Patents

Literature

36results about How to "Solve the problem of static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC (polyvinyl chloride) sole material suitable for high-temperature steam sterilization and production method thereof

ActiveCN105670176ASolve the problem of static electricityGood flexibilitySolesFiberPolyvinyl chloride

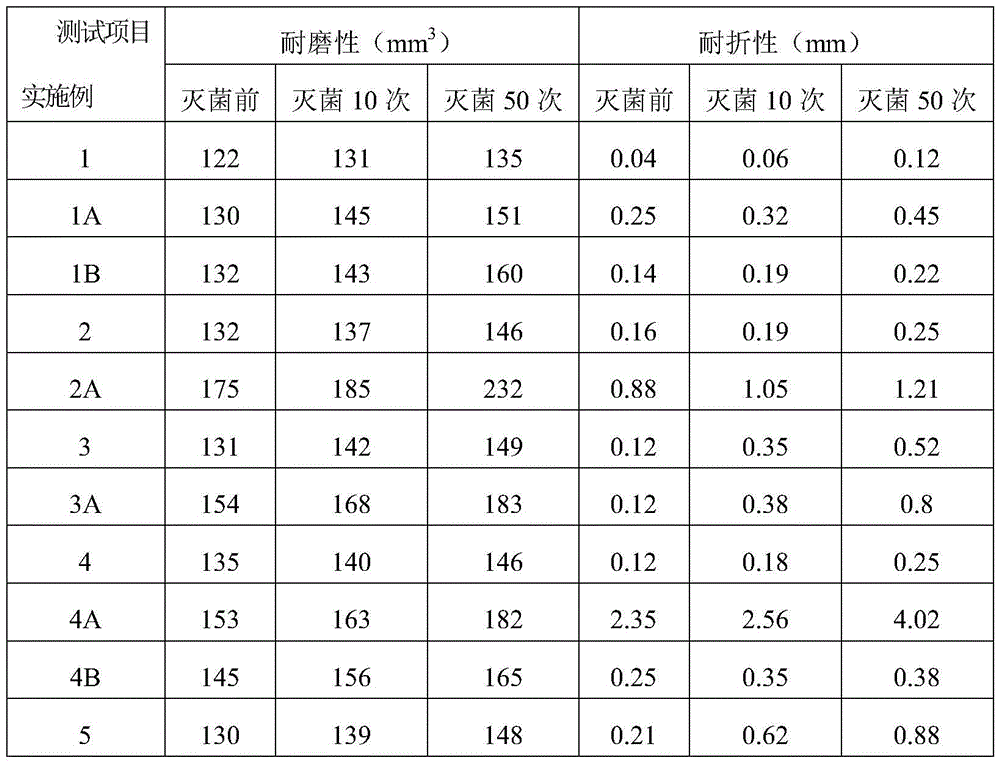

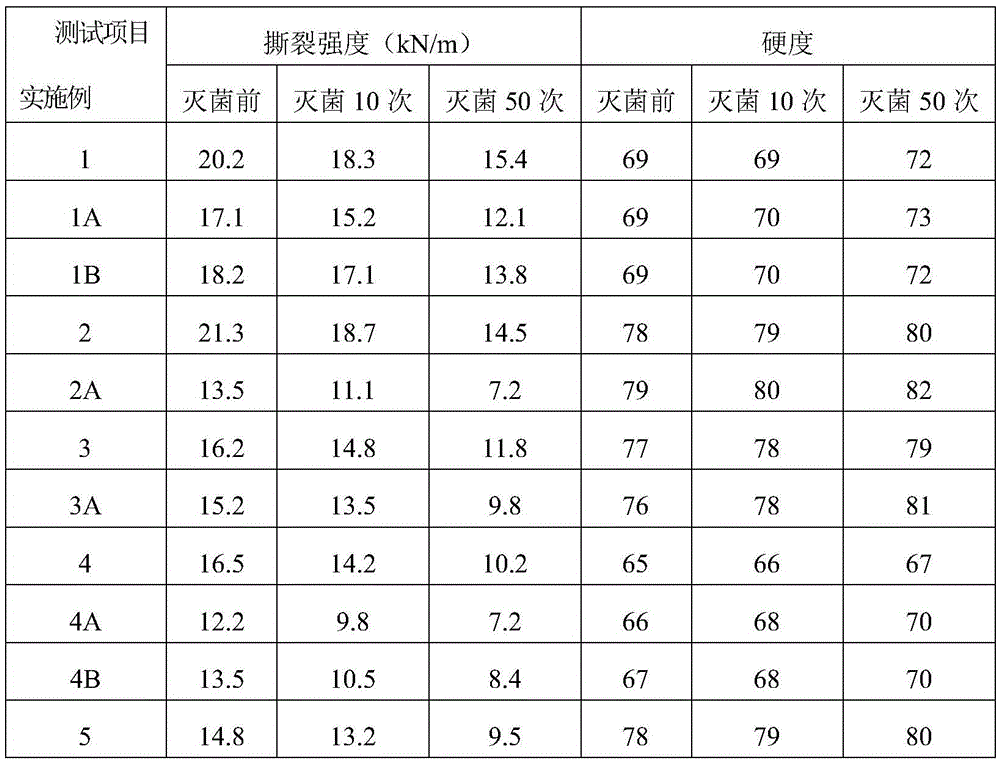

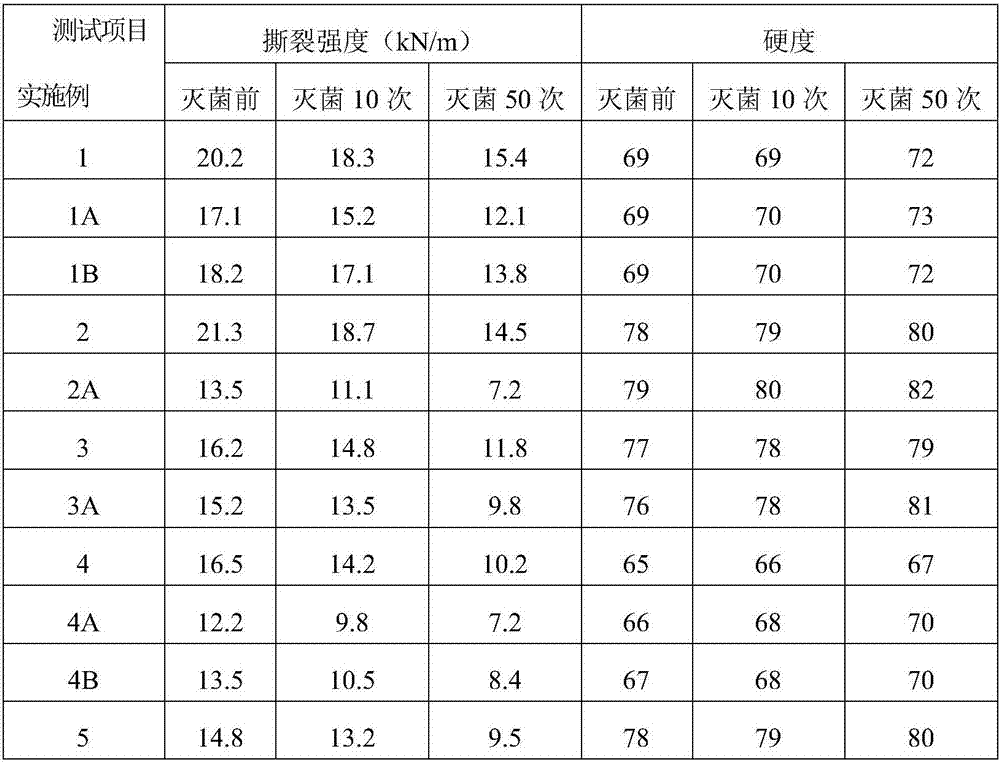

The invention discloses a medical PVC (polyvinyl chloride)) sole material suitable for high-temperature steam sterilization, mainly comprising PVC resin, a plasticizer, an auxiliary plasticizer, a thermal stabilizer, an auxiliary thermal stabilizer, a lubricant, split-film fiber, a compatibilizer, an antibacterial agent and the like. The problems that an existing medical PVC sole material suffers sole yellowing, decreased mechanical performances and softening deformation after being subjected to high-temperature steam sterilization are solved, and the medical PVC sole material is better in high-temperature stability, folding resistance, tear resistance, wear resistance and size stability; in addition, by adding an antistatic agent, the problem that high-temperature steam sterilized PVC shoe material is prone to static generation is solved; the invention also provides a production method of the medical PVC sole material suitable for high-temperature steam sterilization, comprising: preparation of a composite thermal stabilizer, mixing of resin and an aid, extrusion granulating, and injection molding; the production method is simple and easy to industrialize.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

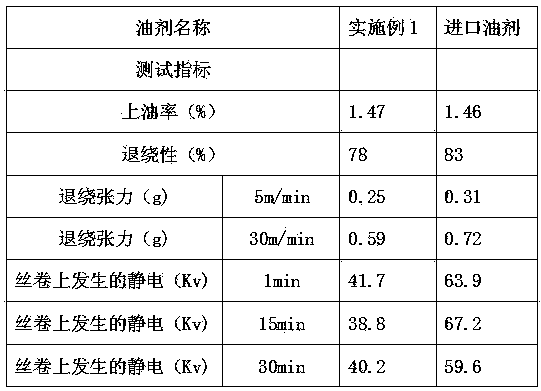

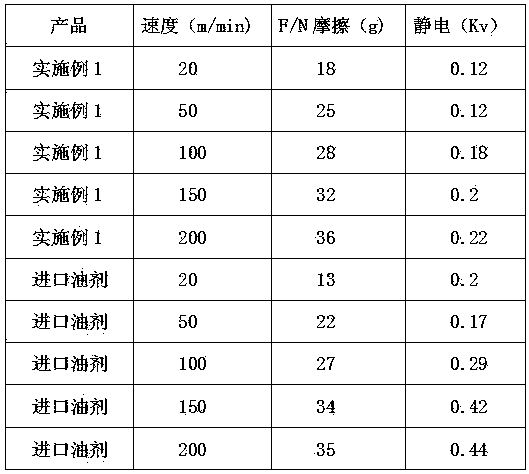

Dry-process polyimide spinning oil

ActiveCN104213414ASolve the problem of static electricitySolve the problem of unwindingFibre typesFiber bundlePhosphate

The invention relates to a dry-process polyimide spinning oil which is prepared from the following raw materials in parts by weight: 30 to 60 parts of simethicone, 10 to 30 parts of refined mineral oil, 3 to 9 parts of sorbitan tristearate polyoxyethylene ether, 5 to 10 parts of dodecyl phosphate diethanolamine salt, 8 to 14 parts of hexadecyl potassium phosphate and 10 to 20 parts of fatty alcohol-polyoxyethylene ether. The dry-process polyimide spinning oil prepared from the simethicone, the refined mineral oil, sorbitan tristearate polyoxyethylene ether, the dodecyl phosphate diethanolamine salt, hexadecyl potassium phosphate and fatty alcohol-polyoxyethylene ether is reasonable in formula, good in application effect and low in production cost; and in addition, the problems that fibers cannot be easily unwound and fiber bundles cannot be well gathered due to large static electricity among the fibers and the like are solved well.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

