An antistatic and antifouling plastic film for packaging

A plastic film, anti-static technology, applied in the field of packaging, can solve the problems of unsanitary food or items, film or bag vacuuming or oil fume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

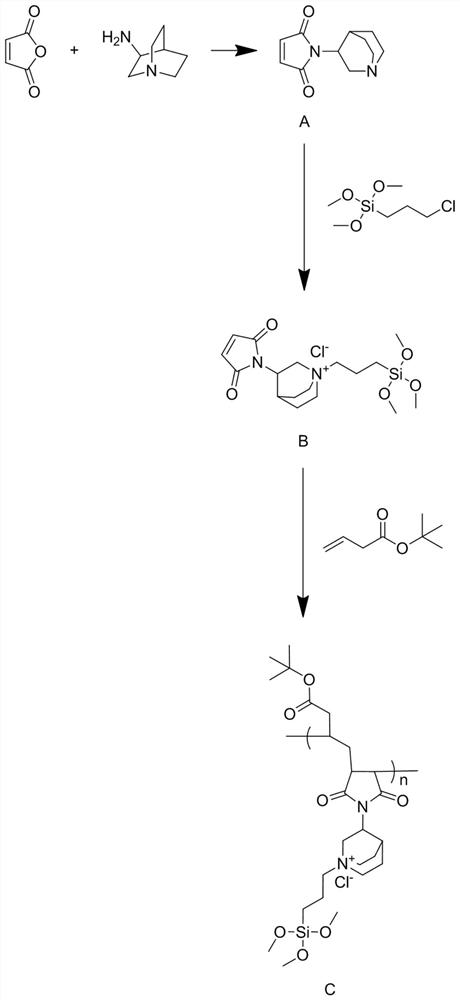

Method used

Image

Examples

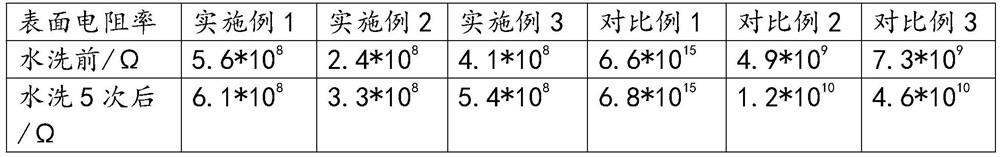

Embodiment 1

[0036] An antistatic and antifouling plastic film for packaging, made of the following raw materials in parts by weight: 50 g of low-density polyethylene, 40 g of linear low-density polyethylene, 3 g of plasticizer, 0.5 g of antistatic and antifouling additives, heat-stabilizing Agent 0.5g, lubricant 2g,

[0037] Described plasticizer is polyethylene glycol;

[0038] Described thermal stabilizer is triphenyl phosphite;

[0039] Described lubricant is magnesium stearate;

[0040] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0041] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0042]The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude ...

Embodiment 2

[0046] An antistatic and antifouling plastic film for packaging, made of the following raw materials in parts by weight: 80g of low-density polyethylene, 30g of linear low-density polyethylene, 2g of plasticizer, 1.2g of antistatic and antifouling additives, heat-stabilizing Agent 1g, lubricant 1.5g,

[0047] Described plasticizer is polyethylene glycol;

[0048] Described thermal stabilizer is triphenyl phosphite;

[0049] Described lubricant is zinc stearate;

[0050] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0051] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0052] The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude it into ...

Embodiment 3

[0055] An antistatic and antifouling plastic film for packaging, made of the following raw materials in parts by weight: 70g of low-density polyethylene, 35g of linear low-density polyethylene, 3g of plasticizer, 1g of antistatic and antifouling additive, heat stabilizer 1g, lubricant 2g,

[0056] Described plasticizer is polyethylene glycol;

[0057] Described thermal stabilizer is triphenyl phosphite;

[0058] Described lubricant is sodium stearate;

[0059] The production process of the antistatic and antifouling plastic film for packaging specifically includes the following steps:

[0060] The first step, premixing: mix low-density polyethylene, linear low-density polyethylene, plasticizer, antistatic and antifouling additives, heat stabilizer, and lubricant;

[0061] The second step, blow molding: inject the premixed material into the plastic blown film machine, melt it at high temperature in four stages of 130°C, 140°C, 150°C, and 160°C, and extrude it into a film aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com