Method of producing composite film specially used for novel plastic woven bag

A technology of a plastic woven bag and a manufacturing method, which is applied to the manufacturing field of a special composite film for a new type of plastic woven bag, can solve problems such as easy generation of static electricity, and achieve the effects of improving quality, excellent anti-static, and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

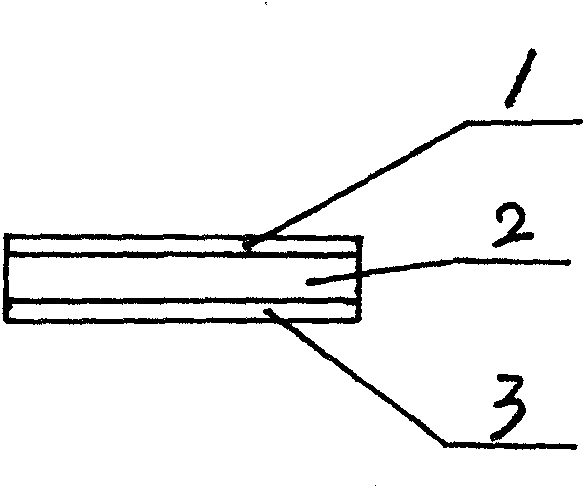

[0020] exist figure 1 Among them, surface layer 1 (1) and surface layer 2 (3) are melt extruded layers of auxiliary extruder (8) and auxiliary extruder (10) respectively, with a thickness of 1 μm. The core layer (2) is a layer melted and extruded by the main extruder (9), with a thickness of 11-16 μm, and contains an antistatic agent.

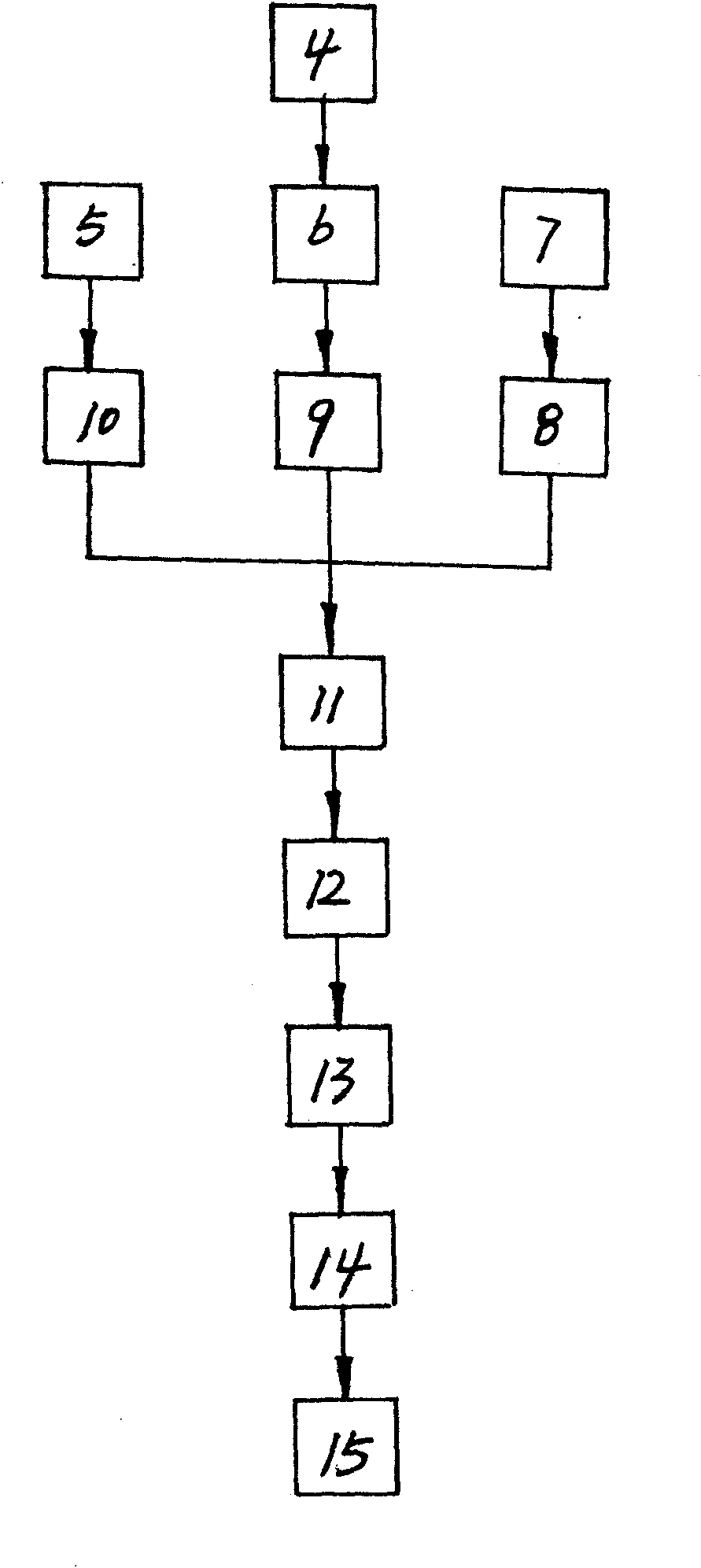

[0021] figure 2 , add biaxially stretched grade polypropylene and antistatic agent to the main hopper (4) by volumetric metering method, and add biaxially stretched grade polypropylene to the auxiliary hopper (5) and auxiliary hopper (7). The material in the main hopper (4) enters the mixer (6) to mix evenly, and is sucked to the main extruder (9) through the negative pressure device, and the material in the auxiliary hopper (5) is sucked to the auxiliary extruder through the negative pressure device (10), the material in the auxiliary hopper (7) is sucked to the auxiliary extruder (8) through the negative pressure device, the main extruder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com