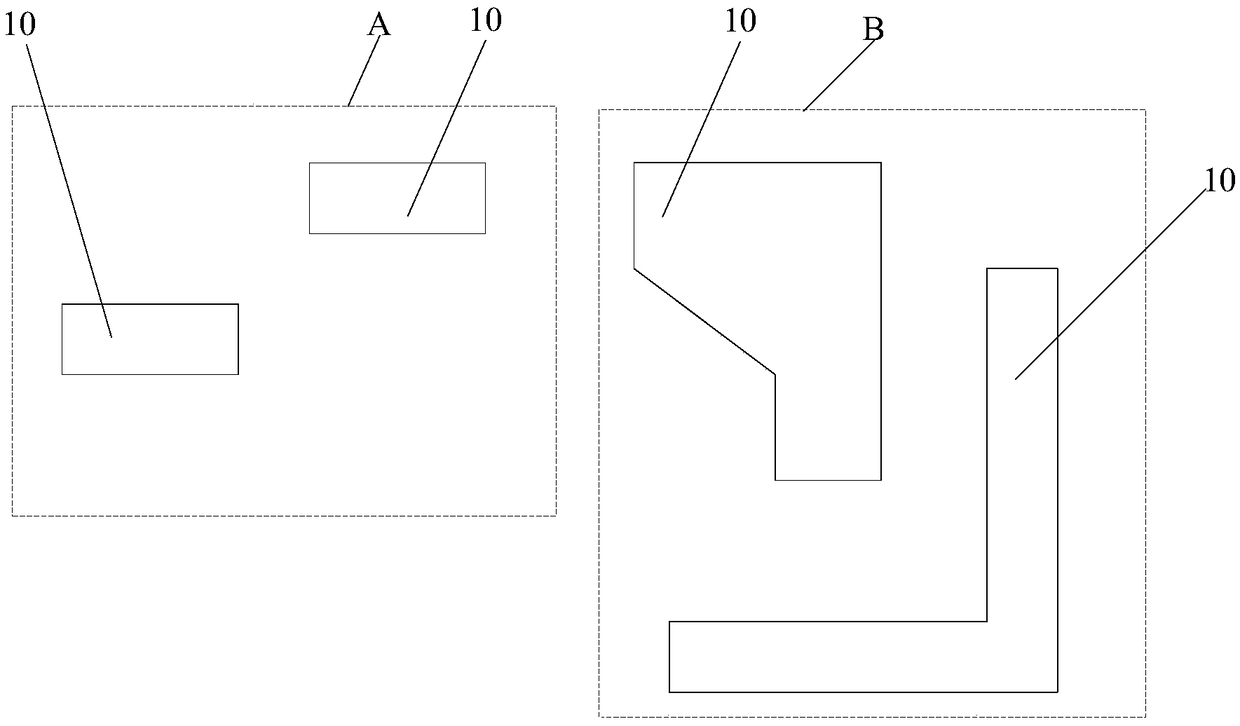

Array substrate, display panel and display device

ActiveCN107863357APrevent crack propagationIncrease productivitySolid-state devicesSemiconductor devicesDisplay deviceFlexible display

The invention discloses an array substrate, a display panel and a display device. The array substrate includes a display area and a non-display area around the display area. The non-display area includes a peripheral circuit area and an edge area. The peripheral circuit area surrounds the display area, and the edge area surrounds the peripheral circuit area. The array substrate includes a substrate, at least one first protective figure arranged on the substrate at intervals, a first inorganic layer arranged on the substrate and the at least one first protective figure, and at least one secondprotective figure arranged on the first inorganic layer at intervals. The at least one first protective figure and the at least one second protective figure are located in the edge area. The orthographic projections of the geometric centers of the first protective figures in the plane of a flexible display plane do not overlap the orthographic projections of the geometric centers of the second protective figures in the plane of the flexible display plane. By using the array substrate, the problem of crack diffusion during display panel cutting can be prevented, and the production efficiency ofthe display panel can be enhanced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

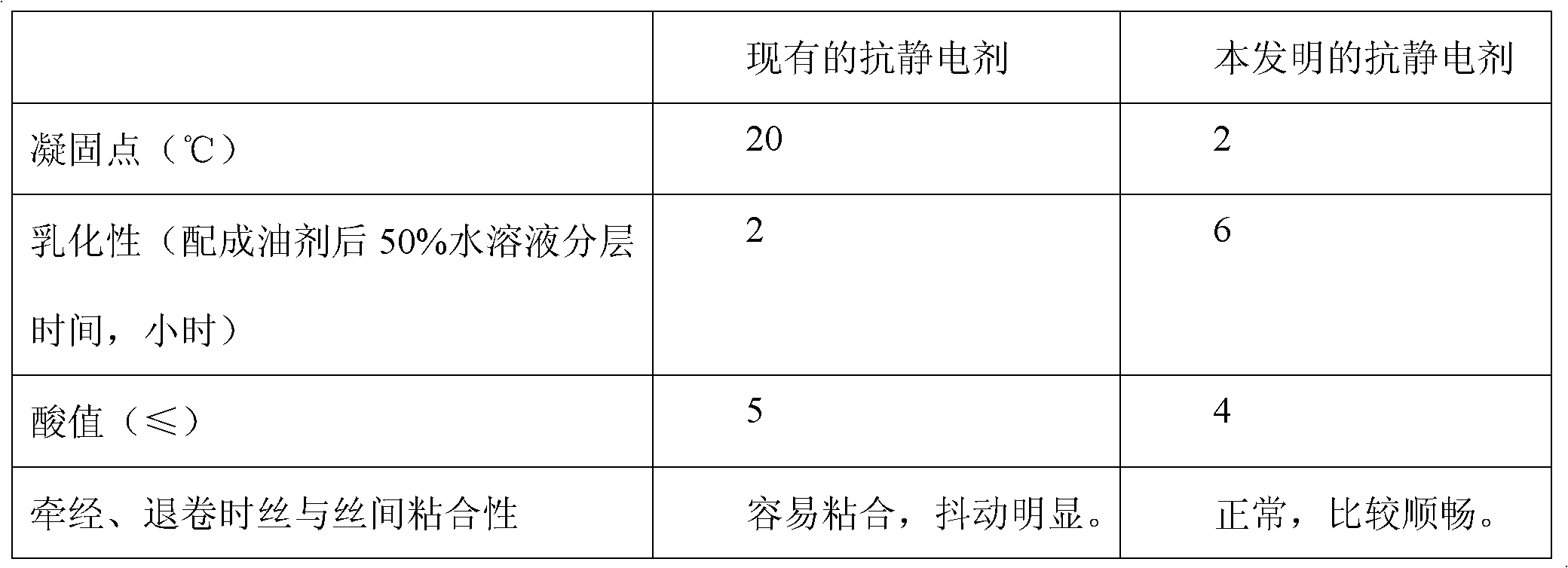

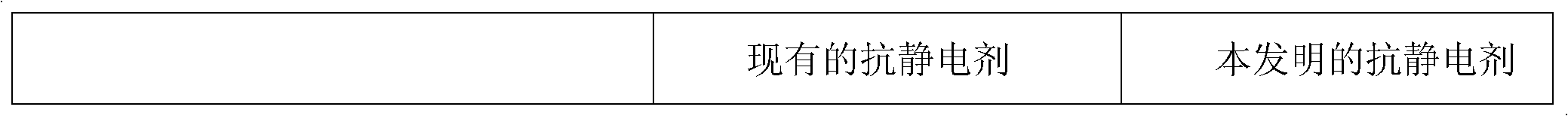

Antistatic agent for polyester elasticizing oiling agent and manufacturing method thereof

InactiveCN102182059ALow costImprove conductivityFibre typesPhosphorus organic compoundsPolyesterAlcohol

The invention discloses an antistatic agent for a polyester elasticizing oiling agent. The antistatic agent comprises the following components in part by weight: 30 to 40 parts of fatty alcohol, 10 to 12 parts of ethylene oxide, 40 to 50 parts of phosphorus pentoxide, 1 to 3 parts of potassium hydroxide and 2 to 5 parts of deionized water. The manufacturing method comprises the follow steps of: firstly, synthesizing the fatty alcohol and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether; secondly, synthesizing the fatty alcohol-polyoxyethylene ether and the phosphorus pentoxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate; thirdly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate and the ethylene oxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester; and fourthly; and fourthly, synthesizing the fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester and the potassium hydroxide to obtain fatty alcohol-polyoxyethylene ether organic phosphate alcohol-polyoxyethylene ester sylvite. The antistatic agent produced by the method has the advantages of high efficiency, low cost, strong frost resistance, easiness in emulsification and capability of meeting series of requirements of post-processing such as elasticizing.