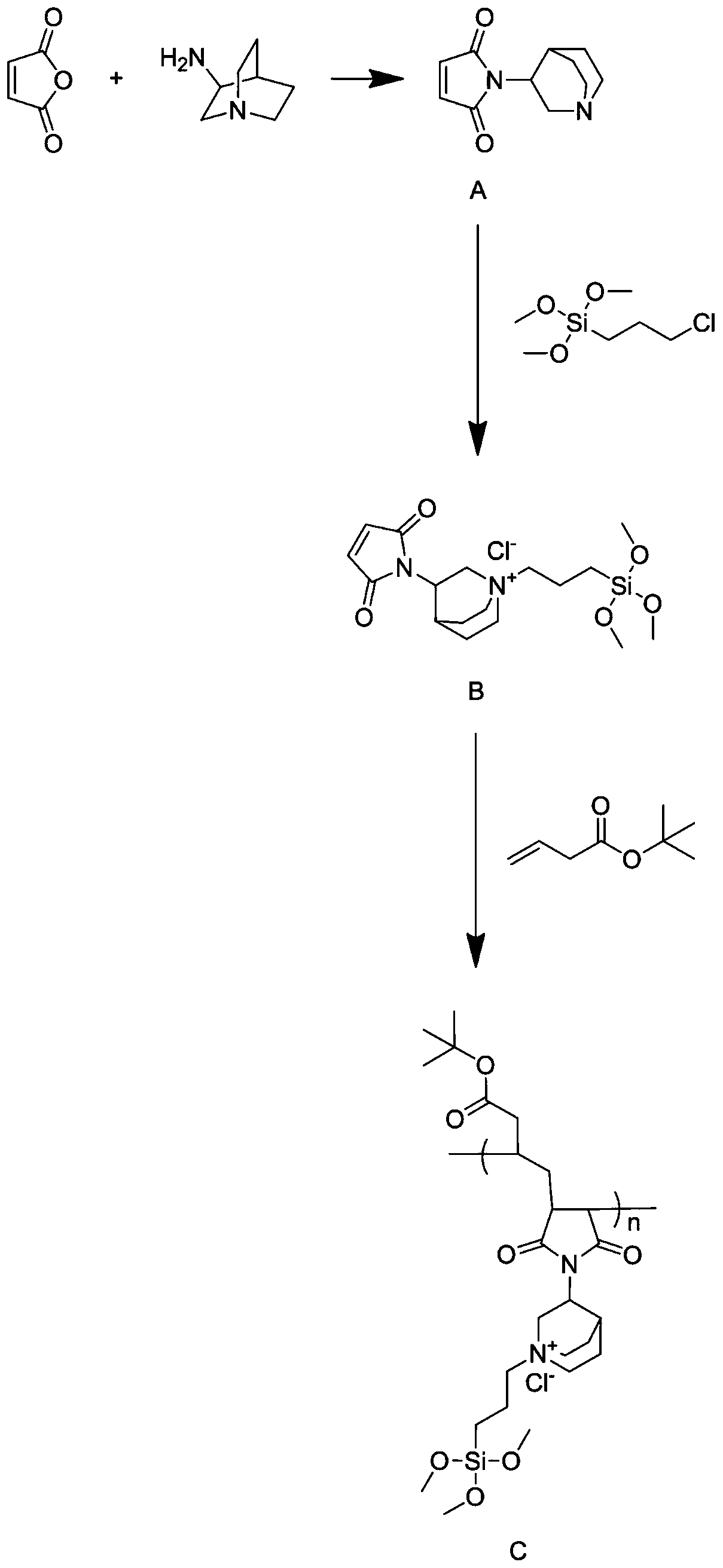

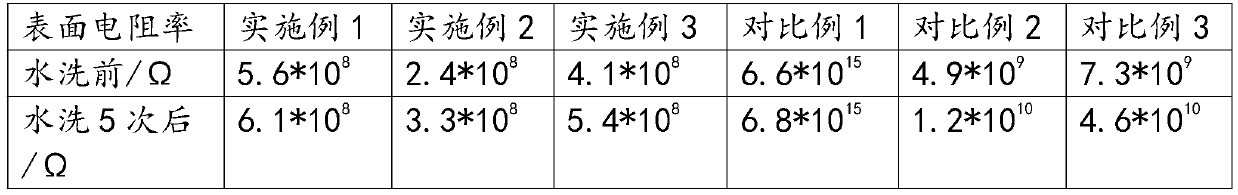

Compound finishing agent for improving antistatic performance of polyester fabrics

The invention discloses a compound finishing agent for improving the antistatic performance of polyester fabrics, and relates to the technical field of fabric finishing. The compound finishing agent is prepared from the following raw materials in parts by weight: 15 to 25 parts of cactus, 1 to 5 parts of polyaspartic acid / glucosamine, 1 to 5 parts of hydroxypropyl methyl cellulose, 0.5 to 1 part of cationic polyacrylamide, 0.5 to 1 part of rice bran wax, 0.05 to 0.5 part of polydimethyl diallyl ammonium chloride, and 0.05 to 0.5 part of sodium gluconate. The compound finishing agent is rich in natural components, and after polyester fabrics are processed by the finishing agent, the polyester fabrics have an excellent and stable hydrophilic property, good antistatic performance, and good durability.

Owner:安徽华锦柏亚纤纺科技有限公司

A kind of plastic hose for mine and its preparation method

InactiveCN102297295ASolve flame retardancySolve antistaticFlexible pipesDi n butyl phthalatePolyvinyl chloride

The invention relates to a plastic hose for a mine and a preparation method. The plastic hose comprises 90-110 parts of polyvinyl chloride, 28-34 parts of dibutyl phthalate, 36-44 parts of chlorinated paraffin-52, 3-5 parts of stabilizing agent, 1 part of stearic acid, 7-9 parts of flame retardant and 14-16 parts of carbon black. The preparation method comprises the following steps: adding the polyvinyl chloride into a stirrer; respectively adding half of the dibutyl phthalate, half of the chlorinated paraffin-52, half of the stabilizing agent and half of the stearic acid while stirring; adding the rest of the dibutyl phthalate, the rest of the chlorinated paraffin-52, the rest of the stabilizing agent and the rest of the stearic acid when the temperature of the materials is 50 DEG C; adding the lame retardant and the carbon black when the temperature of the materials is 75-80 DEG C; stopping stirring when the temperature of the materials is 85-90 DEG C; granulating to obtain plastic soft layer granular materials when the temperature of the materials is cooled to 50-60 DEG C; and feeding a mold and the plastic soft layer granular materials into an extruder and preparing a product.The plastic hose for the mine, provided by the invention, has the advantages of big crankshaft radius, easiness for bending, high antistatic coefficient and good flame-retardant effect, good sealing effect; and the preparation method is simple and convenient and is convenient to operate.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

Processing technology of wear-resistant and flame-retardant fabric

InactiveCN113279109AImprove wear resistanceImprove flame retardant performanceHeat resistant fibresBiochemical treatment with enzymes/microorganismsYarnPolymer science

The invention discloses a processing technology of a wear-resistant and flame-retardant fabric. The processing technology comprises the following steps of S1, dip-coating the surface of polyamide fiber with graphene for modification; S2, blending the modified polyamide fiber, mercerized wool fiber and flame-retardant viscose fiber as raw materials into single yarns, plying and twisting two single yarns into yarns, and weaving the yarns with warps and wefts to obtain a fabric base material; and S3, enabling the fabric base material to be subjected to water washing, first mixed solution based soaking, flame-retardant finishing solution based dipping and flame-retardant finishing, and performing water washing and drying to obtain the wear-resistant and flame-retardant fabric. The fabric obtained through processing has excellent wear resistance and flame retardance and also has good wearability, and a more suitable fabric choice is provided for protective clothing of special work types; and the graphene is firmly attached to the surface of the polyamide fiber, so that the wear resistance of the polyamide fiber is improved, meanwhile, the conductivity is improved, and the problem that the wear-resistant and flame-retardant fabric is prone to generating static electricity due to addition of the polyamide fiber is effectively solved.

Owner:安徽弋尚纺织科技有限公司

Antistatic and anti-pilling acrylic fiber modal blended yarn and preparation method thereof

InactiveCN108866716ASolve the problem of static electricityAbrasion resistant fibresYarnWinding machineYarn

The invention provides an antistatic and anti-pilling acrylic fiber modal blended yarn and a preparation method thereof. The preparation method comprises the following steps of: adding modal fiber, acrylic fiber, viscose fiber, cellulose acetate fiber and flax fiber into a drawing frame for mixing and processing to obtain a drawn sliver; drafting the drawn silver by using a roving frame to obtaina roving, spraying antistatic agent on the roving by using a spraying machine, and standing for a first preset time; adding the roving into a processing barrel filled with an anti-pilling agent for soaking a second preset time, taking out the roving, standing for a third preset time at a first preset temperature, and pre-drying at a second preset temperature for a fourth preset time; winding the roving in a winding machine to form cylindrical roving, and carrying out winding, twisting and warping to obtain the blended yarn. The blended yarn has good antistatic and anti-pilling properties, andthe product quality is improved.

Owner:FUJIAN YONGTAI COUNTY JINTAI TEXTILE

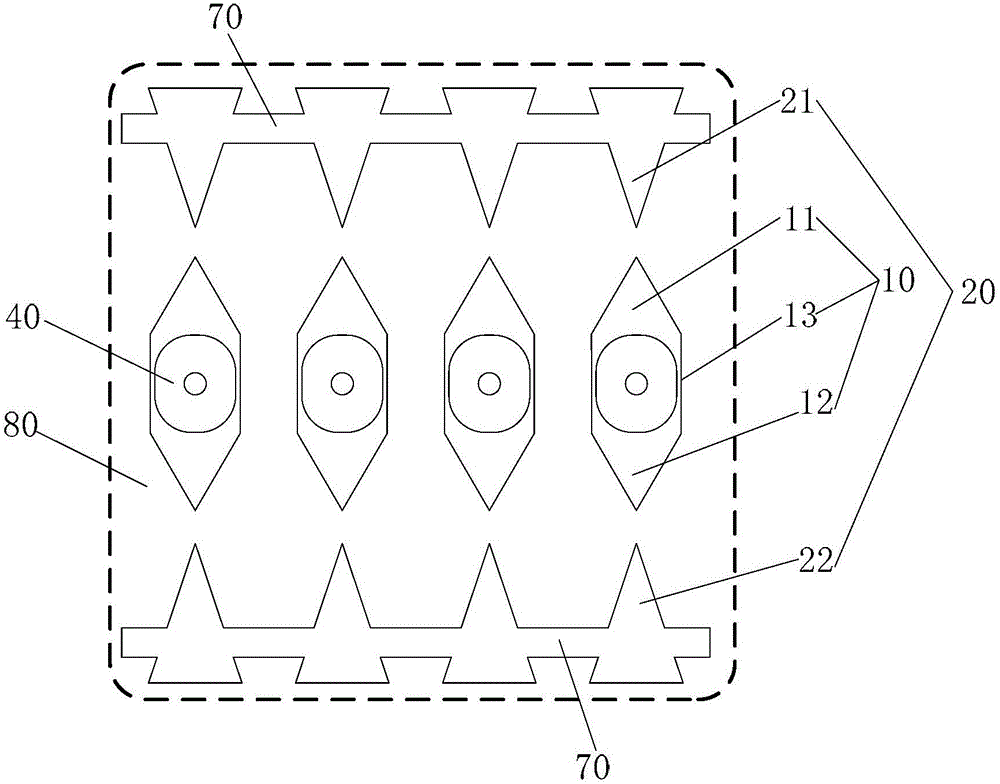

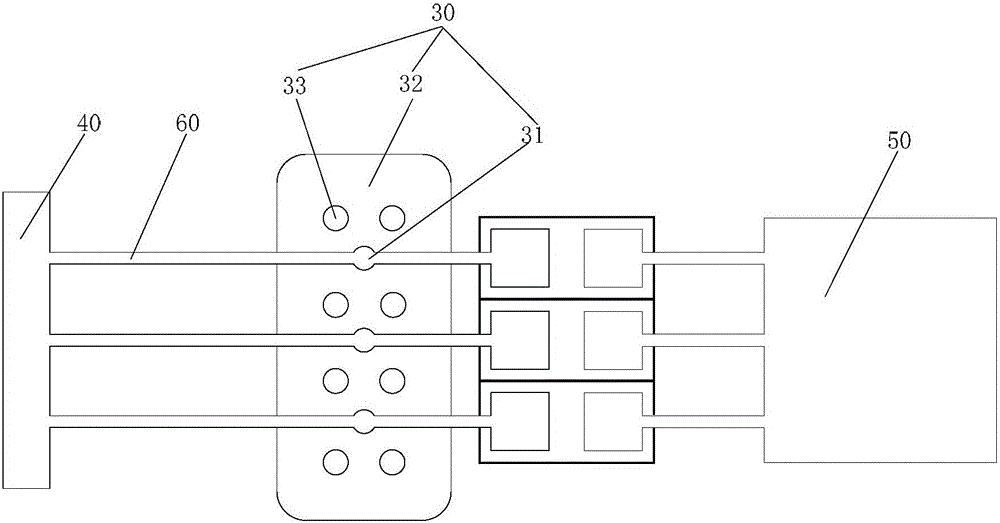

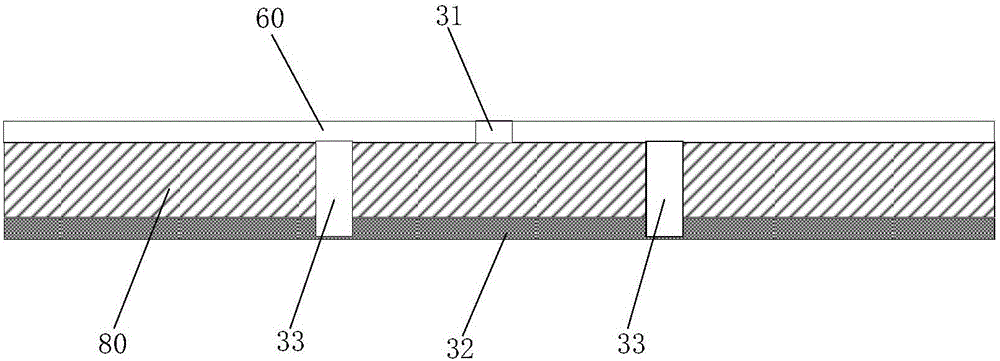

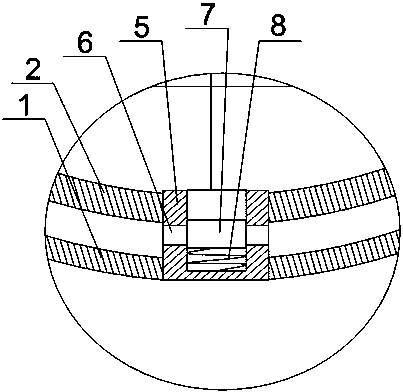

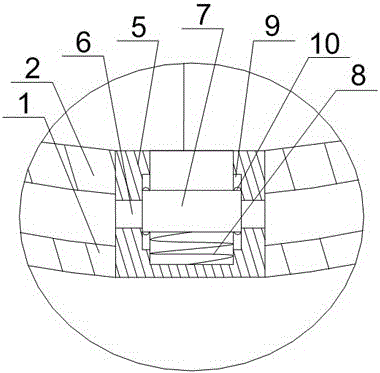

Antistatic structure, controller and air conditioner

PendingCN106016639ASolve the problem of static electricityFix damageMechanical apparatusPrinted circuit groundingEngineeringGrounding line

