Patents

Literature

37results about How to "To achieve the purpose of antistatic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

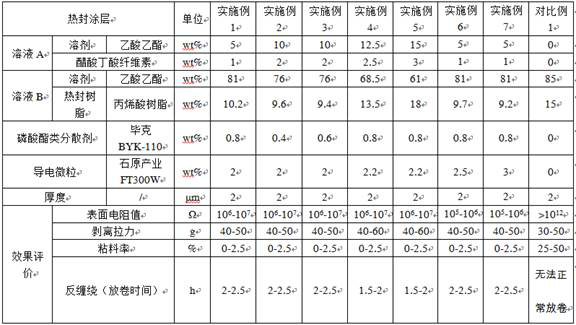

Antistatic spandex fiber and production method thereof

InactiveCN104593900AShort half-lifeSmall specific resistivityElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses an antistatic spandex fiber. The antistatic spandex fiber comprises a modified titanium dioxide antistatic agent, wherein the modified titanium dioxide antistatic agent is especially structurally characterized in that the surfaces of titanium dioxide particles are coated with antimony-doped stannic oxide layers. A production method of the antistatic spandex fiber comprises the following steps: reacting polyether glycol and diisocyanate in a DMAC solution according to a mole ratio of 1 to (1.55-2.15) to obtain a pre-polymer; carrying out chain-extension reaction by the pre-polymer and a mixed amine chain extender to prepare a polyurethane polymer solution with the required viscosity; and adding the modified titanium dioxide antistatic agent, an antioxidant, a dyeing assistant and other additives into the polyurethane polymer solution, uniformly mixing, curing and spinning. Compared with the prior art, the antistatic spandex fiber is free of other antistatic agents; the antistatic performance of the antistatic spandex fiber is obviously superior to that of the conventional spandex filament; the modified titanium dioxide antistatic agent is highly compatible with DMAC and the polyurethane polymer, is high in thermal stability and can be widely applied to production of the antistatic spandex fiber.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

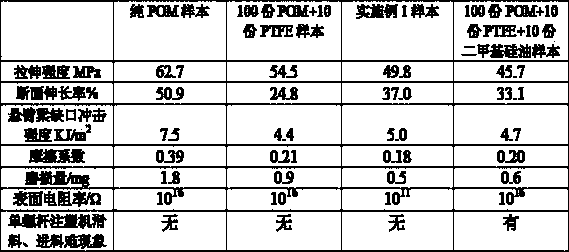

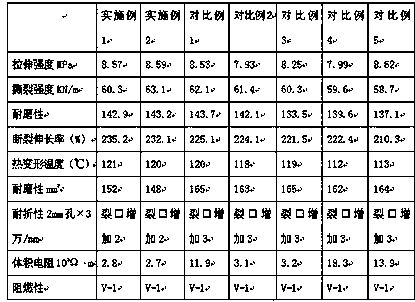

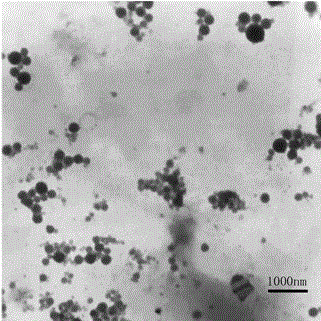

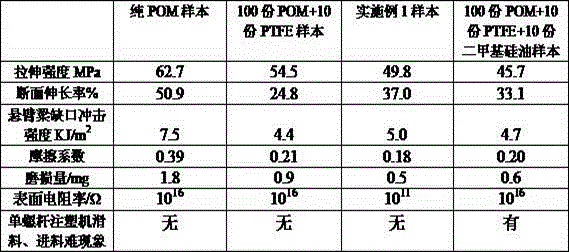

Novel wear-resistant anti-static polyformaldehyde material and preparation method thereof

The invention provides a novel wear-resistant anti-static polyformaldehyde material and a preparation method thereof. The polyformaldehyde material is prepared from the following raw materials in parts by weight: 100 parts of polyformaldehyde, 5-20 parts of polytetrafluoroethylene and 1-10 parts of antistatic agent. According to the novel polyformaldehyde material provided by the invention, since the wear-resistant additive polytetrafluoroethylene is added into a polyformaldehyde system to form a POM / PTFE (Polyformaldehyde / Polytetrafluoroethylene) system, so that the system has excellent wear-resistant performance. Meanwhile, polyether-modified silicone oil with a unique performance is added into the POM / PTFE system, so that the compatibility and the dispersibility of PTFE in a matrix are improved and the antistatic performance of the system is greatly improved. The novel polyformaldehyde material provided by the invention not only has excellent wear-resistant performance, but also has good antistatic performance. Compared with existing polyformaldehyde materials, the polyformaldehyde material provided by the invention has a wider scope of application.

Owner:SICHUAN UNIV

Healthy polyolefine foam material and preparation method thereof

The invention relates to a healthy polyolefine foam material and a preparation method thereof. The healthy polyolefine foam material is prepared from the following original auxiliary materials subjected to mixing, smelting, extrusion, preheating and foaming in parts by weight: 70-100 parts of polyolefine resin, 20-50 parts of anion functional master batch, 15-30 parts of hydrophilic functional master batch, 1-5 parts of a foaming agent, 1-5 parts of a cross-linking agent and 0-5 parts of color master batch. According to the healthy polyolefine foam material provided by the invention, the anion mineral materials and hydrophilic fullerene compounds are added into the formula, so that the foam material has the advantages of air purifying, surface oil contamination resistance, electrostatic prevention and the like; the anion concentration of ambient environment can be effectively increased in virtue of the pyroelectricity and piezoelectricity of the anion mineral material; besides, the hydrophilic groups of the hydrophilic fullerene compounds can form hydrogen bonds with water, so that the contact of pollutants and the polyolefine surface is prevented, accumulated static charges can be leaked quickly, and the antistatic purpose can be further achieved.

Owner:TAISHAN SPORTS IND GRP +1

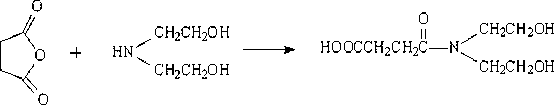

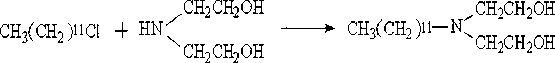

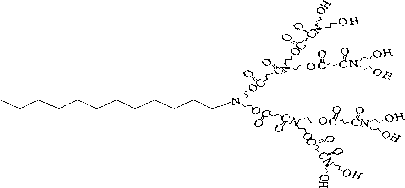

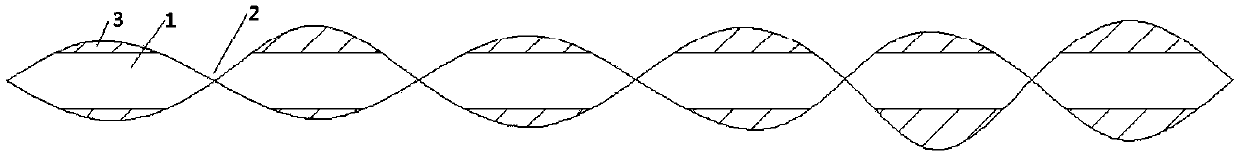

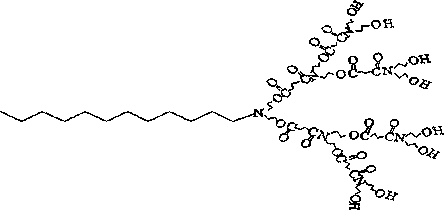

Application of hyperbranched polymer in antistatic agent on flame retardant conveyor belt

InactiveCN103265875AAvoid accumulationEfficient conductionPolyester coatingsPolymer scienceConveyor belt

The invention relates to the technology field of flame retardant conveyor belt and particularly relates to an application of a hyperbranched polymer in antistatic agent on flame retardant conveyor belt. In the application of a hyperbranched polymer in antistatic agent on flame retardant conveyor belt, the general formula of the hyperbranched polymer is CH3(CH2)mN(CH2O)2([CO(CH2)2CON(CH2O)2]m[H]P)2. The hydroxyl-terminated hyperbranched polymer is used as an antistatic agent on PVC conveyor belt, and is directly coated on the surface of a flame retardant conveyor belt to absorb moisture in a mine and then form a more compact and tight conductive water film on the surface of the flame retardant conveyor belt, thus conducting and leaking electrostatic charges efficiently, preventing the accumulation of electrostatic charges and finally reaching the anti-static object.