Owner:TONGXIANG HENGLONG CHEM CO LTD

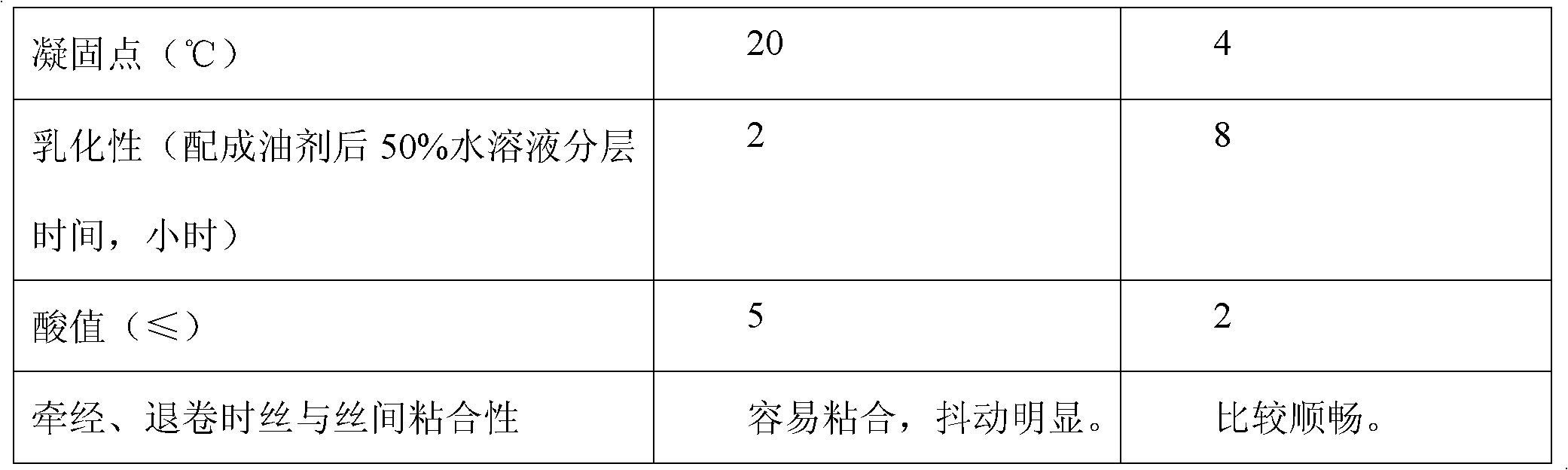

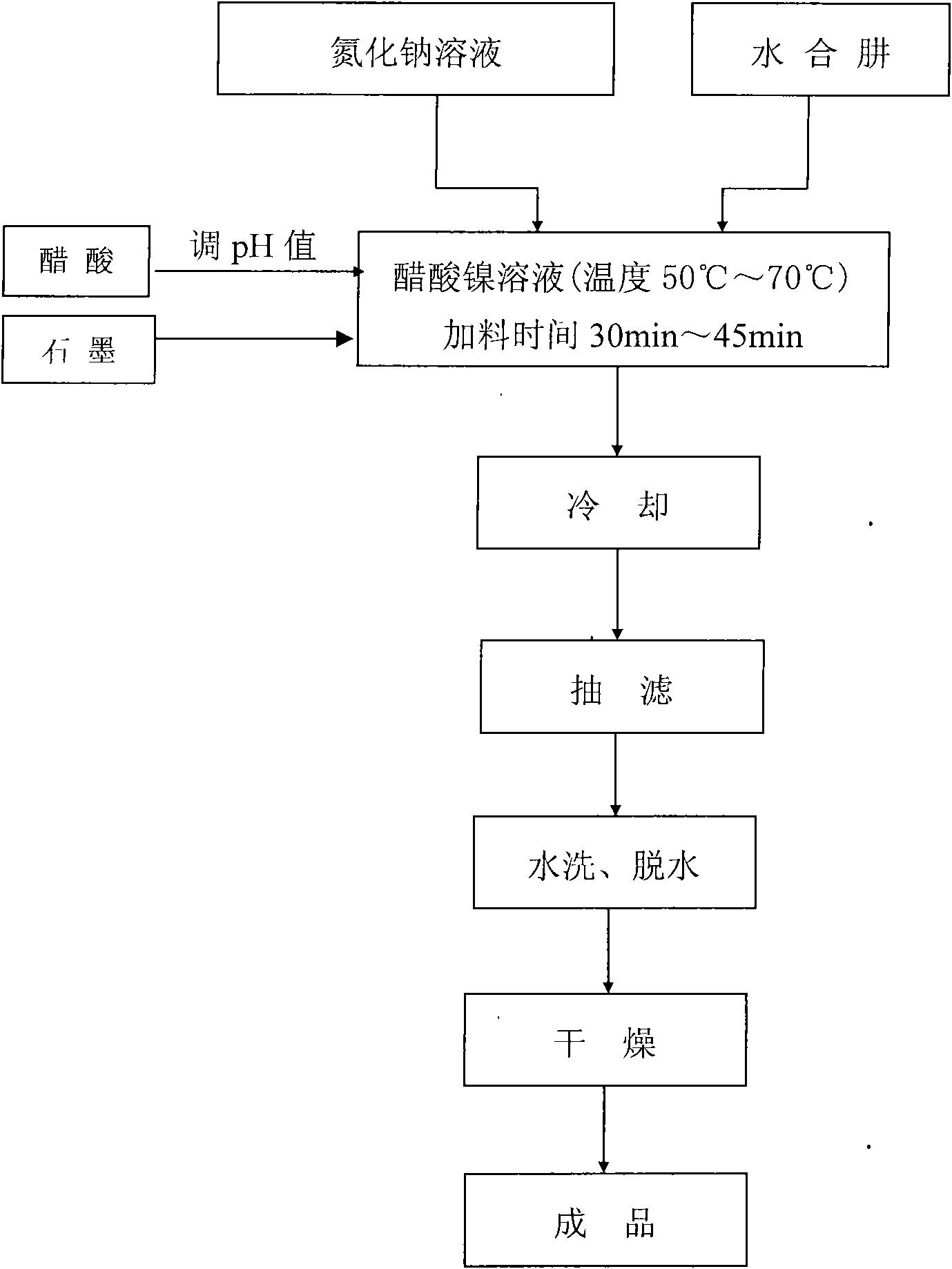

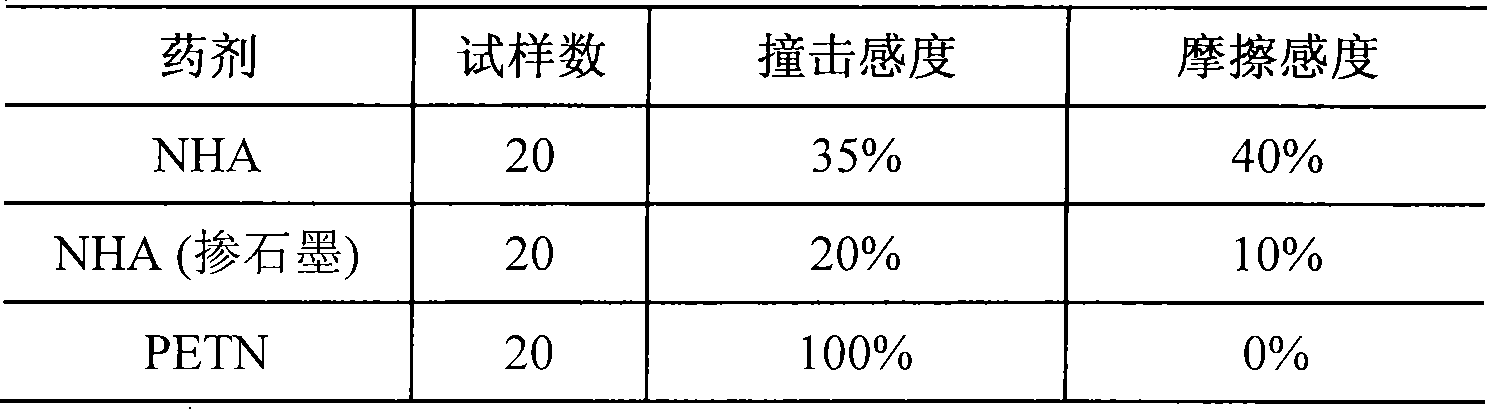

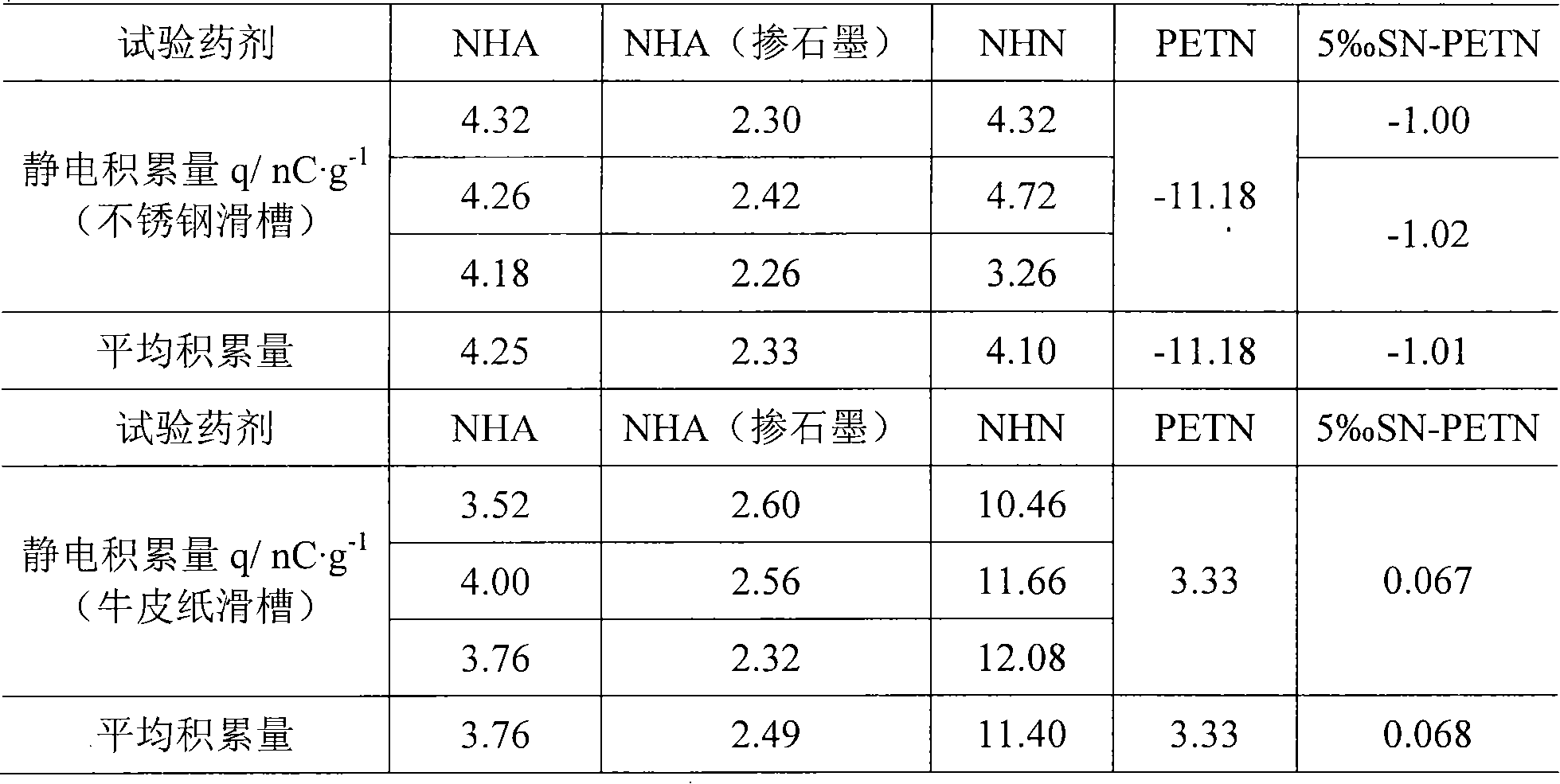

Nickel hydrazine azide, its preparation method and uses as explosive ignitor

InactiveCN1970514ASafer, more energy-saving and more efficient synthesis methodsEnergy-saving and more efficient synthesis meansMetal azide explosive compositionsNickel saltHydrazine compound

The invention discloses an azide hydrazine nickel and making method of detonating medicinal compound, which comprises the following steps: adding soluble nickel salt and azide liquid and hydrazine hydrate solution in the water to do combination reaction; or adding azide solution and hydrazine hydrate solution in the nickel solution to do combination reaction; setting the feeding time for 30-40 min under 50-70 deg.c; cooling; sucking; washing; dehydrating; drying to obtain the product; adjusting pH value through adding diluted acid. The invention provides a safer, more energy-saving and effective pharmaceutical synthetic method, which improves flame sensitivity with low mechanic sensitivity and electrostatic accumulation.

Owner:NANJING UNIV OF SCI & TECH

Method for manufacturing yarns with aramid fiber 1414 waste silk short fibers

The invention relates to the technical field of spinning, dyeing and finishing, and discloses a method for manufacturing aramid fiber yarns with aramid fiber 1414 waste silk short fibers. According to the characteristics of aramid fiber 1414 waste silks, on the basis of the traditional work flow, a set of suitable spinning technologies are provided through control over the fiber moisture regain, control over temperature and humidity of each spinning working procedure, allocation of card clothing of a carding machine, control over the speed of a drawing frame and allocation of the hardness of a rubber covered roller. The method can effectively improve the spinning performance of the aramid fiber 1414 waste silk short fibers, and the spinning quality of the aramid fiber 1414 waste silk short fibers can be guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

