A kind of environment-friendly oil agent for continuous spun viscose filament and preparation method thereof

An environmentally friendly, oil-based technology, applied in textiles and papermaking, wear-resistant fibers, plant fibers, etc., can solve the problems of negative environmental impact, low fiber oiling rate, and inability to meet high-speed looms, etc., to achieve resistance reduction , good compatibility, enhance the effect of moisture absorption and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

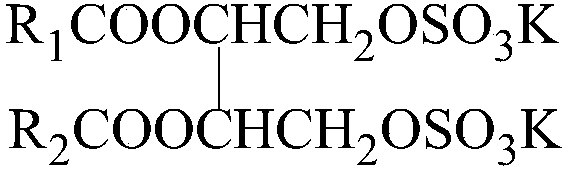

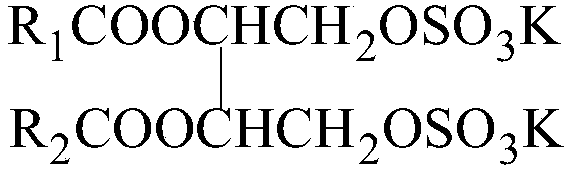

[0027] An environmentally friendly oil agent for continuous spun viscose filaments, which is prepared from the following raw materials in parts by mass: heating 30 parts of deionized water with a conductivity of 5 μS / cm to 60 °C, adding fatty acid poly Ethylene oxide [C 10 h 21 COO(EO) 15 H] 30 parts, ethylene oxide-propylene oxide block polyether R 1 O(PO) m (EO) n H (R is C 6 straight chain alkyl, m=3, n=15) 8 parts, gemini surfactant (R 1 and R 2 Both are C 10 6 parts of straight-chain alkyl) and 7 parts of pentaerythritol oleate, mixed and stirred for 35 minutes, then added 1 part of morpholine, 0.8 part of triethanolamine to adjust the pH value to 8, and obtained an oil agent for continuous spunbonded adhesive filaments.

Embodiment 2

[0029] An environmentally friendly oil agent for continuous spun viscose filaments, which is prepared from the following raw materials in parts by mass: heating 35 parts of deionized water with a conductivity of 5 μS / cm to 60 ° C, adding fatty acid poly Ethylene oxide [C 12 h 25 COO(EO) 18 H] 30 parts, ethylene oxide-propylene oxide block polyether R 1 O(PO) m (EO) n H (R is C 10 straight-chain alkyl, m=3, n=20) 6 parts, gemini surfactant (R 1 and R 2 Both are C 12 6 parts of straight-chain alkyl), 8 parts of pentaerythritol oleate, mixed and stirred for 35 minutes, then added 0.8 part of isothiazolinone, 0.8 part of triethanolamine to adjust the pH value to 8, and obtained the oil for continuous spun viscose filament agent.

Embodiment 3

[0031] An environmentally friendly oil agent for continuous spun viscose filaments, which is prepared from the following raw materials in parts by mass: heating 40 parts of deionized water with a conductivity of 5 μS / cm to 60 °C, adding fatty acid poly Ethylene oxide [C 14 h 29 COO(EO) 20 H] 30 parts, ethylene oxide-propylene oxide block polyether (R is C 8 straight chain alkyl, m=5, n=17) 10 parts, gemini surfactant (R 1 and R 2 Both are C 12 8 parts of straight chain alkyl), 10 parts of pentaerythritol oleate, mixed and stirred for 35 minutes, then added 1.5 parts of isothiazolinone, 0.8 parts of triethanolamine to adjust the pH value to 8, and obtained the oil for continuous spun viscose filament agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com