Antistatic fabric and preparation method thereof

A technology of antistatic and antistatic yarn, which is applied in the manufacture of conductive/antistatic filaments, rayon, and single-component polyester rayon, etc. It can solve electrostatic interference, affect product quality and fabric wear performance, Affect processing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

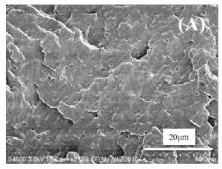

Image

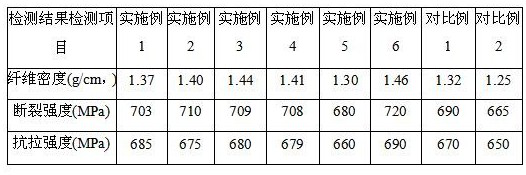

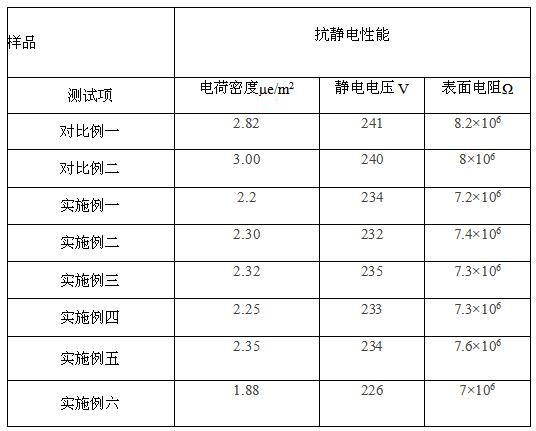

Examples

Embodiment 1

[0041] A preparation method of antistatic fabric, comprising the following steps:

[0042] The preparation method of composite nanoparticles of silica airgel and titanium dioxide is as follows: adding silica airgel nanoparticles to deionized water and ultrasonicating for 5 minutes, removing the deionized water, and quick freezing to obtain silica airgel containing ice cubes Nanoparticles, then slowly drop titanium tetrachloride into the silica airgel nanoparticles containing ice cubes, dry them at 60 degrees for 20 minutes, then put them into a muffle furnace and heat them to 400 degrees, and put them into the muffle furnace The middle heating curve is to raise the temperature to 200 degrees at a heating rate of 5 degrees per minute, and then increase the temperature from 200 degrees to 400 degrees at a heating rate of 2 degrees per minute to prepare composite nanoparticles of silica airgel and titanium dioxide.

[0043] The preparation method of polyether surfactant is as fol...

Embodiment 2

[0048] A preparation method of antistatic fabric, comprising the following steps:

[0049] The preparation method of composite nanoparticles of silica airgel and titanium dioxide is as follows: adding silica airgel nanoparticles to deionized water and ultrasonicating for 10 minutes, removing the deionized water, and quick freezing to prepare silica airgel containing ice cubes Nanoparticles, and then slowly drop titanium tetrachloride into the silica airgel nanoparticles containing ice cubes, dry them at 70 degrees for 30 minutes, then put them into a muffle furnace and heat them to 400 degrees, and put them into the muffle furnace The middle heating curve is to raise the temperature to 200 degrees at a heating rate of 5 degrees per minute, and then increase the temperature from 200 degrees to 400 degrees at a heating rate of 2 degrees per minute to prepare composite nanoparticles of silica airgel and titanium dioxide.

[0050] The preparation method of polyether surfactant is ...

Embodiment 3

[0055] A preparation method of antistatic fabric, comprising the following steps:

[0056] The preparation method of composite nanoparticles of silica airgel and titanium dioxide is as follows: adding silica airgel nanoparticles to deionized water and ultrasonicating for 8 minutes, removing the deionized water, and quick freezing to obtain silica airgel containing ice cubes Nanoparticles, and then slowly drop titanium tetrachloride into the silica airgel nanoparticles containing ice cubes, dry them at 65 degrees for 28 minutes, then put them into a muffle furnace and heat them to 400 degrees, and put them into the muffle furnace The middle heating curve is to raise the temperature to 200 degrees at a heating rate of 5 degrees per minute, and then increase the temperature from 200 degrees to 400 degrees at a heating rate of 2 degrees per minute to prepare composite nanoparticles of silica airgel and titanium dioxide.

[0057] The preparation method of polyether surfactant is as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com