FDY/POY differential shrinkage blended filament of biomass nylon 56 fiber/PBT fiber, and preparation method thereof

A technology of different shrinkage mixed fiber yarn and biomass nylon, which is applied in the field of FDY/POY different shrinkage mixed fiber yarn, can solve the problems of poor hydrophilicity of PBT fiber, and achieve good hydrophilicity, improved hydrophilicity, good return elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

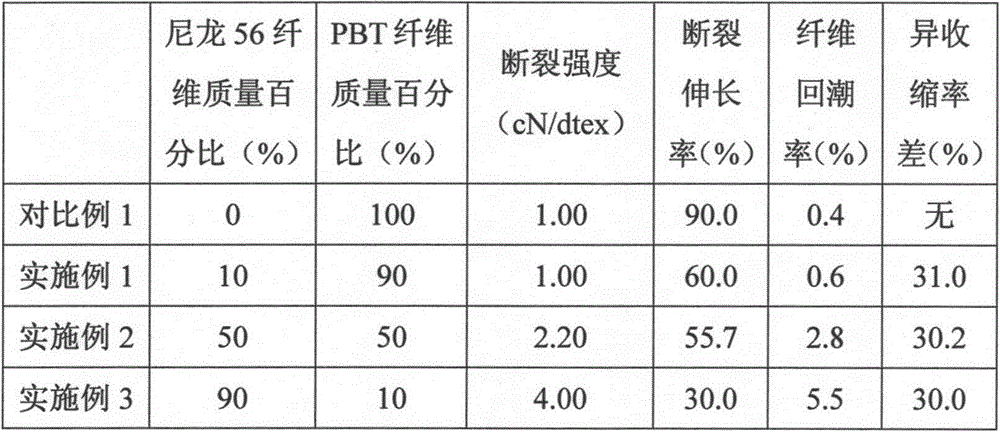

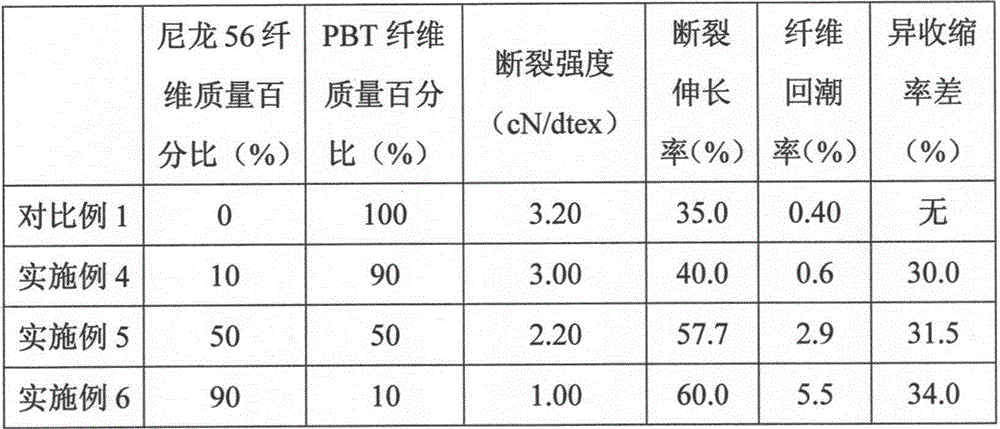

Embodiment 1

[0023] A different shrinkage mixed fiber yarn in which biomass nylon 56 fiber is FDY fiber and PBT fiber is POY fiber, and the mass ratio of biomass nylon 56 fiber and PBT fiber is 1:9.