The invention provides an antistatic structure, a controller and an air conditioner. The antistatic structure comprises a first discharge part which is connected with a bonding pad, and a second discharge part which is arranged opposite to the first discharge part and connected with a ground line. According to the antistatic structure applying the technical scheme, due to the fact that the first discharge part and the second discharge part are arranged, the first discharge part is connected with the bonding pad and the second discharge part is arranged opposite to the first discharge part and connected with the ground line, static electricity on the bonding pad is conducted to the ground line through the first discharge part and the second discharge part and is effectively eliminated, and the problem that a PCB of an air conditioner controller in the prior art is damaged because static electricity is likely to be generated is solved.

Owner:GREE ELECTRIC APPLIANCES INC

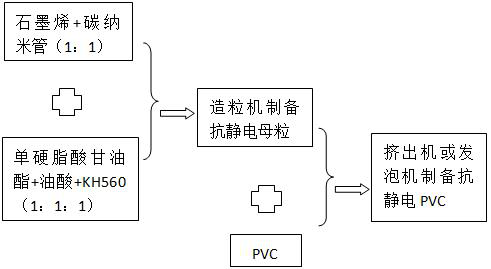

Long-acting antistatic foamed polyvinyl chloride

PendingCN112266548AImprove interface compatibilitySolve the problem of static electricityActive agentSurface-active agents

The invention relates to long-acting antistatic foamed polyvinyl chloride. The designed long-acting antistatic foamed polyvinyl chloride adopts reduced graphene oxide and carbon nanotubes as antistatic agents. In the preparation process of the antistatic foamed polyvinyl chloride, the reduced graphene oxide and the carbon nanotubes are prepared to form an antistatic master batch; in order to improve the dispersity of the reduced graphene oxide and the carbon nanotubes in the polyvinyl chloride, oleic acid, glyceryl monostearate and KH-560 (3-glycidyl ether oxypropyl trimethoxy silane) are usedas surfactants, and the oleic acid, the glyceryl monostearate and the KH-560 are not removed any more in a foaming process; a ratio of the reduced graphene oxide to the carbon nanotubes can be changed within a certain range, but the specific surface area of a mixture of the reduced graphene oxide and the carbon nanotubes is greater than 80 m<2> / g; and the ratio of the reduced graphene oxide and the carbon nanotubes to polyvinyl chloride is in a range of 1: 50 to 1: 400, optimally in a range of 1: 100 to 1: 300.

Owner:JINING GOLD POWER

Production method of polyester film

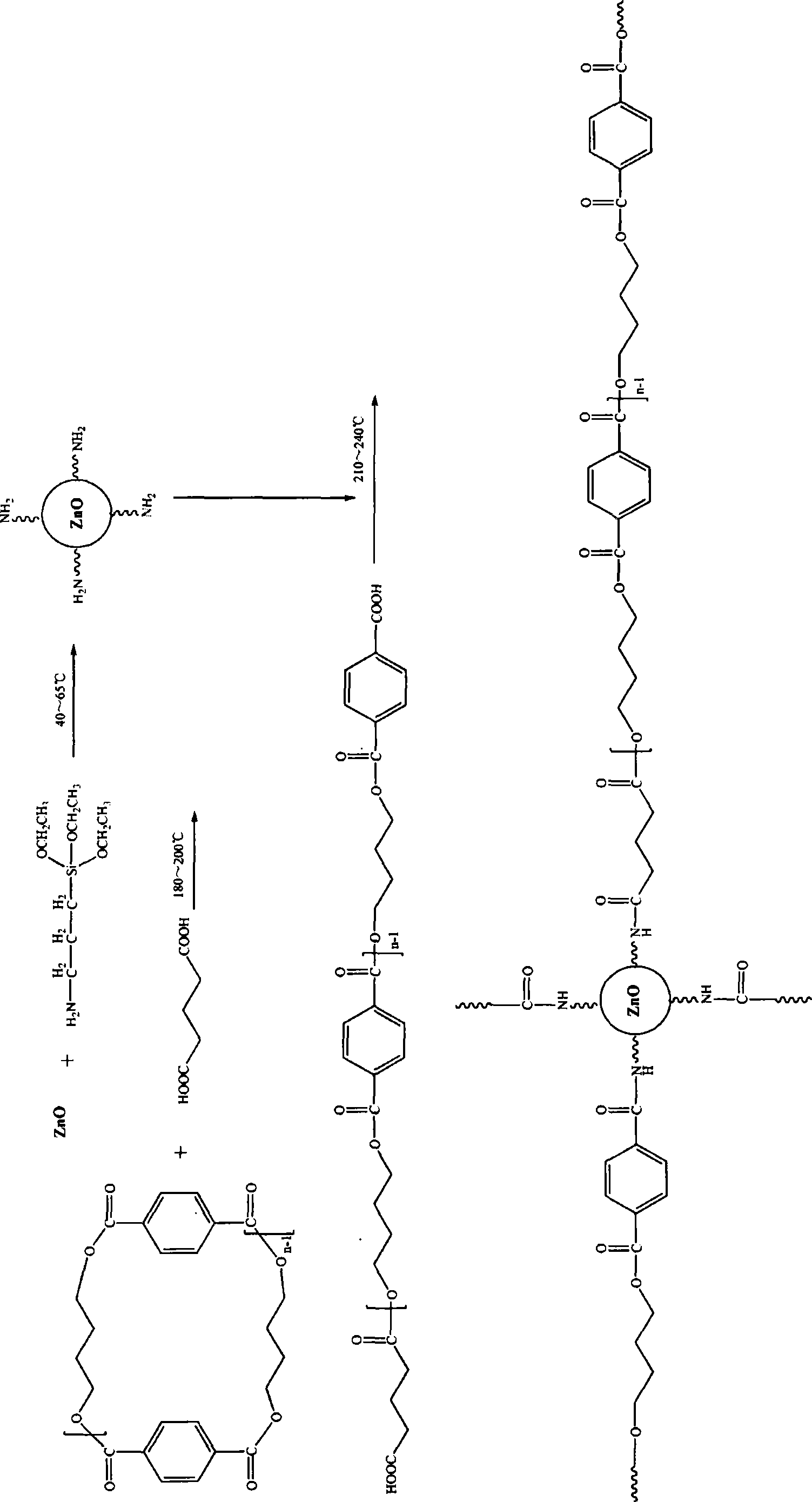

The invention relates to a production method of a polyester film. The production method comprises the following steps of (1) respectively feeding an antistatic super-bright polyester slice at an upper surface layer, an antistatic super-bright polyester slice at a lower surface layer and a super-bright polyester slice at an intermediate core layer into a three-layer co-extrusion bi-directional stretching device; (2) extruding and melting modified super-bright polyester slices at the upper surface layer and the lower surface layer and the super-bright polyester slice at the intermediate core layer at the temperature of 260 to 280 DEG C to obtain a melt, cooling the melt and casting the cooled melt to generate PET pieces at the temperature of less than 30 DEG C; (3) preheating the cast PET pieces, longitudinally stretching at the temperature of 80 to 100 DEG C, cooling, and setting the cooled PET pieces at the temperature of less than 35 DEG C; (4) then preheating the PET pieces, and transversely stretching at the temperature of 86 to 110 DEG C, setting and crystallizing the set PET pieces at the temperature of 150 to 200 DEG C; and (5) finally removing waste edges of the PET pieces, performing corona treating on the PET pieces, detecting the thickness of each PET piece, and coiling the PET pieces to form the antistatic polyester film with the thickness of 23 to 75 micrometers. Nano zinc oxide is chemically grafted into a PBT (polybutylece terephthalate) material, so that the antistatic effect of a product can be improved.