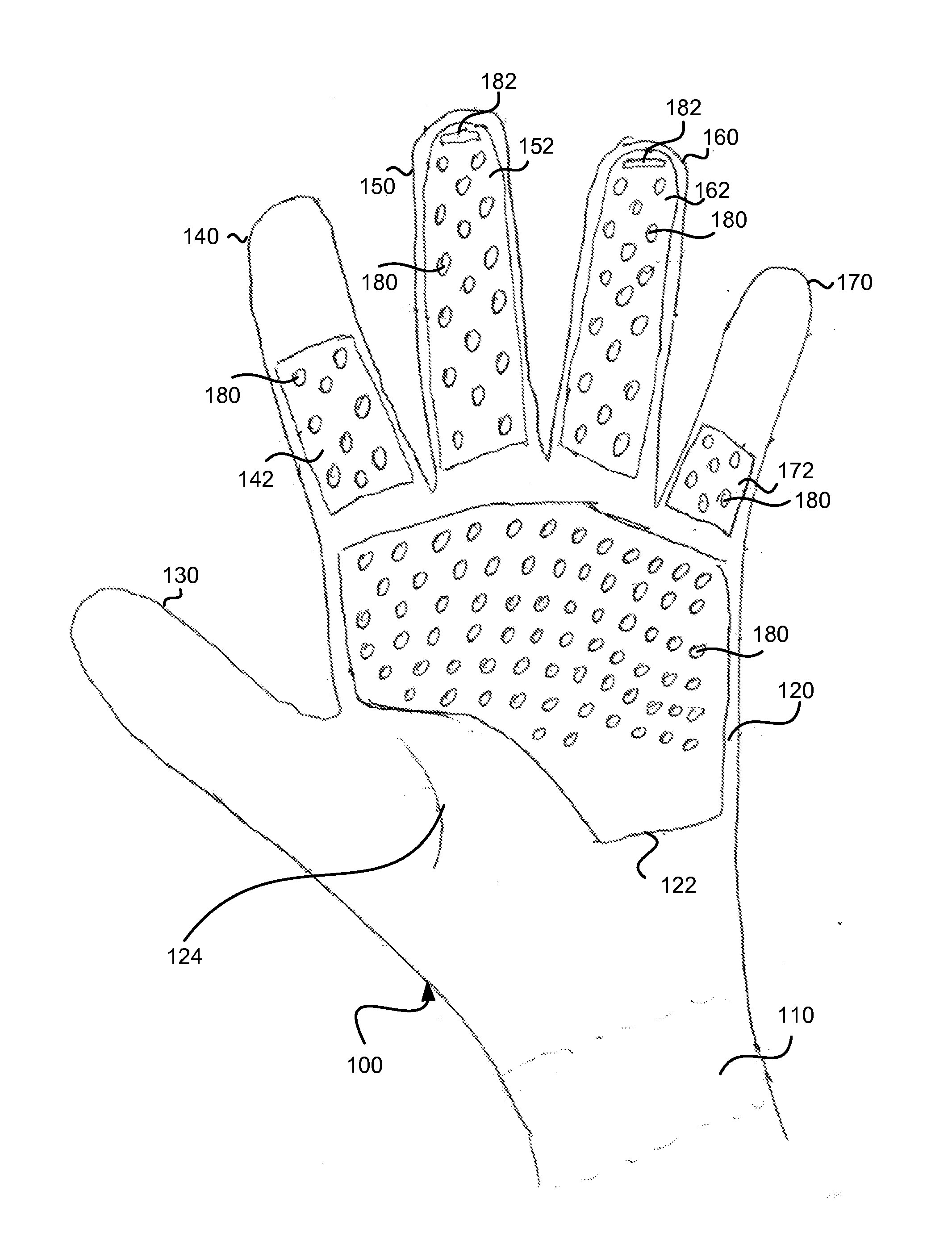

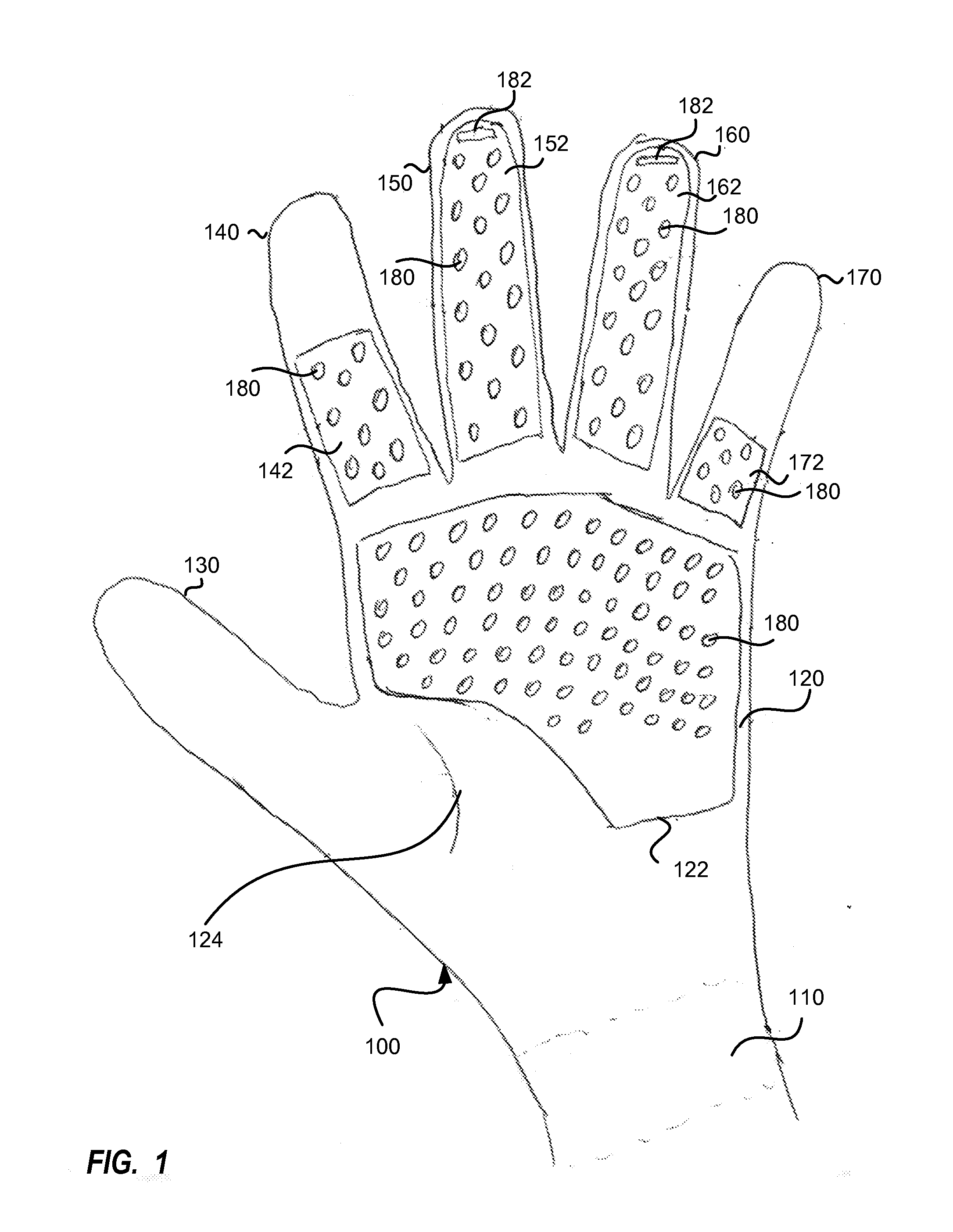

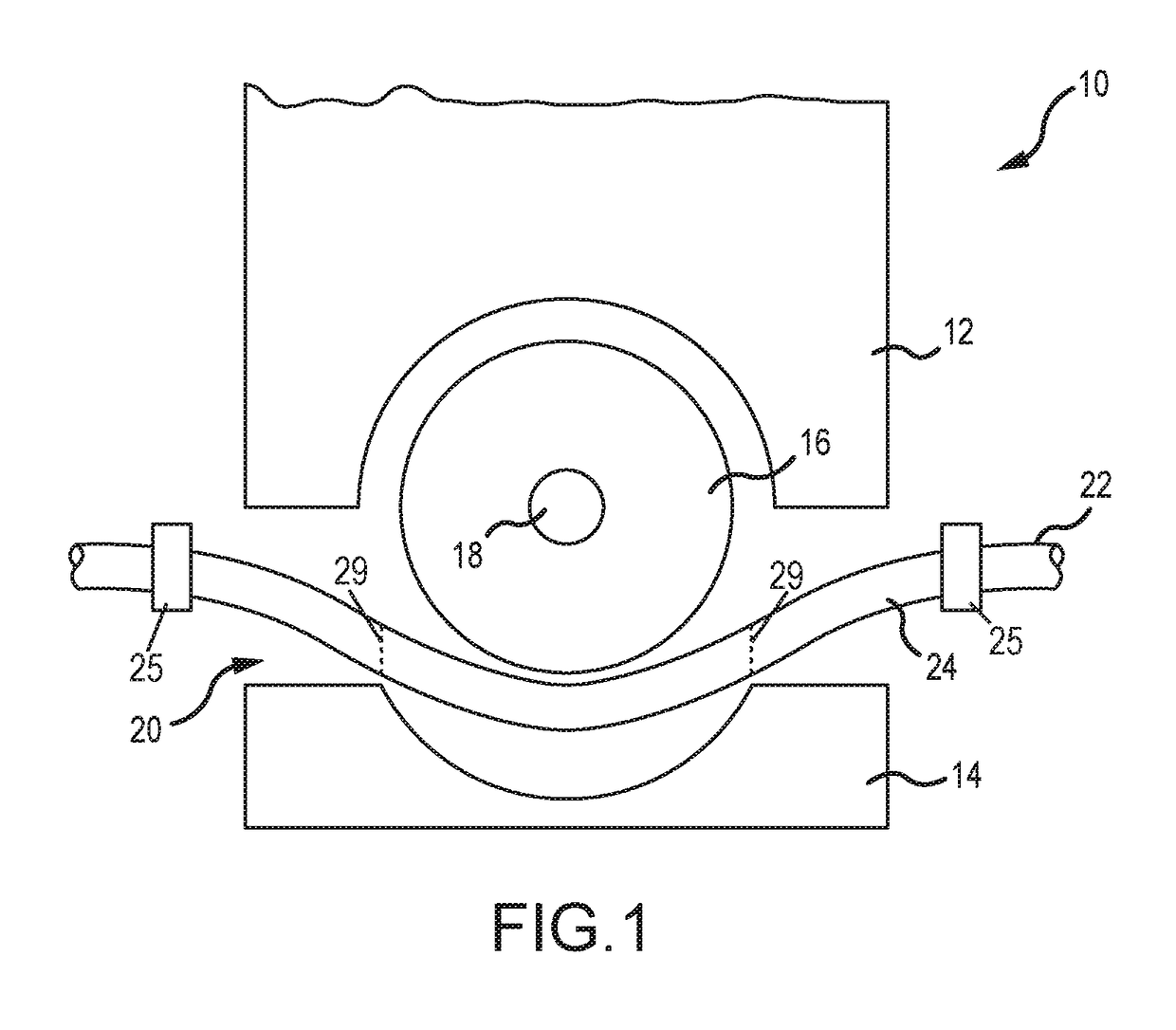

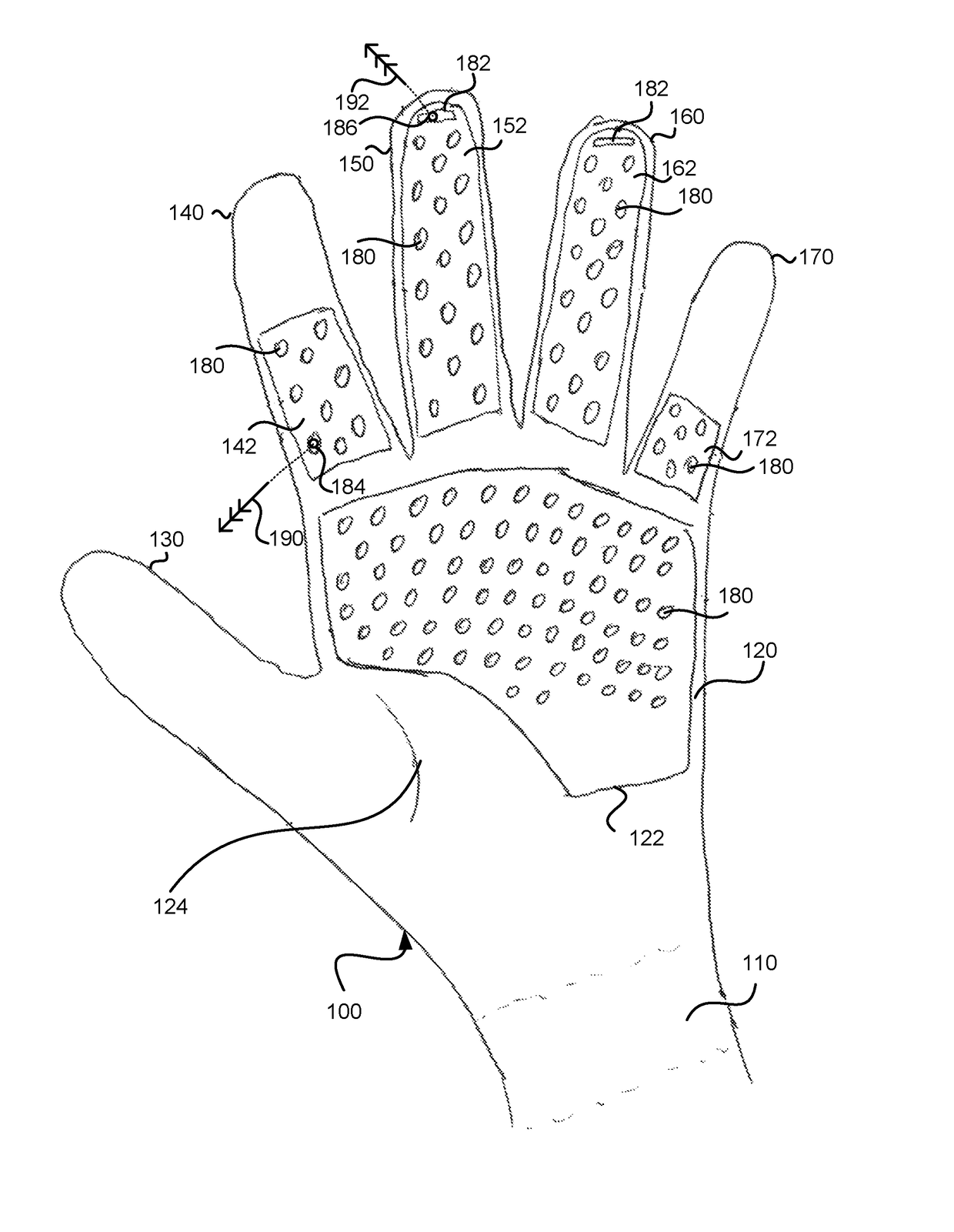

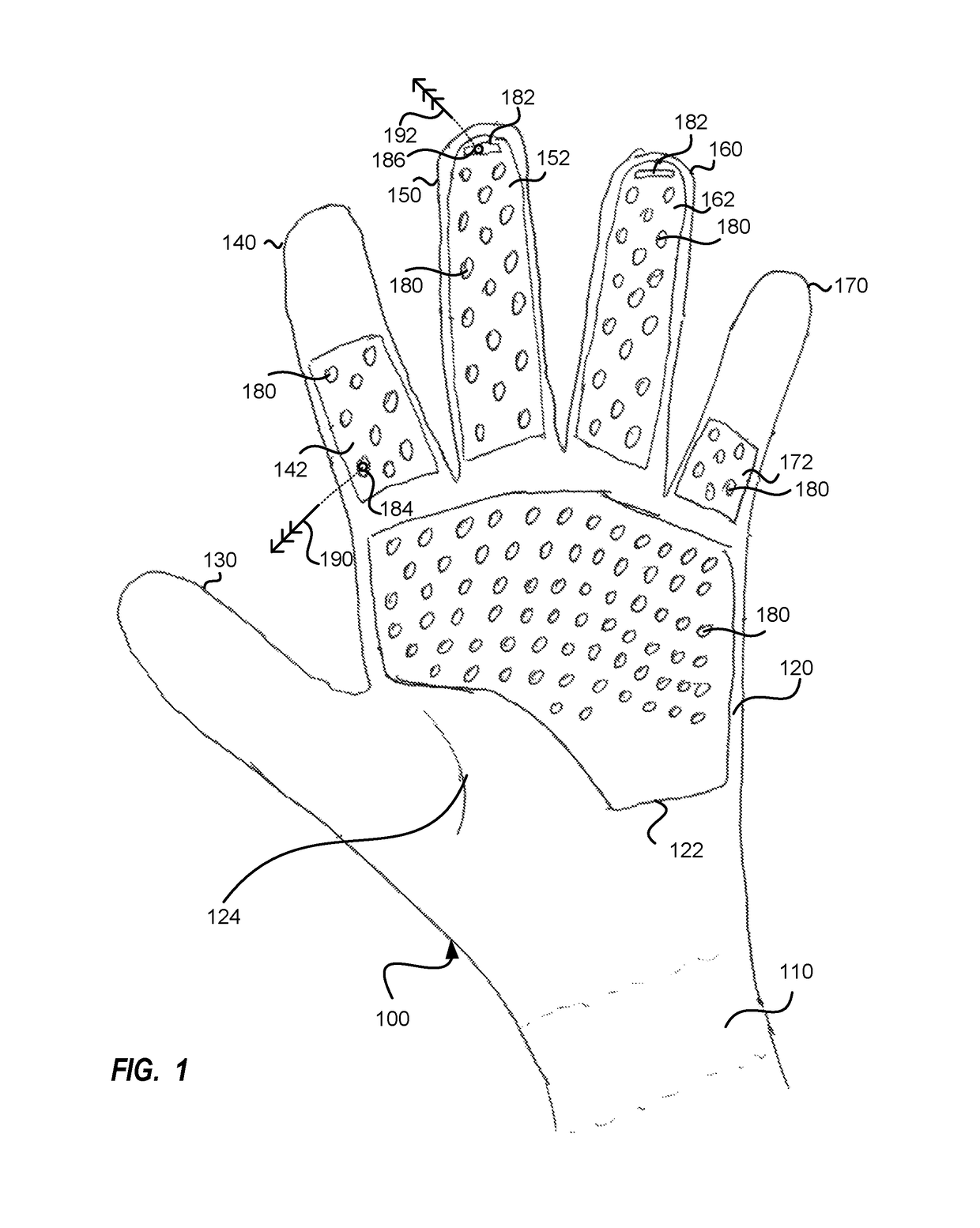

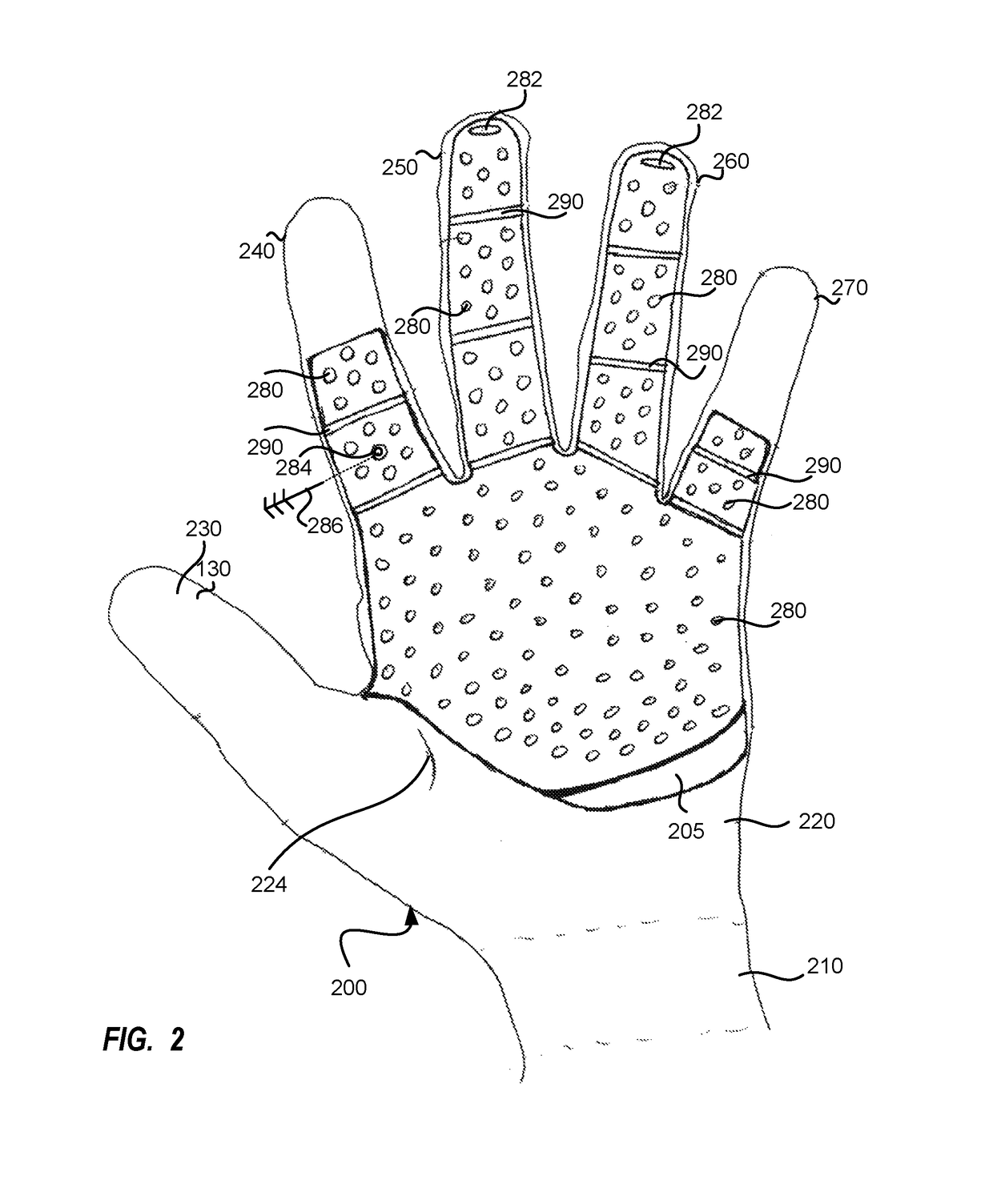

Anti-Static Grooming Device

ActiveUS20160037750A1Ample dexterityReduction of static buildupBrush bodiesOther apparatusAntistatic MaterialsEngineering

A grooming device for animals includes a glove and one or more grooming pads affixed (possibly molded) thereto. The glove is made from anti-static material, and may additionally be treated with a spray or solution, that is resistant to electrostatic accumulation and discharge caused by friction during the grooming process. The grooming pads include multiple protrusions that are used to cling to and collect extraneous debris and hair from the animal's body and coat. Due to the materials and the placement of the molded pad, the glove facilitates hand movement dexterity and reach. The device also allows the user increased tactility between the thumb and index finger by keeping them free of coverage by the grooming surface. The device may include a soft material on the back of the glove for grooming and brushing sensitive areas of the animal's coat.

Owner:SCHUSTER BARBARA

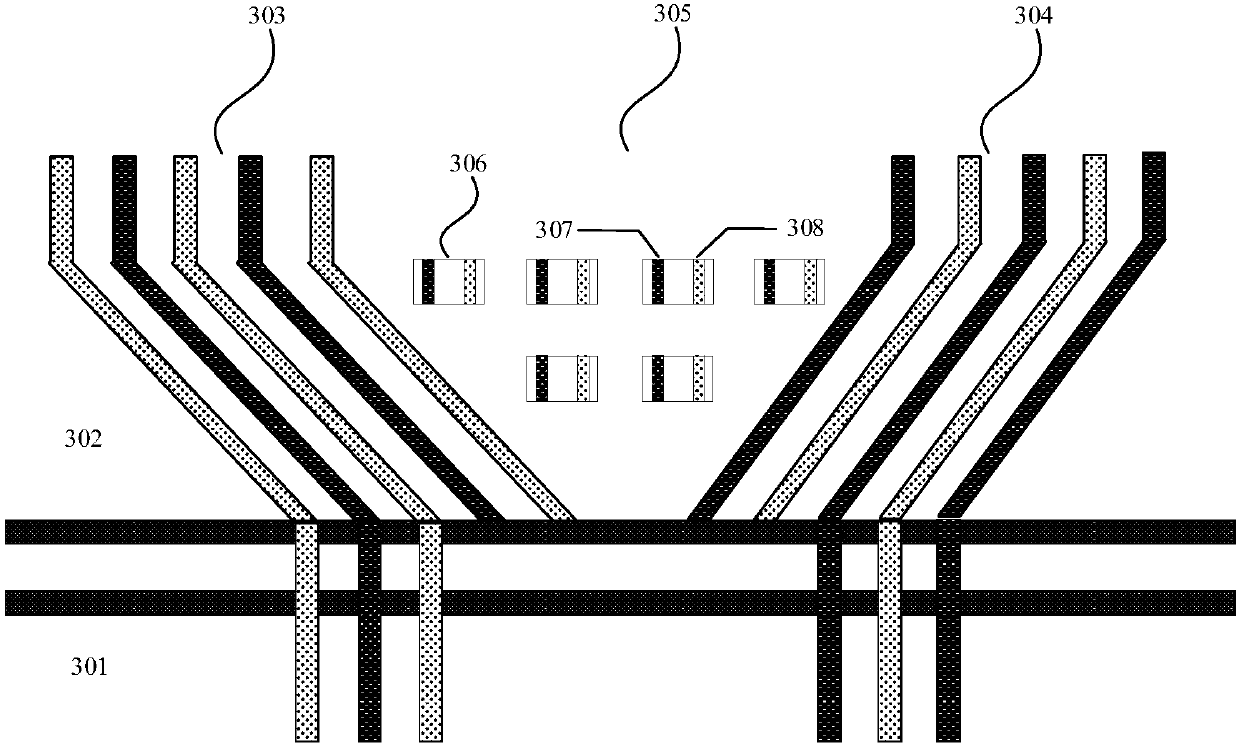

Array substrate, liquid crystal display panel and display device

ActiveCN103926773ASolving Corrosion ProblemsAvoid the problem of displaying exceptionsSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayDisplay device

The invention discloses an array substrate, a liquid crystal display panel and a display device. The array substrate comprises a signal line, a wiring terminal gasket corresponding to the signal line and a peripheral routing line connected with the signal and the corresponding wiring terminal gasket. In the array substrate, since the peripheral routing line is composed of multiple leads which are arranged in different layers and in series connection, compared with an existing integral peripheral routing line, the peripheral routing line has the advantage that even if the wiring terminal gasket exposed to the air is corroded as moisture and oxygen in air are in contact, corrosion cannot extend inwardly to the signal line along the peripheral routing line so as to avoid the problem of abnormal display caused by the fact that the signal line is corroded. Besides, the peripheral routing line is arranged to be composed of the multiple leads arranged in different layers, compared with the integral peripheral routing line in the prior art, the peripheral routing line has the advantage that accumulation of static electricity on the peripheral routing line can be reduced since each lead is small in area.

Owner:BOE TECH GRP CO LTD +1

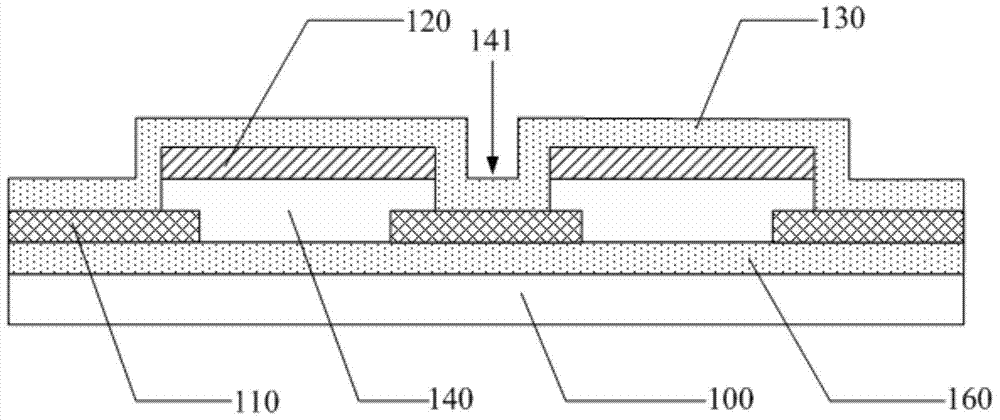

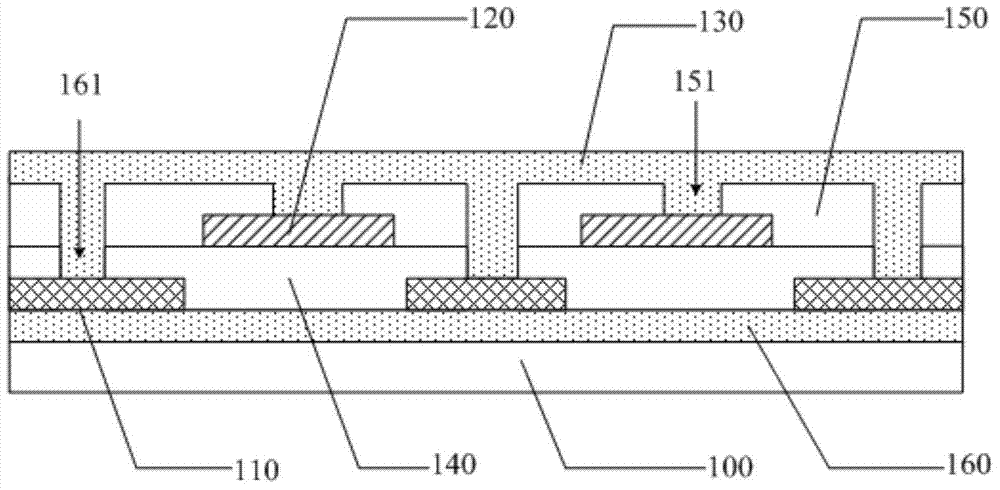

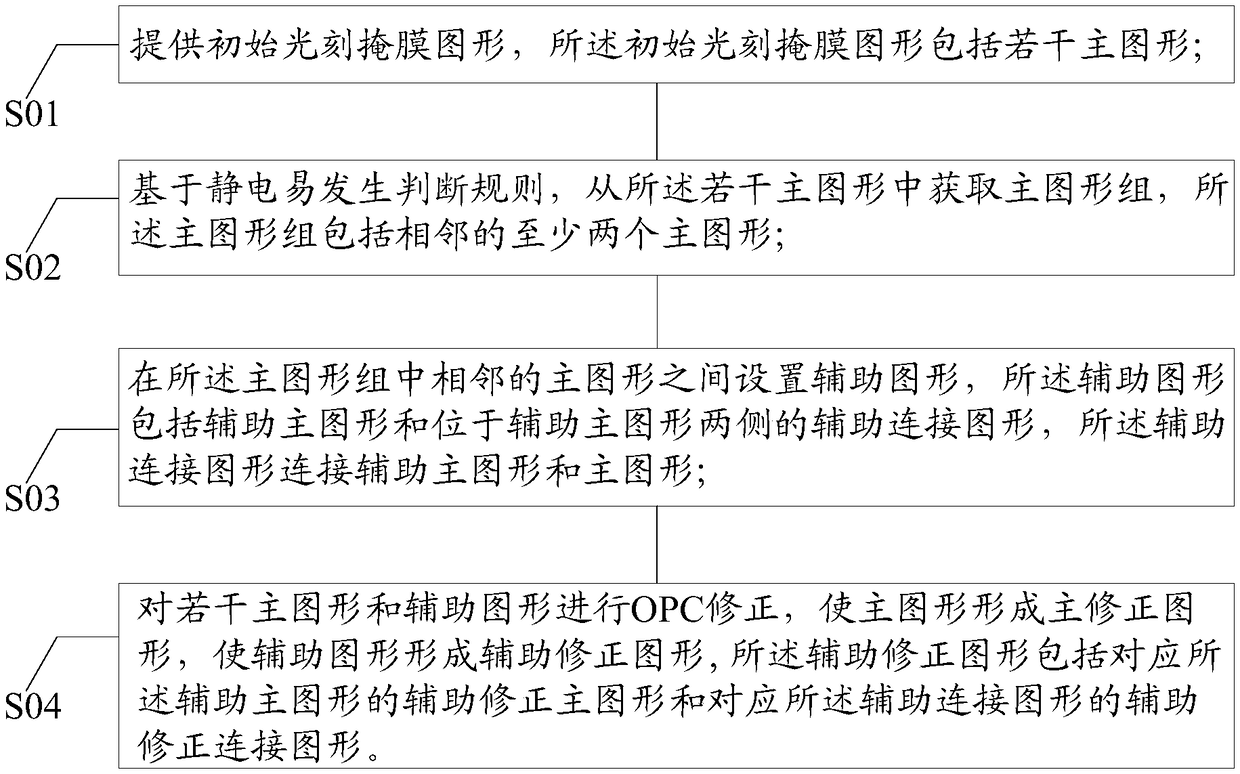

Optical proximity correction method and mask making method

InactiveCN109085736AReduce static buildupPrevent electrostatic breakdownOriginals for photomechanical treatmentOptical proximity correctionGraphics

