Anti-static garment and processing method thereof

An anti-static and anti-static layer technology, which is applied in the direction of clothing, clothing, protective clothing, etc., can solve the problems of not having anti-static function, etc., and achieve the effects of good elasticity, improved functional group activity, and enhanced anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

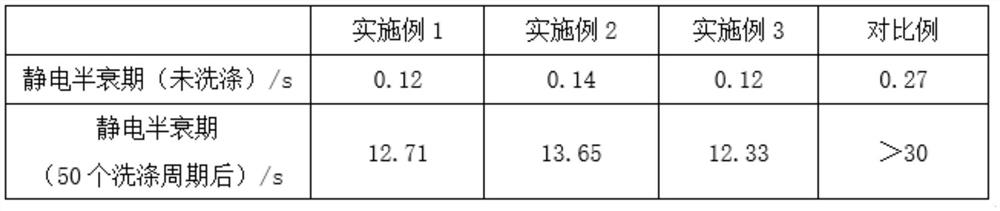

Embodiment 1

[0045] A kind of antistatic clothing, this antistatic clothing comprises clothes body, and described clothes body comprises antistatic layer, thermal insulation layer and soft layer that are arranged in order from outside to inside; Described antistatic layer is made of antistatic fiber and bamboo charcoal fiber Blended.

[0046] In the antistatic layer, the mass ratio of the antistatic fiber to the bamboo charcoal fiber is 1:1.8.

[0047] The insulation layer is made of blended polyamide fiber and wool fiber; wherein, the mass ratio of polyamide fiber and wool fiber is 1:4.4.

[0048] The polyamide fiber in the heat insulation layer has a hollow structure.

[0049] The soft layer is formed by interweaving warp threads and weft threads, the warp threads are made of blended cotton fibers and polyurethane fibers, and the weft threads are made of blended hemp fibers and modal fibers.

[0050] In the warp of the soft layer, the mass ratio of cotton fiber to polyurethane fiber is...

Embodiment 2

[0075] A kind of antistatic clothing, this antistatic clothing comprises clothing body, and described clothing body comprises antistatic layer, thermal insulation layer and soft layer that are arranged in order from outside to inside; Described antistatic layer is made of antistatic fiber and bamboo charcoal fiber Blended.

[0076] In the antistatic layer, the mass ratio of the antistatic fiber to the bamboo charcoal fiber is 1:1.2.

[0077] The insulation layer is made of blended polyamide fiber and wool fiber; wherein, the mass ratio of polyamide fiber and wool fiber is 1:2.5.

[0078] The polyamide fiber in the heat insulation layer has a hollow structure.

[0079] The soft layer is formed by interweaving warps and wefts, the warps are blended with cotton fibers and polyurethane fibers, and the wefts are blended with hemp fibers and modal fibers.

[0080] In the warp of the soft layer, the mass ratio of cotton fiber to polyurethane fiber is 1:0.2; in the weft of the soft ...

Embodiment 3

[0105] A kind of antistatic clothing, this antistatic clothing comprises clothes body, and described clothes body comprises antistatic layer, thermal insulation layer and soft layer that are arranged in order from outside to inside; Described antistatic layer is made of antistatic fiber and bamboo charcoal fiber Blended.

[0106] In the antistatic layer, the mass ratio of the antistatic fiber to the bamboo charcoal fiber is 1:2.2.

[0107] The insulation layer is made of blended polyamide fiber and wool fiber; wherein, the mass ratio of polyamide fiber and wool fiber is 1:6.8.

[0108] The polyamide fiber in the heat insulation layer has a hollow structure.

[0109] The soft layer is formed by interweaving warp threads and weft threads, the warp threads are made of blended cotton fibers and polyurethane fibers, and the weft threads are made of blended hemp fibers and modal fibers.

[0110] In the warp of the soft layer, the mass ratio of cotton fiber to polyurethane fiber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com