Spinning method for woolen spinning of rabbit wool and rabbit hair

A rabbit hair and roving technology, applied in spinning machine, liquid/gas/vapor fiber/sliver/roving treatment, deburring device, etc., can solve the problem that rabbit hair resources are not properly utilized and rabbit hair products are not obtained. Successful, unable to solve problems such as the unique characteristics of rabbit hair, achieve ideal results, small fiber damage, and solve the effect of small elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

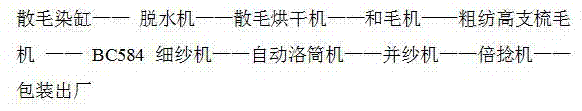

[0018] Such as figure 1 Process flow shown:

[0019] 1. Boiling to eliminate static electricity: put rabbit hair and velvet into the loose hair dyeing vat as required, add water to heat up, turn on the water pump, add 6% antistatic agent, keep the water temperature at 60~65°C and boil for 30 minutes, take out the vat for dehydration, and put it into drying Machine drying, the temperature of the drying room is kept at 60~70°C, and the moisture regain is 16~20% after drying.

[0020] 2. Blending wool: choose FX902 and 4% crude oil, FX-AS201 antistatic agent 2% and more than three times the water to blend, add water to the wool for the first time, and blend four times to ensure that the oil and water are even, and then regain moisture for 30~ 33%, put in a box for 30 hours and then supply to the combing machine.

[0021] 3. Carding: On the "Slubbing High-Count Carding Machine", ultra-conventional carding with a small speed ratio is adopted. Based on the domestic BC272 carding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com