An optical proximity correction method and a mask making method are provided. The optical proximity correction method includes: providing an initial photolithographic mask pattern including a plurality of main patterns; obtaining a main graphic group from a plurality of main graphics based on an electrostatic prone judgement rule, wherein the main graphic group comprises at least two adjacent maingraphics; setting auxiliary graphics between adjacent main graphics in the main graphics group, wherein the auxiliary graphics includes auxiliary main graphics and auxiliary connecting graphics on both sides of the auxiliary main graphics, and the auxiliary connecting graphics connect the auxiliary main graphics and the main graphics; performing OPC correction on the plurality of main graphics and auxiliary graphics to form main correction graphics from the main graphics and auxiliary correction graphics from the auxiliary graphics, wherein the auxiliary correction graphics comprise auxiliarycorrection main graphics corresponding to the auxiliary main graphics and auxiliary correction connection graphics corresponding to the auxiliary connection graphics. The optical proximity correctionmethod avoids the occurrence of graphic missing angles or bridging damage at opposite cusps of adjacent main correction graphics.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

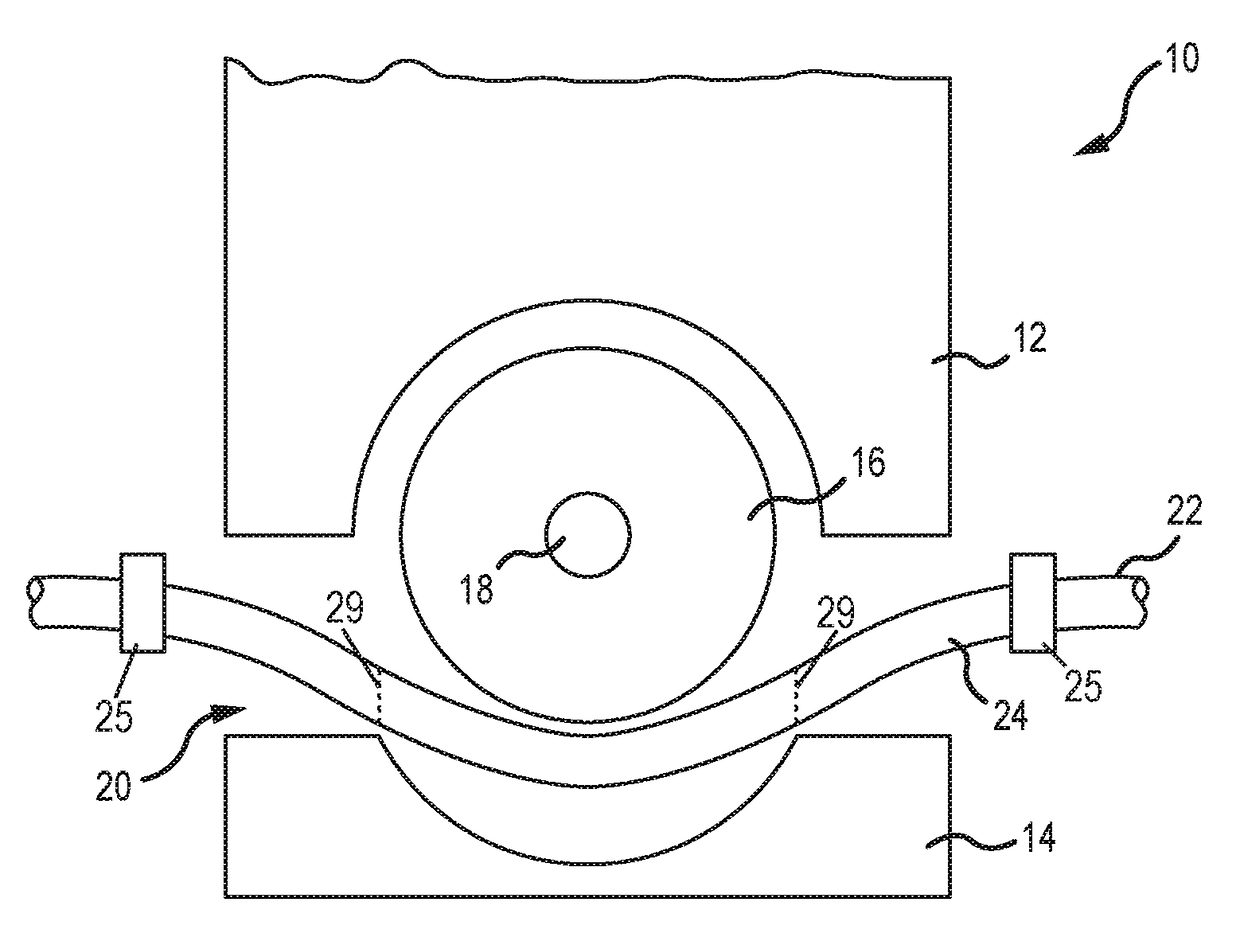

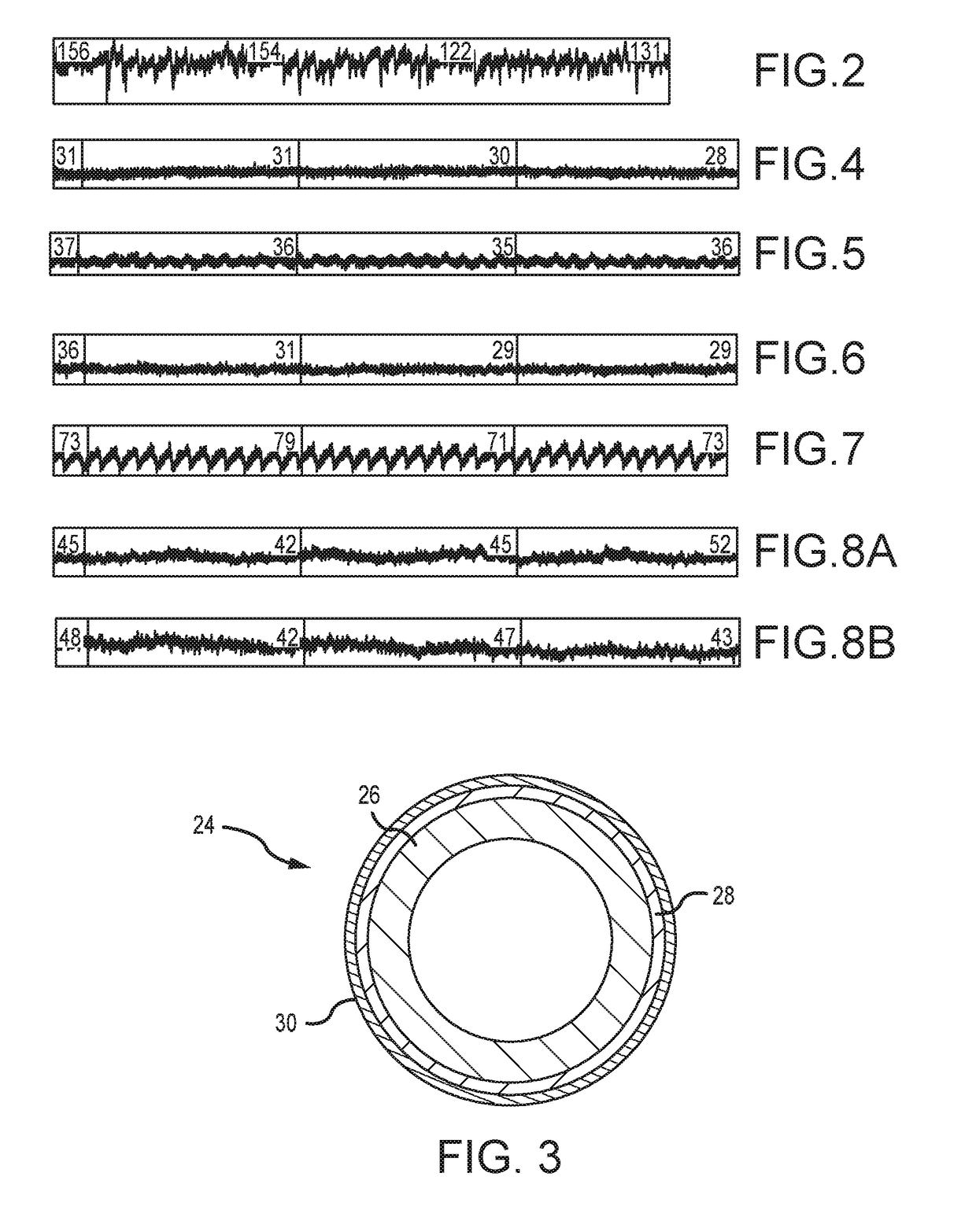

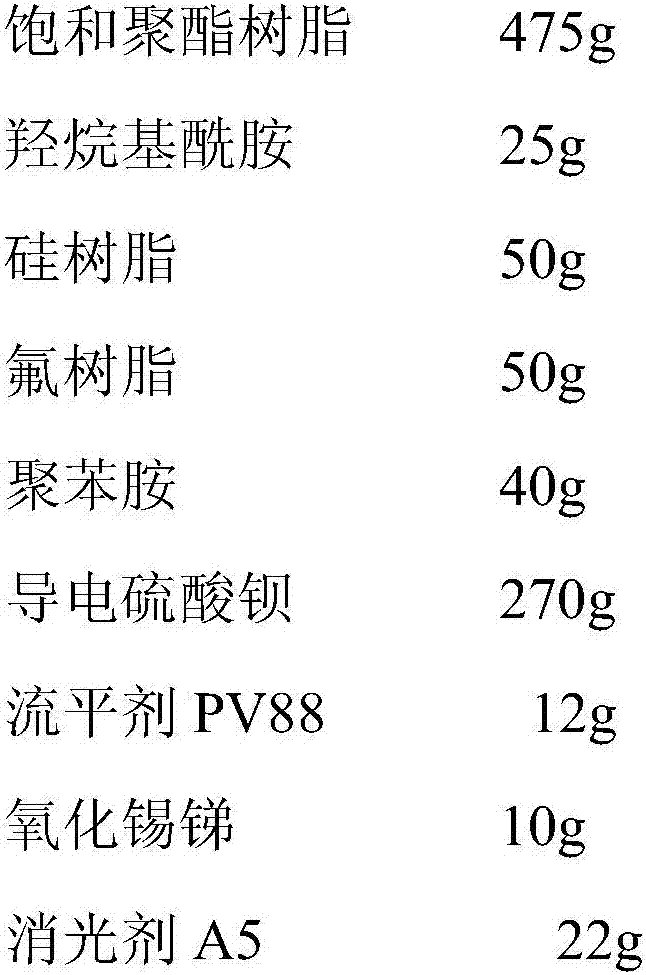

Interface Tubing for Peristaltic Pump

InactiveUS20180117239A1Reduces static charge buildupResist abrasionLiquid surface applicatorsElectrocardiographyPeristaltic pumpEngineering

A pump interface tubing for use in a peristaltic pump includes a tubular core having an outer surface and a treatment on the outer surface. The treatment reduces static charge buildup on the tubular core during operation of the peristaltic pump, and thereby reduces the noise signal that might otherwise undesirably couple to a signal of interest. Treatments include nitrile layers, heat shrink layers, cotton fiber layers, and anti-static sprays.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

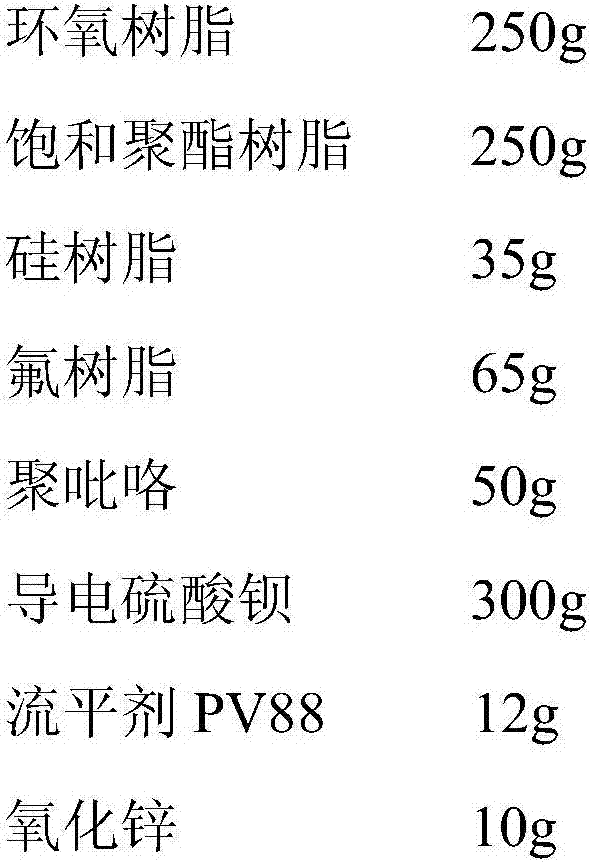

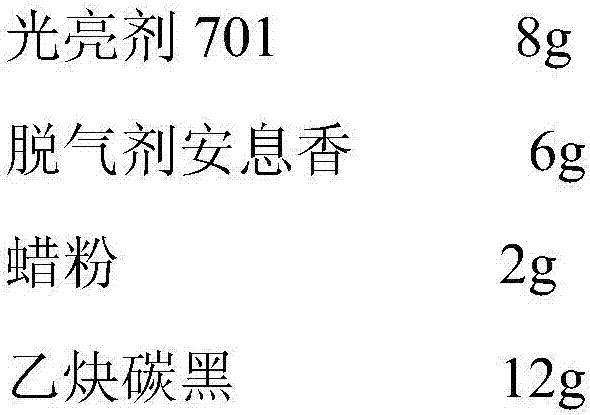

Dust-proof and anti-fouling powder coating, preparation method and application thereof and dust-proof and anti-fouling product

PendingCN107033731AExcellent dust-proof, anti-static, anti-fouling, easy-to-clean performanceLower volume resistivityAntifouling/underwater paintsPaints with biocidesConductive polymerPowder coating

The invention relates to the field of powder coatings and discloses a dust-proof and anti-fouling powder coating, a preparation method and an application thereof and a dust-proof and anti-fouling product. In terms of 1,000 parts by weight of the powder coating, the powder coating is prepared from 400-750 parts by weight of matrix resin, 200-500 parts by weight of filler, 10-80 parts by weight of a general additive, 20-100 parts by weight of a conductive polymer, 10-100 parts by weight of an anti-static auxiliary and 0-50 parts by weight of a pigment. The dust-proof and anti-fouling powder coating has excellent dust-proof, anti-static and anti-fouling performance and is easy to clean.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG

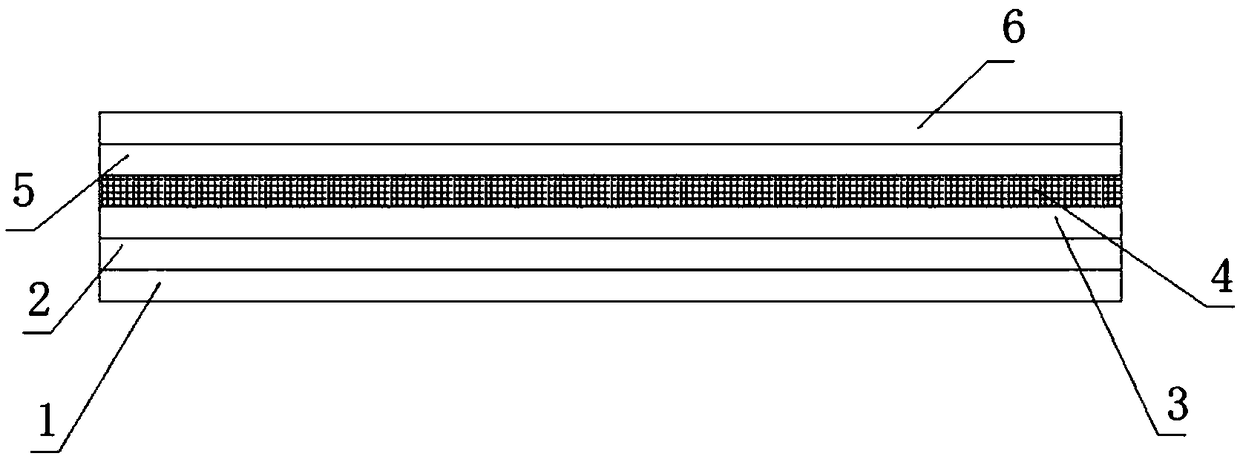

Water-based environmental-friendly sandpaper and production method thereof

ActiveCN109290971AImprove water resistanceReduce cloggingAbrasion apparatusSandpaperFolding endurance

The invention provides water-based environmental-friendly sandpaper. The water-based environmental-friendly sandpaper comprises a base paper layer (1), a waterproof treatment layer (2), a bottom gluelayer (3), an abrasive layer (4), a compound glue layer (5) and an anti-blocking treatment layer (6) which are sequentially arranged from bottom to top. The waterproof treatment layer in the sandpaperimproves the waterproof capability, tensile strength, softness, folding endurance and smoothness of the base paper layer and effectively prevents base glue and compound glue from penetrating to the back of the base paper layer. The anti-blocking treatment layer in the sandpaper can make abrasive dust fall off and be not adhered to the sandpaper, so that the blocking phenomenon generated during the grinding of the sandpaper is reduced effectively, the service life of the sandpaper is greatly prolonged, and the grinding efficiency is improved.

