Preparation method cyano-alkyl and polyether co-modified polysiloxane

A technology of cyanohydrocarbyl silane and polysiloxane, which is applied in the chemical industry, can solve the problems of silicon-based oils with single structure, low heat resistance, and unsuitability for high-speed preparation of carbon fibers, so as to reduce surface defects and static electricity accumulation, prevent thermal The effect of fusion bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Cyanohydrocarbyl polyether co-modified polysiloxane C1 is prepared by the following steps: add 8.00 grams of cyanoethylsilane hydrolyzate obtained by hydrolysis of cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 20.00 grams of side chain modified polyether silicone oil with a molecular weight of 700 and an EO number of 8, 69.00 grams of octamethylcyclotetrasiloxane, adding 0.01 grams of sodium hydroxide as a catalyst, and 3.00 grams of hexamethyldisiloxane as a capping The reaction was carried out under stirring conditions at 130° C., and the reaction time was 1 hour.

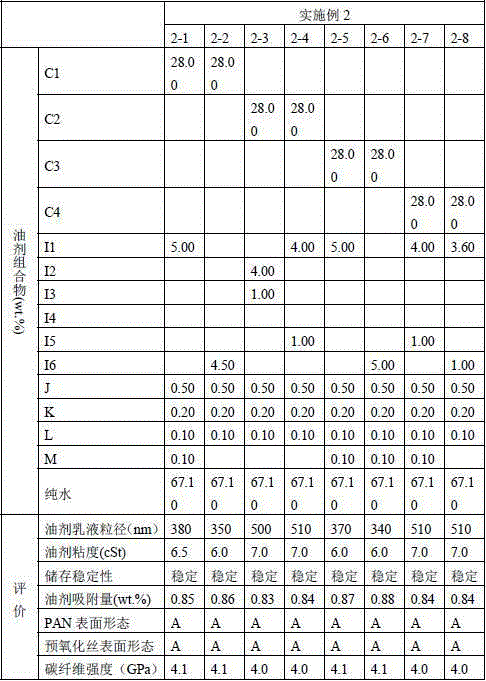

Embodiment 2

[0059] Cyanohydrocarbyl polyether co-modified polysiloxane C2 is prepared by the following steps: add 48.00 grams of cyanoethylsilane hydrolyzate obtained by hydrolysis of cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 20.00 grams of side chain modified polyether silicone oil with a molecular weight of 15,000 and an EO number of 16, 44.00 grams of octamethylcyclotetrasiloxane, adding 0.01 grams of sodium hydroxide as a catalyst, and 2.00 grams of hexamethyldisiloxane as a capping The reaction was carried out under stirring conditions at 100°C, and the reaction time was 4 hours.

Embodiment 3

[0061] Cyanohydrocarbyl polyether co-modified polysiloxane C3 is prepared by the following steps: add 48.00 grams of cyanoethylsilane hydrolyzate obtained by hydrolysis of cyanoethylmethyldimethoxysilane into a reaction flask in a nitrogen atmosphere, 20.00 grams of side chain modified polyether silicone oil with a molecular weight of 1200 and an EO number of 16, 44.00 grams of octamethylcyclotetrasiloxane, adding 0.01 grams of sodium hydroxide as a catalyst, and 3.00 grams of hexamethyldisiloxane as a capping The reaction was carried out under the condition of stirring at 90° C., and the reaction time was 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com