Owner:UNIV OF JINAN

Antistatic fabric and preparation method thereof

ActiveCN112779660ALarge specific surface areaSmall sizeElectroconductive/antistatic filament manufactureWarp knittingPolyesterFiber

The invention aims to provide an antistatic fabric and a preparation method thereof. The antistatic fabric is formed by warp-knitting antistatic yarns and polyamide yarns, wherein the density of the antistatic yarns is 80-100 yarns / cm, and the density of the polyamide yarns is 50-90 yarns / cm; and the antistatic yarns are prepared from antistatic polyester fibers, and the antistatic polyester fibers are prepared from polyester chips and antistatic polyester master batches through a melt blending spinning method. The antistatic PET polyester fibers are added into a carbon nanotube with a conductive filler; the carbon nanotube has the advantages of large specific surface area and small size and has a special macroscopic quantum tunnel effect, a quantum size effect and a surface effect; and the prepared PET polyester fibers have excellent antistatic performance and good comprehensive performance. Meanwhile, the antistatic PET polyester fibers are made into yarns and then the yarns and polyamide are woven into the composite antistatic fabric, the advantages of the yarns and the polyamide are combined, and the performance of a PET polyester material is further improved.

Owner:吴江嘉伦织造有限公司

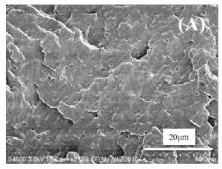

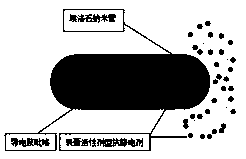

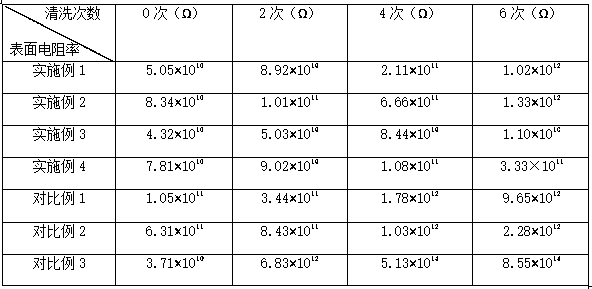

Halloysite nanotube-loaded surfactant/conductive polypyrrole composite antistatic agent, and preparation method and application thereof

The invention discloses a halloysite nanotube-loaded surfactant / conductive polypyrrole composite antistatic agent, and a preparation method and an application thereof. Compared with the prior art, thepreparation method has the following advantages: a halloysite nanotube with a special hollow tubular structure and multiple layers of tube wall gaps are used as a carrier, molecules of a surfactant type antistatic agent are packaged in the tube cavity of the halloysite nanotube, polypyrrole is adopted for surface coating through a polymerization reaction, and the special tubular structure of thehalloysite nanotube is utilized to make the surfactant type antistatic agent adsorbed in the tube cavity be slowly released and orderly migrated to the surface of the material, so the timeliness and durability of the antistatic effect are effectively improved; and the halloysite nanotube is used as a template, the surface of the halloysite nanotube is coated with a layer of a conductive polypyrrole material through the polymerization reaction to form a nanotube material with conductivity and form a conductive network in the nanotube material, so the antistatic purpose is achieved. The novel long-acting composite antistatic agent with double effects is prepared and is applied to an antistatic plastic film, and the preparation method has the advantages of simplicity, convenience in operation, easiness in industrial production and the like.

Owner:泉州嘉宸科技有限公司

Antistatic DAP molding compound for injection molding and preparing method thereof

The invention discloses an antistatic DAP molding compound for injection molding and a preparing method thereof. The antistatic DAP molding compound for injection molding is prepared from, by weight, 20-50% of DAP resin, 1-6% of cross-linking agent, 1-5% of plasticizer, 1-10% of conductive filler, 17-43% of inorganic filler, 1-5% of release agent and 10-30% of glass fiber. DAP resin, peroxide cross-linking agent with high half-time temperature, conductive filler, plasticizer and other components are reasonably matched to improve the plasticizing capacity of DAP resin and avoid solidification of the DAP molding compound in an injection molding machine charging barrel while realizing the antistatic purpose, so that the requirement for injection molding is met. The surface resistivity of the DAP molding compound prepared according to the formula is 1.0E+7 omega or more, bending strength is larger than 90 MPa, and thermal deformation temperature is higher than 240 DEG C.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Preparation method of flame-retardant antistatic coal mine ventilating pipeline

The invention discloses a preparation method of a flame-retardant antistatic coal mine ventilating pipeline, belonging to the technical field of preparation of ventilating pipelines. According to thepreparation method, poplar powder, maleic anhydride and polypropylene are mixed and fermented so as to obtain grafted modified wood powder, polypropylene and various additives are doped into the woodpowder so as to obtain a mixture, a sufficient amount of conductive carbon black is added, conductive particles in a composite material are uniformly distributed, so that the internal conductivity ofthe ventilating pipeline is improved; and ammonium polyphosphate and glycerin are taken as compound flame retardants, ammonium polyphosphate is heated and decomposed to generate phosphoric acid and ammonia gas in a combustion decomposing process, phosphoric acid and glycerin generate esterification reaction to generate carbon through dehydration, added zinc borate absorbs heat to remove crystal water, meanwhile, crystal water absorbs heat to evaporate and dilute combustible components and oxygen in air, zinc borate is heated to be fused to form a glass body covering layer so as to inhibit combustible gas, and generated boron and boron oxides are capable of inhibiting oxidizing reaction of carbon-containing compounds, so that the ventilating pipeline has good flame retardance and wide application prospects.

Owner:常州欣彬纺织品有限公司

Method of producing composite film specially used for novel plastic woven bag

The invention relates to method of producing a composite film specially used for a novel plastic woven bag. A three-layer thin film is produced by coextruding and biaxially orienting special material of biaxially-oriented polystyrene; the biaxially-oriented polystyrene is coextruded into a cast piece at 230-260 DEG C; the cast piece is rapidly cooled to be crystallized and solidified into a thick film; and the thick piece is preheated at 95-145 DEGC, longitudinally oriented at 80-135 DEG C by the orientation ratio of 4.5-5.5 times, thermally shaped at 100-160 DEG C, latitudinally oriented, preheated again at 180-210 DEG C, latitudinally oriented again at 130-180 DEG C by the latitudinal orientation ratio of 7.9-9.0 times and towed and winded at the speed of 100-325 m / min. Therefore, the composite film specially used for the novel plastic woven bag, which is 13-18 mu m thick, is produced with simple process.

