Preparation method of cyano-alkyl and aryl co-modified polysiloxane

A technology of cyanohydrocarbyl silane and polysiloxane, which is applied in the field of chemical additives, can solve the problems of single structure of silicone oil, low heat resistance, and inability to completely inhibit the bonding between fibers, so as to reduce surface defects and static electricity Cumulative, prevents the effect of hot-melt adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

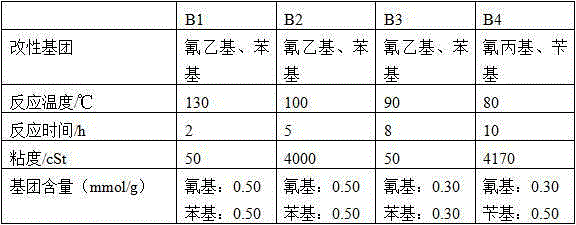

[0060] Cyanoalkyl aryl co-modified polysiloxane B1 is prepared by the following steps: add 8.00 grams of cyanoethylsilane hydrolyzate obtained by hydrolyzing cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 8.60 grams of phenylmethyldimethoxysilane, 79.40 grams of octamethylcyclotetrasiloxane, adding 0.01 grams of sodium hydroxide as a catalyst, and 4.00 grams of hexamethyldisiloxane as an end-capping agent, at 130 ° C The reaction was carried out under stirring condition, and the reaction time was 2 hours.

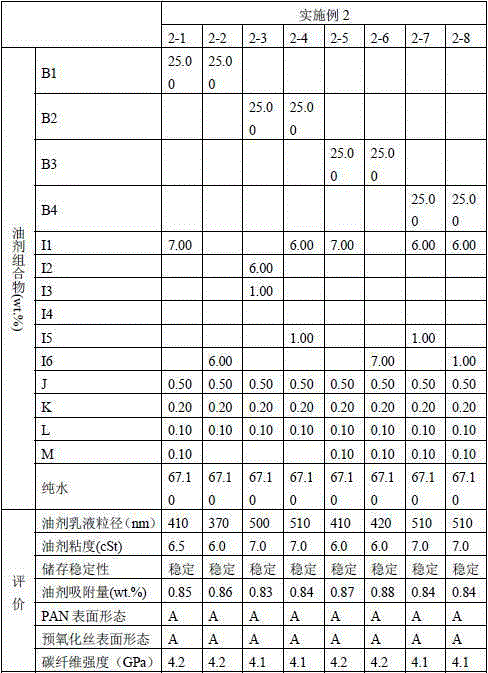

Embodiment 2

[0062] Cyanoalkyl aryl co-modified polysiloxane B2 is prepared by the following steps: add 8.00 grams of cyanoethylsilane hydrolyzate obtained by hydrolyzing cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 8.60 grams of phenylmethyldimethoxysilane, 79.40 grams of octamethylcyclotetrasiloxane, adding 0.01 grams of sodium hydroxide as a catalyst, 0.30 grams of hexamethyldisiloxane as a capping agent, at 100 ° C The reaction was carried out under stirring condition, and the reaction time was 5 hours.

Embodiment 3

[0064] Cyanoalkyl aryl co-modified polysiloxane B3 is prepared by the following steps: add 4.80 grams of cyanoethylsilane hydrolyzate obtained by hydrolysis of cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 5.16 grams of phenylmethyldimethoxysilane, 86.04 grams of octamethylcyclotetrasiloxane, add 0.01 grams of sodium hydroxide as a catalyst, and 4.00 grams of hexamethyldisiloxane as a capping agent, at 90 ° C The reaction was carried out under stirring condition, and the reaction time was 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com