Release film and preparation method thereof

A technology of release film and release layer, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc. It can solve the problem of PET substrates not having release properties, uneven peeling force, silicone oil loss, etc. Problems, achieve low cost, improve antistatic and mold release, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a kind of preparation method of release film, and this preparation method comprises the steps:

[0049] Step 1, surface-treating the inorganic nano-particles to have dispersing groups on the surface. Specifically, the silane coupling agent is added to ethanol, and then inorganic nanoparticles are added, the above mixture is stirred and centrifuged, and the clear liquid located in the upper layer is poured off to obtain the mixture; the obtained mixture is added to absolute ethanol for washing, and dried Inorganic nanoparticles with dispersed groups on the surface are obtained.

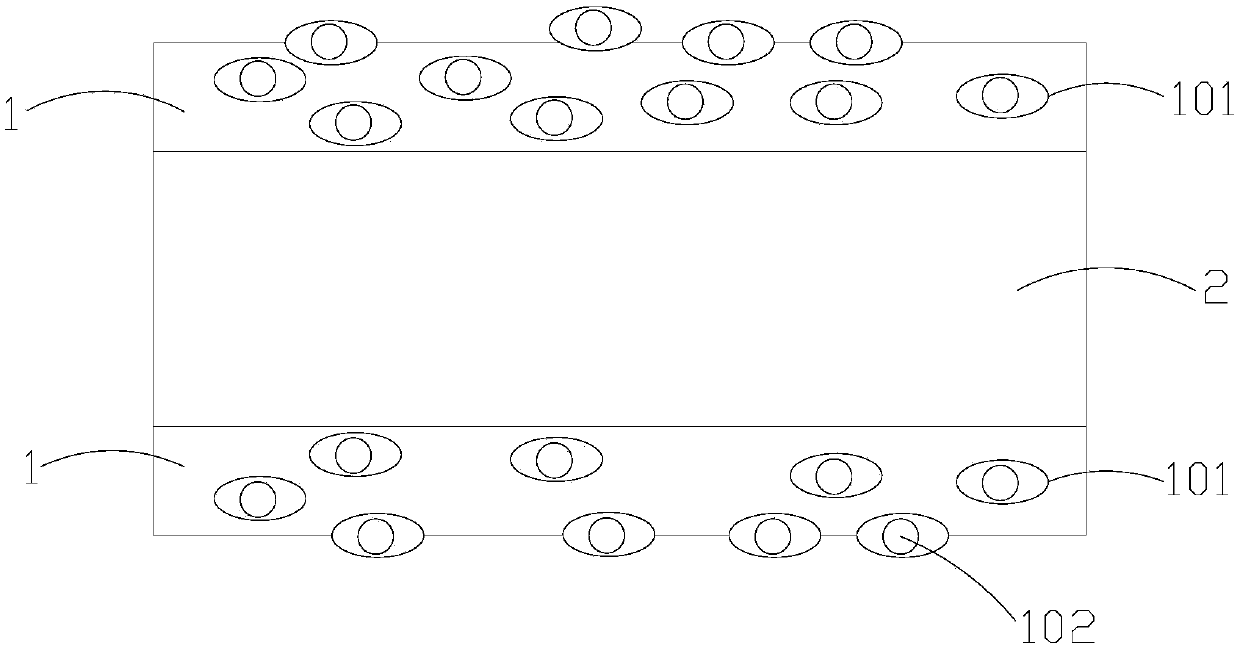

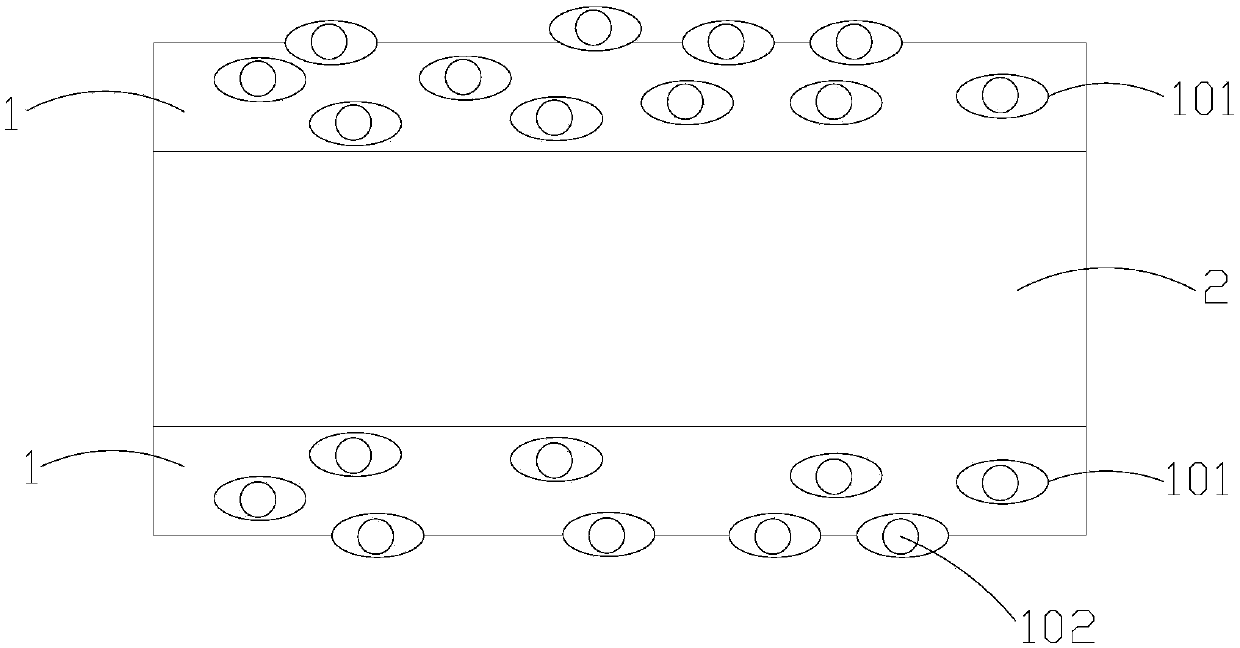

[0050] Step 2, forming a release layer, the surface of the release layer is formed with a hollow bubble structure. Specifically, the raw materials of the release layer and the surface-modified inorganic nanoparticles are uniformly mixed according to the proportion and added to the auxiliary extruder.