Owner:福建百宏高新材料实业有限公司

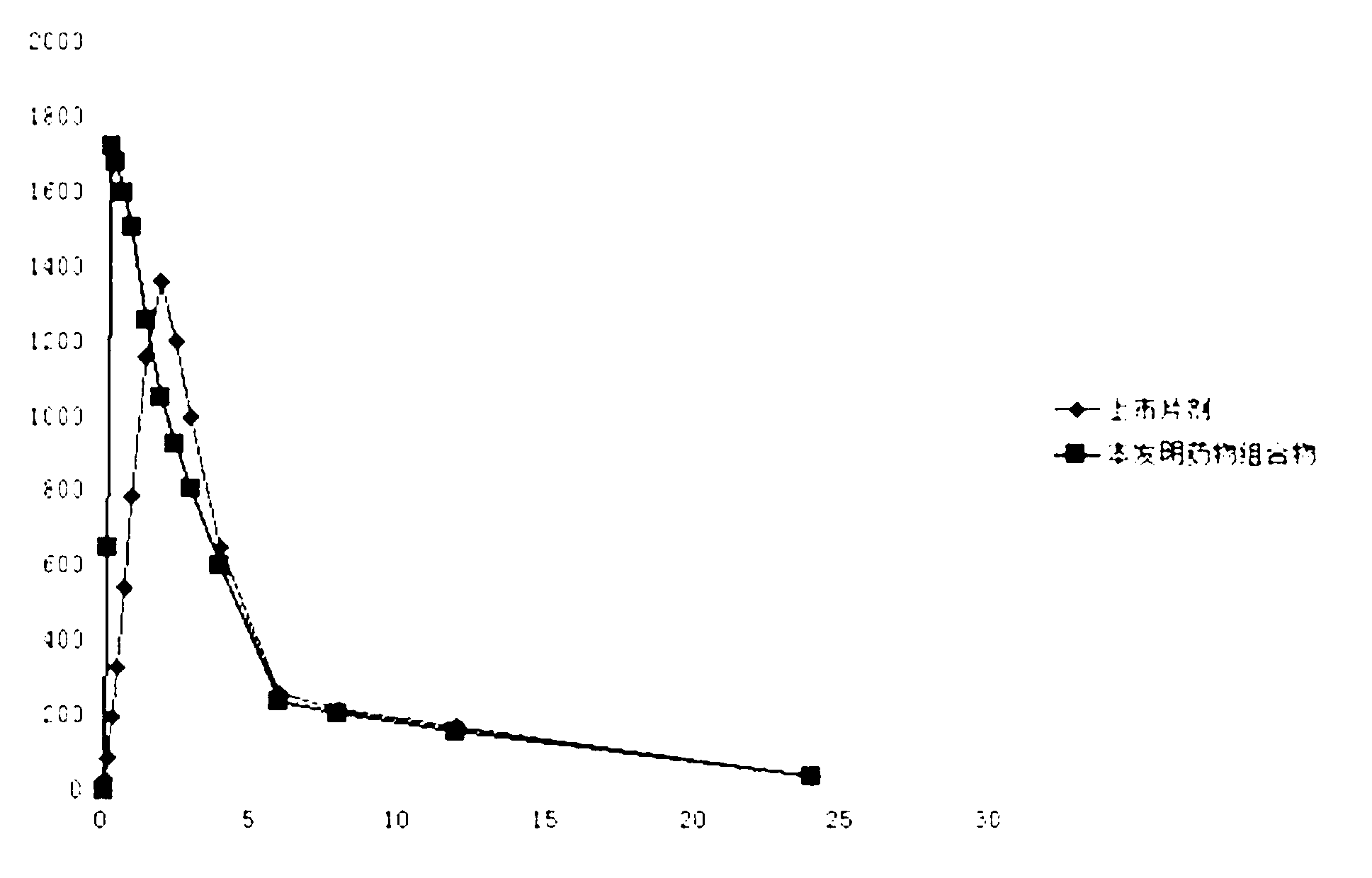

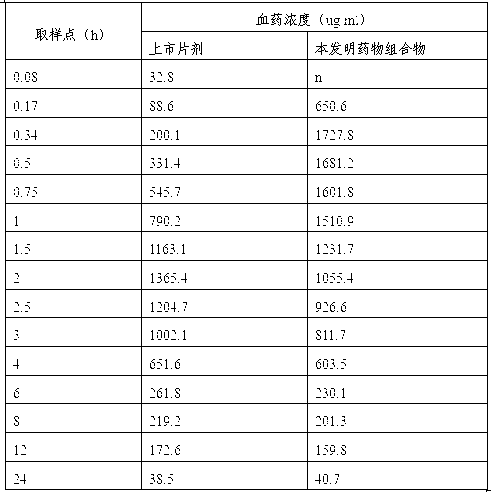

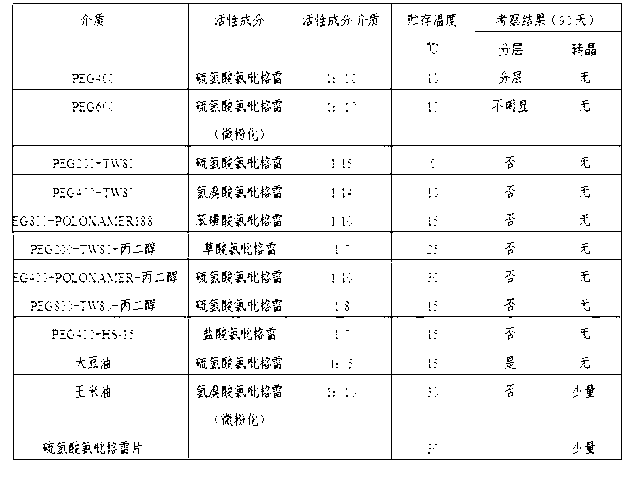

Medicinal composition of pharmaceutically-acceptable salt containing clopidogrel and preparation method thereof

InactiveCN102697752AImprove bioavailabilitySolve the crystal formOrganic active ingredientsCapsule deliveryHard CapsuleEthyl Chloride

The invention discloses a medicinal composition of a pharmaceutically-acceptable salt, i.e., (+)-(s)-alpha-(2-chlorphenyl)-6,7-dihydrothieno-[3,2-c]pyridine-5(4H) and a preparation method thereof. According to the medicinal composition, the limitations of polycrystalline types and electrostatic properties of bulk pharmaceuticals on the preparation of solid oral preparations with stable product quality and high bioavailability are broken through. A medicinal composition and an appropriate medicinal medium construct a novel medicinal composition creatively, so that possible adverse effects of crystal transformation caused in the preparation process of bulk pharmaceuticals on the product quality and a clinical treatment effect are eliminated completely, and the bioavailability is enhanced remarkably. The medicinal composition is suitable for industrially preparing soft capsules or liquid hard capsules.

Owner:SHIJIAZHUANG SAIRUI MEDICAL TECH

Terylene and pure cotton blended fabric

InactiveCN107653676ASimple processImprove antistatic performanceStain/soil resistant fibresSingeingAntistatic agentManufacturing technology

The invention provides a terylene and pure cotton blended fabric. The fabric is mainly prepared by blending terylene and pure cotton threads. The fabric manufacturing technology comprises the steps ofweaving, singeing, mercerizing and after-treatment which are performed in sequence, wherein the step of mercerizing is specifically that the fabric interacts in 25% by concentration of NaOH in the environment of 20+ / -2 DEG C; the after-treatment comprises antistatic treatment and high-temperature setting treatment; an antistatic treatment agent in the antistatic treatment comprises 10-25% by massof epichlorohydrin, 20-35% by mass of xylene, 50-60% by mass of an isopropanol solvent, and 5-10% by mass of octadecylamine. According to the terylene and pure cotton blended fabric, simple technicalprocesses are performed, and moreover, the antistatic treatment agent being high in economy is independently developed, so that the fabric is outstanding in antistatic performance, and the problem that an existing terylene and cotton fabrics easily generate static electricity leading to dust attracting can be solved; the preparation method of the fabric is simple, and easy to carry out, and has good application prospect.

Owner:JIANGSU MINGYUAN TEXTILE

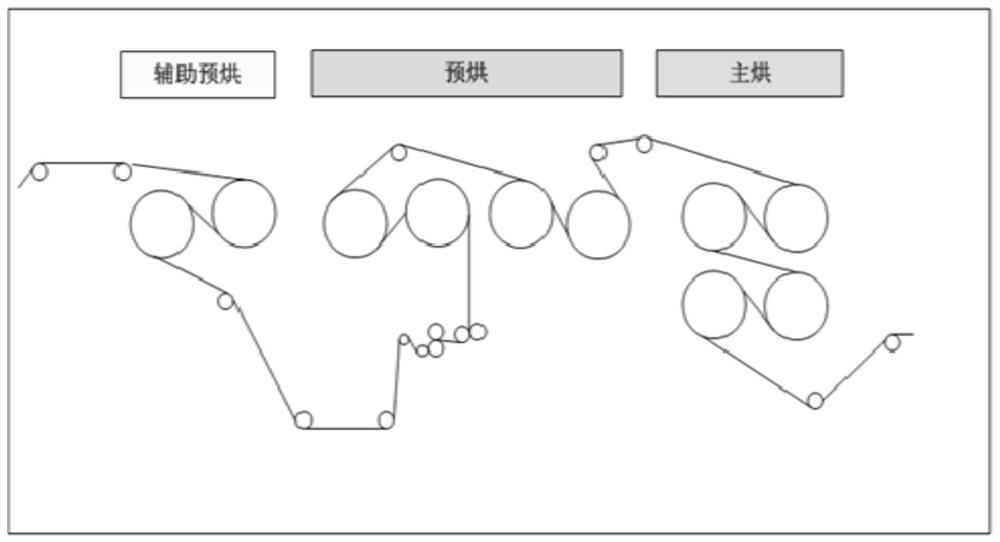

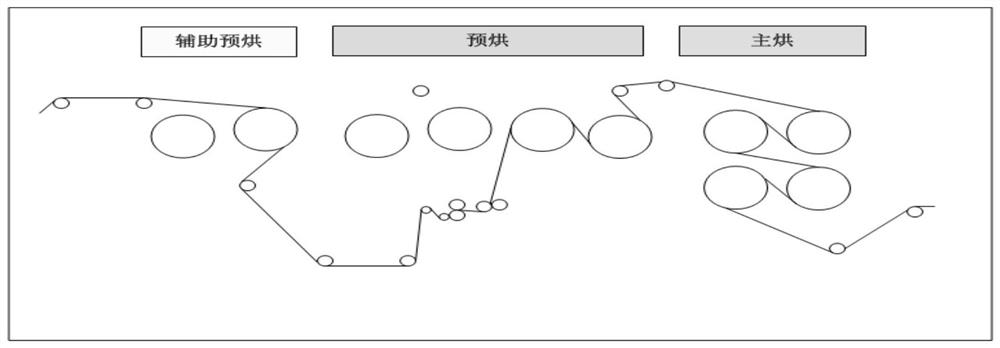

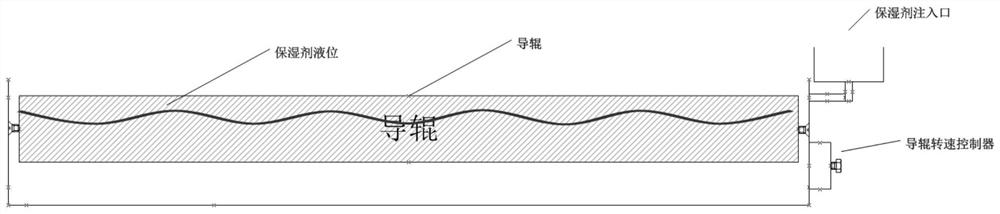

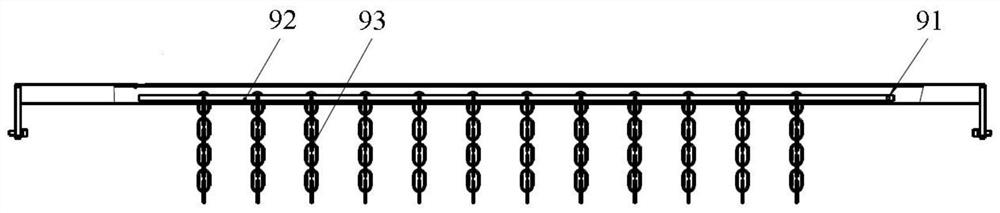

Sizing process of synthetic fiber filament in short fiber sizing machine

InactiveCN111648130ASolve the problem of static electricitySolve many broken warp beamsFibre typesLiquid/gas/vapor removalYarnTextile technology

The invention belongs to the technical field of textiles, and specifically relates to a sizing process of a synthetic fiber filament on a short fiber sizing machine. The synthetic fiber filament adopts a production process of dyeing first and then sizing; the sizing process is: sizing - drying - moisturizing treatment - antistatic treatment; wherein low-viscosity slurry is used for sizing at roomtemperature when sizing, a single-group drying process is used for drying, and then the yarn after sizing is treated with moisturizing and antistatic treatment. According to the invention, the PVA content in the sizing agent is low; the sizing is performed at room temperature, which ensures the color fastness of the fiber and is more environmentally friendly; meanwhile, by optimizing the drying process route and adding the moisturizing and antistatic treatment process, the defects that the filament fiber is easy to be static during the sizing process on the short fiber sizing machine, the yarndiverges, and the warp beam is broken are perfectly solved; and the weaving efficiency is improved, the steam is saved by more than 30%, the double sizing tank production can be realized, the vehiclespeed is stable, the variety production adaptability is better, and the sizing process of the synthetic fiber filament on the short fiber sizing machine meets the requirements of low-consumption andenvironmentally friendly sizing.

Owner:LUTAI TEXTILE

Anti-static anti-fouling plastic film for packaging

ActiveCN111019225AGood compatibilityImprove thermal stabilityLinear low-density polyethyleneLow-density polyethylene

The invention discloses an anti-static anti-fouling plastic film for packaging. The anti-static anti-fouling plastic film is prepared from the following raw materials in parts by weight: 50-80 parts of low-density polyethylene, 30-45 parts of linear low-density polyethylene, 2-5 parts of a plasticizer, 0.5-1.2 parts of an anti-static anti-fouling additive, 0.5-1 part of a heat stabilizer and 1-2 parts of a lubricant. According to the invention, the low-density polyethylene and the linear low-density polyethylene are used as main raw materials; in order to solve the problem that an existing packaging plastic film is not resistant to static electricity, the anti-static anti-fouling additive is added into a formula for the plastic film, so dust adsorption is avoided due to the excellent anti-static property of the manufactured plastic film; and a packaging bag is endowed with anti-pollution capacity since the plastic film is doped with organic silicon, the packaging effect of the packaging bag is better played, and the packaging bag is practical and convenient to use.

