A method for preparing yarn from aramid 1414 waste short fiber

A short fiber and aramid fiber technology, which is applied in the spinning process of aramid fiber waste to prepare aramid yarn. It can solve the problems of high surface friction coefficient, difficulty in normal spinning, and poor fiber cohesion, etc., and improve hardness , reduce mass specific resistance, increase conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

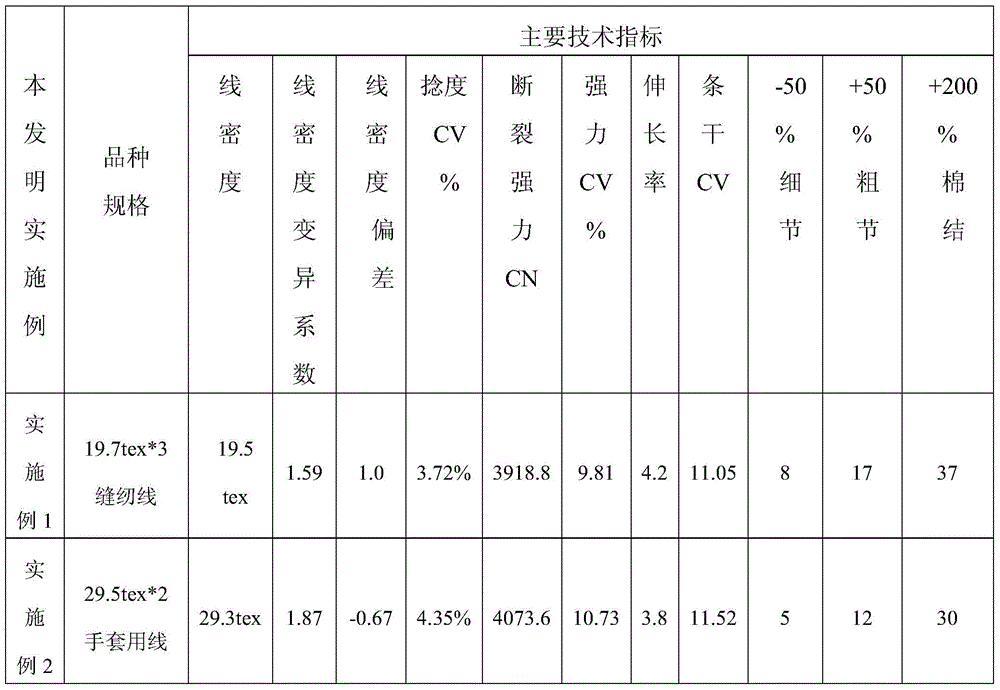

Embodiment 1

[0037] Using 100% aramid 1414 waste silk to process fibers, it is produced through fiber pretreatment, cotton opening and cleaning, carding, drawing, roving, spun yarn, winding, heat setting twist, yarn joining, two-for-one twisting, heat setting twist and other processes. Aramid 1414 yarn. In this embodiment, the cut length of the aramid 1414 waste processed fiber is 38 mm, and the specifications and uses of the yarn are aramid 1414, 19.7tex three-ply sewing thread.

[0038] The specific content is:

[0039] (1) Control the fiber moisture regain before feeding and the fiber moisture regain after milk balance

[0040] The moisture regain of the fiber before feeding is controlled at about 5%. After the fiber is pretreated and sprayed with an oil agent composed of SN antistatic agent produced by Jiangyin Goldwind Synthetic Resin Co., Ltd., dimethyl hydroxyl emulsified silicone oil and water, and balanced for 24 Hours later, the moisture regain of the fiber will reach between 1...

Embodiment 2

[0049] Using 100% aramid 1414 waste silk to process fibers, it is produced through fiber pretreatment, cotton opening and cleaning, carding, drawing, roving, spun yarn, winding, heat setting twist, yarn joining, two-for-one twisting, heat setting twist and other processes. Aramid 1414 yarn. In this embodiment, the cut length of the aramid 1414 waste processed fiber is 51 mm, and the specifications and uses of the yarn are aramid 1414, 29.5tex two-ply cut-resistant glove yarn.

[0050] The specific content is:

[0051] (1) Control the fiber moisture regain before feeding and the fiber moisture regain after milk balance

[0052] The moisture regain of the fiber before feeding is controlled at about 5%. After the fiber is pretreated and sprayed with an oil agent composed of SN antistatic agent produced by Jiangyin Goldwind Synthetic Resin Co., Ltd., dimethyl hydroxyl emulsified silicone oil and water, and balanced for 24 Hours later, the moisture regain of the fiber will reach ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com