Owner:群力塑胶有限公司

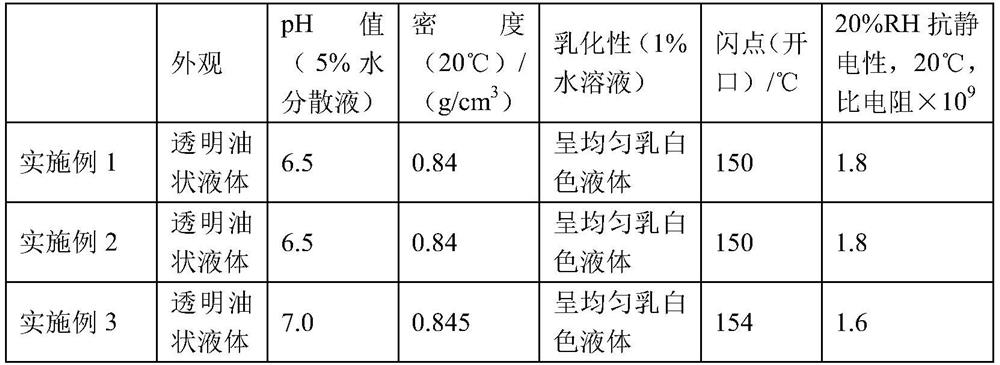

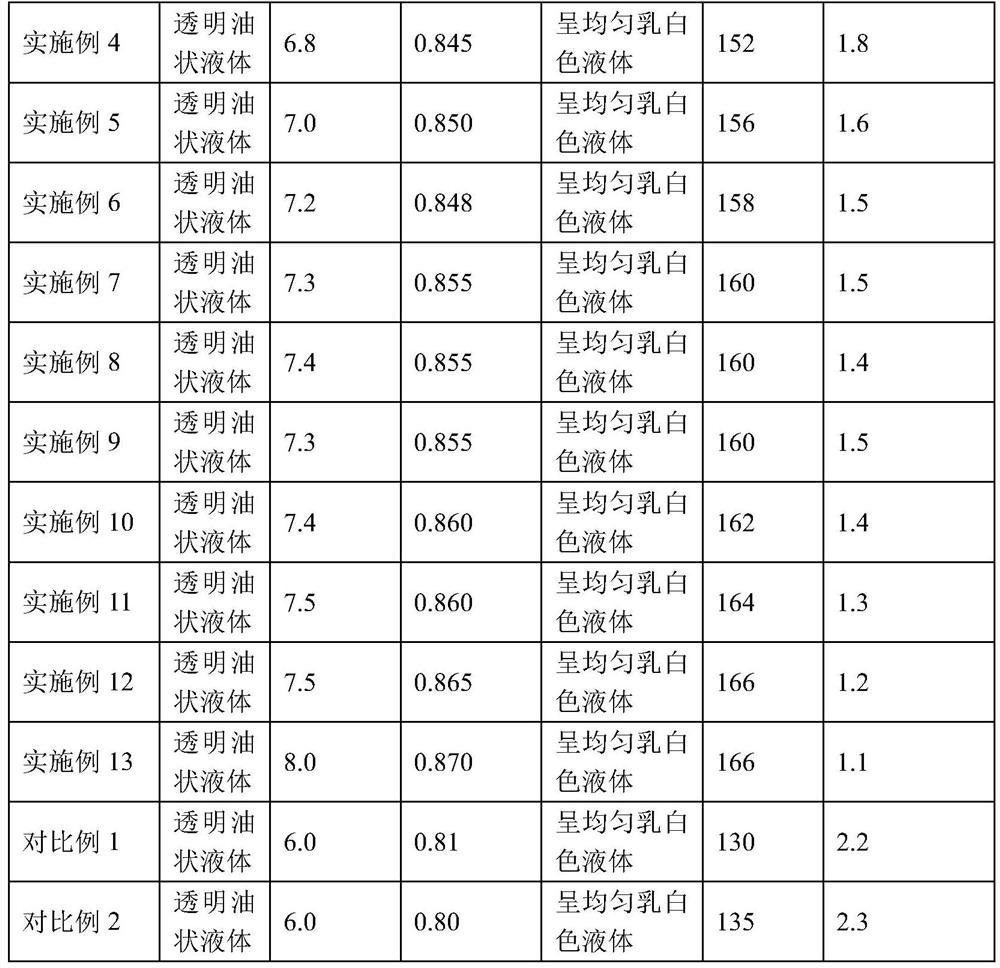

Silk yarn elasticizing oiling agent and preparation method thereof

The invention relates to the field of silk yarn processing, and particularly discloses a silk yarn elasticizing oil agent and a preparation method thereof.The silk yarn elasticizing oil agent is prepared from, by weight, 85-95 parts of base oil, 15-25 parts of an emulsifier, 20-30 parts of a detergent, 2-6 parts of an antistatic agent, 0.2-0.6 part of a penetrating agent and 0.5-1.5 parts of an anti-splashing agent; the prepared silk yarn elasticizing oiling agent has good antistatic performance, static accumulation in the polyester production process can be reduced, and the production efficiency is improved.

Owner:杭州临港化纤有限公司

A kind of healthy polyolefin foam material and preparation method thereof

The invention relates to a healthy polyolefin foam material and a preparation method thereof, which is prepared by mixing, melting and extruding, preheating and foaming the following raw and auxiliary materials in mass ratio: 70-100 parts of polyolefin resin, negative ion functional master 20-50 parts of raw material, 15-30 parts of hydrophilic functional masterbatch, 1-5 parts of foaming agent, 1-5 parts of cross-linking agent, and 0-5 parts of color masterbatch. The health-type polyolefin foam material of the present invention adds negative ion mineral materials and hydrophilic fullerene compounds into the formula, and has the advantages of air purification, surface anti-greasy, anti-static effects and the like. Utilizing the pyroelectricity and piezoelectricity of negative ion mineral materials can effectively increase the concentration of negative ions in the surrounding environment. At the same time, the hydrophilic group of the hydrophilic fullerene compound can form a hydrogen bond with water, which cuts off the connection between the pollutant and the polyolefin surface, and can also quickly leak the accumulated static charge to achieve the purpose of antistatic.

Owner:TAISHAN SPORTS IND GRP +1

Anti-static lace fabric

InactiveCN107700061ALong-lasting good conductive effectGood for healthWarp knittingYarnSurface layer

The invention discloses an antistatic lace cloth, belonging to the field of textiles, comprising a weaving part and a hollow part, the surface layer of the weaving part contains cotton fibers, and the ratio of the area of the weaving part to the hollow part is 1: (3-5). The lace cloth is braided by more than three bars, at least one bar is braided with yarn containing viscose fiber. The beneficial effect of the present invention is: add viscose fiber and cotton fiber to lace cloth, utilize the hygroscopic performance of viscose fiber and cotton fiber, keep the water content on the lace cloth at a higher level, by improving the hygroscopic effect of lace cloth to achieve Antistatic purpose.

Owner:福州市晋安区技智企业管理咨询有限公司

Application of Hyperbranched Polymer in Antistatic Agent for Flame Retardant Conveyor Belt

InactiveCN103265875BAvoid accumulationEfficient conductionPolyester coatingsAntistatic agentPolymer science

The invention relates to the technology field of flame retardant conveyor belt and particularly relates to an application of a hyperbranched polymer in antistatic agent on flame retardant conveyor belt. In the application of a hyperbranched polymer in antistatic agent on flame retardant conveyor belt, the general formula of the hyperbranched polymer is CH3(CH2)mN(CH2O)2([CO(CH2)2CON(CH2O)2]m[H]P)2. The hydroxyl-terminated hyperbranched polymer is used as an antistatic agent on PVC conveyor belt, and is directly coated on the surface of a flame retardant conveyor belt to absorb moisture in a mine and then form a more compact and tight conductive water film on the surface of the flame retardant conveyor belt, thus conducting and leaking electrostatic charges efficiently, preventing the accumulation of electrostatic charges and finally reaching the anti-static object.

Owner:UNIV OF JINAN

Method for preparing plastic granules for antistatic flame-retardant shoes

The invention belongs to the technical field of plastics processing and particularly relates to a method for preparing plastic granules for antistatic flame-retardant shoes. Prepared antistatic flame-retardant shoes are lightweight, portable, soft, comfortable and convenient and are convenient in washing and high in drying speed; white shoe soles are free of traces to floors and are applicable toassembly and checkout areas of electronic and semiconductor factories; and the antistatic shoes can effectively eliminate harm to human bodies caused by static charges. A working principle is as follows: static charges of a human body are conducted to the ground from the human body through wearing the antistatic shoes, an antistatic ground, and the like, and thus, the static charges of the human body are eliminated; and surface resistance of a shoe sole is low in release under the influence of wear and pollution, so that the antistatic flame-retardant shoes have the properties of acid resistance, alkali resistance, oil resistance and the like and the advantages of durability, good antislipping and antistatic properties, and the like. The antistatic flame-retardant shoes are applied to sites: any purification room or antistatic place of electronics, semiconductors, biomedicines, foods, optics and the like.