Owner:湖北重泰研磨工具有限公司

A method for preparing yarn from aramid 1414 waste short fiber

Owner:CHANGSHU BAOFENG SPECIAL FIBER

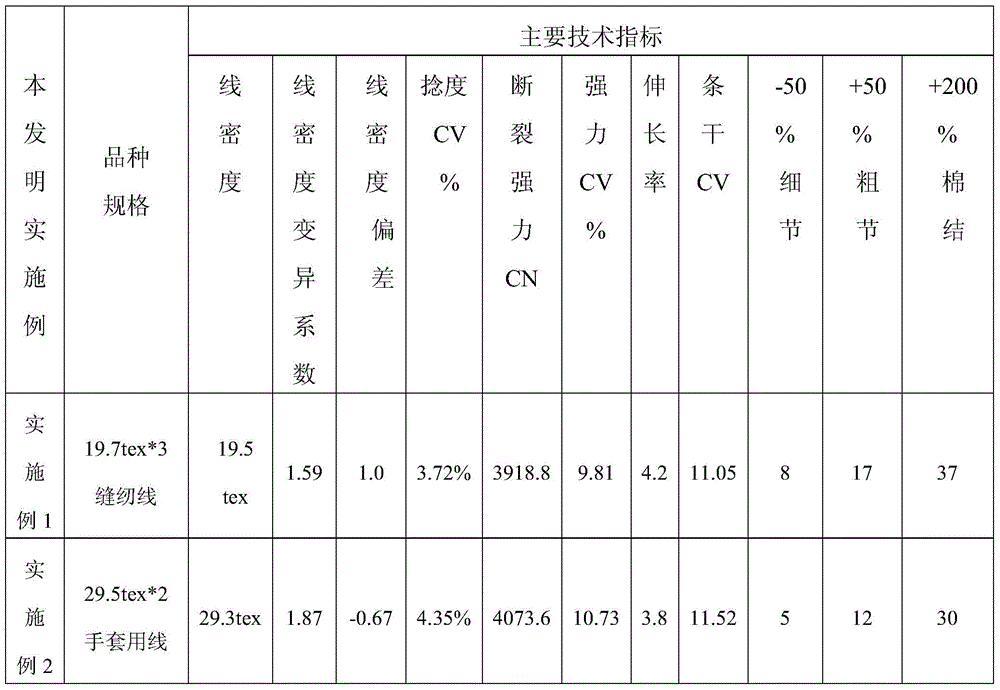

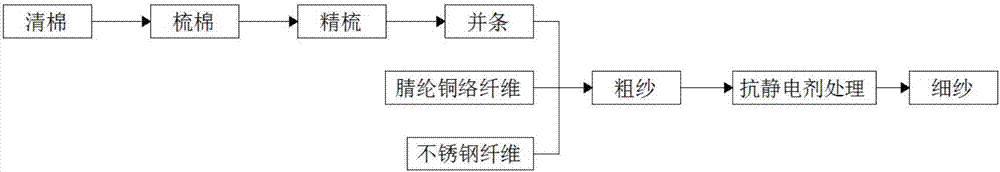

Processed textile thread and production flow thereof

InactiveCN106906547AImprove antistatic performanceImprove conductivityYarnVegetal fibresMetallurgySingle fiber

The invention discloses a processed textile thread, which is characterized in that the processed textile thread is produced by blending doubling threads prepared from natural fibers and doubling threads prepared from acrylic copper complex fibers at a ratio of 60 to 40 and then adding 1% to 2% of stainless steel fibers. A production flow comprises the following steps: the stainless steel fibers added in the process for processing the textile thread have relatively low bending stiffness, and good bendability and spinnability, and the relatively high single fiber strength can well resist the tensile deformation of clothing materials. The stainless steel fibers are mixed with the doubling threads prepared from the natural fibers to be blended, so that the antistatic properties of the textile thread can be improved, and the long-term antistatic properties can be provided. By blending the doubling threads prepared from the natural fibers, the stainless steel fibers and the doubling threads prepared from the acrylic copper complex fibers, the antistatic property of the textile thread can be effectively improved. The electrical conductivity of the processed textile thread can be improved, the static electricity is difficult to form, and the antistatic property and aesthetic comfort requirements of the textile thread are simultaneously met.

Owner:江苏红磨坊纺织品有限公司

Antistatic rubber conveyor belt

InactiveCN110202887AGood wear resistanceReduce static buildupConveyorsSynthetic resin layered productsPolyesterNatural rubber

The invention discloses an antistatic rubber conveyor belt. The antistatic rubber conveyor belt is used for effectively avoiding adverse effects of static electricity on a material during conveying. The antistatic conveyor belt is formed by an upper layer material, an intermediate layer material and a lower layer material. Each of the upper layer material and the lower layer material is formed bynatural rubber and a small amount of thermoplastic polyurethane filled with acetylene black. The intermediate layer material is formed by a polyester cord material cloth. The antistatic rubber conveyor belt adopting the intermediate layer as a skeleton is obtained by laminating, calendering, vulcanizing and molding the three layer materials. The directed aggregation of the acetylene black in the thermoplastic polyurethane is used to form an effective conductive path, o the effective antistatic effect is achieved under the premise of maintaining the wear resistance of the conveyor belt.

Owner:扬州赛思新材料科技有限公司

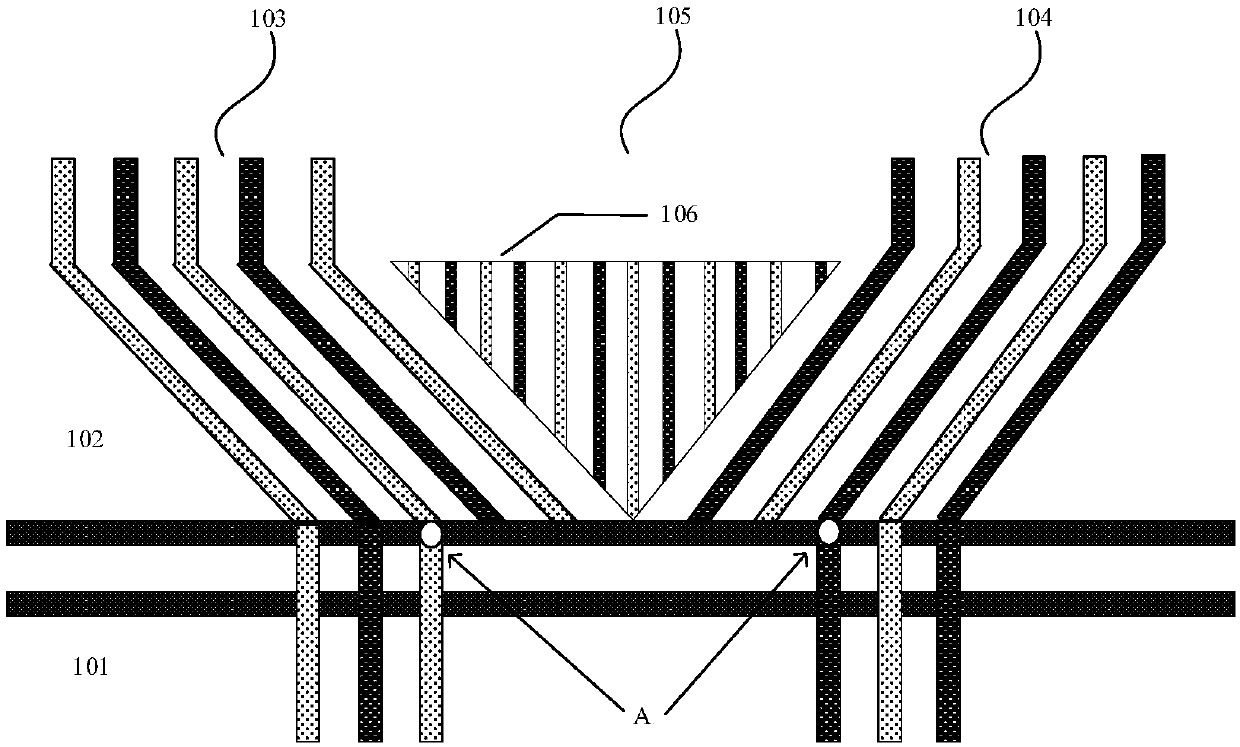

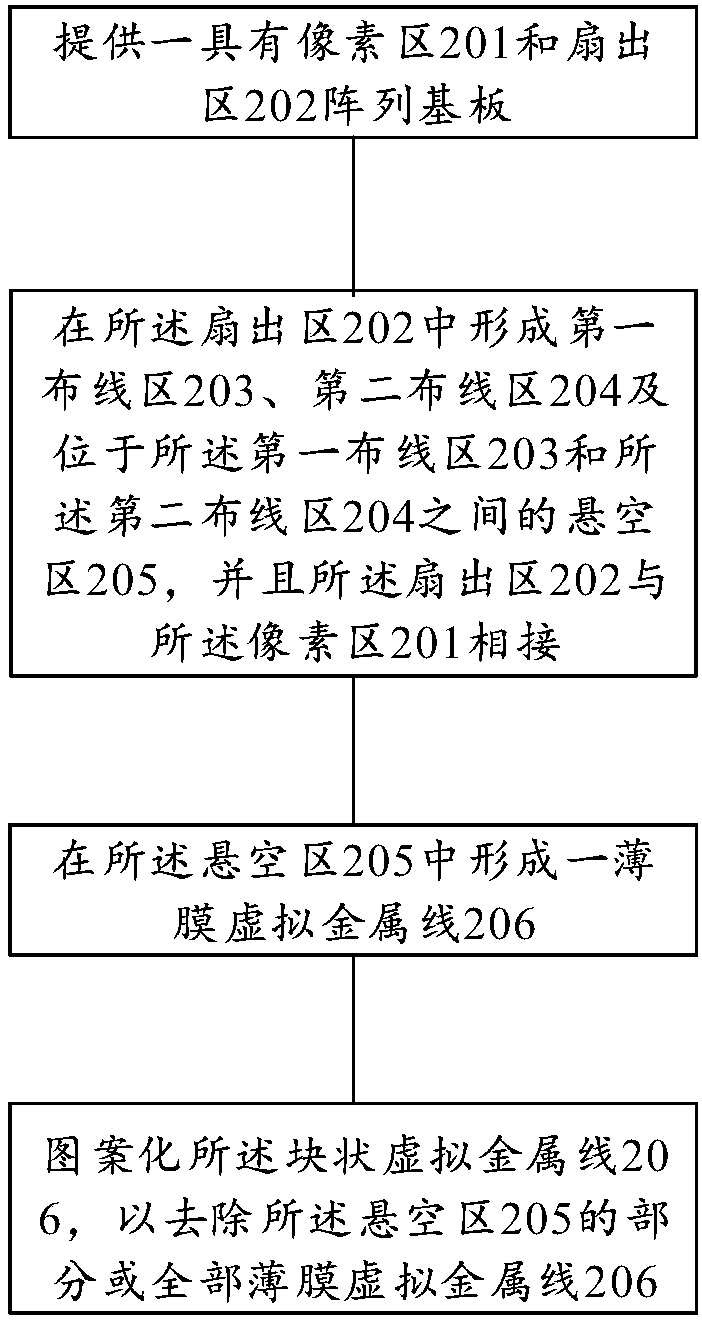

Array substrate, manufacturing method thereof, display panel and display device

ActiveCN107658294AAvoid processReduce processing technologySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the field of displaying, and provides an array substrate, a manufacturing method thereof, a display panel and a display device. The manufacturing method of the array substratecomprises the steps of supplying the array substrate which is provided with a pixel region and a fan-out region; forming a first wiring region, a second wiring region and a suspended region between the first wiring region and the second wiring region in the fan-out region, and connecting the fan-out region with the pixel region; forming a film virtual metal wire in the suspended region; and patterning the film virtual metal wire. Through patterning the film virtual metal wire, accumulated static charges are reduced for preventing static breakdown; and on the other hand, Rubbing Mura in friction orientation of an alignment film is prevented, thereby improving product performance. Furthermore simple operation is realized in removing the film virtual metal wire according to the method. The number of processing procedures of the array substrate and manufacturing cost are reduced.

Owner:BOE TECH GRP CO LTD +1

Polylactic acid film and preparation method thereof

InactiveCN110272551AReduce coefficient of frictionReduce vacuumSynthetic resin layered productsFlat articlesCelluloseSurface layer

The invention relates to a polylactic acid film. The polylactic acid film comprises an inner layer prepared from a polylactic acid copolymer, at least one middle layer mainly prepared from cellulose and chitin, and at least one surface layer prepared from a polylactic acid copolymer; and based on a weight of the surface layer, the surface layer contains 0.05%-0.6% by weight of crosslinked polymer spherical particles having particle diameters of 2-6 [mu]m, and the middle layer is located between the inner layer and the surface layer. The invention also relates to a preparation method of the polylactic acid film. The preparation method comprises the steps of performing co-extrusion cast compounding on the inner layer, the middle layer and the surface layer, and performing biaxial stretching to obtain the polylactic acid film. According to the multi-layer co-extruded film containing the polylactic acid polymer and the cellulose-chitin prepared by the invention, the friction coefficient is reduced, the adhesion is reduced, the heat sealing property is increased, electrostatic formation and film dust collection are reduced, the film has high biodegradability, the cellulose-chitin layer has a crystal structure through which gas cannot pass, the crystal structure can effectively resist invasion of oxygen, and the prepared film is more suitable as a packaging film for fresh food.

Owner:梁真

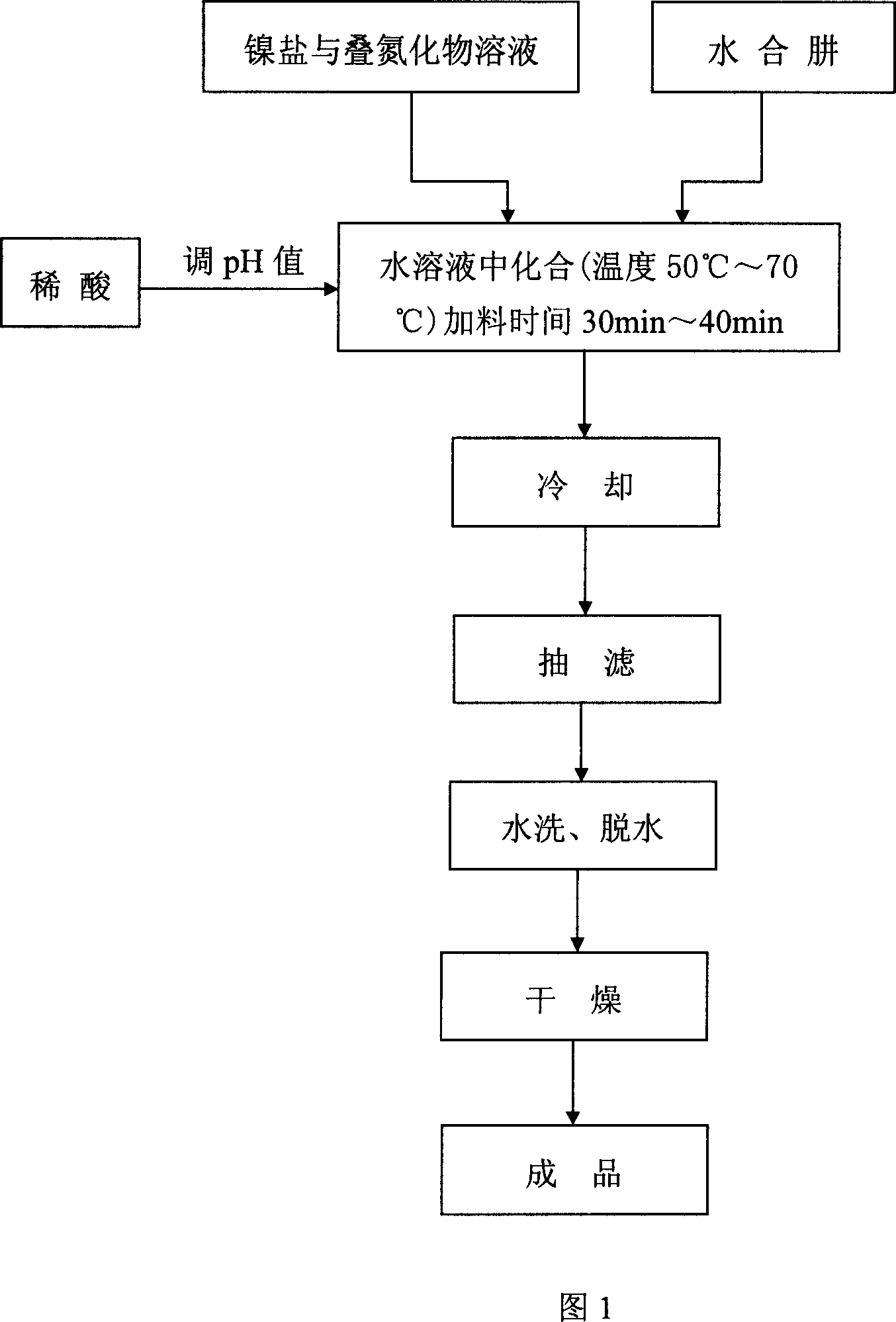

Method for preparing nickel hydrazine azide

InactiveCN101618866AGuaranteed singularityImprove detonation abilityHydrazoic-acids/azides/halogen-azidesNickel saltHydrazine compound

The invention discloses a method for preparing nickel hydrazine azide. The method comprises: taking soluble nickel salts as base solution; using acetic acid to adjust the pH of the formed base solution; using graphite as modified additives of medicaments; adding sodium nitride solution and hydrazine hydrate solution to the base solution dropwise to perform chemical combination; preserving heat, cooling, leaching, washing, dehydrating and drying; and obtaining a finished product of nickel hydrazine azide. The method is simple in pH control, and buffer solution consisting of weak acid and weak-acid salts ensures stable pH, longer effectiveness and the unicity of medicament composition, and significantly improves explosion initiation capacity, so the buffer solution is more suitable to be used as a primary explosive. By adopting nickel acetate as raw material, a small quantity of nickel hydrazine nitrate substances which are formed by use of nitrates and result in worse or unstable pharmaceutical performance can be avoided. Dropping and time difference ensure the complete reaction of sodium nitride and high yield of nickel hydrazine azide.