Owner:浙江保禄包装科技股份有限公司

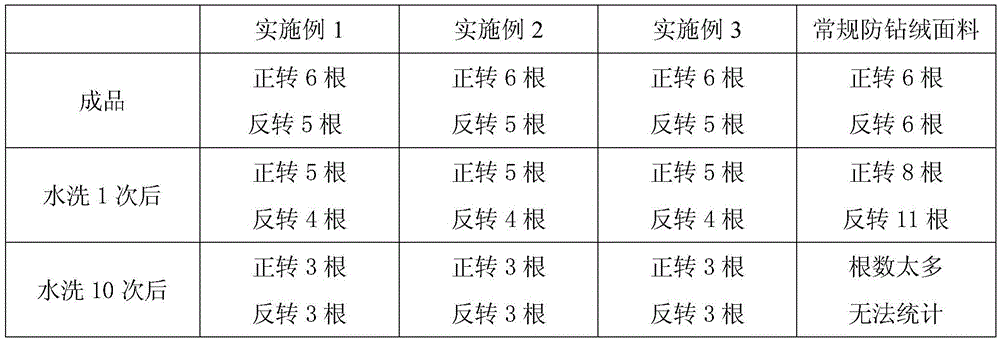

A kind of preparation method of ultra-soft washable anti-drilling velvet fabric

ActiveCN103469516BImprove tightnessGood flexibilityVegetal fibresTextile shapingYarnAgricultural engineering

The invention provides a method for preparing a supersoft and washable anti-drilling fleece fabric, which comprises the steps of raw material selection, gray cloth weaving, pretreatment, singeing treatment and whitening treatment. In the dyeing and finishing process, the present invention adopts the process of prior treatment and then singeing. Compared with the conventional process of singeing first and then pretreatment, it reduces the trouble of pretreatment and desizing caused by the short fibers remaining on the cloth surface after singeing. Full question, can significantly improve fabric softness and finish. In addition, in the pre-shrinking process, the molecular chains of polyester fibers or polyamide fibers are rearranged through overfeeding and high-temperature steaming. With overfeeding and setting, the yarn can shrink to the greatest extent during the finishing process, and the buckling wave height Significantly increased, the tightness of the fabric is increased, so that the anti-drilling effect can be achieved without adding windproof finishing agents or coatings, and without calendering.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Dye formula for indigo blue printing fabric

The invention discloses a dye formula for an indigo blue printing fabric, and relates to the technical field of dyes. Dye comprises the following components of polygonum tinctorium lour, baphicacanthus cusia bremek, acrylic resin, an enzyme preparation, a color fixing agent, a dispersant, an antibacterial agent, an antistatic agent and water, wherein the dye comprises the components of, in parts by weight, 30-50 parts of the polygonum tinctorium lour, 20-30 parts of the baphicacanthus cusia bremek, 3-7 parts of the acrylic resin, 4-6 parts of the enzyme preparation, 2-6 parts of the antibacterial agent, 3-5 parts of the antistatic agent, 1-3 parts of the color fixing agent, 1-3 parts of the dispersing agent and 60-80 parts of the water. According to the formula, plant raw materials serve as main raw materials, safety and non-toxicity are achieved, natural and environment-protecting effects are achieved, and the cost is low; and by adding the acrylic resin, the color fixing agent, the dispersing agent, the antibacterial agent and the antistatic agent, the printed indigo blue printing fabric is uniform in coloring, pure in color, not prone to fade, has the antibacterial and antistatic effects, and is wide in application range.

Owner:湖南蓝印文化发展股份有限公司

Silicone protective cover with good thermal conductivity

InactiveCN108467588AImproved heat resistance and thermal conductivityImprove the conductive effectCopperSilicone oil

The invention belongs to the technical field of electronic product accessories, and particularly relates to a silicone protective cover with good thermal conductivity. The silicone protective cover isprepared from silicone rubber, vinyl silicone oil, hydroxyl silicone oil, catalyst, polydimethylsiloxane, zinc stearate, alumina powder, copper powder and coupling agent. The silicone rubber is selected from one of dimethyl silicone rubber, fluorosilicone rubber and methyl phenyl vinyl silicone rubber; the catalyst is a platinum complex catalyst; alumina is modified by an ethanol solution of a silane coupling agent. The silicone protective cover has better impact resistance, excellent protection performance, comfortable touch feeling and improved thermal conductivity.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

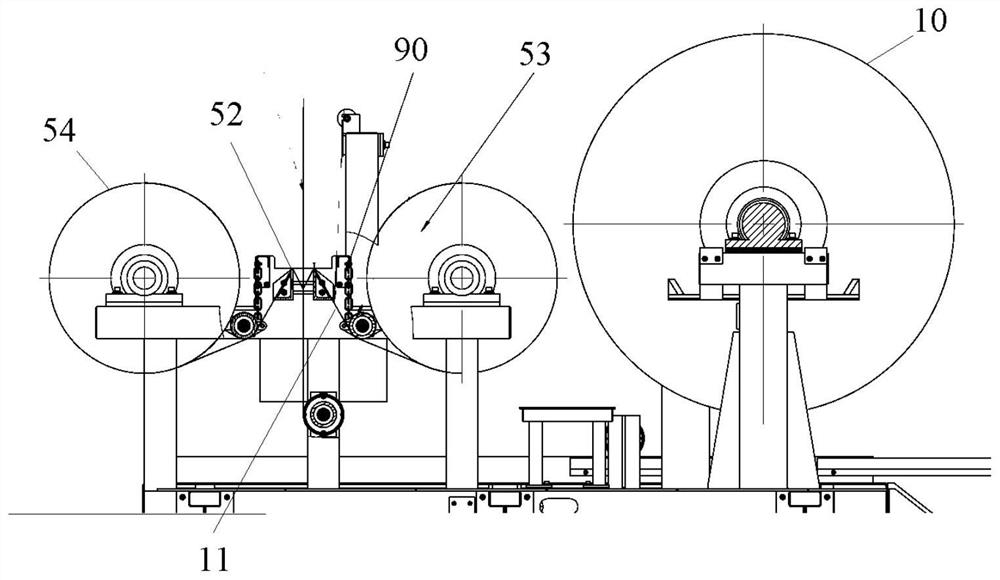

Static electricity removing mechanism and cord fabric unwinding device

PendingCN112678581ASo as not to damageReduce wearLayered productsLaminationElectrical conductorEngineering

The invention provides a static electricity removing mechanism and a cord fabric unwinding device. The static electricity removing mechanism is used for removing static electricity on pasted films separated from a cord fabric, and the static electricity removing mechanism comprises two conductor assemblies and a grounding assembly, wherein the two conductor assemblies are respectively arranged at two sides of a separation mechanism, so as to be in conductive contact with two pasted films separated from the cord fabric separately; each conductor assembly is of a flexible structure, one end of each conductor assembly is arranged above one pasted film, and the other end of each conductor assembly is propped against the pasted film under the action of gravity; and the grounding assembly is connected with the two conductor assemblies, so as to introduce current on the conductor assemblies into the ground. According to the static electricity removing mechanism provided by the invention, the problem that in the prior art, the static electricity is left on the pasted films in the pasted film removing process of the sizing material cord fabric is solved.

Owner:MESNAC +1

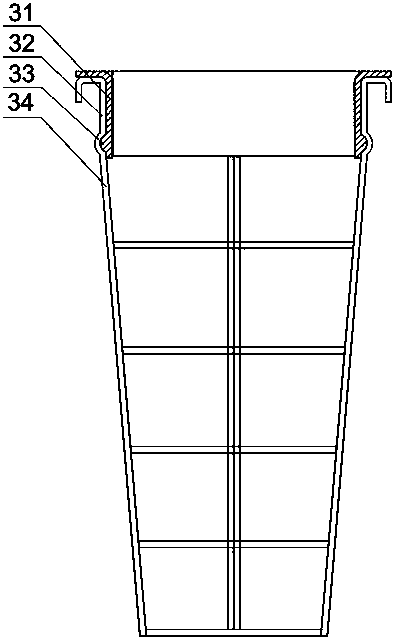

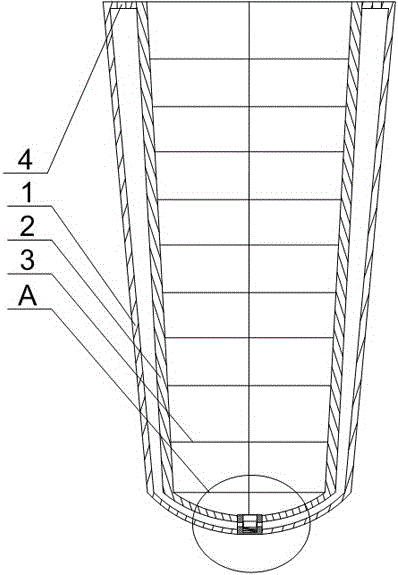

Filter bag for flue gas treatment of coke furnace charging car

The invention discloses a filter bag for flue gas treatment of a coke oven coal-charging vehicle, which includes an outer bag body, an inner bag body and a skeleton. There is an air outlet connected to the secondary air channel, and a cylinder is installed between the bottom of the inner bag and the bottom of the outer bag. The open end of the cylinder communicates with the inside of the inner bag, and openings There is an air hole communicating with the secondary air flow channel, the slider is slidably arranged in the barrel, and a spring is installed at the bottom of the slider. The stress generated by the second expansion of the outer bag is much greater than the stress generated by the first expansion, that is, the dust attached to the outer bag is completely ejected. Compared with the single-layer dust bag, the dust removal efficiency is greatly improved. , and the expansion of the outer bag is driven by the expansion of the inner bag, which reduces the direct erosion of the outer bag by the air flow, thereby reducing the loss of the outer bag.

Owner:付建军

Dry dust removal filter bag for coke oven

InactiveCN105771457AReduce direct washoutReduce lossDispersed particle filtrationCoke ovenEngineering

The invention discloses a dry dust removal filter bag for a coke oven. The dry dust removal filter bag, which comprises an outer bag body, an inner bag body and a skeleton, wherein a secondary air flow path is annularly arranged between the outer bag body and the inner bag body, and an air outlet connected with the secondary air flow path is formed in the upper end of the outer bag body; a barrel is arranged between the bottom of the inner bag body and the bottom of the outer bag body, and the open end of the barrel is communicated with the inside of the inner bag body; pores communicated with the secondary air flow path are formed in the two side walls of the barrel, and a sliding block is arranged in the barrel in a sliding way; a spring is arranged at the bottom of the sliding block. The acting stress generated by secondary expansion of the outer bag body is much larger than the acting stress generated by primary expansion thereof, i.e., dust attached to the outer bag body is completely ejected; compared with a dust removal cloth bag with a single-layer structure, the dust removal efficiency is greatly improved, and the expansion of the outer bag body is driven by the expansion of the inner bag body, so that the direct sweeping of air flow on the outer bag body is reduced, and thus the loss of the outer bag body is reduced.