Owner:界首市鸿鑫塑业有限公司

Antibacterial and antistatic functional composite fabric

InactiveCN110682618AImprove antistatic performanceImprove antibacterial propertiesSynthetic resin layered productsClothingsFiberPolymer science

The invention discloses an antibacterial and antistatic functional composite fabric. The antibacterial and antistatic functional composite fabric includes a base fabric layer, a radiation protection layer is connected to the top of the base fabric layer through an adhesive, an antistatic layer is connected to the top of the radiation protection layer through an adhesive, the antistatic layer is composed of carbon fiber filaments and carbon black-based conductive fiber filaments, and an abrasion-resistant layer is connected to the top of the antistatic layer through an adhesive. According to the antibacterial and antistatic functional composite fabric, the combination of the antistatic layer, the carbon fiber filaments and the carbon black-based conductive fiber filaments, static electricity in a human body can be conducted to the outside and released, and the antistatic purpose is achieved, so that the fabric has a good antistatic effect; through the combination of an antibacterial layer, bamboo fiber filaments and activated carbon fiber filaments, the antibacterial layer is filled with silver-bearing antibacterial masterbatches, the antibacterial property of the fabric is improved, and the situation that bacteria is prone to breeding on fabric to cause uncomfortableness of users during use is avoided; and by arranging the abrasion-resistant layer, the abrasion performance of the fabric is increased, and the phenomenon that the fabric is prone to being damaged is avoided.

Owner:苏州恒可鸣纺织有限公司

Anti-static anti-fouling plastic film for packaging

ActiveCN111019225AGood compatibilityImprove thermal stabilityLinear low-density polyethyleneLow-density polyethylene

The invention discloses an anti-static anti-fouling plastic film for packaging. The anti-static anti-fouling plastic film is prepared from the following raw materials in parts by weight: 50-80 parts of low-density polyethylene, 30-45 parts of linear low-density polyethylene, 2-5 parts of a plasticizer, 0.5-1.2 parts of an anti-static anti-fouling additive, 0.5-1 part of a heat stabilizer and 1-2 parts of a lubricant. According to the invention, the low-density polyethylene and the linear low-density polyethylene are used as main raw materials; in order to solve the problem that an existing packaging plastic film is not resistant to static electricity, the anti-static anti-fouling additive is added into a formula for the plastic film, so dust adsorption is avoided due to the excellent anti-static property of the manufactured plastic film; and a packaging bag is endowed with anti-pollution capacity since the plastic film is doped with organic silicon, the packaging effect of the packaging bag is better played, and the packaging bag is practical and convenient to use.

Owner:浙江保禄包装科技股份有限公司

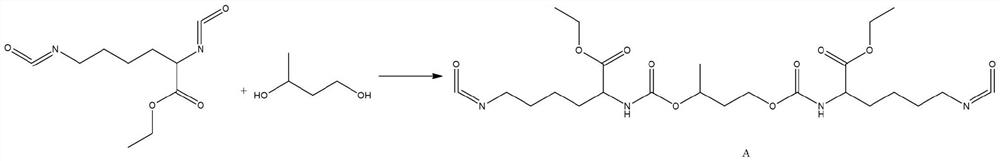

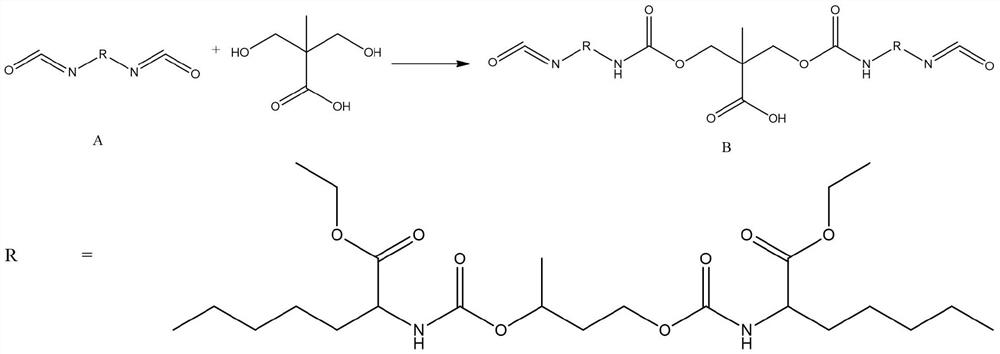

Production process of anti-static plastic net

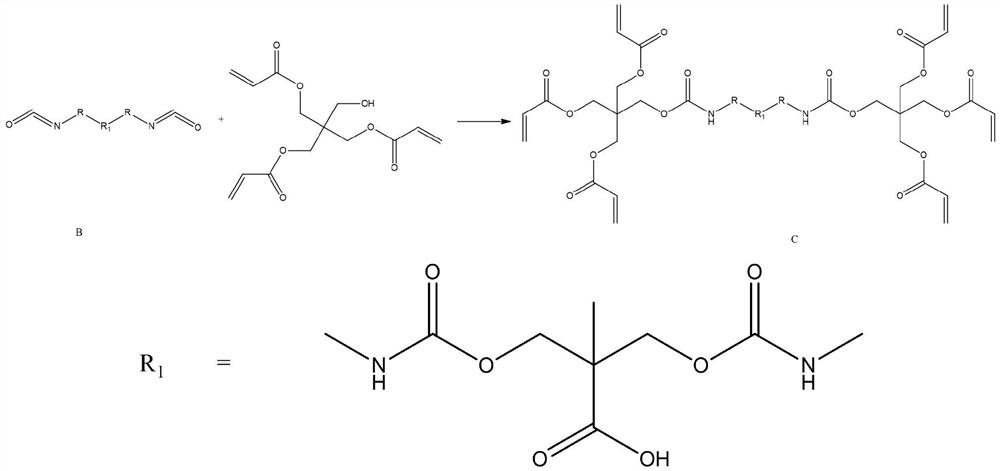

InactiveCN113463219AFast curingNo pollution in the processCarbamic acid derivatives preparationOrganic compound preparationPolyesterPolymer science

The invention discloses a production process of an anti-static plastic net. The process comprises the following steps of mixing polyvinyl chloride, plant cellulose fiber, a modified plasticizer, an antioxidant and a dispersing agent to obtain a blended material, putting the blended material into an extruder to be heated and melted, performing screw extrusion to enter a rotating machine head, enabling the molten blended material to flow through a mold hole to form two strands of molten material filaments, rotating the machine head, and discontinuously converging the two strands of material filaments at one point to form the net. A prepared macromolecular cross-linked structure can improve the intermolecular conductivity, effectively evacuate electrons and achieve the antistatic purpose; and ricinoleic acid with branched chains can generate linear polymerization with relatively high polymerization degree in the polyesterification reaction process, and polyester long chains and chain segments generated during plasticization are stable, so that the flexibility and toughness of the prepared plastic net are enhanced, and the purpose of enhancing the mechanical property of the plastic net is achieved.