Owner:NANJING UNIV OF SCI & TECH

Automatic ignition powder for air bag restraint system and preparation method thereof and gas generator for automobile air bag restraint system

InactiveCN108238836ARaw material safety and environmental protectionGood long-term storage stability at high temperatureExplosivesPressure gas generationPhthalocyanineProduct gas

The invention provides automatic ignition powder for an air bag restraint system and a preparation method thereof and an air bag containing the automatic ignition powder. The automatic ignition powdercontains a fuel, an oxidant, an auxiliary oxidant and an additive, wherein the additive is bamboo carbon-loaded metal phthalocyanine. The automatic ignition powder provided by the invention has relatively good long heat accumulation stability and is suitable for a long service of an automobile.

Owner:BYD CO LTD

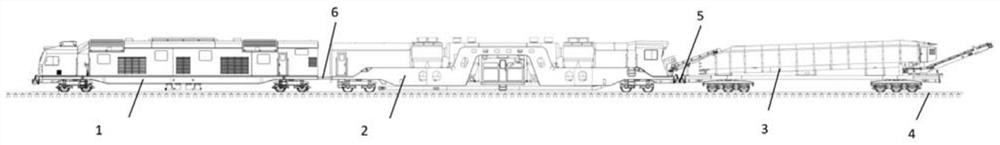

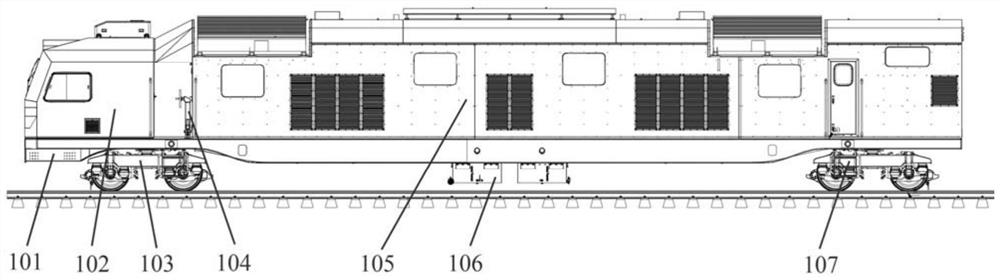

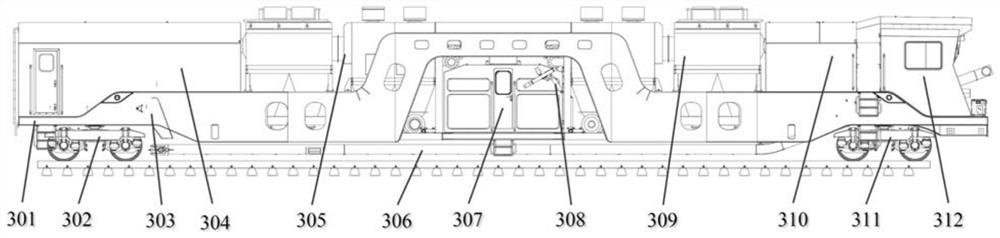

Railway tunnel sleeper outer ballast bed coal suction vehicle set and operation method thereof

PendingCN112301938AImprove movement stabilityMeet the static strength standardRailway cleaningBogieRailway tunnel

The invention discloses a novel railway tunnel ballast bed coal suction vehicle set and a corresponding operation method. The coal suction vehicle set comprises a side suction vehicle and a material vehicle, and a side suction vehicle frame (301) is installed on a third driving walking bogie (302) and a fourth driving walking bogie (311); the side suction vehicle frame (301) is n-shaped, at leastone set of the side suction working device (308) is arranged and located at the right-angle portion of an operation cab (307), the side suction working device (308) is connected with the side suctionvehicle frame (301) through a rotary supporting rotary table, the side suction working device (308) is fixedly connected with the rotary supporting rotary table, and a hydraulic motor drives a worm wheel to rotate via a worm, so that a mechanical arm swings out and in along the rotation axis. According to the railway tunnel sleeper outer ballast bed coal suction vehicle set, speed reduction designis conducted on the air ducts in the tops of a front draught fan chamber and a rear draught fan chamber of the side suction vehicle set, so that the ultrahigh air speed of a draught fan outlet is reduced to 2 m / s, and pulverized coal flying dust around the outlet is prevented.

Owner:CRCC HIGH TECH EQUIP CORP LTD

Anti-static grooming device

ActiveUS10064389B2Reduce and effectively eliminate static electricity buildup and dischargeAmple dexterityBrush bodiesOther apparatusHand movementsIndex finger

A grooming device for animals includes a glove and one or more grooming pads affixed (possibly molded) thereto. The glove is made from anti-static material, and may additionally be treated with a spray or solution, that is resistant to electrostatic accumulation and discharge caused by friction during the grooming process. The grooming pads include multiple protrusions that are used to cling to and collect extraneous debris and hair from the animal's body and coat. Due to the materials and the placement of the molded pad, the glove facilitates hand movement dexterity and reach. The device also allows the user increased tactility between the thumb and index finger by keeping them free of coverage by the grooming surface. The device may include a soft material on the back of the glove for grooming and brushing sensitive areas of the animal's coat.

Owner:SCHUSTER BARBARA

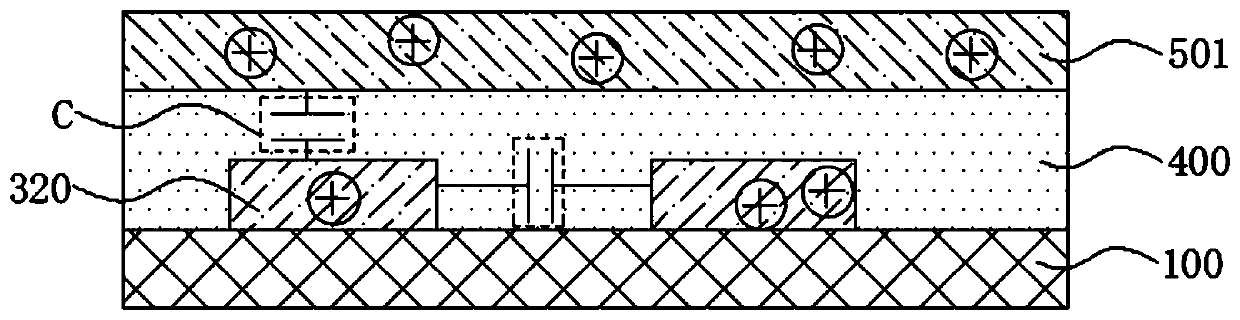

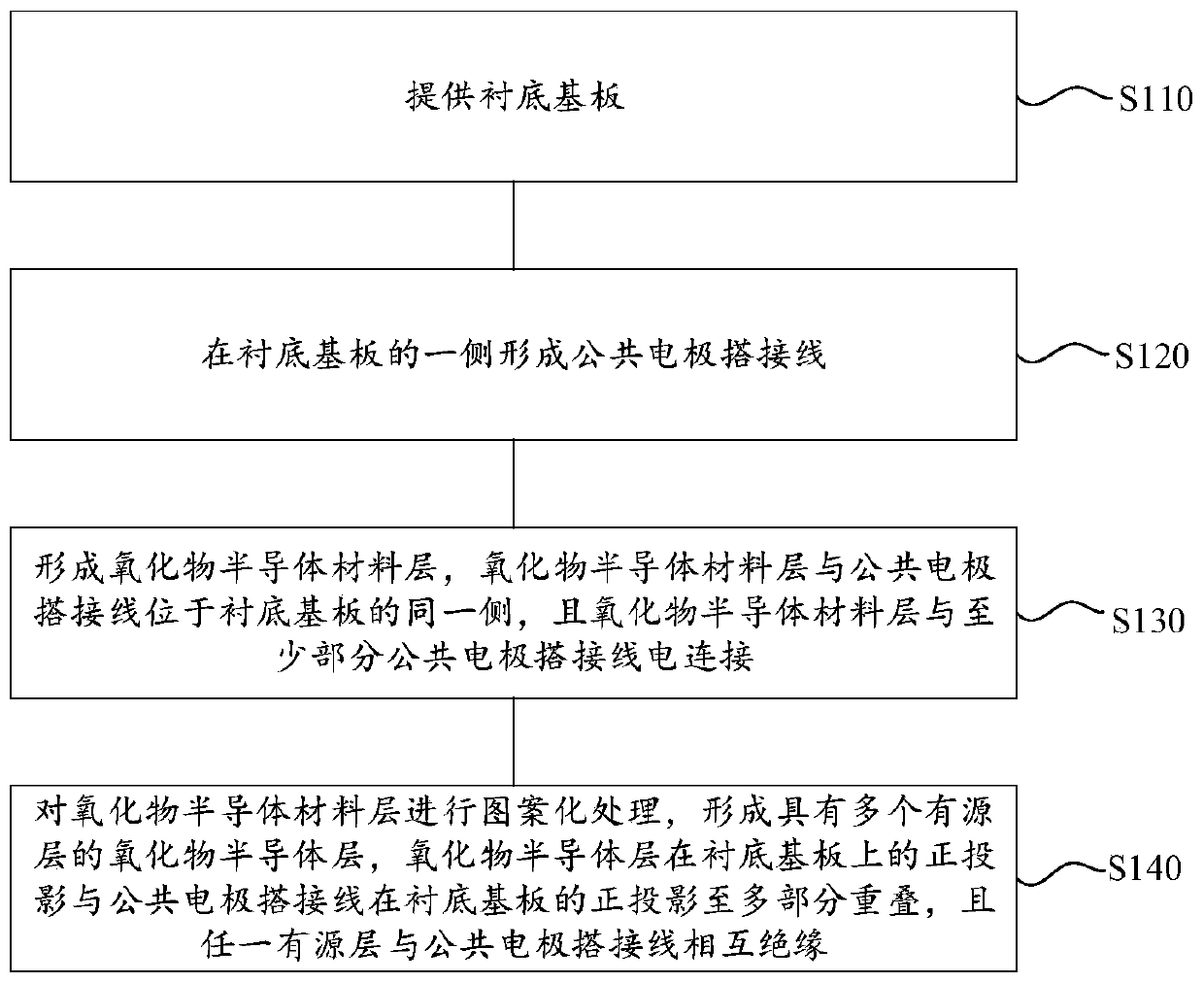

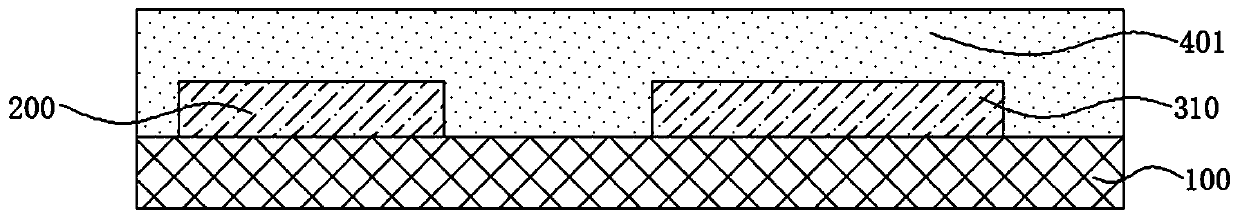

Array substrate and preparation method thereof

ActiveCN110518023AGood electrical conductivityReduce static buildupSolid-state devicesSemiconductor/solid-state device manufacturingOxide semiconductorLap joint

The invention provides an array substrate and a preparation method thereof, and belongs to the technical field of display. The preparation method of the array substrate comprises the steps of providing an underlayer substrate; forming a common electrode lap joint line on one side of the underlayer substrate; forming an oxide semiconductor material layer, wherein the oxide semiconductor material layer and the common electrode lap joint line are located on the same side of the underlayer substrate, and the oxide semiconductor material layer is electrically connected with at least part of the common electrode lap joint line; and carrying out patterning treatment on the oxide semiconductor material layer to form an oxide semiconductor layer with a plurality of active layers, wherein the orthographic projection of the oxide semiconductor layer on the underlayer substrate is at most partially overlapped with the orthographic projection of the common electrode lap joint line on the underlayersubstrate, and any active layer is insulated from the common electrode lap joint line. According to the preparation method of the array substrate, electrostatic breakdown of the array substrate in the preparation process can be avoided.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

