Color film substrate, display panel and display device

A color film substrate and display panel technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of ITO film mechanical damage and static electricity accumulation, and achieve the effects of reducing static electricity accumulation, improving transmittance, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

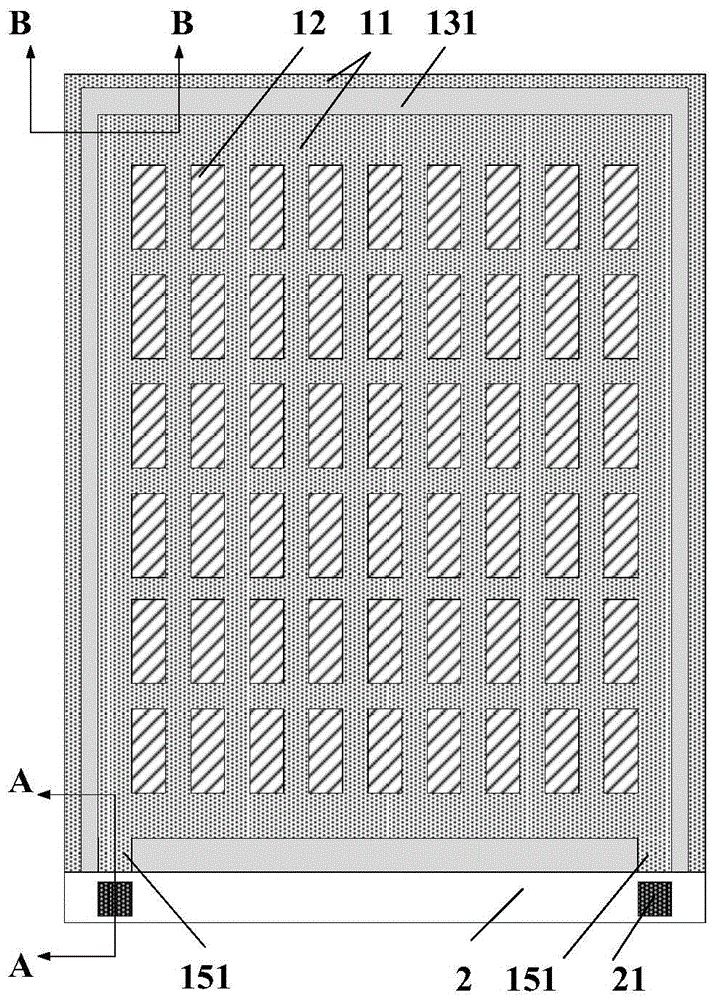

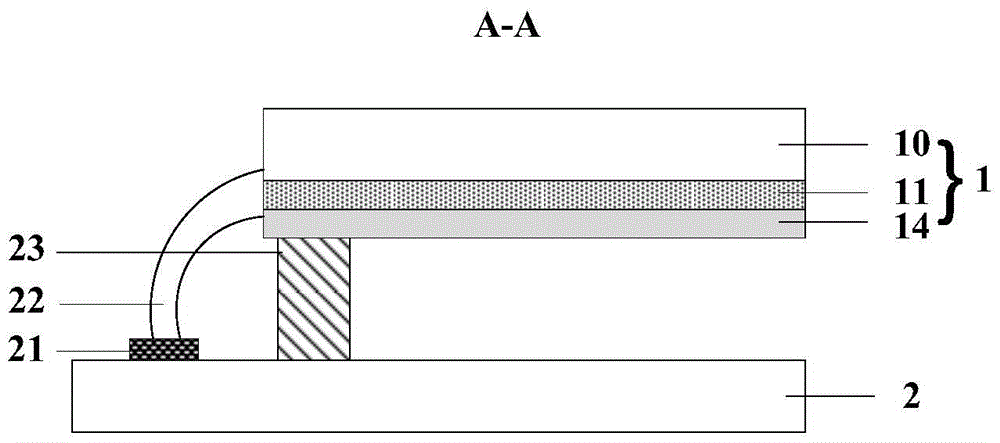

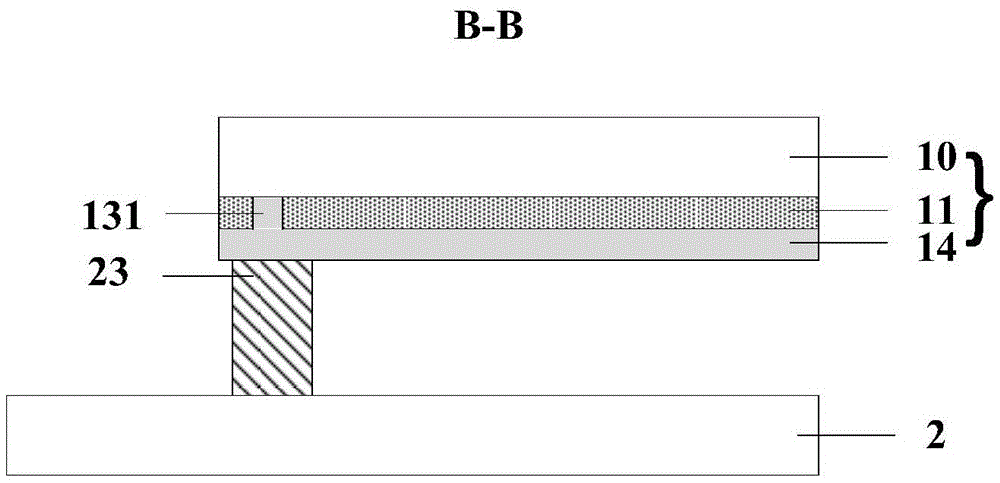

[0034] This embodiment provides a color filter substrate and a display panel including the color filter substrate. figure 1 It is a plan view of the color filter substrate and the display panel of this embodiment. figure 2 It is a cross-sectional view along the A-A direction of the color filter substrate and the display panel of this embodiment. image 3 It is a cross-sectional view of the color filter substrate and the display panel along the B-B direction of this embodiment. The color filter substrate 1 includes a conductive layer located on the color filter side of the color filter substrate, and an isolation strip disposed on a peripheral portion of the conductive layer, and the isolation strip is used to isolate external static electricity.

[0035] In this embodiment, the conductive layer is a black matrix 11 with conductive properties. like figure 1 , 2 As shown in and 3 , the color filter substrate 1 further includes a first substrate 10 and a color filter 12 . T...

Embodiment 2

[0045] This embodiment provides a color filter substrate and a display panel. The difference from Embodiment 1 is that the isolation zone of this embodiment is the first isolation zone 132 extending from the edge of the black matrix of the conductive layer to the edge