Owner:安徽乙纤新材料科技有限公司

Anti-static fabric for pregnant women and preparation method thereof

InactiveCN111376556ASoft and comfortableGood hygroscopicityCarbon fibresBiochemical fibre treatmentPolyesterPolymer science

The invention relates to the technical field of fabrics, and provides an anti-static fabric for pregnant women and a preparation method thereof. The problems that in the prior art, fabric is poor in antistatic property, and static electricity is easy to accumulate to cause harm can be solved. The anti-static fabric comprises a base fabric layer, wherein a surface layer is arranged on the base fabric layer; wherein an anti-radiation layer is arranged between the base fabric layer and the surface layer; wherein the base fabric layer is formed by interweaving first warp yarns and first weft yarns; the surface layer is formed by interweaving second warp yarns and second weft yarns; the first warp yarns are copper ammonia / cotton blended yarns; the first weft yarns are polylactic acid / cotton blended yarns; wherein the first warp yarns are chitin / polyester blended yarns, the second weft yarns are modal / bamboo charcoal fibers, the anti-radiation layer raw materials are uniformly mixed and thencoated on the base fabric layer, then the surface layer is bonded on the anti-radiation layer through an adhesive, and finally the fabric is soaked in an anti-static finishing liquid and dried to obtain the anti-static fabric for pregnant women.

Owner:诸暨市孕创互联服饰有限公司

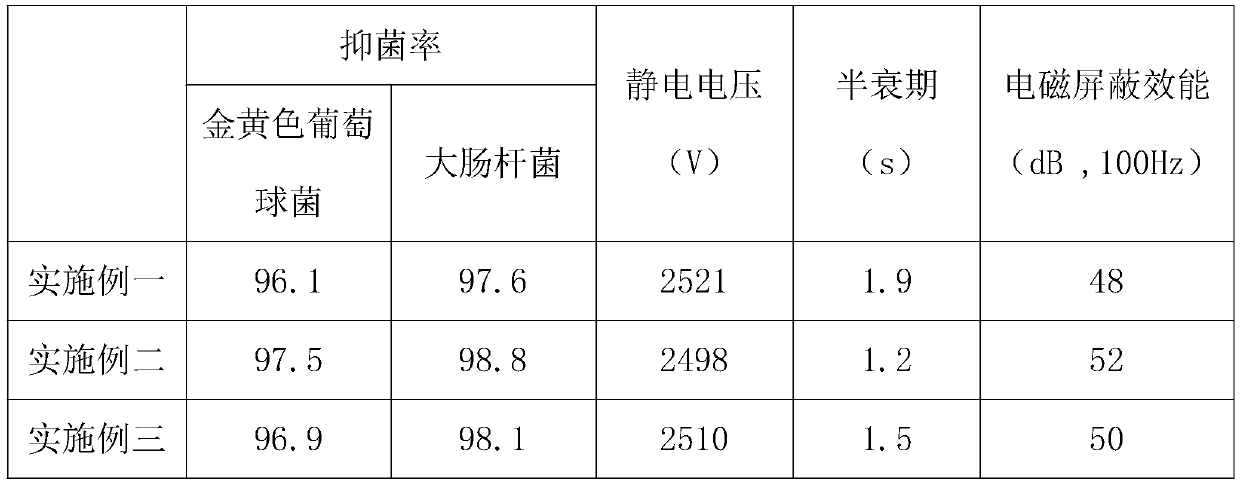

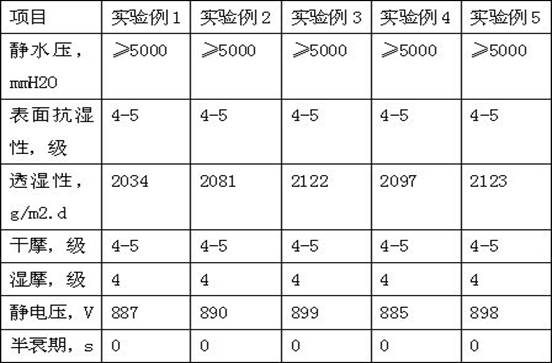

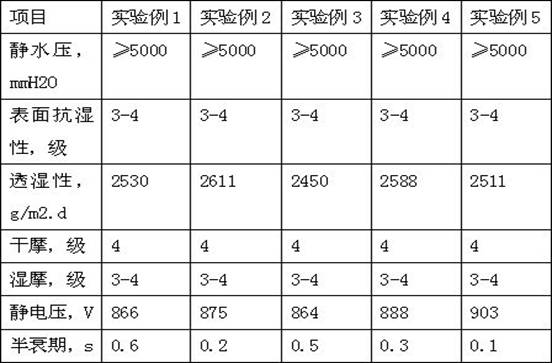

Durable antistatic, friction-resistant, waterproof and moisture-permeable, anti-seepage jacket fabric processing method

ActiveCN108824007BImprove antistatic performanceImprove friction resistanceLiquid/gas/vapor textile treatmentTextile shapingPolyesterPolymer science

The production and treatment method of the durable antistatic, friction-resistant, waterproof and moisture-permeable, anti-seepage outerwear fabrics, (1) use 20-30g / L C8 fluorine-based waterproof finishing liquid to carry out water-repellent finishing on 70D nylon or 75D polyester fabrics, two dips Two calendering, pre-baking-baking; (2) calendering finishing, (3) dry coating of fabrics with coating glue, dry weight gain 25-30g / m 2 , the coating glue is made of water-based waterproof and moisture-permeable polyurethane adhesive 80-100, water 5-15, graphene oxide sol 5-10, PTFE powder 2-4, blocked isocyanate crosslinking agent 5-10 . It is especially suitable for 70D nylon and 75D polyester fabrics. After production and treatment, the products have excellent antistatic, friction resistance, waterproof and moisture permeability, water seepage resistance, and water washing resistance. The production process is short, environmentally friendly, and easy to operate.

Owner:DANDONG UNIK TEXTILE

A kind of environment-friendly oil agent for continuous spun viscose filament and preparation method thereof

ActiveCN106498741BNot disorderlyImprove wear resistanceAbrasion resistant fibresVegetal fibresPentaerythritolEthylene oxide

Owner:SHENYANG HAOBO IND CO LTD

Preparation method of corn bio-based fiber double-sided double-layer elastic multifunctional woven fabric

ActiveCN112680856BIncrease elasticityNot easy to fluffHeating/cooling textile fabricsMulti-ply fabricsFiberYarn

The invention discloses a preparation method of corn bio-based fiber double-sided double-layer elastic multifunctional woven fabric, specifically relates to the field of woven fabric preparation technology, comprising the following steps: S1, raw material selection: selecting corn bio-based fiber, polyester cationic fiber, Conductive fiber and spandex are used as basic raw materials; S2, mechanical coating: spandex yarn is used as the core, and corn bio-based fiber is used to wrap the elongated spandex yarn in a spiral manner; S3, fiber network composite, winding and Twisting: use corn bio-based fiber, polyester cationic fiber and conductive fiber for three-in-one network composite, and then use network composite yarn for winding and twisting; S4, weaving; S5, dyeing, finishing. The invention adopts the above-mentioned raw materials and preparation process, and the double-sided double-layer woven fabric prepared by corn bio-based fiber has good elasticity, is low-carbon, environmentally friendly, anti-wrinkle, anti-static, fine in texture, can form rich pattern textures and colors, and feels soft and comfortable. .