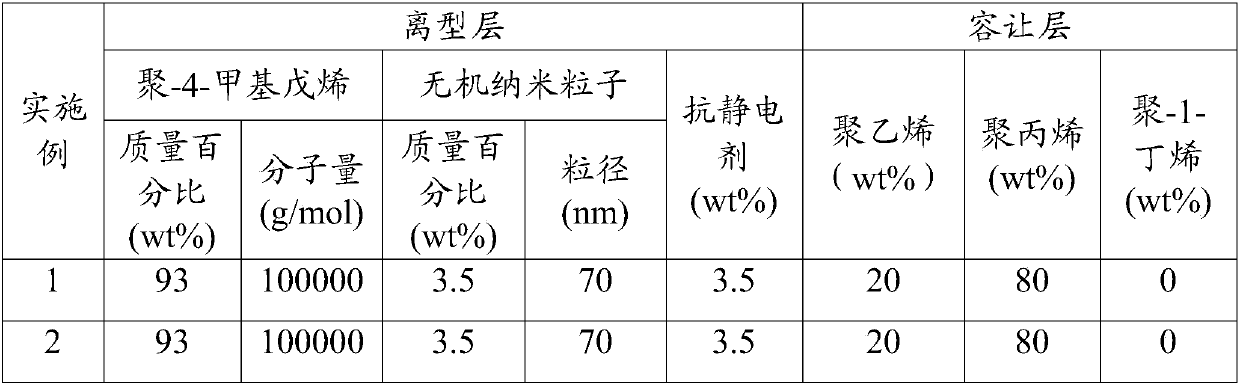

Release film and preparation method thereof

Owner:NINGBO CHANGYANG TECH

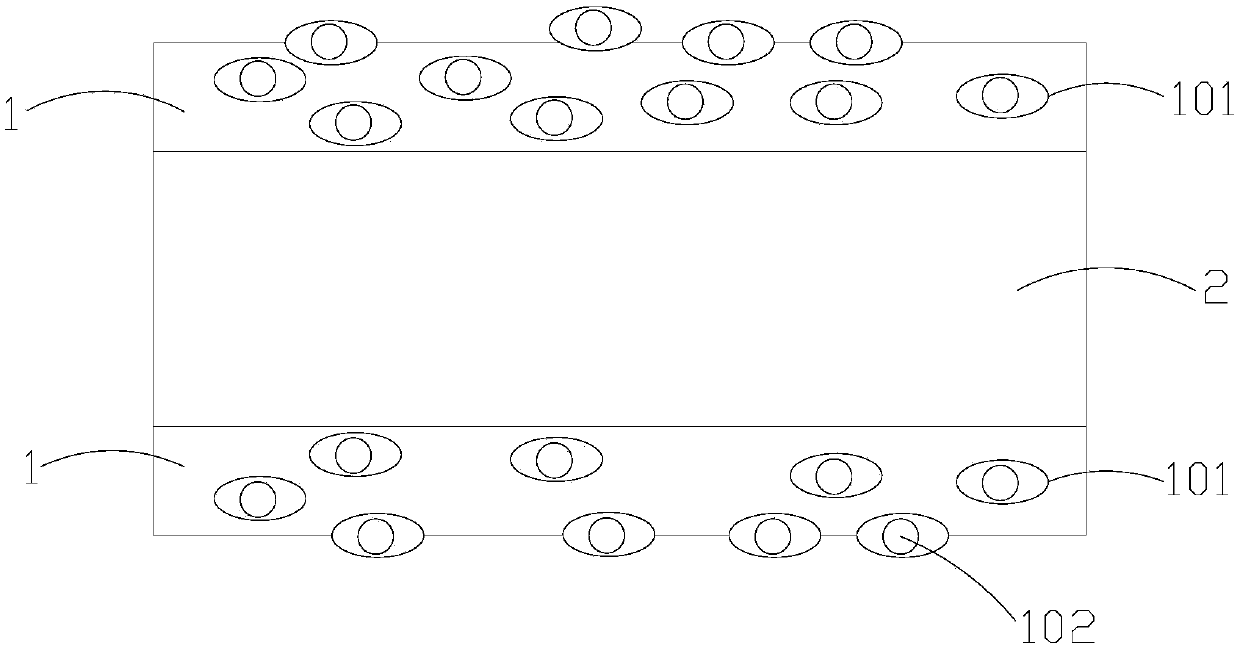

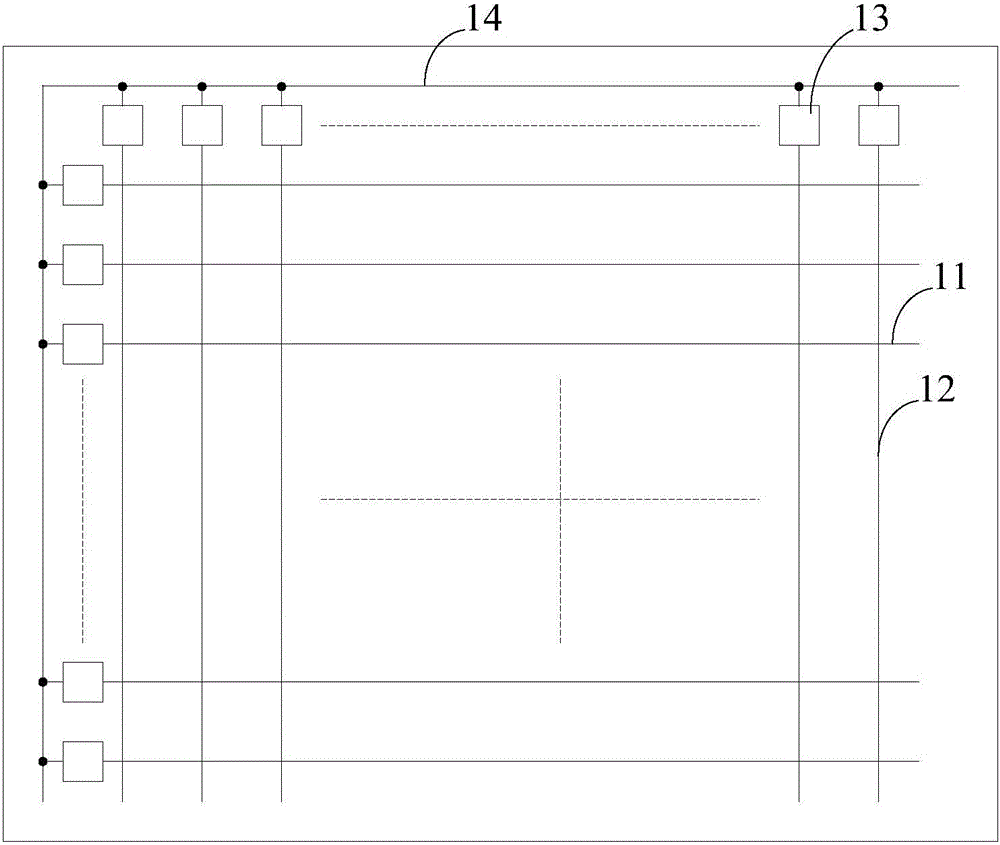

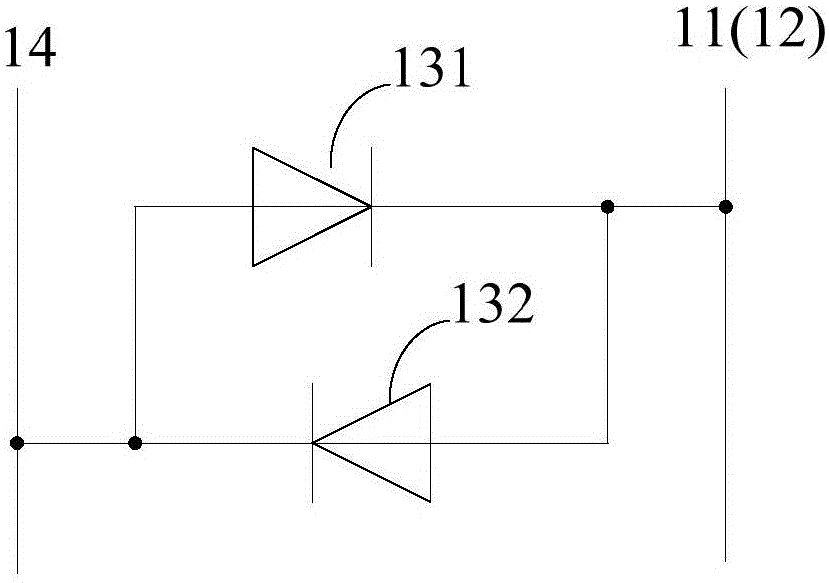

Liquid crystal display panel and antistatic array substrate thereof

InactiveCN105093739AReduce static buildupReduce wiringNon-linear opticsLiquid-crystal displayElectricity

The invention discloses a liquid crystal display panel and an antistatic array substrate thereof. The array substrate comprises a substrate, a plurality of scanning lines, a plurality of data lines and a plurality of first antistatic circuits. The scanning lines and the data lines are intersected on the substrate to define a display area. One first antistatic circuit is arranged between every two adjacent scanning lines or data lines, so that every two adjacent scanning lines or data lines discharge electricity to each other through the corresponding first antistatic circuit. In this way, static electricity accumulation can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

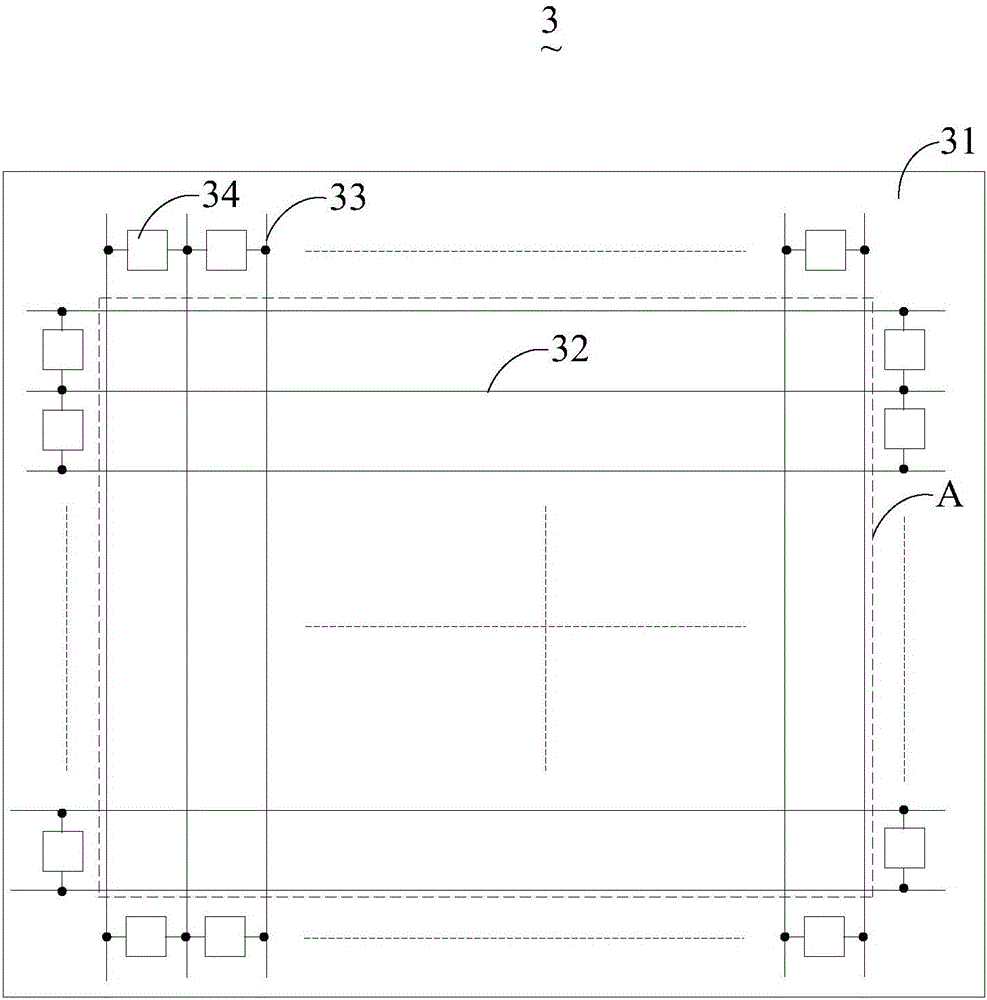

Manufacturing method for touch screen

InactiveCN107765923AReduce static buildupImprove yieldInput/output processes for data processingPotential differenceTouchscreen

The invention discloses a manufacturing method for a touch screen. The method comprises the steps that a first touch routing of a first touch electrode is connected with a first anti-static connectingportion, a second touch routing of a second touch electrode is connected with a second anti-static connecting portion, and the first anti-static connecting portion and the second anti-static connecting portion which are oppositely arranged are cut and removed during the following cutting. Before the cutting, the first touch routing is at an equal potential state through the first anti-static connecting portion, the second touch routing is at the equal potential state through the second anti-static connecting portion, static electricity accumulation of a single touch routing is greatly decreased, electrostatic discharge phenomenon caused by potential difference between different touch routings is effectively reduced, and therefore the problem of the touch routings and touch electrodes breaking down by the static electricity are prevented, and the finished product yield rate is improved.

Owner:TRULY OPTO ELECTRONICS

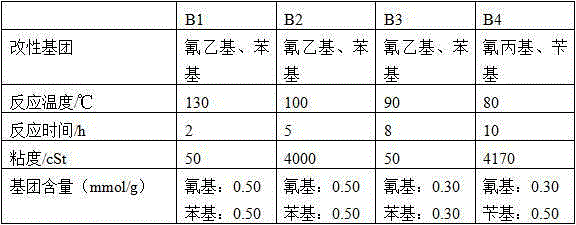

Preparation method of cyano-alkyl and aryl co-modified polysiloxane

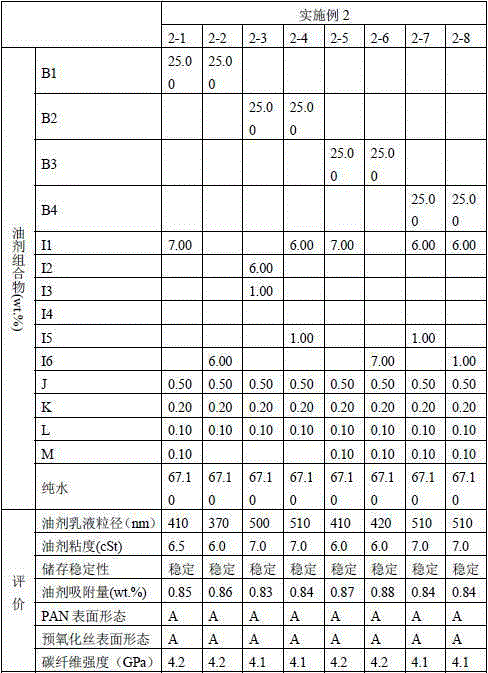

The invention provides a preparation method of cyano-alkyl and aryl co-modified polysiloxane. The method includes the following steps that cyano-alkyl silane is hydrolyzed, cyano-alkyl silane hydrolyzate is obtained, an alkali catalyst and an end-capping agent are added into the cyano-alkyl silane hydrolyzate, an aryl coupling agent and cyclosiloxane under protection of inert gas, and reaction is performed at 80-130 DEG C; the cyano-alkyl and aryl co-modified polysiloxane is prepared; the content of cyano-alkyl in the cyano-alkyl and aryl co-modified polysiloxane is 0.05-5 mmol / g, and the content of aryl in the cyano-alkyl and aryl co-modified polysiloxane is 0.1-3 mmol / g, and viscosity is 50-10,000 cST. The cyano-alkyl and aryl co-modified polysiloxane prepared through the method can serve as auxiliaries for producing high-performance carbon fibers. Particularly, the cyano-alkyl and aryl co-modified polysiloxane can serve as silicon oil agents for producing carbon fibers and can effectively moisten the surfaces of the fibers, reduce friction between the fibers and friction between the fibers and a guide roller, reduce surface defects and electrostatic accumulation caused by friction, and effectively prevent hot-melting adhesion of precursor fibers at the pre-oxidization stage and at the low-temperature carbonization stage.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD +1

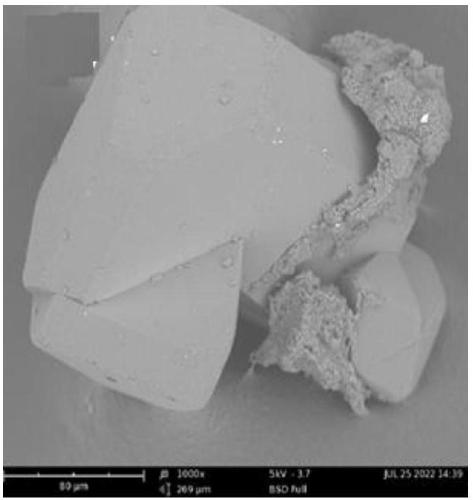

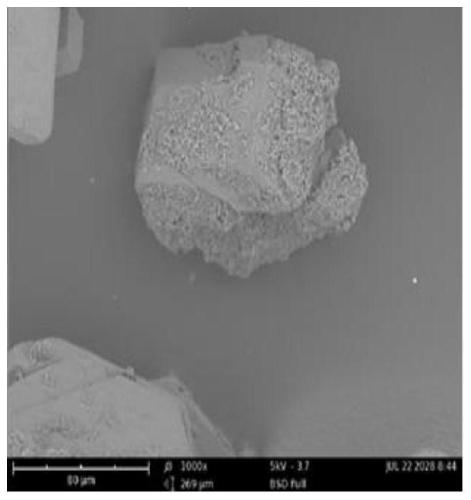

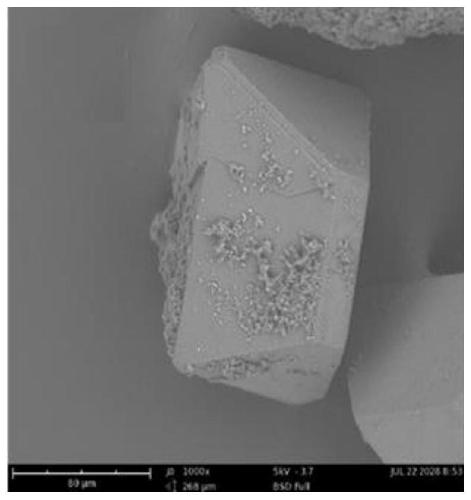

Polyaniline-coated nitro-amine high-energy explosive composite material and preparation method thereof

InactiveCN111320513AReduce static buildupTightly boundNon-explosive desensitisers/phlegmatisersSingle substance explosivesTEX-explosiveAniline

The invention provides a polyaniline coated nitro-amine high-energy explosive composite material. The preparation method sequentially comprises the following steps: step 1, dispersing an explosive: adding a high-energy single-compound explosive into an acidic solution of aniline, and stirring to obtain a uniform explosive dispersion liquid; step 2, reacting and coating: dropwise adding an acid solution of ammonium persulfate, and stirring until white particles in the reaction liquid turns into dark green particles, (the reactions are finished); step 3, carrying out solid-liquid separation, andfiltering the reaction solution to obtain a solid product namely the polyaniline-coated high-energy explosive; and step 4, washing and drying the solid product, filtering, and drying to obtain a loose finished product. Polyaniline not only can play a role in protecting the surface of the nitro-amine high-energy explosive and reduce the mechanical sensitivity, but also can significantly reduce theelectrostatic accumulation amount of the nitro-amine high-energy explosive and ensure the safety during transportation, storage and use. The synthesis method is simple, and the synthesized compositematerial is low in sensitivity and has a good application prospect.

