Production method of polyester film

A technology of polyester film and production method, applied in the field of polyester film manufacturing, can solve the problems of inconvenient electrostatic accumulation and potential safety hazards, and achieve the effects of high glossiness, solving electrostatic problems and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

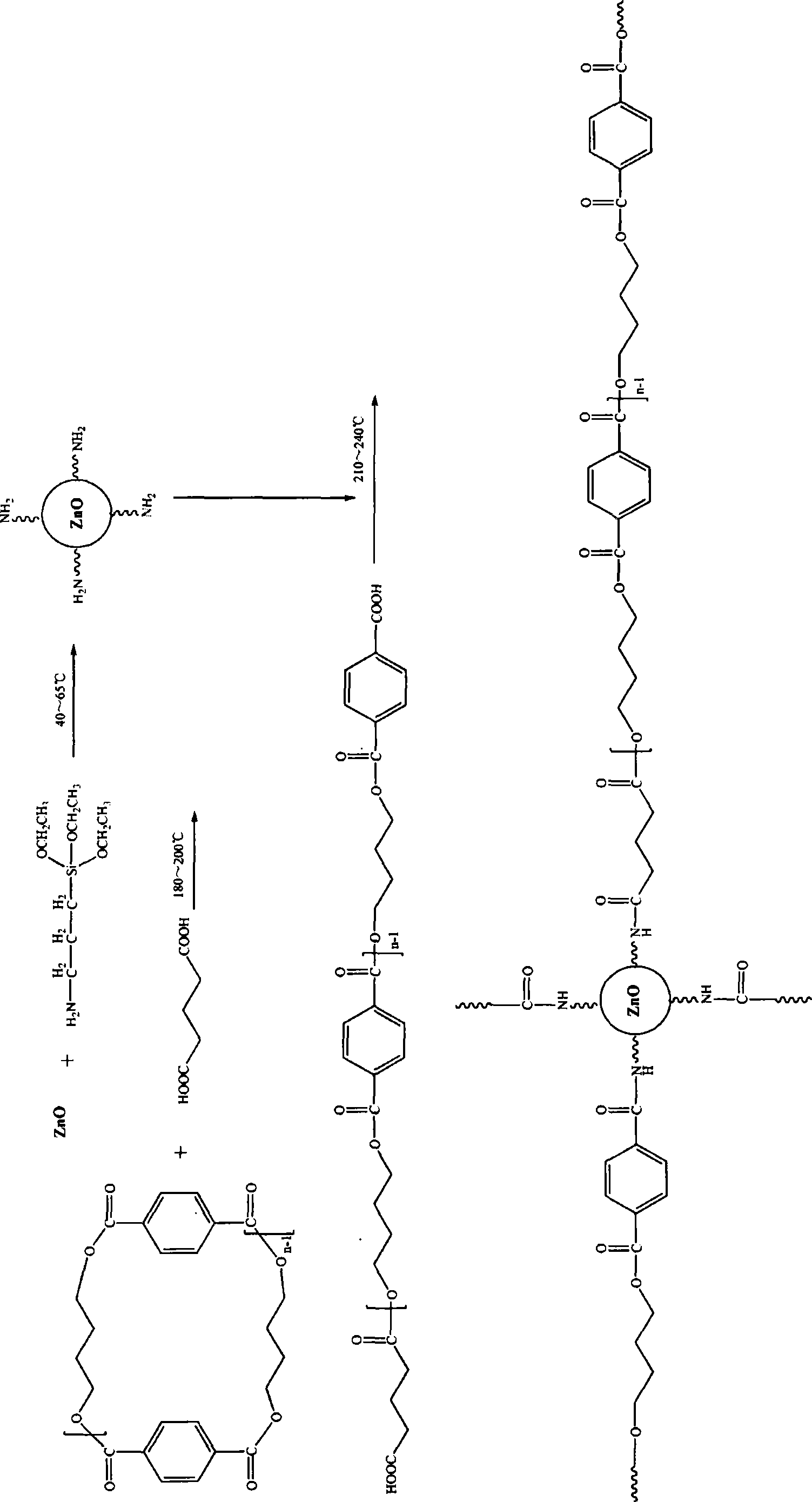

Method used

Image

Examples

Embodiment 1

[0053] A kind of production method of polyester film, its concrete steps are:

[0054] (1) The antistatic bright polyester chips of the upper surface layer, the antistatic bright polyester chips of the lower surface layer and the bright polyester chips of the middle core layer are respectively sent to the three-layer co-extrusion biaxial stretching equipment (ie Three-layer co-extrusion biaxial stretching production line);

[0055] The raw material mass percent of described antistatic bright polyester chip is:

[0056] Antistatic PBT chips 5%

[0057]PEN slices 1%

[0058] Bright polyester chips 94%

[0059] (2) Extrude and melt the antistatic bright polyester chips of the upper and lower surface layers and the bright polyester chips of the middle core layer at 260-280 ° C, and the melt is cooled below 30 ° C to form PET sheets ;

[0060] (3) The cast PET sheet is preheated at 80-100°C for longitudinal stretching and cooled at a temperature below 35°C;

[0061] (4) The P...

Embodiment 2

[0081] A kind of production method of polyester film, its concrete steps are:

[0082] (1) The antistatic bright polyester chips of the upper surface layer, the antistatic bright polyester chips of the lower surface layer and the bright polyester chips of the middle core layer are respectively sent to the three-layer co-extrusion biaxial stretching equipment (ie Three-layer co-extrusion biaxial stretching production line);

[0083] The raw material mass percent of described antistatic bright polyester chip is:

[0084] Antistatic PBT chips 8%

[0085] PEN slices 2%

[0086] Glossy Polyester Chip 90%

[0087] (2) Extrude and melt the antistatic bright polyester chips of the upper and lower surface layers and the bright polyester chips of the middle core layer at 260-280 ° C, and the melt is cooled below 30 ° C to form PET sheets ;

[0088] (3) The cast PET sheet is preheated at 80-100°C for longitudinal stretching and cooled at a temperature below 35°C;

[0089] (4) The P...

Embodiment 3

[0108] A kind of production method of polyester film, its concrete steps are:

[0109] (1) The antistatic bright polyester chips of the upper surface layer, the antistatic bright polyester chips of the lower surface layer and the bright polyester chips of the middle core layer are respectively sent to the three-layer co-extrusion biaxial stretching equipment (ie Three-layer co-extrusion biaxial stretching production line);

[0110] The raw material mass percent of described antistatic bright polyester chip is:

[0111] Antistatic PBT chips 10%

[0112] PEN slices 3%

[0113] Bright polyester chips 87%

[0114] (2) Extrude and melt the antistatic bright polyester chips of the upper and lower surface layers and the bright polyester chips of the middle core layer at 260-280 ° C, and the melt is cooled below 30 ° C to form PET sheets ;

[0115] (3) The cast PET sheet is preheated at 80-100°C for longitudinal stretching and cooled at a temperature below 35°C;

[0116] (4) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com