[0051] Step 3, forming a tolerance layer. Specifically,...

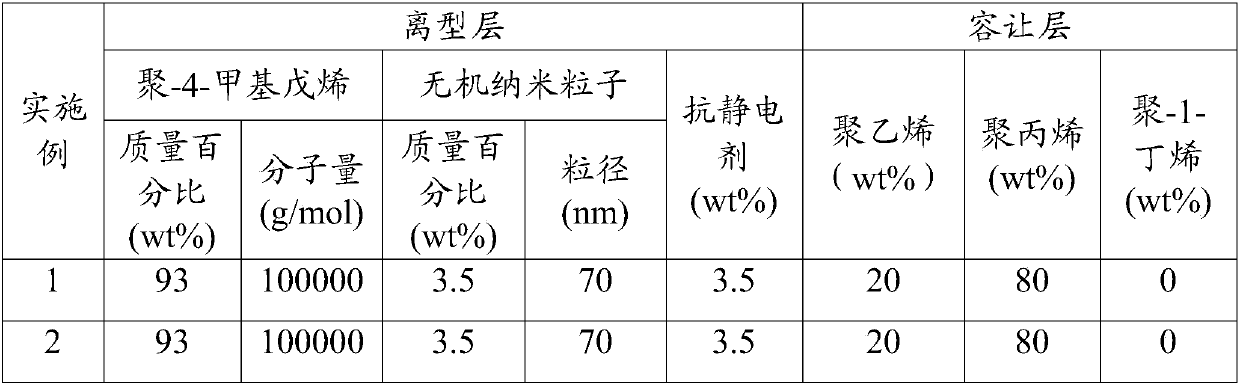

Embodiment 1

[0067] For the release film provided in this embodiment, the release layer ratio is 93% poly-4-methylpentene, 3.5% silica nanoparticles, and 3.5% polythiophene antistatic agent; the poly-4- The molecular weight of methylpentene is 100,000 g / mol, the particle size of silica particles is 70 nm, and the surface is modified with octyltrimethoxysilane. The proportion of the containment layer is 20% low density polyethylene, 80% polypropylene. The electrostatic layer is arranged on both sides of the tolerance layer. The total thickness of the release layer accounts for 40% of the total thickness and its outer surface is embossed. The thickness of the tolerance layer accounts for 60% of the total thickness. The thickness of the obtained reflective film is 120μm. See Table 2.

Embodiment 2

[0069] The same parts as those in Example 1 will not be repeated, and the difference from Example 1 is that the outer surface has not been embossed, and the thickness of the B layer accounts for 60% of the total thickness. The thickness of the obtained reflective film is 120 μm, and the relevant properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com