Owner:NANJING UNIV OF SCI & TECH

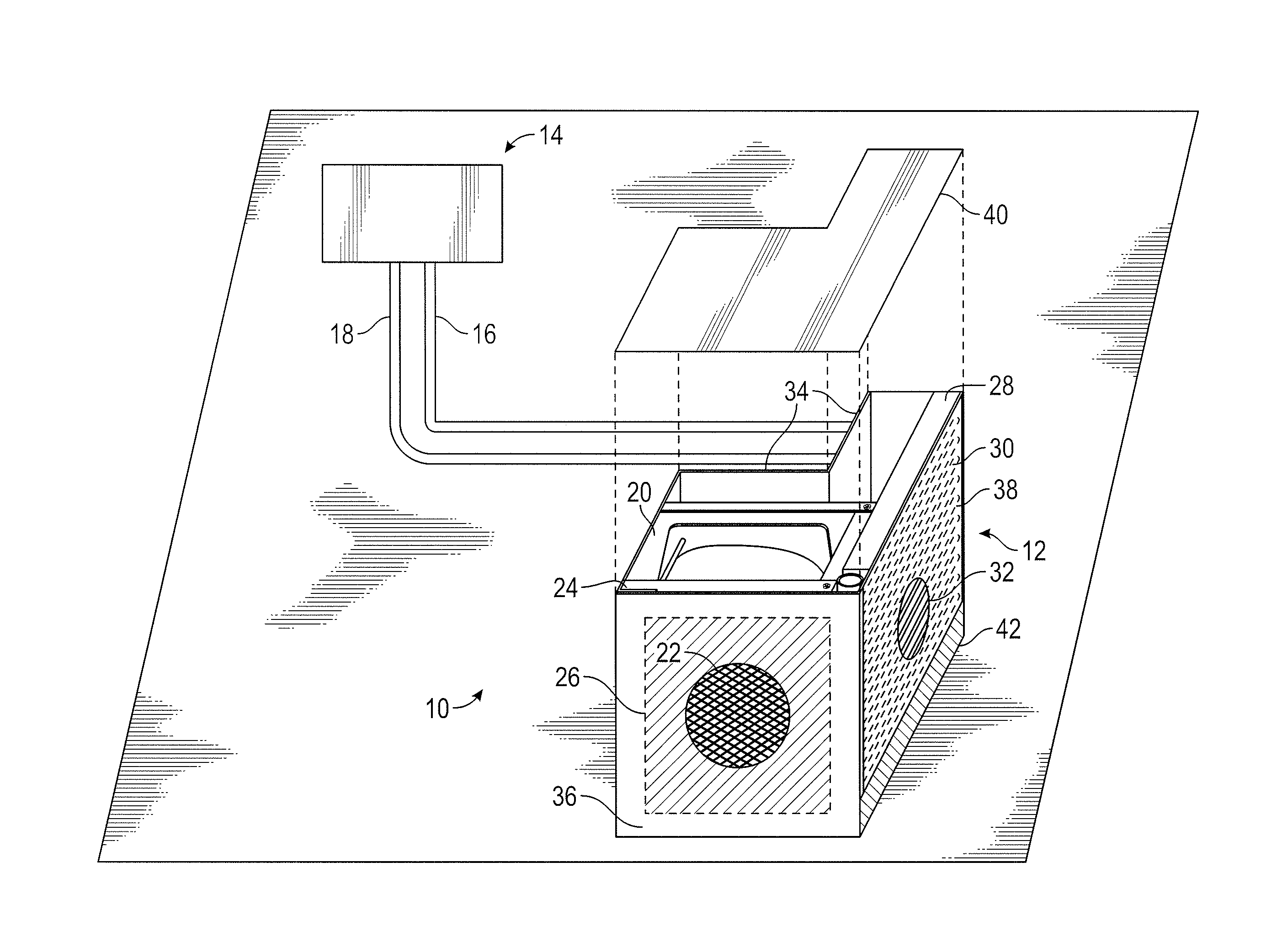

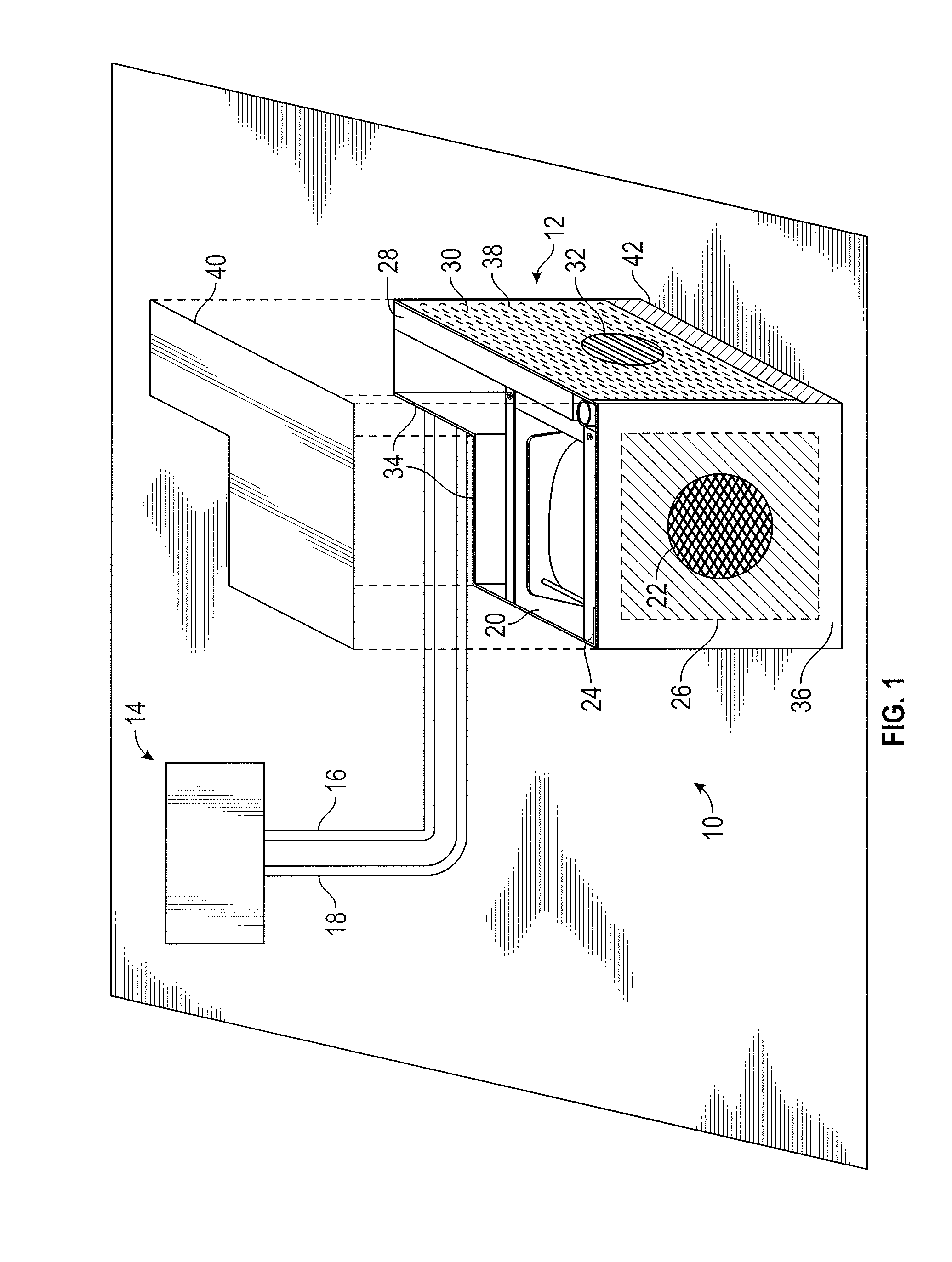

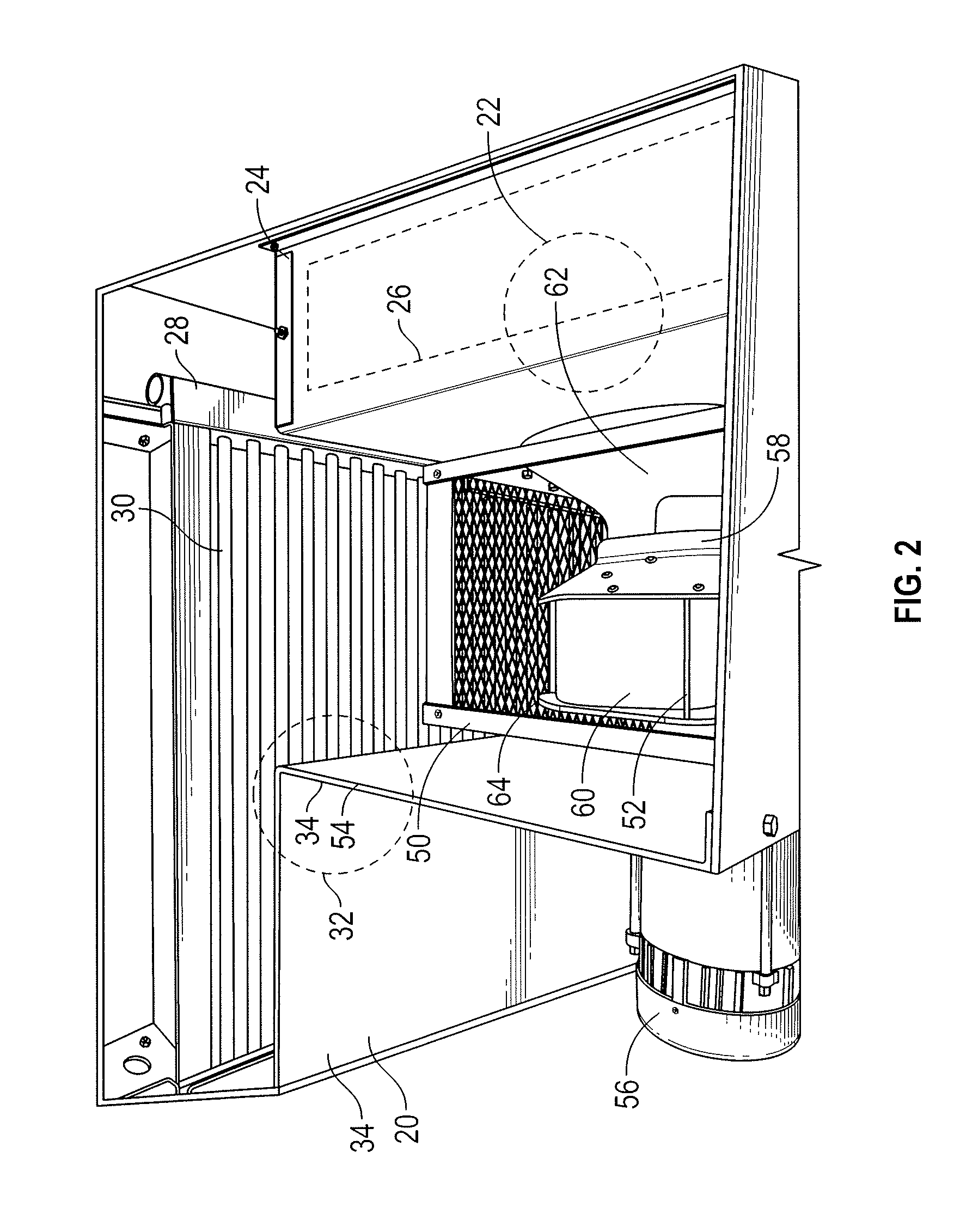

Heating and cooling system for hazardous environments

InactiveUS20160370019A1Disadvantages problemsProblems heatingMechanical apparatusAir heatersImpellerAir filter

A heating and cooling apparatus for hazardous environments is disclosed. The apparatus has a housing having an air inlet and an air outlet. The apparatus further comprises a motor having a shaft and an electrical component and a metallic impeller having an impeller inlet and blades. The impeller inlet faces the air inlet of the housing and the impeller is coupled to the shaft of the motor. The apparatus also has an air filter removably positioned at the air inlet of the housing. A coil is removably positioned inside the housing between the air outlet and the impeller blades. A valve is also coupled to the coil, the valve being operable to regulate the temperature of the coil by controlling the flow of fluid into the coil.

Owner:THERMA STOR LLC

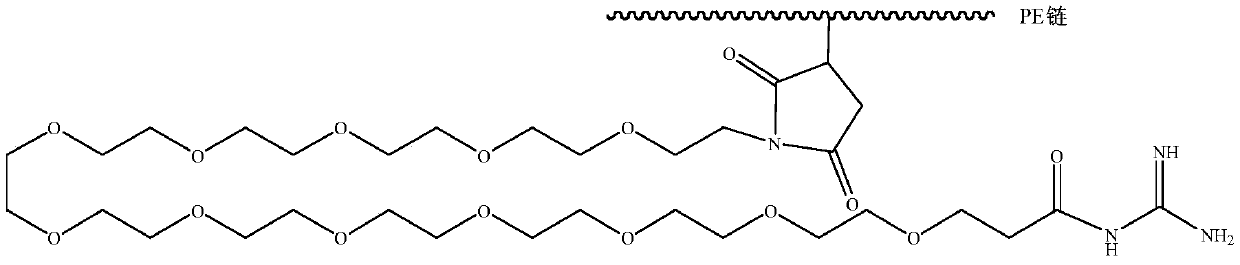

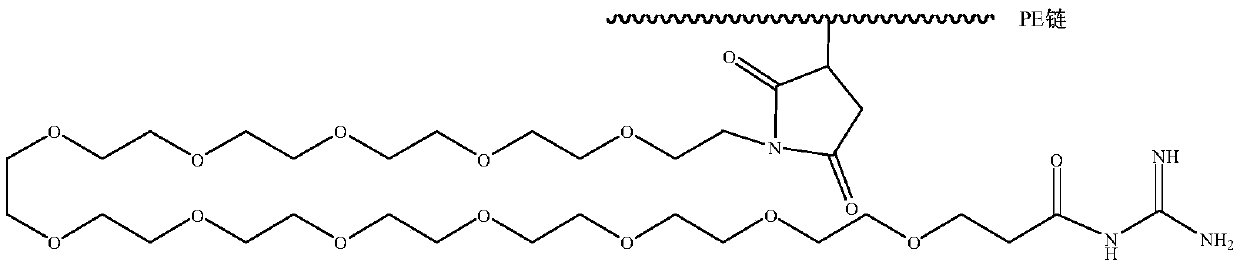

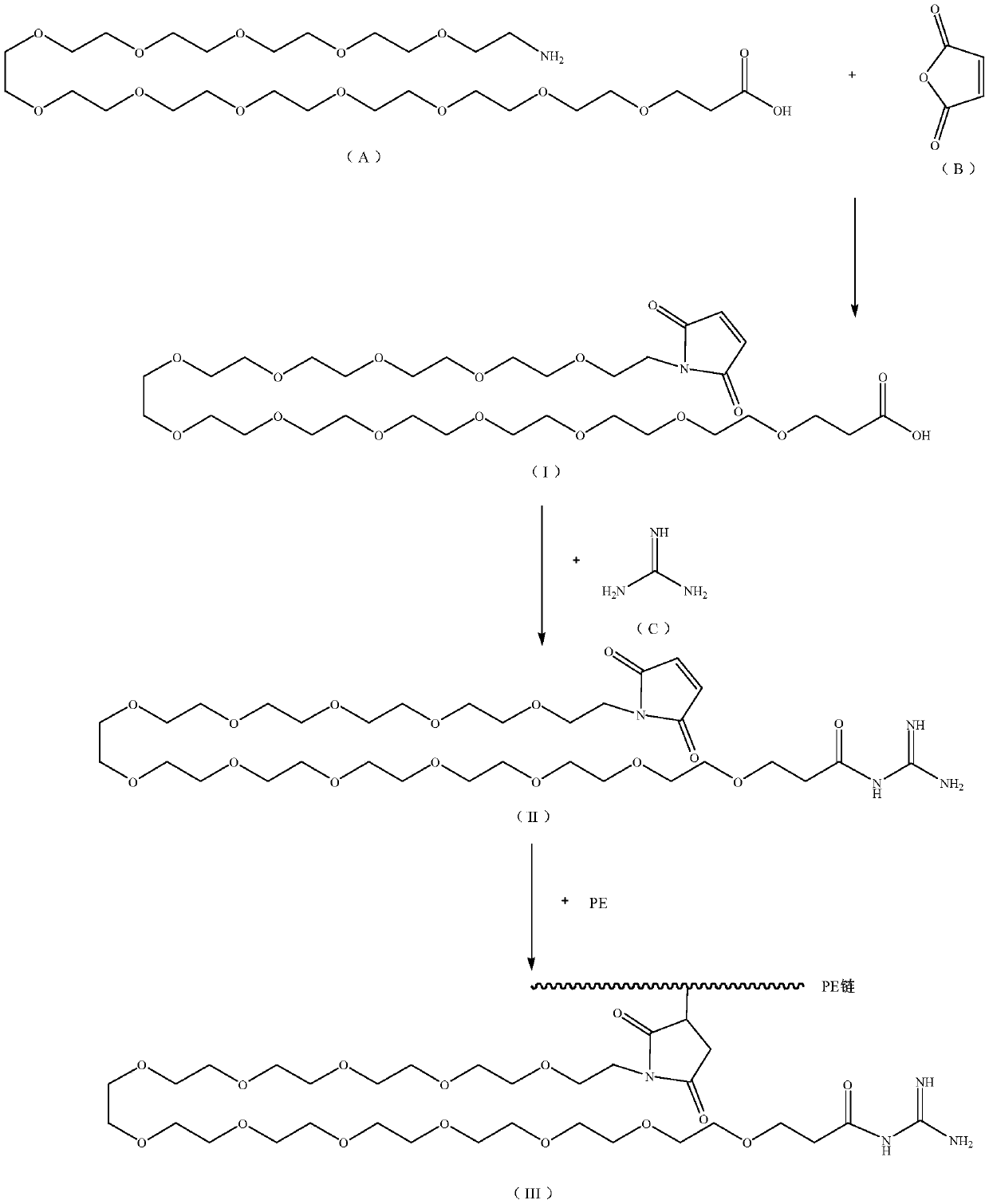

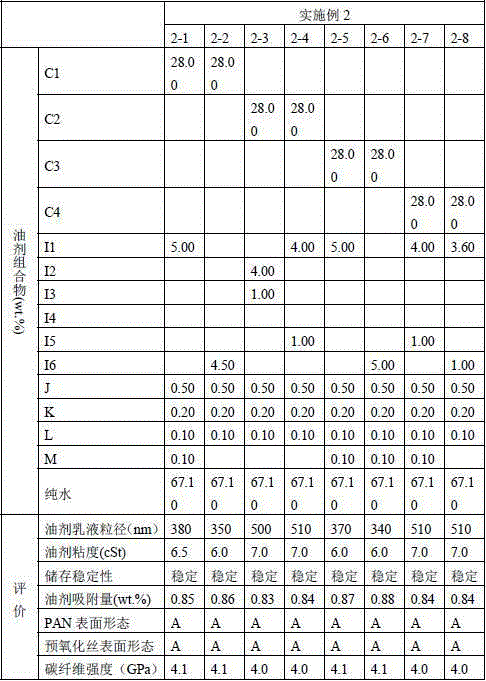

Novel antibacterial antistatic additive for PE and preparation method thereof

ActiveCN111171375AEasy to operateSuitable for industrial productionOrganic chemistryPolymer sciencePolythylene glycol

The invention belongs to the field of plastic processing aids. The invention relates to a novel antibacterial antistatic additive for PE and a preparation method of the novel antibacterial antistaticadditive. The method comprises the following steps: with amino-dodecapolyethylene glycol-carboxylic acid (A), maleic anhydride (B), guanidine (C) and polyethylene as raw materials, performing multi-step amidation reaction; and performing blending extrusive blow-molding treatment to obtain a target product, namely the novel antibacterial and antistatic additive. The antistatic agent has certain flame-retardant and plasticizing effects while effectively overcoming the defects of durability and no bacterium resistance of the existing antistatic agent, structurally provides antibacterial and antistatic groups, reduces the consumption of a plasticizer, reduces electrostatic accumulation, improves the flame retardancy, prolongs the service life, enriches the application field, and is particularly suitable for food packaging films.

Owner:泉州绿陆新材料科技有限公司

Preparation method cyano-alkyl and polyether co-modified polysiloxane

The invention provides a preparation method of cyano-alkyl and polyether co-modified polysiloxane. The method includes the following steps that cyano-alkyl silane is hydrolyzed, cyano-alkyl silane hydrolyzate is obtained, an alkali catalyst is added into the cyano-alkyl silane hydrolyzate, a polyether silicon oil and cyclosiloxane under protection of inert gas, and reaction is performed at 80-130 DEG C; the cyano-alkyl and polyether co-modified polysiloxane is prepared; the content of cyano groups in the cyano-alkyl and polyether co-modified polysiloxane is 0.05-5 mmol / g, the molecular weight of the polyether silicon oil is 500-100,000, the number of EOs in the polyether silicon oil is 3-100, and the number of POs in the polyether silicon oil is 0-40. The cyano-alkyl and polyether co-modified polysiloxane prepared through the method can serve as auxiliaries for producing high-performance carbon fibers. Particularly, the cyano-alkyl and polyether co-modified polysiloxane can serve as silicon oil agents for producing carbon fibers and can effectively moisten the surfaces of the fibers, reduce friction between the fibers and friction between the fibers and a guide roller, reduce surface defects and electrostatic accumulation caused by friction, and effectively prevent hot-melting adhesion of precursor fibers at the pre-oxidization stage and at the low-temperature carbonization stage.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com