A kind of preparation method of ultra-soft washable anti-drilling velvet fabric

An anti-drilling and fabric technology, applied in the direction of fabric surface trimming, fiber type, textiles and papermaking, etc., can solve the problems of softness, poor comfort, poor air permeability, decreased fabric finish, etc., to improve softness and finish. , the effect of increased fabric tightness, softness and finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

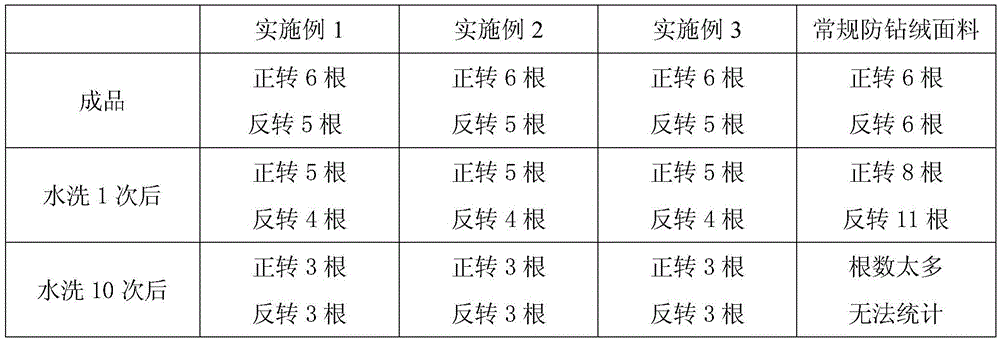

Examples

Embodiment 1

[0023] A preparation method of a super-soft washable anti-drilling fleece fabric includes the following steps: raw material selection→spinning→weaving→pre-treatment, de-boiling and bleaching→singeing→whitening→soft setting→preshrinking.

[0024] Choose the blended yarn of cotton and polyester fiber as the warp yarn, and choose the full cotton yarn as the weft yarn.

[0025] Use cationic antistatic agent TANASTATWP for antistatic treatment on polyester fiber, and use dip dyeing method. During treatment, place the fabric in a cold dye solution at room temperature, adjust the pH of the dye solution to 5.8 with acetic acid, and add 3% cation Type antistatic agent to make the bath ratio 1:5. After processing for 10 minutes, heat the dye solution to 40°C for 10 minutes, then take out the fabric and dry it at 110°C, and finally bake the fabric at 148°C for 80s.

[0026] Other main process conditions are:

[0027] Pre-treatment process: The recipe is caustic soda 3g / L, refining agent 8g / L, hy...

Embodiment 2

[0033] A preparation method of a super-soft washable anti-drilling fleece fabric includes the following steps: raw material selection→spinning→weaving→pre-treatment, de-boiling and bleaching→singeing→whitening→soft setting→preshrinking.

[0034] Choose the blended yarn of cotton and polyester fiber as the warp yarn, and choose the full cotton yarn as the weft yarn.

[0035] Use cationic antistatic agent SP to carry out antistatic treatment on polyester fiber and use dip dyeing method. During treatment, place the fabric in a cold dye solution at room temperature, adjust the pH of the dye solution to 5.5 with acetic acid, and add 2% cationic Antistatic agent, make the bath ratio 1:5, after treatment for 10min, heat the dye solution to 40℃, keep it for 10min, then take out the fabric and dry it at 100℃, and finally bake the fabric at 145℃ for 60s.

[0036] Other main process conditions are:

[0037] Pre-treatment process: Process prescription is 3.5g / L caustic soda, 9g / L refining agent, ...

Embodiment 3

[0043] A preparation method of a super-soft washable anti-drilling fleece fabric includes the following steps: raw material selection→spinning→weaving→pre-treatment, de-boiling and bleaching→singeing→whitening→soft setting→preshrinking.

[0044] Choose the blended yarn of cotton and polyester fiber as the warp yarn, and choose the full cotton yarn as the weft yarn.

[0045] Cationic antistatic agent SN is used to conduct antistatic treatment on polyester fiber, and use dip dyeing method. During treatment, place the fabric in a cold dye solution at room temperature, adjust the pH of the dye solution to 5.5 with acetic acid, and add 2% cation Type antistatic agent to make the bath ratio 1:5. After processing for 10 minutes, heat the dye solution to 40°C, keep it for 10 minutes, then take out the fabric and dry it at 100°C, and finally bake the fabric at 145°C for 60s.

[0046] Other main process conditions are:

[0047] Pre-treatment process: The process prescription is 4g / L caustic sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com