Production process of anti-static plastic net

A production process and technology of plastic mesh, applied in the field of plastic mesh, can solve problems such as fracture, low strength of plastic mesh, stretching deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

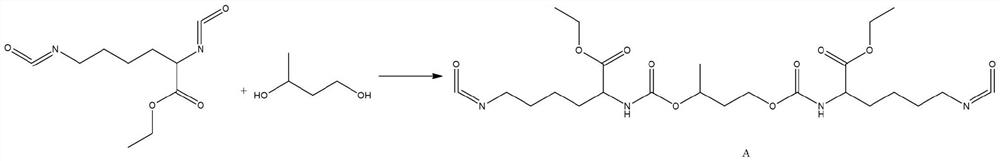

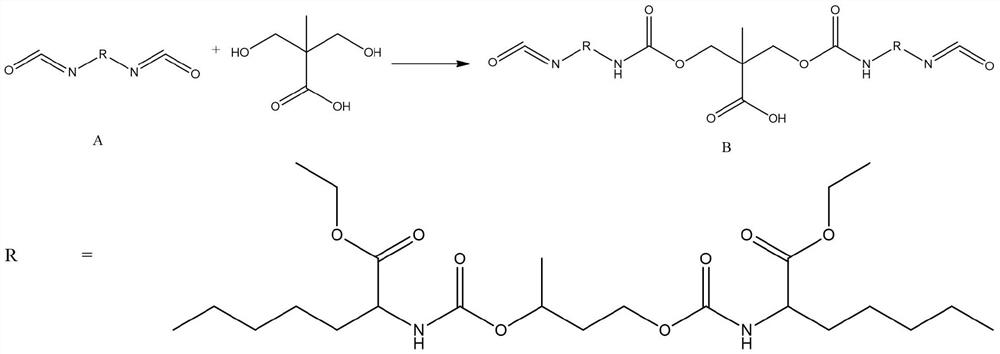

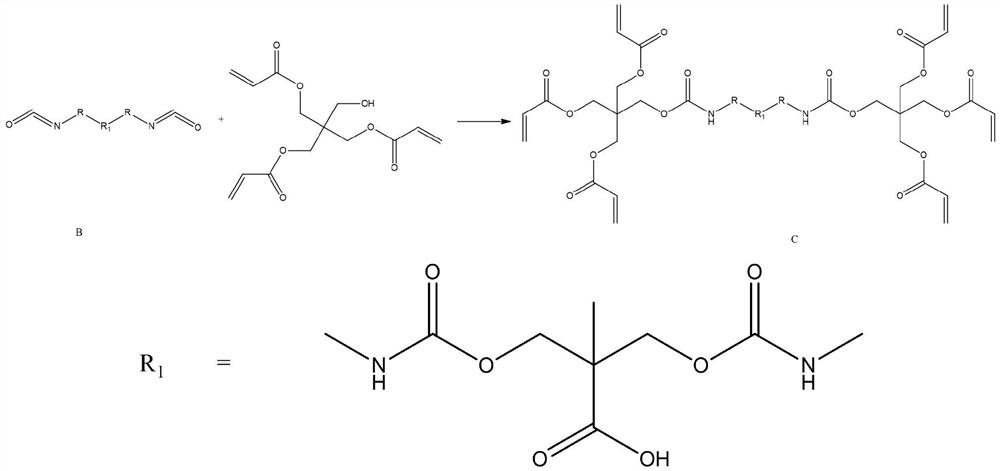

Method used

Image

Examples

Embodiment 1

[0049] The present embodiment is a kind of antistatic plastic net, comprises the steps:

[0050] S1: Mix polyvinyl chloride, plant cellulose fiber, modified plasticizer, antioxidant and dispersant to obtain a blend;

[0051] S2: Put the blended material into the extruder to be heated and melted, extruded by the screw into the rotating machine head, the molten blended material flows through the hole of the die mouth to form two strands of molten material, and the machine head rotates, and the two strands of material are intermittently merged at one point , forming a network;

[0052] S3: Cool the blended material forming the network to room temperature through cooling with cold air, and evenly coat the antistatic agent on the plastic net, move it to an ultraviolet curing machine for curing, and obtain an antistatic plastic net.

[0053] Wherein the preparation process of antistatic agent is as follows:

[0054] S21: drying 1,3-butanediol in a vacuum drying oven at 80° C. for ...

Embodiment 2

[0064] The present embodiment is a kind of antistatic plastic net, comprises the steps:

[0065] S1: Mix polyvinyl chloride, plant cellulose fiber, modified plasticizer, antioxidant and dispersant to obtain a blend;

[0066] S2: Put the blended material into the extruder to be heated and melted, extruded by the screw into the rotating machine head, the molten blended material flows through the hole of the die mouth to form two strands of molten material, and the machine head rotates, and the two strands of material are intermittently merged at one point , forming a network;

[0067] S3: Cool the blended material forming the network to room temperature through cooling with cold air, and evenly coat the antistatic agent on the plastic net, move it to an ultraviolet curing machine for curing, and obtain an antistatic plastic net.

[0068] Wherein the preparation process of antistatic agent is as follows:

[0069] S21: Dry 1,3-butanediol in a vacuum drying oven at 90° C. for 2 h...

Embodiment 3

[0079] The present embodiment is a kind of antistatic plastic net, comprises the steps:

[0080] S1: Mix polyvinyl chloride, plant cellulose fiber, modified plasticizer, antioxidant and dispersant to obtain a blend;

[0081] S2: Put the blended material into the extruder to be heated and melted, extruded by the screw into the rotating machine head, the molten blended material flows through the hole of the die mouth to form two strands of molten material, and the machine head rotates, and the two strands of material are intermittently merged at one point , forming a network;

[0082] S3: Cool the blended material forming the network to room temperature through cooling with cold air, and evenly coat the antistatic agent on the plastic net, move it to an ultraviolet curing machine for curing, and obtain an antistatic plastic net.

[0083] Wherein the preparation process of antistatic agent is as follows:

[0084] S21: Dry 1,3-butanediol in a vacuum drying oven at 90° C. for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com