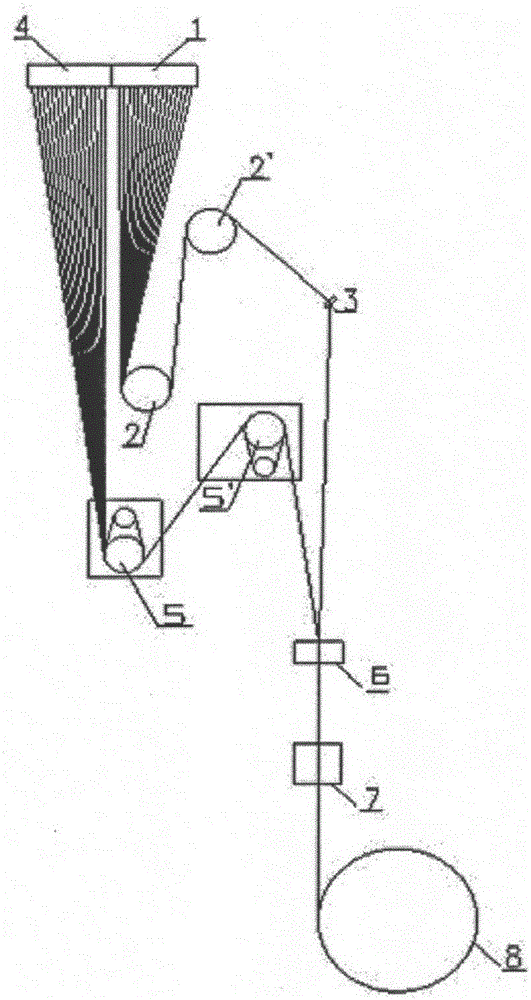

[0024] use as figure 1 The shown device prepares different shrinkage mixed filaments:

[0025] Biomass nylon 56 slices were crystallized at 130°C for 0.5h and dried at 150°C for 8h under the protection of nitrogen, and then melted and extruded into the spinning box at 270-290°C by a screw extruder. The temperature of the spinning box was 280°C. After being extruded and cooled by the second spinning assembly 4, the temperature of the first hot roller 5 is 60° C., and the speed is 1000 m / min. Then the temperature of the second hot roller 5' is 100°C, and the speed is 2500m / min to form a fully drawn yarn (FDY), and the fully drawn yarn is input into the doubling device 6. PBT slices are crystallized at 130°C for 0.5h, dried at 150°C for 8h, melted and extruded by a screw extruder at 260°C to 2...

Embodiment 2

[0027] A different shrinkage mixed fiber yarn in which biomass nylon 56 fiber is FDY fiber and PBT fiber is POY fiber, and the mass ratio of biomass nylon 56 fiber and PBT fiber is 1:1.

[0028] use as figure 1 The shown device prepares different shrinkage mixed filaments:

[0029] Biomass nylon 56 slices were crystallized at 130°C for 0.5h and dried at 150°C for 8h under the protection of nitrogen, and then melted and extruded into the spinning box at 270-290°C by a screw extruder. The temperature of the spinning box was 280°C. After being extruded and cooled by the second spinning assembly 4, the temperature of the first hot roller 5 is 60° C., and the speed is 1000 m / min. Then the temperature of the second hot roller 5' is 100°C, and the speed is 2500m / min to form a fully drawn yarn (FDY), and the fully drawn yarn is input into the doubling device 6. PBT slices are crystallized at 130°C for 0.5h, dried at 150°C for 8h, melted and extruded by a screw extruder at 260°C to 2...

Embodiment 3

[0031] A kind of different shrinkage mixed fiber yarn in which biomass nylon 56 fiber is FDY fiber and PBT fiber is POY fiber, and the mass ratio of biomass nylon 56 fiber and PBT fiber is 9:1.

[0032] use as figure 1 The shown device prepares different shrinkage mixed filaments:

[0033] Biomass nylon 56 slices were crystallized at 130°C for 0.5h and dried at 150°C for 8h under the protection of nitrogen, and then melted and extruded into the spinning box at 270-290°C by a screw extruder. The temperature of the spinning box was 280°C. After being extruded and cooled by the second spinning assembly 4, the temperature of the first hot roller 5 is 60° C., and the speed is 1000 m / min. Then the temperature of the second hot roller 5' is 100°C, and the speed is 2500m / min to form a fully drawn yarn (FDY), and the fully drawn yarn is input into the doubling device 6. PBT slices are crystallized at 130°C for 0.5h, dried at 150°C for 8h, melted and extruded by a screw extruder at 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com