Owner:DANYANG DANQI YUYUE TEXTILE

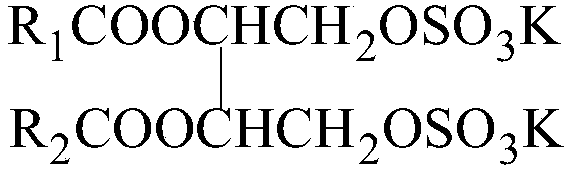

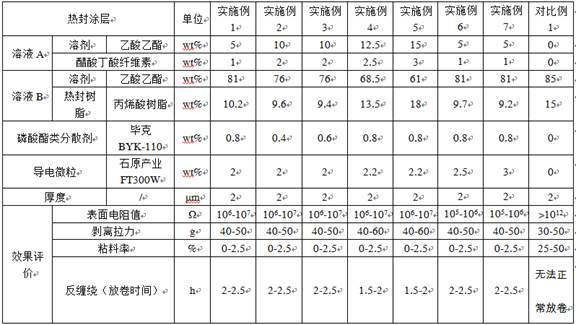

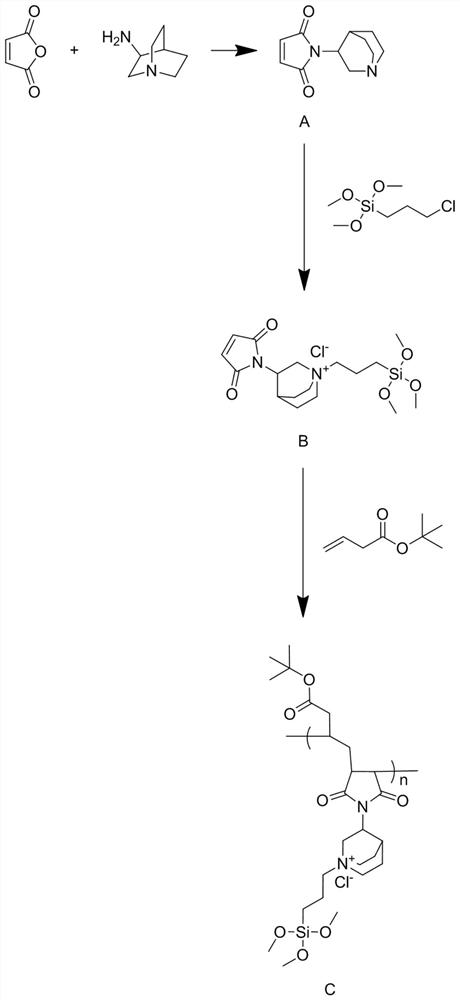

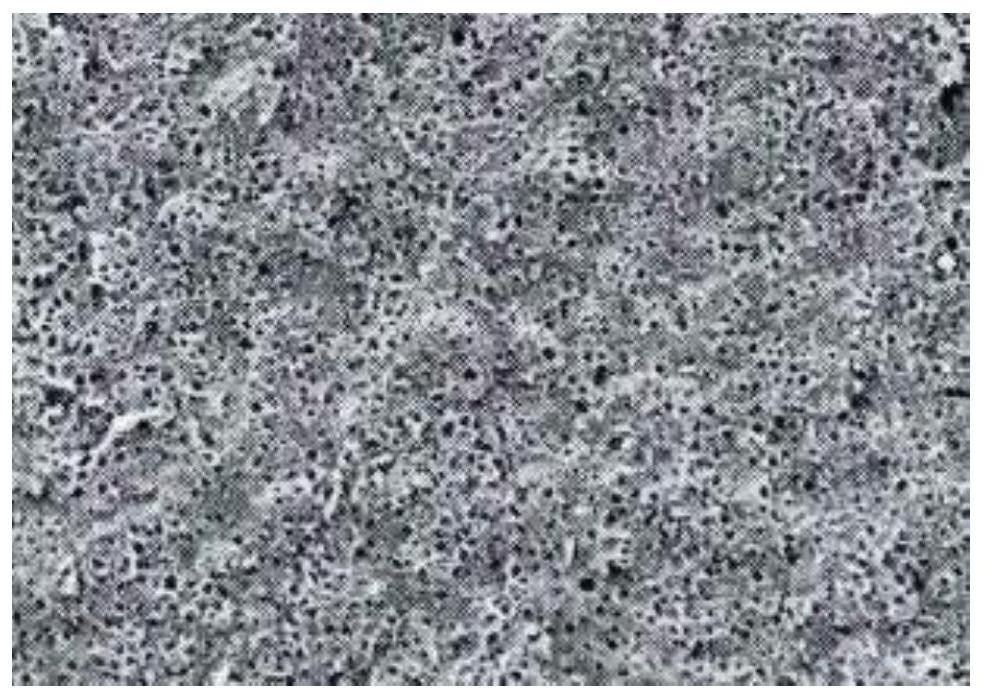

Anti-adhesion and anti-static heat-seal coating and cover tape

ActiveCN112500753AMaintain antistatic effectReduce adhesionElectrically-conductive paintsThin membranePolymer chemistry

The invention belongs to the technical field of cover tape films, and particularly discloses an anti-adhesion and anti-static heat-seal coating and a cover tape. The anti-blocking and anti-static heat-seal coating is formed by applying a coating liquid with Tg of 60-80 DEG C. The coating liquid comprises the following components: 1-3wt% of cellulose acetate butyrate, 9-18wt% of heat-seal resin, 76-86wt% of a solvent, 2-3wt% of titanium dioxide conductive particles and 0.4-0.8wt% of a dispersing agent. The cover tape comprises a base material layer and the anti-adhesion and anti-static heat-seal coating applied to the base material layer. According to the invention, the problems of high adhesion and non-ideal antistatic effect of the heat-seal layer resin of the existing cover tape can be effectively solved, and the prepared cover tape does not have the phenomena of adhesion and reverse winding; the tension is large, and damage is not likely to happen; and the antistatic effect is lasting.

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

Wear-resistant, antistatic polyoxymethylene material and preparation method thereof

The invention provides a wear-resistant and antistatic polyoxymethylene material and a preparation method thereof. The polyoxymethylene material is prepared from the following raw materials. In parts by weight, the raw material includes the following components: polyoxymethylene 100, polytetrafluoroethylene 5-20, antistatic agent 1-10; the polyoxymethylene material of the present invention is passed through The wear-resistant additive polytetrafluoroethylene is added to the polyoxymethylene system to form a POM / PTFE system, which makes the system have excellent wear resistance. The compatibility and dispersion of PTFE in the matrix are improved, and the antistatic performance of the system is greatly improved. The polyoxymethylene material of the present invention not only has excellent wear resistance, but also has good antistatic performance, and has wider applications than existing polyoxymethylene materials.

Owner:SICHUAN UNIV

Anti-static garment and processing method thereof

InactiveCN112553745AHigh strengthIncrease elasticityElectroconductive/antistatic filament manufactureMulti-ply fabricsProcess engineeringMechanical engineering

The invention relates to an anti-static garment. The anti-static garment comprises a garment body, and the garment body comprises an anti-static layer, a heat preservation layer and a soft layer whichare sequentially arranged from outside to inside; and the anti-static layer is formed by blending anti-static fibers and bamboo charcoal fibers. The problems that the electrostatic phenomenon can interfere with normal work of a computer and other sensitive electronic instruments, static electricity can bring discomfort to a wearer, and potential safety hazards can be possibly brought in special industrial operation are solved. According to the anti-static garment, the anti-static layer, the heat preservation layer and the soft layer are woven, so that the anti-static garment is prepared, integrates heat preservation, comfort and static prevention, and is very suitable for being worn in cold and dry seasons in autumn and winter.

