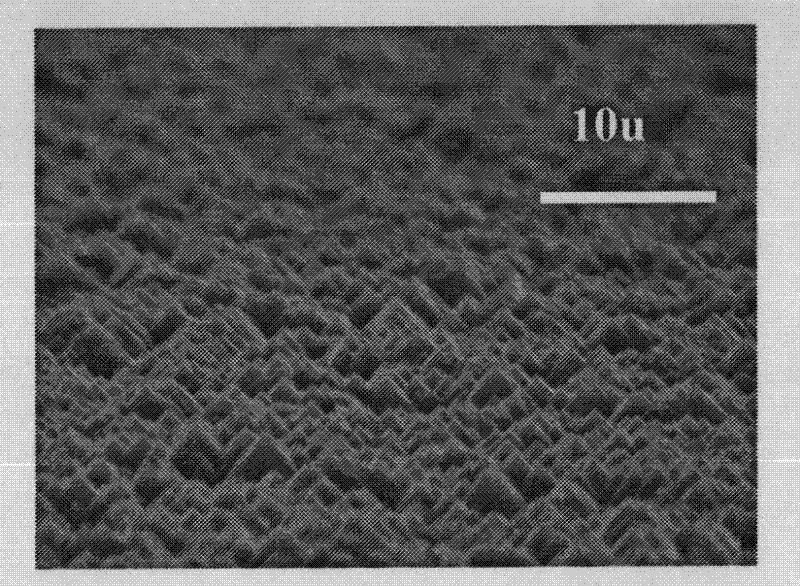

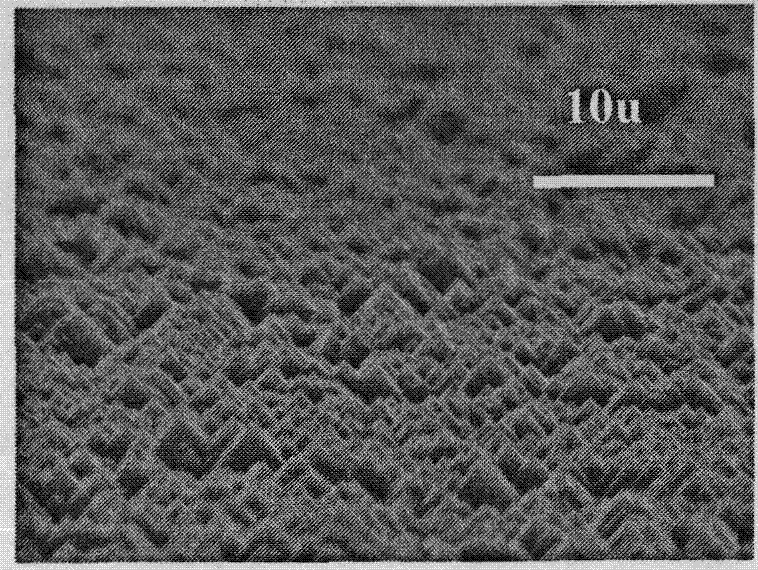

Velvet manufacturing solution of monocrystalline silicon additive

A technology of texturing liquid and additives, applied in crystal growth, post-processing details, post-processing, etc., can solve problems such as difficult single crystal silicon, and achieve the effect of uniform size, controllable size, and uniform textured pyramid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A monocrystalline silicon additive texturing solution, which is composed of an alkaline etching solution, a surfactant, and an organic acid or salt, wherein the amount of the surfactant is equivalent to 0.05% to 0.5% of the mass or volume of the alkaline etching solution (for example, 0.05% , 0.2%, 0.5%), the amount of organic acid or salt is equivalent to 0.1% to 10.0% of the mass or volume of the alkaline corrosion solution (eg 0.1%, 5%, 10%). Described alkaline etchant is by the sodium hydroxide (or potassium hydroxide, sodium carbonate, potash, sodium silicate or sodium phosphate) of 0.2%~5% (for example 0.2%, 2%, 5%) mass percent A corrosive solution composed of one or several kinds) and water.

[0026] Organic acid or salt is one or more of fatty acids containing 4-10 carbons or fatty acid salts containing 4-10 carbons and phenyl fatty acids (such as butyric acid, pentanoic acid, heptanoic acid, tartaric acid or sodium benzoate) ; The surfactant is one or more of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com