Novel antibacterial antistatic additive for PE and preparation method thereof

An antistatic and additive technology, which is applied in the field of new antibacterial and antistatic additives for PE and its preparation, can solve the problems of unsustainable antistatic effect and easy to be affected by ambient temperature and humidity, and achieve long-term antistatic, excellent Compatibility, reaction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

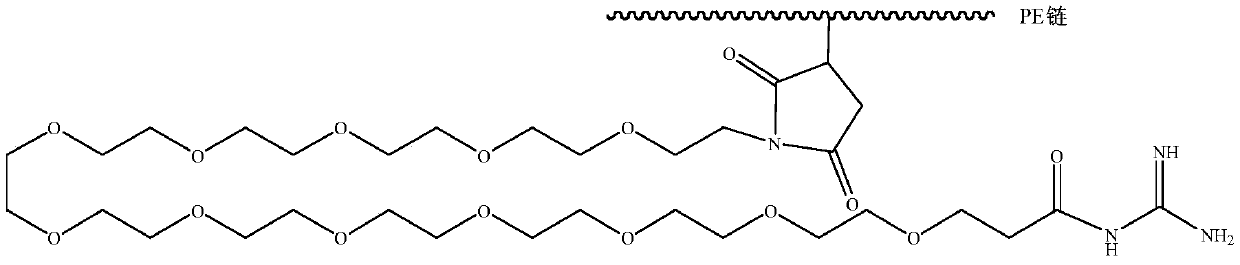

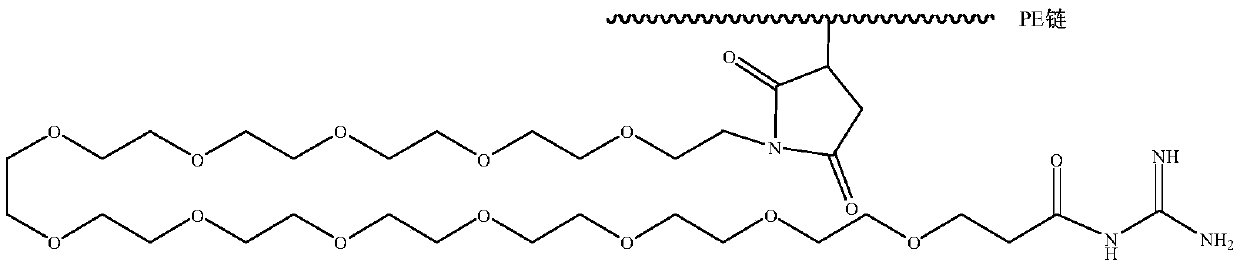

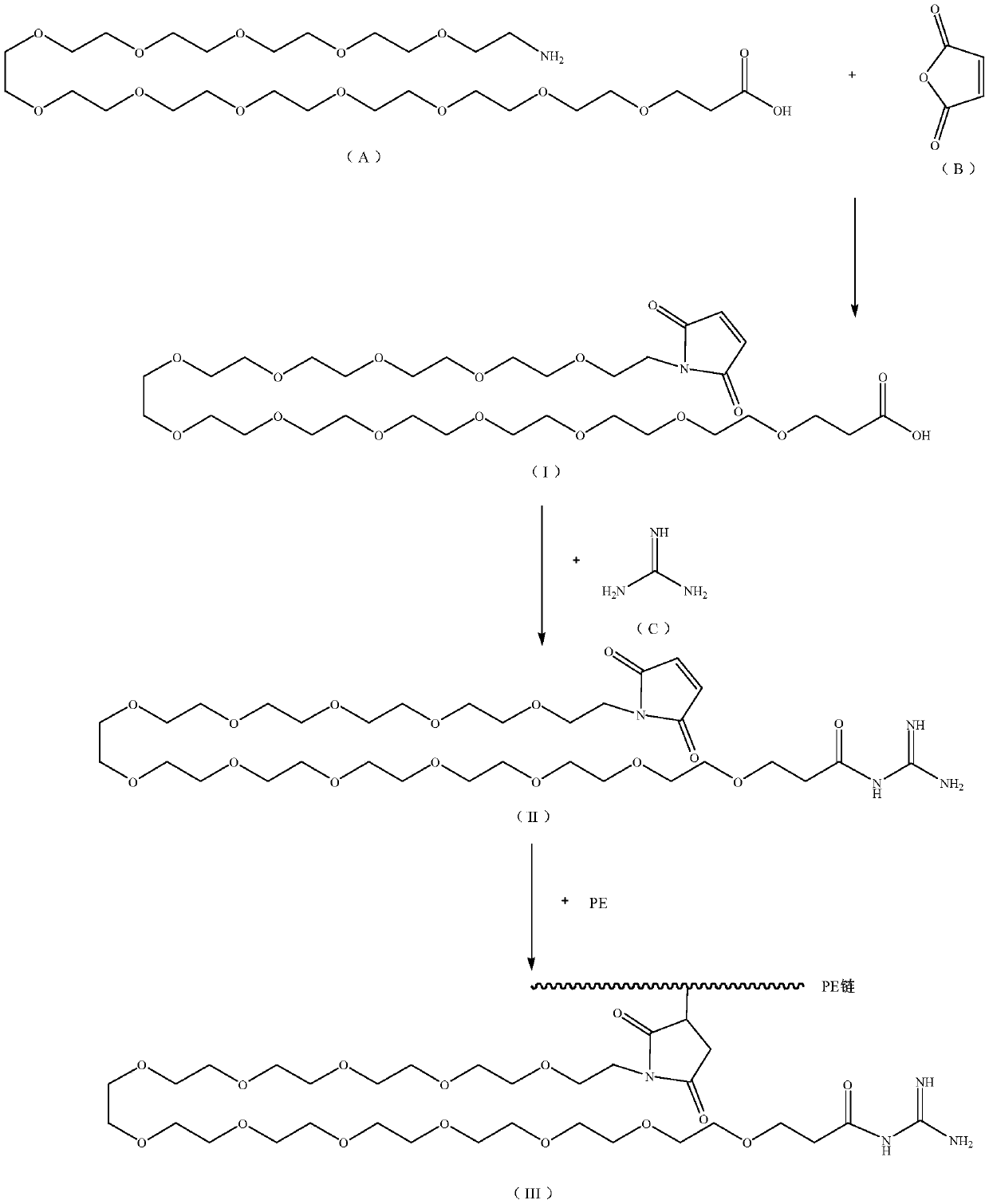

[0037] Step (1) Dissolve 1mol of amino-dodecaethylene glycol-carboxylic acid (A) and 1mol of maleic anhydride (B) in tetrahydrofuran, heat to reflux for 30h, filter, wash, and dry to obtain amic acid; 1mol Dissolve amic acid in benzene, add 1.2mol anhydrous zinc chloride, heat to 80°C, add dropwise benzene dissolved in 1.8mol hexamethyldisilazane, after the dropwise addition, heat to reflux for 8h, filter, and the filtrate Concentrate to get oil. Use 10% hydrochloric acid to adjust the pH to 1, solids precipitate out, add ethyl acetate to dissolve, separate the liquids, extract the aqueous phase with ethyl acetate for 3 times, combine the organic phases, and wash with anhydrous Na 2 SO 4 Drying. Filtration, concentration, in intermediate product I (IR: 1649cm -1 : the presence of -C=O of the amide bond; 1720cm -1 :-C=O generation; 3505cm -1 : -OH exists; 1601cm -1 、810cm -1 :-C=C-exists).

[0038] Step (2) Dissolve the mixture of 1.2mol I, 1.2mol dicyclohexylcarbodiimid...

specific Embodiment 2-6

[0040] Specific embodiment 2-6, other are with specific embodiment 1, difference is following table:

[0041]

[0042]

[0043] The antibacterial and antistatic additive obtained in specific example 1 is used as the basic material of the application example, added to PE pellets, and blown into a film to obtain an antibacterial and antistatic PE film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com