Owner:宁波共振运动科技有限公司

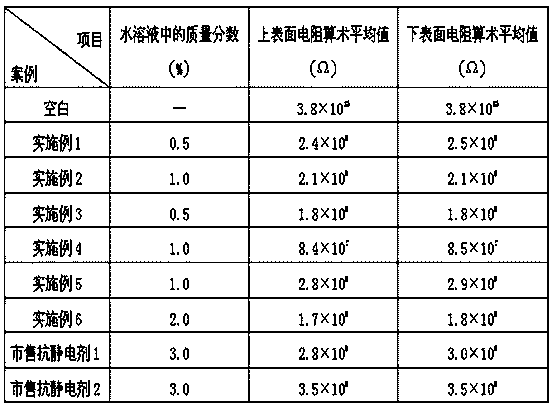

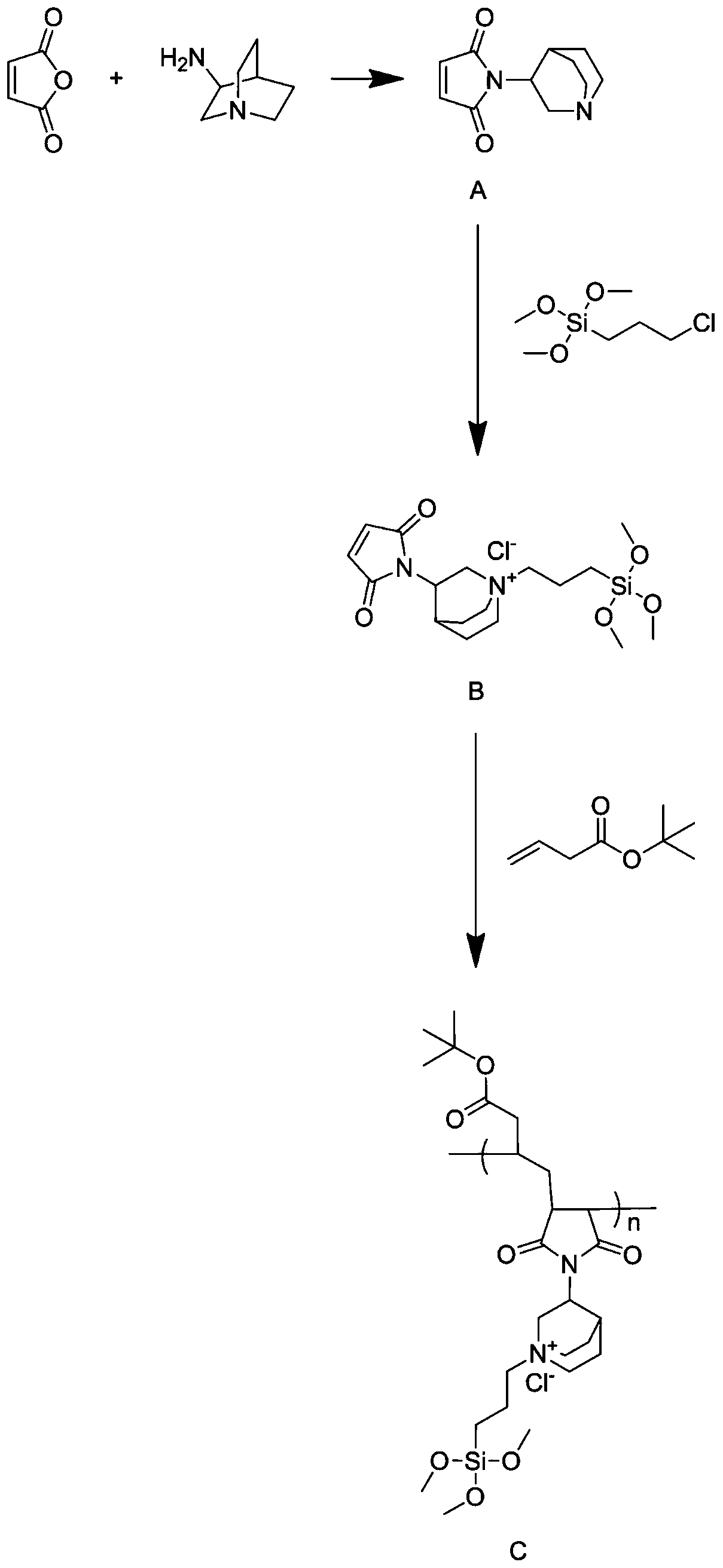

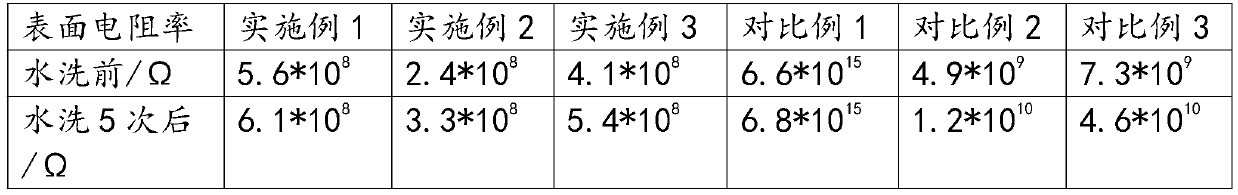

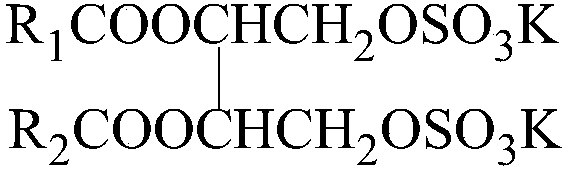

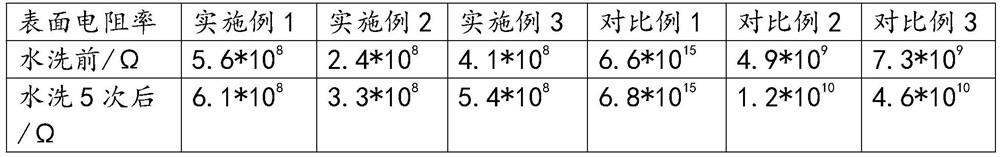

A kind of preparation method of antistatic agent

ActiveCN109797553BGood hygroscopicityImprove antistatic performanceFibre typesPolyesterPhosphoric Acid Esters