Owner:SICHUAN ANCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

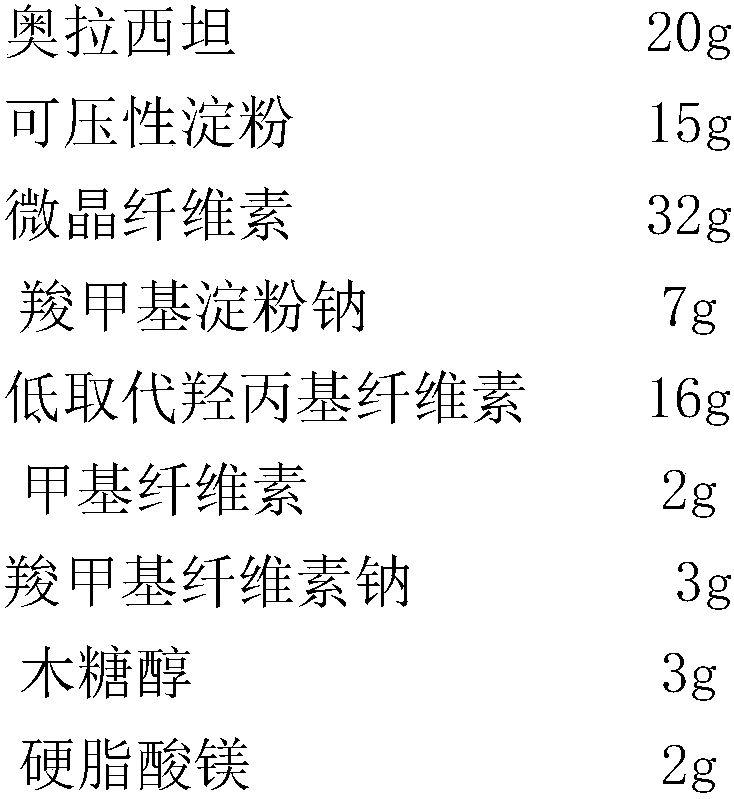

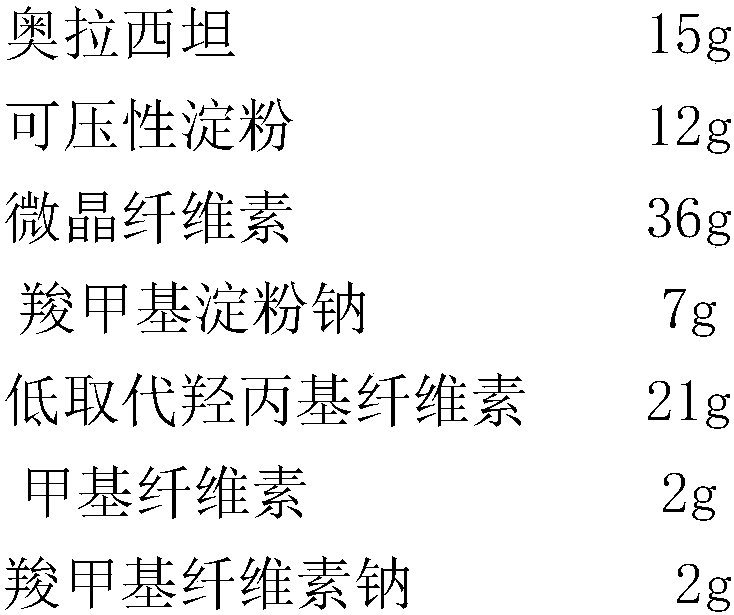

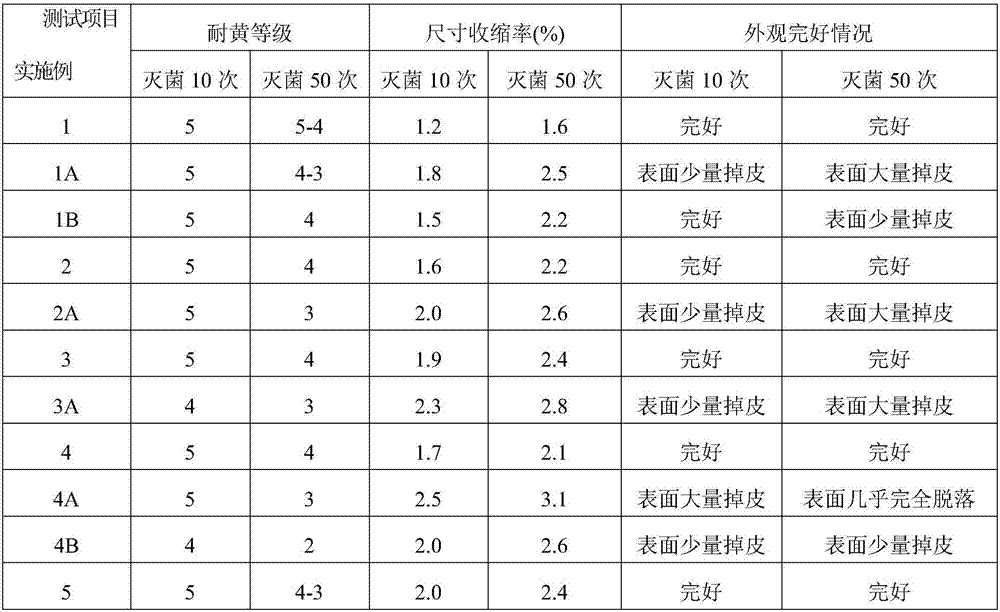

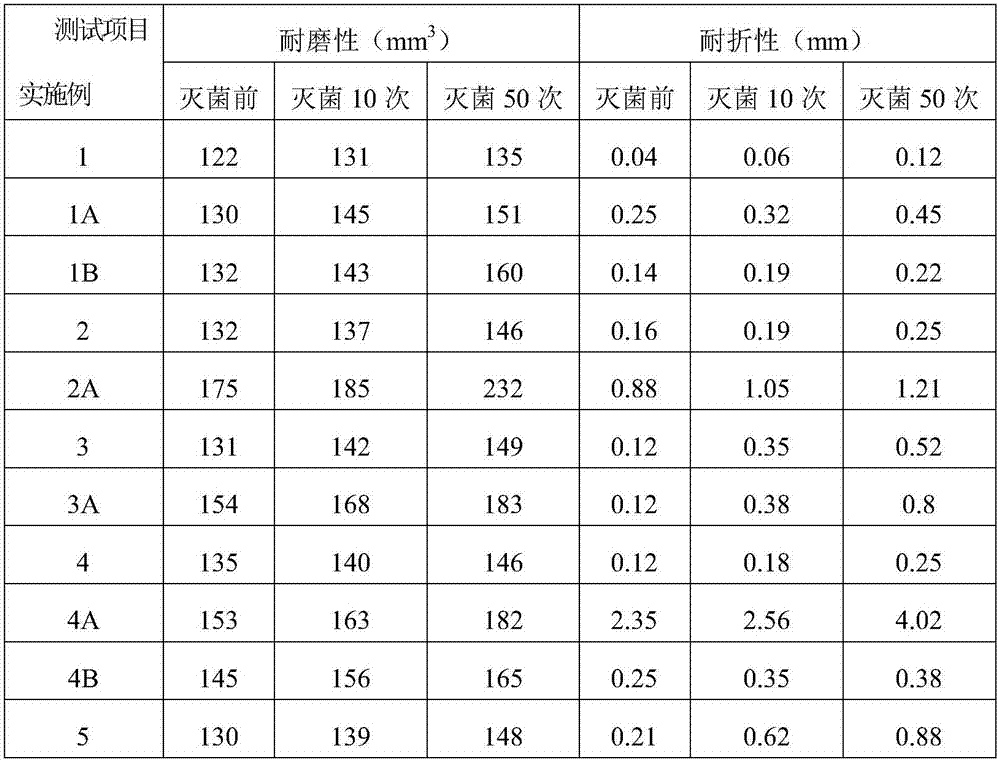

Preparation method of oral oxiracetam preparation suitable for old people to take

InactiveCN108567575AEliminate the disadvantage of poor tasteShort disintegration timeOrganic active ingredientsNervous disorderOld patientsOrally disintegrating tablet

The invention provides a preparation method of an oral oxiracetam preparation suitable for old people to take. Medicines and auxiliary materials are reasonably compatible and are granulated and tableted through a fluidized bed to prepare the preparation, the preparation can quickly disintegrate in the oral cavity under the waterless condition (or under the condition that only a small amount of water exists) and enter the digestive tract with swallowing actions, is consistent with a common tablet in the body about behaviors and is very suitable for old patients difficulty in swallowing. The prepared orally disintegrating oxiracetam tablet is reasonable in composition, prepared fluidized bed granules are thin, small and uniform, the angle of repose ranges from 30 degrees to 35 degrees, the liquidity is good, tablets do not break or is not softened or sticky, astringent and odd flavor phenomena do not occur in the tableting process, and the hardness of the prepared disintegrating oxiracetam tablet is 35-50 N. The disintegrating time limit is 30-40 S, the taste is better, no gravel feeling exists, the dissolution rate accumulated within 20 minutes exceeds 80%, and the oral oxiracetam preparation does not need special production conditions, has the advantages of being low in production cost and convenient to carry, store, transport and take, improves the taking compliance of patients and has a higher practical value.

Owner:CHONGQING RUNZE PHARM CO LTD

A kind of high temperature steam sterilization medical pvc sole material and production method thereof

ActiveCN105670176BSolve the problem of static electricityGood flexibilitySolesFiberPolyvinyl chloride

The invention discloses a medical PVC (polyvinyl chloride)) sole material suitable for high-temperature steam sterilization, mainly comprising PVC resin, a plasticizer, an auxiliary plasticizer, a thermal stabilizer, an auxiliary thermal stabilizer, a lubricant, split-film fiber, a compatibilizer, an antibacterial agent and the like. The problems that an existing medical PVC sole material suffers sole yellowing, decreased mechanical performances and softening deformation after being subjected to high-temperature steam sterilization are solved, and the medical PVC sole material is better in high-temperature stability, folding resistance, tear resistance, wear resistance and size stability; in addition, by adding an antistatic agent, the problem that high-temperature steam sterilized PVC shoe material is prone to static generation is solved; the invention also provides a production method of the medical PVC sole material suitable for high-temperature steam sterilization, comprising: preparation of a composite thermal stabilizer, mixing of resin and an aid, extrusion granulating, and injection molding; the production method is simple and easy to industrialize.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Post-finishing process for superfine fiber pile fabrics

ActiveCN111118880AReduce surface repulsionAdjust hydrophilicity and lipophilicitySucessive textile treatmentsFibre treatmentMechanical engineeringMicrofiber

The present invention discloses a post-finishing process for superfine fiber pile fabrics, and relates to the technical field of fabric rear finishing. The process comprises the following process steps: (1) performing pretreatment on superfine fiber pile fabrics; (2) performing finishing liquid preparation; (3) performing post-finishing; and (4) performing washing. According to the post-finishingprocess for superfine fiber pile fabrics provided by the present invention, excellent antistatic performance is given to the microfiber terry sports fabric through the post-finishing of the antistaticagent, so that the problem that static electricity easily occurs to the microfiber terry sports fabric is solved; and the addition of the dispersant is to promote the uniform dispersion of the antistatic agent in the finishing liquid, so that uniform adhesion of the antistatic agent on the fiber can be ensured.

Owner:LANGXI YUANHUA TEXTILE

Plastic hose for mine and preparation method

InactiveCN102297295BImprove antistatic performanceImprove flame retardant performanceFlexible pipesDi n butyl phthalateMining engineering

The invention relates to a plastic hose for a mine and a preparation method. The plastic hose comprises 90-110 parts of polyvinyl chloride, 28-34 parts of dibutyl phthalate, 36-44 parts of chlorinated paraffin-52, 3-5 parts of stabilizing agent, 1 part of stearic acid, 7-9 parts of flame retardant and 14-16 parts of carbon black. The preparation method comprises the following steps: adding the polyvinyl chloride into a stirrer; respectively adding half of the dibutyl phthalate, half of the chlorinated paraffin-52, half of the stabilizing agent and half of the stearic acid while stirring; adding the rest of the dibutyl phthalate, the rest of the chlorinated paraffin-52, the rest of the stabilizing agent and the rest of the stearic acid when the temperature of the materials is 50 DEG C; adding the lame retardant and the carbon black when the temperature of the materials is 75-80 DEG C; stopping stirring when the temperature of the materials is 85-90 DEG C; granulating to obtain plastic soft layer granular materials when the temperature of the materials is cooled to 50-60 DEG C; and feeding a mold and the plastic soft layer granular materials into an extruder and preparing a product.The plastic hose for the mine, provided by the invention, has the advantages of big crankshaft radius, easiness for bending, high antistatic coefficient and good flame-retardant effect, good sealing effect; and the preparation method is simple and convenient and is convenient to operate.