of the color filter substrate to act as a barrier. Break the role of external static electricity. Figure 4 It is a plan view of the color filter substrate and the display panel of this embodiment. Figure 5 It is a cross-sectional view of the color filter substrate and the display panel along the C-C direction of this embodiment.

[0046] like Figure 4 and Figure 5 As shown, the color filter substrate 1 of this embodiment includes a first substrate 10 , a black matrix 11 , a color filter 12 , and a first isolation zone 132 . The black matrix 11 and the color filter 12 are disposed on the first substrate 10 in the same layer, and the color filter 12 is composed of three color resins of red R, green G and blu...

Embodiment 3

[0049] This embodiment provides a color filter substrate and a display panel. The difference from Embodiment 1 is that the black matrix in this embodiment is a non-conductive conventional black matrix, and the conductive layer is a transparent layer arranged on the color filter side of the color filter substrate. For the conductive layer 16 , the isolation zone is a second isolation groove 133 disposed on the peripheral portion of the transparent conductive layer 16 and dividing the transparent conductive layer into two parts, inner and outer. Image 6 It is a plan view of the color filter substrate and the display panel of this embodiment. Figure 7 It is a cross-sectional view along the D-D direction of the color filter substrate and the display panel of this embodiment. Figure 8 It is a cross-sectional view of the color filter substrate and the display panel along the E-E direction of this embodiment.

[0050] like Image 6 , 7 As shown in and 8 , the color filter subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com