Owner:JIANGSU NIMATE SCI & TECH CO LTD

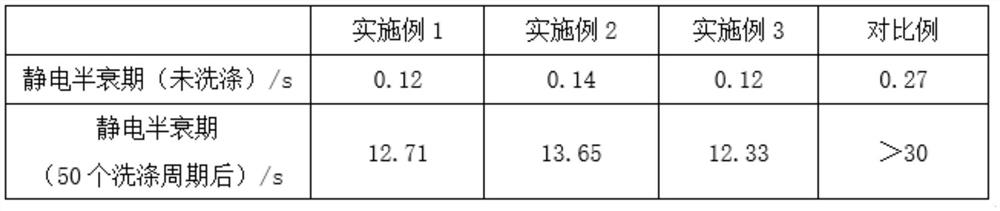

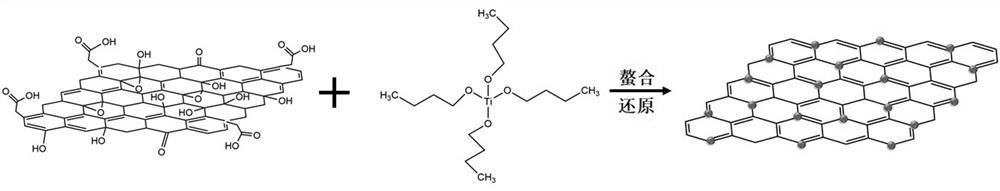

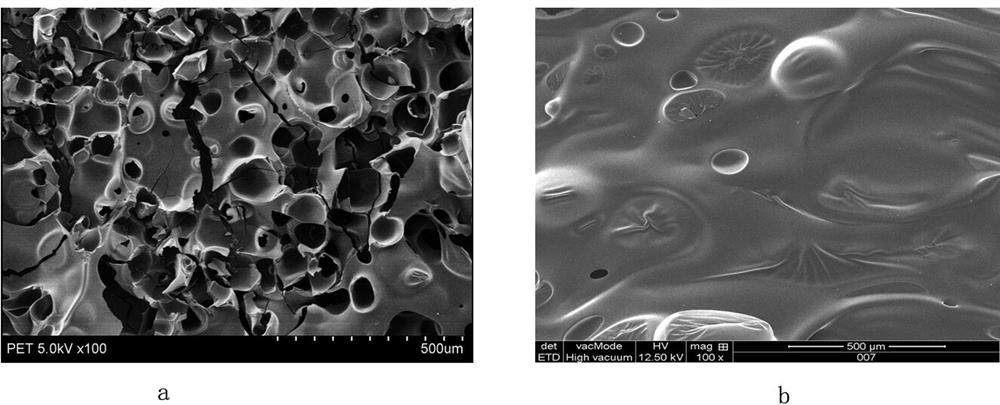

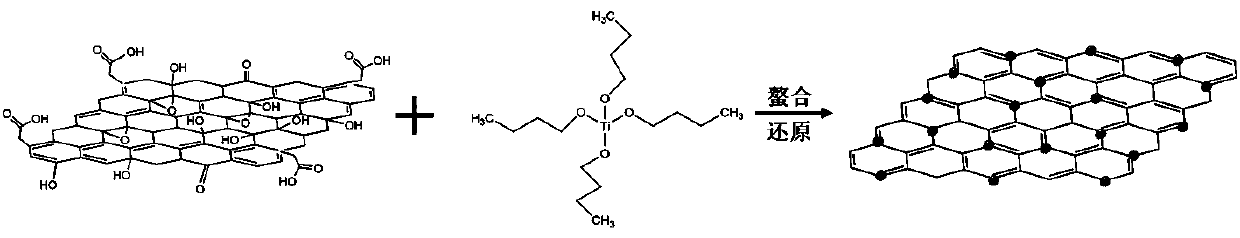

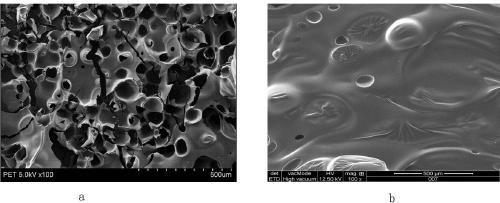

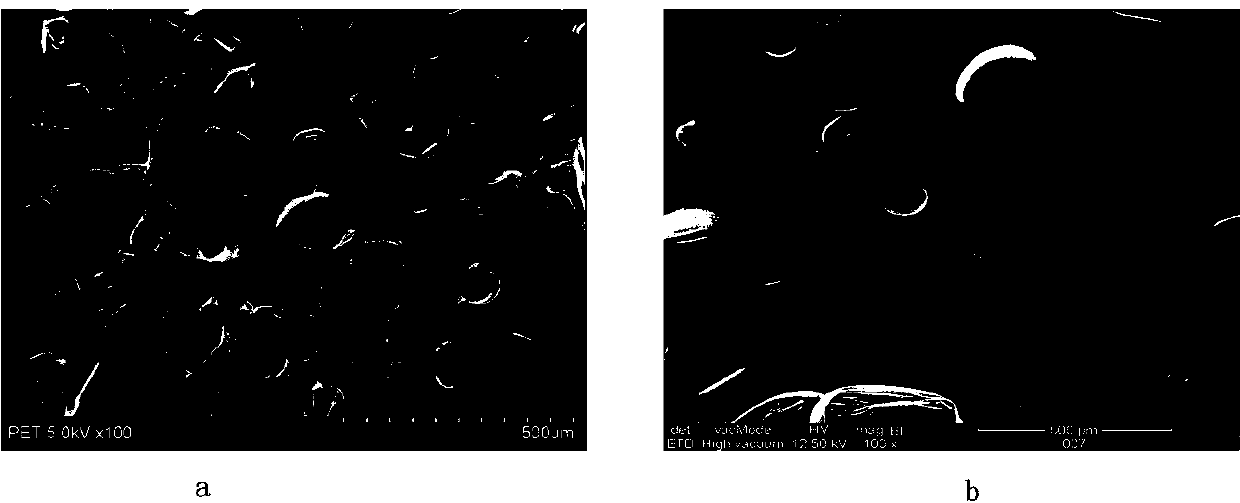

Preparation method and application of antistatic flame retardant polyester resin

ActiveCN111138643BTo achieve the purpose of antistaticImprove antistatic performanceElectroconductive/antistatic filament manufactureFlame-proof filament manufactureFiberPolymer science

The invention discloses a preparation method of antistatic flame-retardant polyester resin, comprising the following steps: chelating carboxylated graphene oxide and a metal oxide precursor with synergistic catalysis and flame retardancy, carrying out heat treatment, and carrying out in-situ polymerization on the obtained product and alkyl phosphinic metal salt to prepare the antistatic flame-retardant polyester resin. The invention also discloses application of the above electrostatic flame-retardant polyester resin. The electrostatic flame-retardant polyester resin is used for preparing antistatic flame-retardant polyester fibers. Carboxylated graphene is chelated with a metal oxide precursor with a catalytic effect, a product obtained after heat treatment is dispersed in a polyester polymerization system, graphene oxide is reduced in situ through heat and reducing atmosphere in the polymerization process, and the anti-static purpose is achieved. The invention belongs to the technical field of preparation of antistatic flame-retardant materials, the preparation method is used for preparing the antistatic flame-retardant polyester resin, and the obtained resin is further applied to preparation of corresponding fibers.

Owner:DONGHUA UNIV

Preparation method and application of antistatic flame-retardant polyester resin

ActiveCN111138643AImprove antistatic and flame retardant abilityGood flame retardant performanceElectroconductive/antistatic filament manufactureFlame-proof filament manufactureIn situ polymerizationCarboxylic group

The invention discloses a preparation method of antistatic flame-retardant polyester resin, comprising the following steps: chelating carboxylated graphene oxide and a metal oxide precursor with synergistic catalysis and flame retardancy, carrying out heat treatment, and carrying out in-situ polymerization on the obtained product and alkyl phosphinic metal salt to prepare the antistatic flame-retardant polyester resin. The invention also discloses application of the above electrostatic flame-retardant polyester resin. The electrostatic flame-retardant polyester resin is used for preparing antistatic flame-retardant polyester fibers. Carboxylated graphene is chelated with a metal oxide precursor with a catalytic effect, a product obtained after heat treatment is dispersed in a polyester polymerization system, graphene oxide is reduced in situ through heat and reducing atmosphere in the polymerization process, and the anti-static purpose is achieved. The invention belongs to the technical field of preparation of antistatic flame-retardant materials, the preparation method is used for preparing the antistatic flame-retardant polyester resin, and the obtained resin is further applied to preparation of corresponding fibers.

Owner:DONGHUA UNIV

Printing ink directly applicable to films and preparation method thereof

The invention discloses printing ink, which is characterized by comprising the following components (by weight): 15%-25% of rosin modified phenolic resin, 10%-15% of polyacrylic resin, 10%-30% of silicon dioxide, 20%-40% of a water-based pigment, 2%-4% of dibutyl ester, 3%-7% of aldehyde ketone resin, 0.1%-2% of triglyceride, 0.1%-1% of polyether acrylate, 0.1%-0.6% of polyvinyl chloride, 0.1%-1%of polyethylene glycol terephthalate, 0.1%-0.7% of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.1%-2% of polyethylene glycol, 1%-2% of alkyl sodium sulfonate, 1-3 of fatty alcohol-polyoxyethylene ether and 15%-25% of distilled water. This printing ink is directly applicable to films. The invention also provides a printing ink preparation method which can reduce the cost and significantly improve the production efficiency.

Owner:广东绿之彩科技股份有限公司

An anti-blocking, antistatic heat-sealing coating and cover tape

ActiveCN112500753BThere is no problem of uneven distribution or even reunionGood effectElectrically-conductive paintsCellulosePolymer science

Owner:ZHEJIANG JIEMEI ELECTRONICS & TECH

An antistatic and antifouling plastic film for packaging

ActiveCN111019225BSolve the problem of static electricityImprove antistatic performanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antistatic and antifouling plastic film for packaging, which is made of the following raw materials in parts by weight: 50-80 parts of low-density polyethylene, 30-45 parts of linear low-density polyethylene, and 2-2 parts of plasticizer 5 parts, 0.5-1.2 parts of antistatic antifouling additive, 0.5-1 part of heat stabilizer, 1-2 parts of lubricant; with low density polyethylene and linear low density polyethylene as the main raw materials, in order to solve the existing packaging plastics The film is not resistant to static electricity. Antistatic and anti-fouling additives are added to the plastic film formula. The excellent antistatic properties of the produced plastic film avoid the adsorption of dust. The plastic film mixed with silicone endows the packaging bag with anti-fouling ability. Make it better play the role of packaging, practical and convenient.

Owner:浙江保禄包装科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com