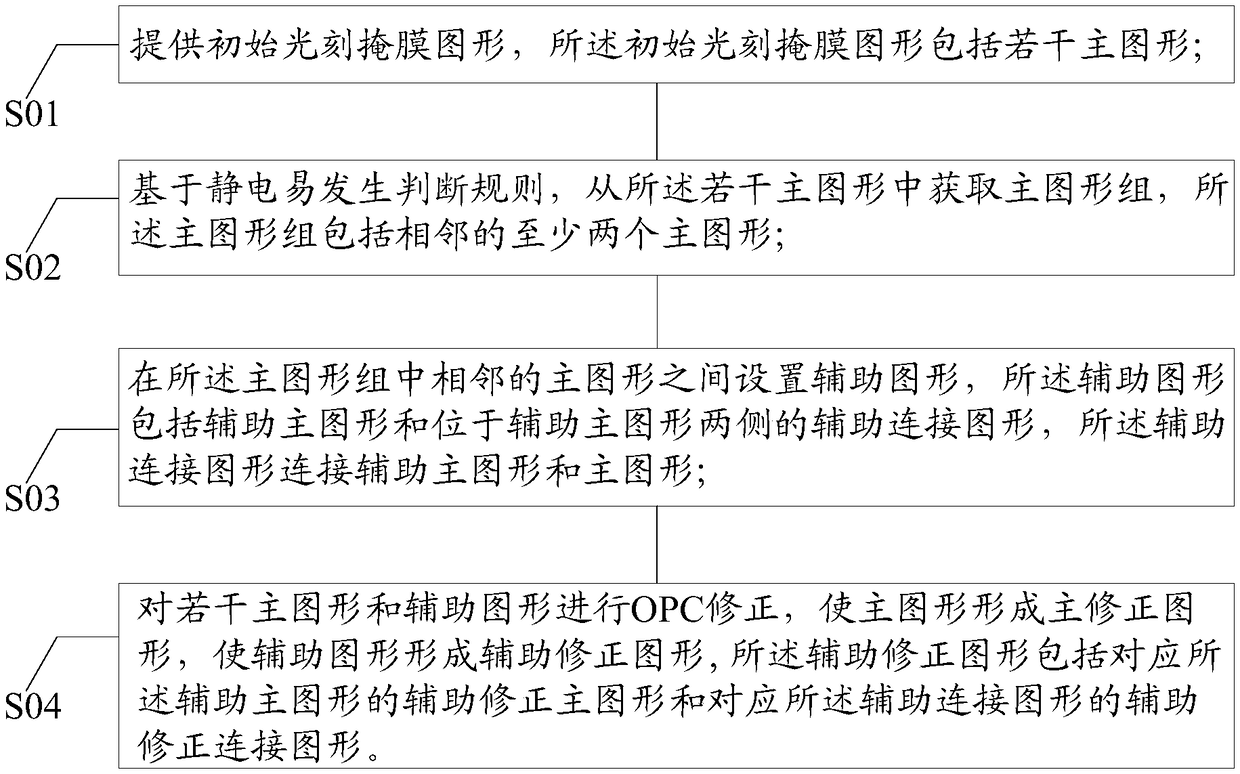

Optical proximity correction method and mask making method

A technology of optical proximity correction and lithography mask, which is applied in the direction of optics, originals for photomechanical processing, photoplate making process of pattern surface, etc., can solve problems such as bridging damage, graphics missing corners, etc., and avoid electrostatic shock Wear, avoid graphics missing corners or bridge damage, reduce the effect of static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

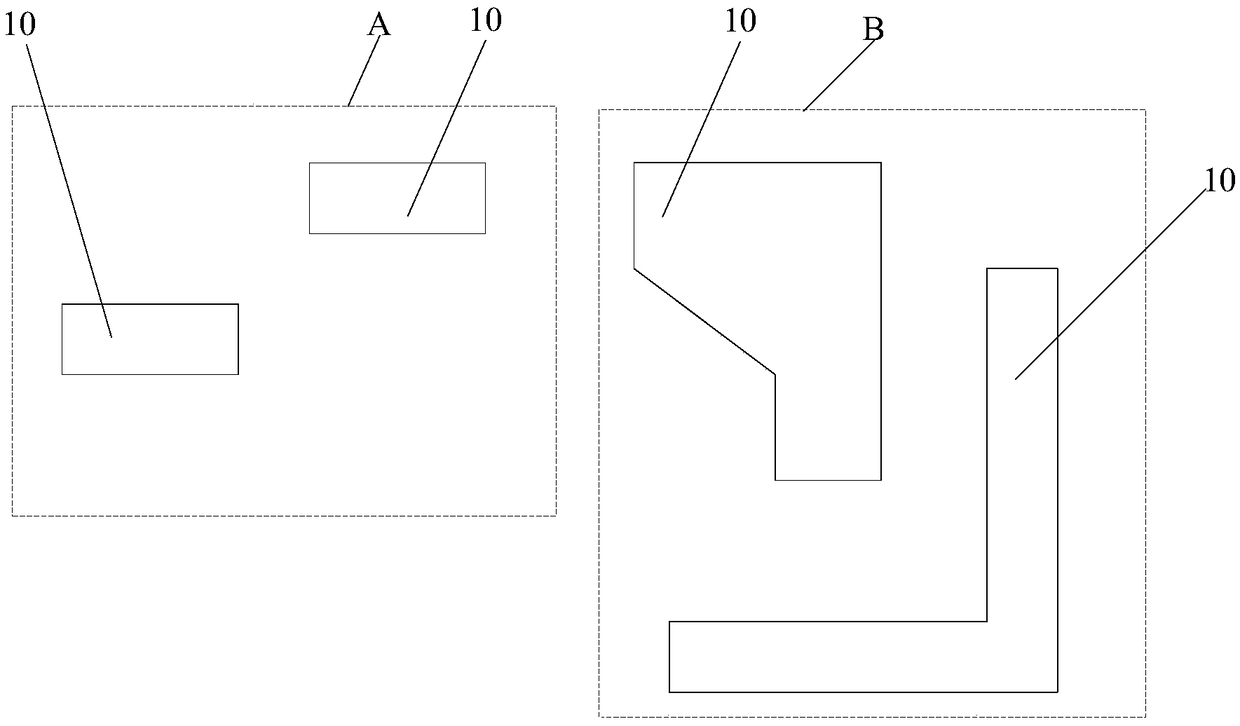

[0026] In the prior art, in the mask pattern corresponding to the corrected pattern of optical proximity correction, charges tend to accumulate at the opposite sharp feet of adjacent patterns to form a high electric field, thereby causing electrostatic breakdown, which in turn leads to the relative sharp feet of adjacent patterns The phenomenon of graphics missing corners or bridge damage occurs.

[0027] In order to avoid the phenomenon of graphic chipping or bridge damage at the opposite sharp feet of adjacent graphics, one method is to add an anti-static protective ring around the mask. The protection ring mainly plays a certain role in protecting the graphics on the periphery of the photomask. However, the protection ring has very little protection effect on the pattern positions where charge accumulation is likely to occur inside the photomask. For the graphics inside the mask, there will still be graphics chipping or bridge damage at the opposite sharp feet of adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com