Polyaniline-coated nitro-amine high-energy explosive composite material and preparation method thereof

A technology of high-energy explosives and composite materials, which is applied in the directions of explosives, single substance as explosives, non-explosive/non-thermal agent components, etc., can solve the problems of sparks caused by electrostatic discharge, high electrostatic sensitivity and high resistivity, and reduce the mechanical sensitivity. , good desensitization effect, close combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

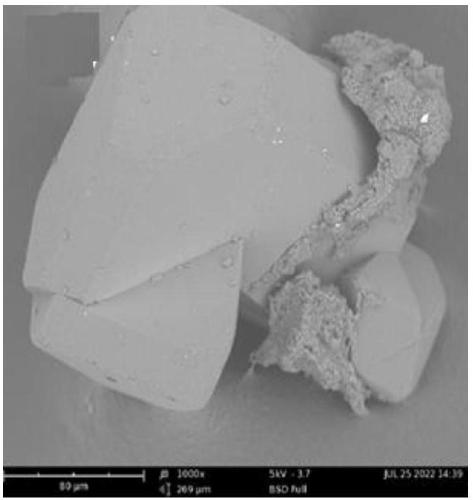

[0054] Step 1: Add 0.5g of HMX to aniline HCl solution (30mL, 1M HCl, 10% aniline), and mechanically stir in an ice-water bath at 0-5°C for 30min to disperse the explosive uniformly at 400rpm.

[0055] Step 2: Slowly add the HCl solution of ammonium persulfate (30ml, 1M HCl, 10% ammonium persulfate) dropwise into the mixed solution after dispersion within 30min. Mechanically stirred in an ice-water bath at 0-5°C, and reacted for 4h.

[0056] Step 3: After the reaction, filter with suction, wash with ethanol and deionized water, and dry in a drying oven at 60°C for 12 hours to obtain a HMX@PANI sample.

[0057] According to the national military standard GJB772A-97 method 601.2, the impact sensitivity test is carried out on the sample, and the test conditions are: the weight of the drop hammer is 5kg, and the dose is 35mg. The measured 50% characteristic drop height is 50.1cm, which is 102.02% higher than that of HMX raw material (24.8cm); according to the national military st...

Embodiment 2

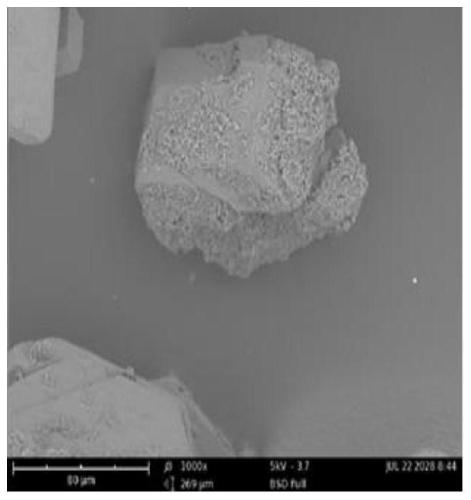

[0059] Step 1: Add 0.5g of HMX to aniline HCl solution (30mL, 1M HCl, 10% aniline), and mechanically stir in an ice-water bath at 0-5°C for 30min to disperse the explosive uniformly at 400rpm.

[0060] Step 2: The HCl solution of ammonium persulfate (30 ml, 1M HCl, 10% ammonium persulfate) was slowly added dropwise to the solution obtained in Step 1: within 30 min. Mechanically stirred in an ice-water bath at 0-5°C, and reacted for 6h.

[0061] Step 3: After the reaction, filter with suction, wash with ethanol and deionized water, and dry in a drying oven at 60°C for 12 hours to obtain a HMX@PANI sample.

[0062] According to the test method identical with embodiment 1, record that this sample 50% characteristic drop height is 52.4cm, has improved 111.29% compared with HMX raw material (24.8cm); Explosion percentage is 44%, has reduced compared with HMX raw material (80%) 36%; static electricity accumulation is -4.2μC·kg -1 , compared with HMX raw material (-7.0μC·kg -1 ) w...

Embodiment 3

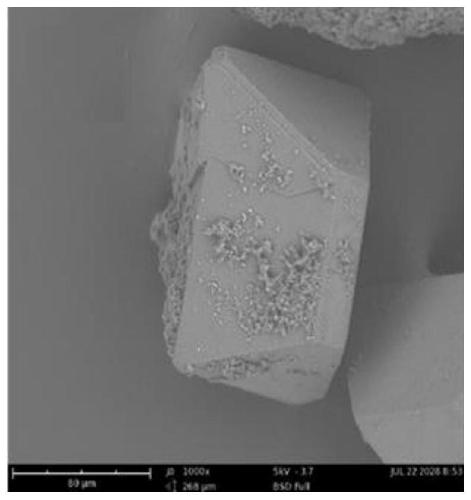

[0064] Step 1: Add 0.5g of HMX to aniline HCl solution (30mL, 1M HCl, 10% aniline), and mechanically stir in an ice-water bath at 0-5°C for 30min to disperse the explosive uniformly at 400rpm.

[0065] Step 2: The HCl solution of ammonium persulfate (30 ml, 1M HCl, 10% ammonium persulfate) was slowly added dropwise to the solution obtained in Step 1: within 30 min. Mechanical stirring was carried out in an ice-water bath at 0-5°C, and the reaction was carried out for 8h.

[0066] Step 3: After the reaction, filter with suction, wash with ethanol and deionized water, and dry in a drying oven at 60°C for 12 hours to obtain a HMX@PANI sample.

[0067] According to the test method identical with embodiment 1, record that this sample 50% characteristic drop height is 50.2cm, has improved 102.42% compared with HMX raw material (24.8cm); Explosion percentage is 48%, has reduced compared with HMX raw material (80%) 32%; static electricity accumulation is -4.2μC·kg -1 , compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com