Owner:PINGDINGSHAN ANTAIHUA MINING SAFETY EQUIP MFG

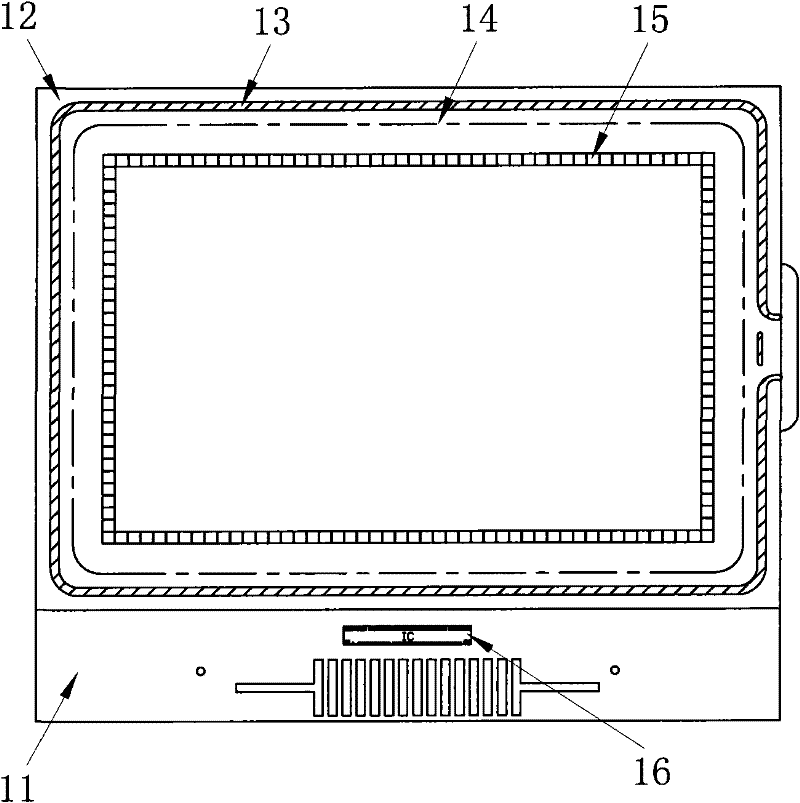

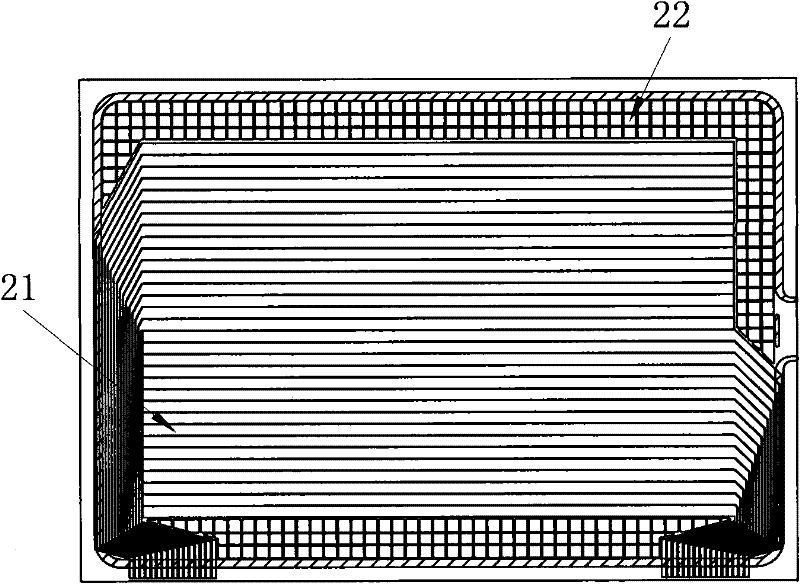

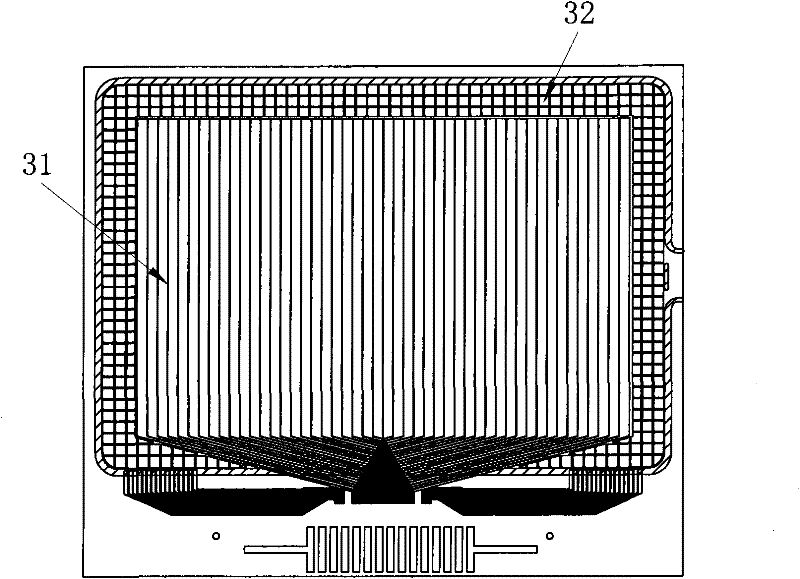

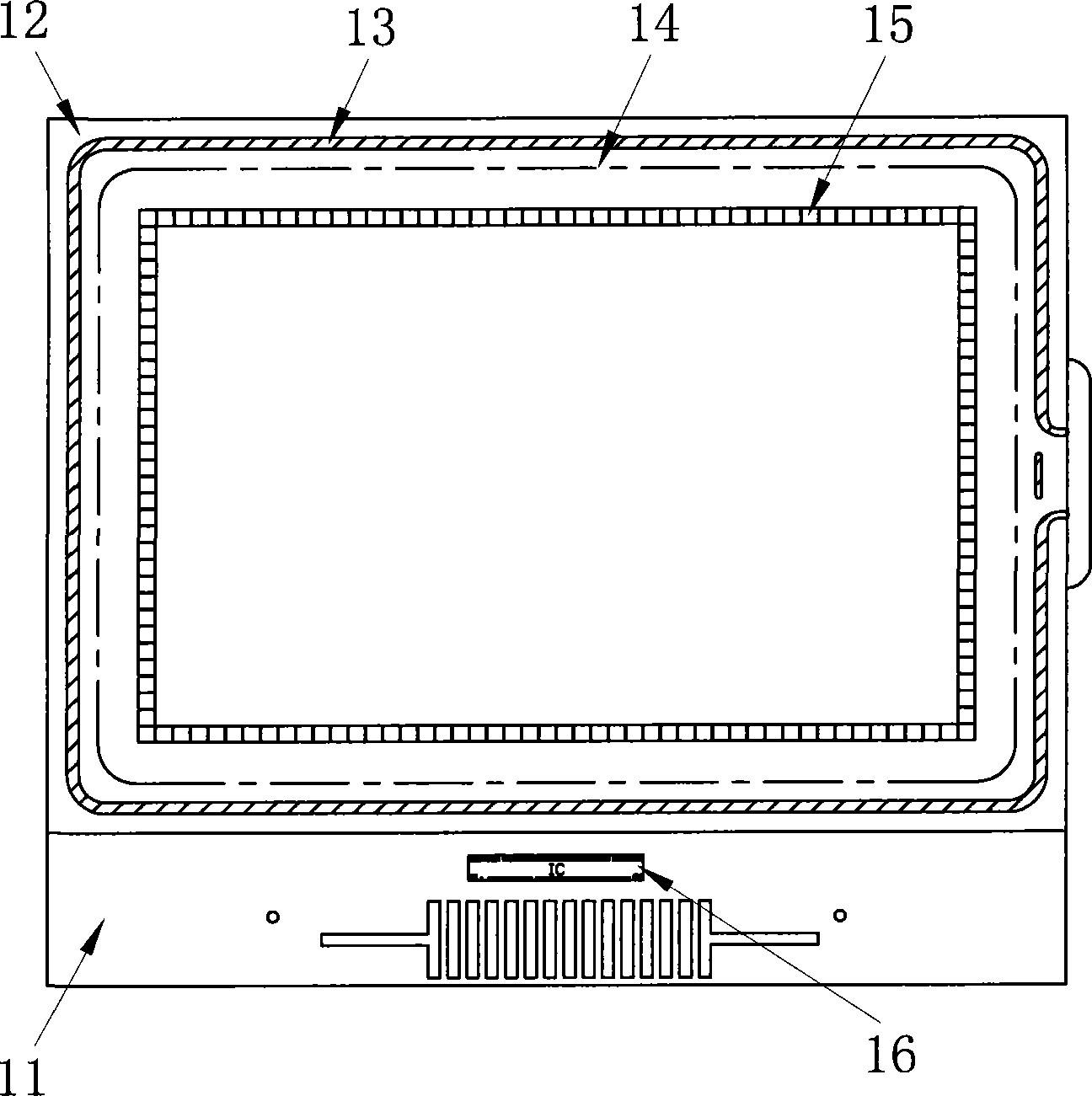

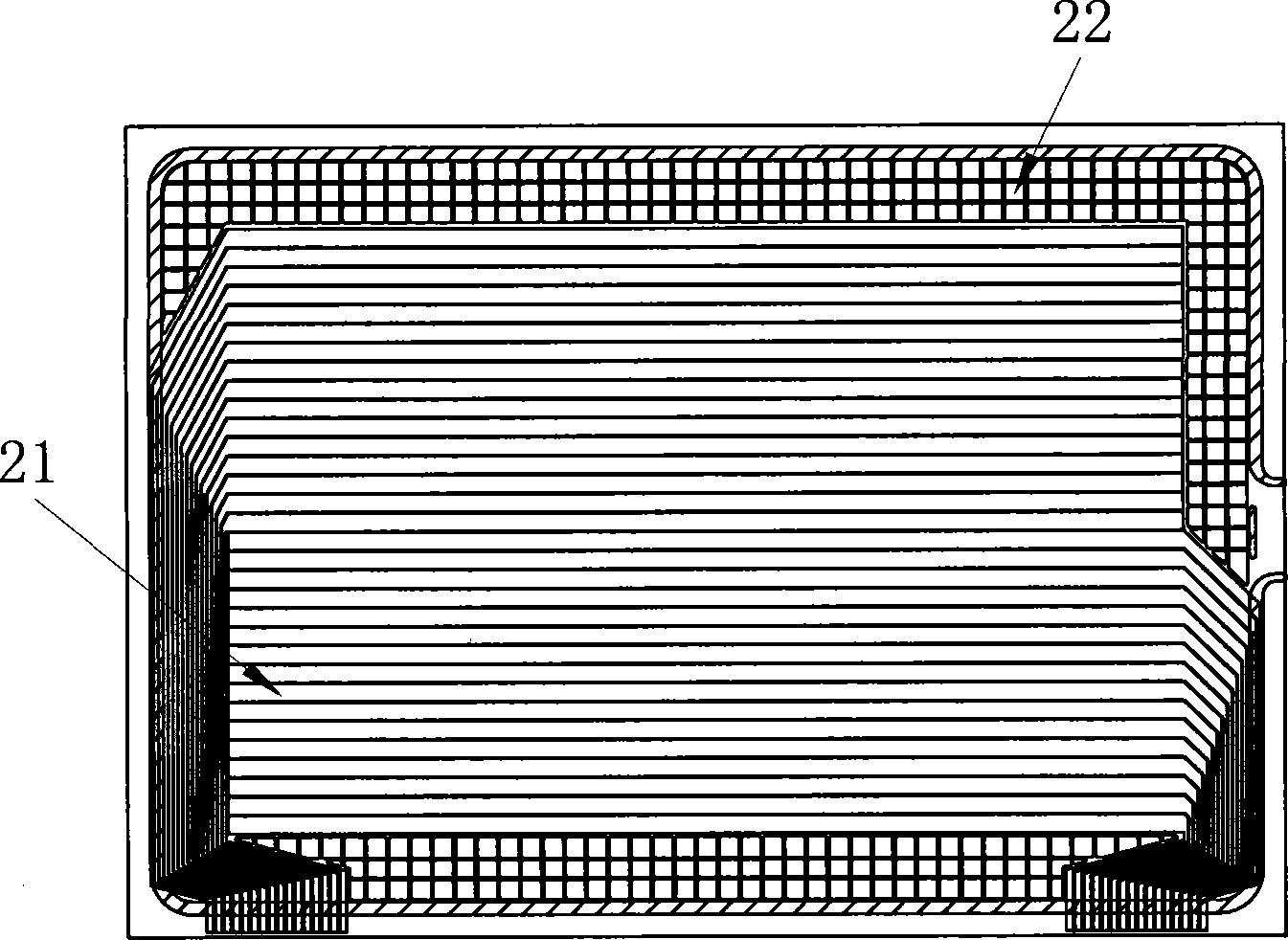

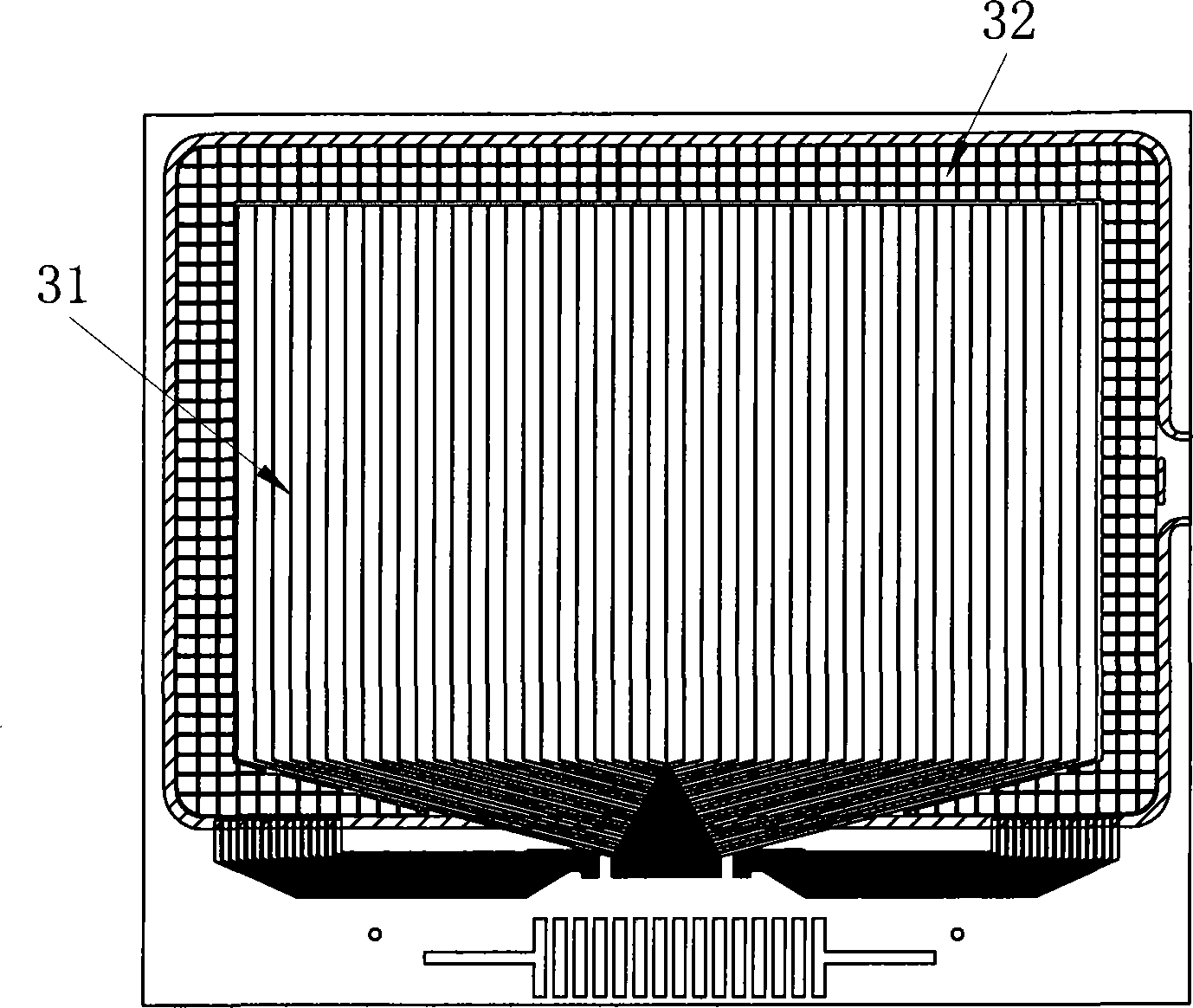

A liquid crystal display device

ActiveCN102298236ASolve the problem of static electricityNon-linear opticsElectrostatic chargesLiquid-crystal displayLine extension

The invention provides a liquid crystal display device, which comprises a first transparent glass substrate and a second transparent glass substrate which are arranged oppositely; at least one column electrode arranged in a visible area and at least one column extension electrode corresponding to the column electrode are arranged on the first transparent glass substrate, wherein the column extension electrode is connected with one end of the column electrode, on which a wire is not drawn out, and extends to frame glue outside the visible area; at least one line electrode and at least one line extension electrode corresponding to the line electrode are arranged on the second transparent glass substrate, wherein the line electrode is intersected with the column electrode in the visible area, and the line extension electrode is connected with one end of the line electrode, on which a wire is not drawn out, and extends to frame glue outside the visible area. According to the invention, the column electrode and the line electrode extend to the frame glue through the column extension electrode and the line extension electrode, and therefore the problems that a small piece filled in the area is easy to generate static electricity and a large piece filled in the area can display a pattern contour line in the prior art are solved.

Owner:深圳市合力泰光电有限公司

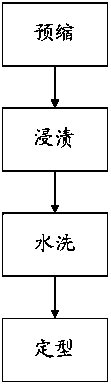

Anti-static technology for men shirts

InactiveCN104313820ASolve the problem of static electricitySolve problems such as easy dust collectionSucessive textile treatmentsTextile shapingFiberEngineering

The invention discloses an anti-static technology for men shirts, the shell fabric of the men shirts comprises 1-3% of conductive fibre, the technology comprises the steps as follows: a, preshrinking, preshrinking the men shirts in the high temperature preshrinking machine, the temperature is 40-60 degrees centigrade; b, dipping, locating the men shirts in the dipping groove filled with the dipping liquid and dipping, the dipping time is 20-30min; c, water washing, putting the men shirts in the bag and water washing in the washing machine, the water temperature is 25-35 degrees centigrade; d, sizing, locating the washed shell fabric in the sizing machine and sizing the shell fabric at the speed of 30-40m / min for preparing the anti-static men shirts. The surface resistance of the material can be obviously reduced by the conductive fibre added in the shell fabric and the anti-static technology during the rear treating process, the static can be effectively controlled and eliminated.

Owner:TAICANG HONGYING PRINTING

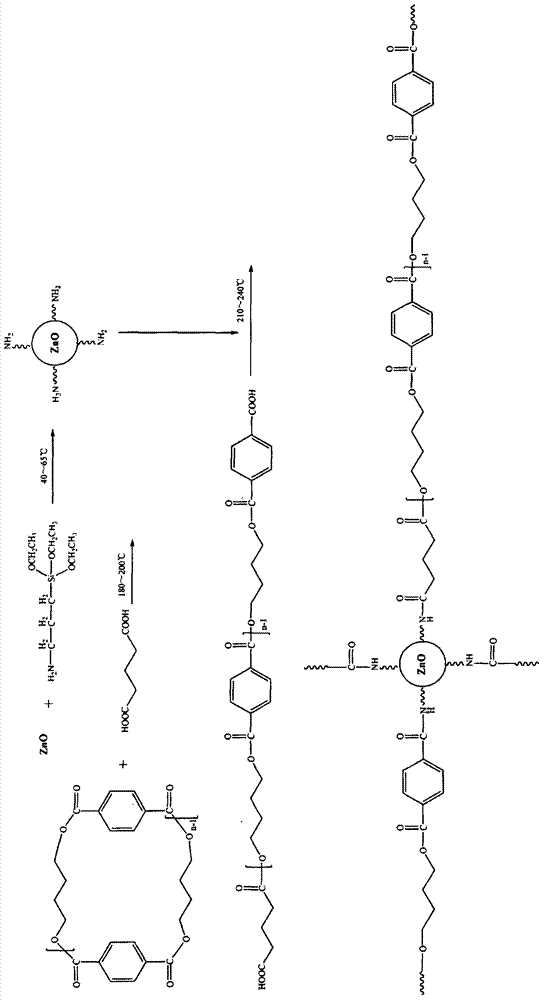

Production method of polyester film

The invention relates to a production method of a polyester film. The production method comprises the following steps of (1) respectively feeding an antistatic super-bright polyester slice at an upper surface layer, an antistatic super-bright polyester slice at a lower surface layer and a super-bright polyester slice at an intermediate core layer into a three-layer co-extrusion bi-directional stretching device; (2) extruding and melting modified super-bright polyester slices at the upper surface layer and the lower surface layer and the super-bright polyester slice at the intermediate core layer at the temperature of 260 to 280 DEG C to obtain a melt, cooling the melt and casting the cooled melt to generate PET pieces at the temperature of less than 30 DEG C; (3) preheating the cast PET pieces, longitudinally stretching at the temperature of 80 to 100 DEG C, cooling, and setting the cooled PET pieces at the temperature of less than 35 DEG C; (4) then preheating the PET pieces, and transversely stretching at the temperature of 86 to 110 DEG C, setting and crystallizing the set PET pieces at the temperature of 150 to 200 DEG C; and (5) finally removing waste edges of the PET pieces, performing corona treating on the PET pieces, detecting the thickness of each PET piece, and coiling the PET pieces to form the antistatic polyester film with the thickness of 23 to 75 micrometers. Nano zinc oxide is chemically grafted into a PBT (polybutylece terephthalate) material, so that the antistatic effect of a product can be improved.

Owner:福建百宏高新材料实业有限公司

Liquid crystal display device

ActiveCN102298236BSolve the problem of static electricityNon-linear opticsElectrostatic chargesLiquid-crystal displayLine extension

The invention provides a liquid crystal display device, which comprises a first transparent glass substrate and a second transparent glass substrate which are arranged oppositely; at least one column electrode arranged in a visible area and at least one column extension electrode corresponding to the column electrode are arranged on the first transparent glass substrate, wherein the column extension electrode is connected with one end of the column electrode, on which a wire is not drawn out, and extends to frame glue outside the visible area; at least one line electrode and at least one line extension electrode corresponding to the line electrode are arranged on the second transparent glass substrate, wherein the line electrode is intersected with the column electrode in the visible area, and the line extension electrode is connected with one end of the line electrode, on which a wire is not drawn out, and extends to frame glue outside the visible area. According to the invention, the column electrode and the line electrode extend to the frame glue through the column extension electrode and the line extension electrode, and therefore the problems that a small piece filled in the area is easy to generate static electricity and a large piece filled in the area can display a pattern contour line in the prior art are solved.

Owner:深圳市合力泰光电有限公司

Production technology of antistatic lining silk

ActiveCN102864662BSolve the problem of static electricityGood flexibilityLiquid/gas/vapor removalDry-cleaning apparatus for textilesYarnFiber

Owner:嘉善罗星创业投资有限公司

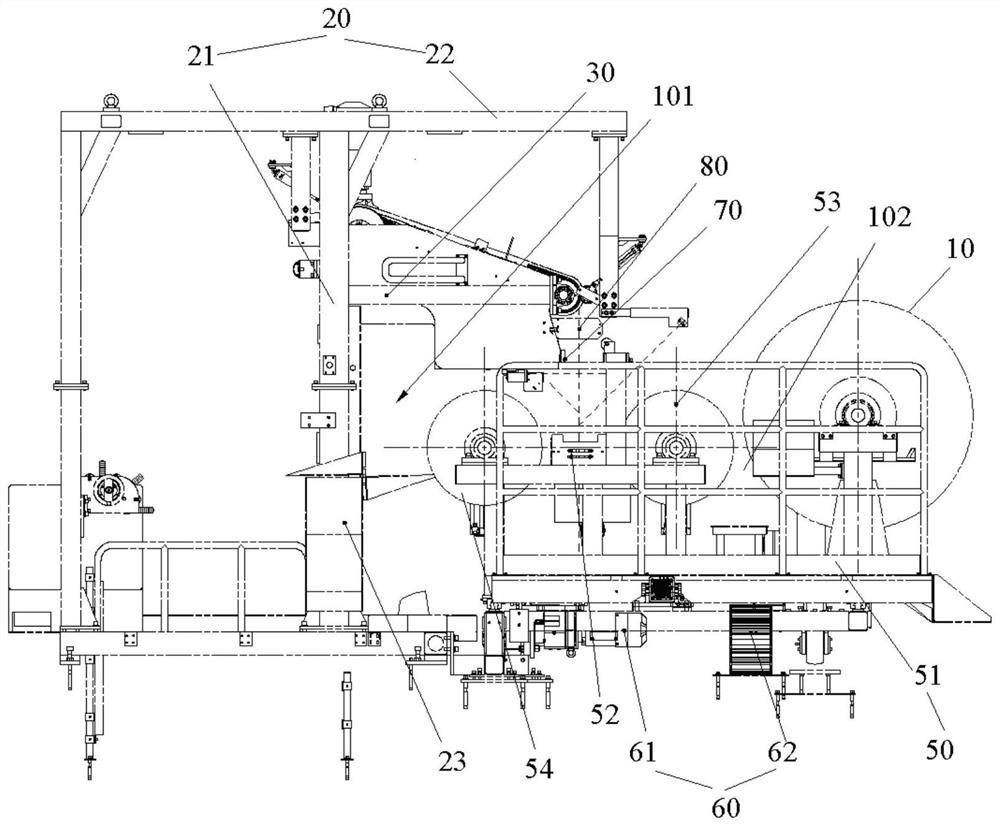

Spinning method for woolen spinning of rabbit wool and rabbit hair

The invention discloses a spinning method for woolen spinning of rabbit wool and rabbit hair, wherein the rabbit wool and rabbit hair are taken as raw materials, a 100% rabbit wool-rabbit hair product is produced on a woolen-spinning high-count carding machine. The method comprises steps such as static electricity removal by water boiling, hair mixing, hair carding and yarn spinning. According to the invention, a hyper-normal small speed ratio on the woolen-spinning high-count carding machine only brings little fiber damage, and static electricity is removed through water boiling of rabbit hair and rabbit wool with application of an anti-static agent, so the problem of large static electricity in spinning is solved. The 15 count-16 count-38 count rabbit wool and rabbit hair yarns produced by the spinning method have unique characteristics of rabbit wool and rabbit hair including softness, smoothness, moist absorption, pilling avoidance, hair slip avoidance and comfortable use according to comprehensive detection results.

Owner:董晓军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com