Anti-static multi-color multi-film release film and production method thereof

A multi-color, anti-static technology, applied in the direction of chemical instruments and methods, layered products, rubber layered products, etc., can solve the problems of obvious dust adsorption, single color, and monotonous surface of the release film, so as to avoid static electricity impact, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

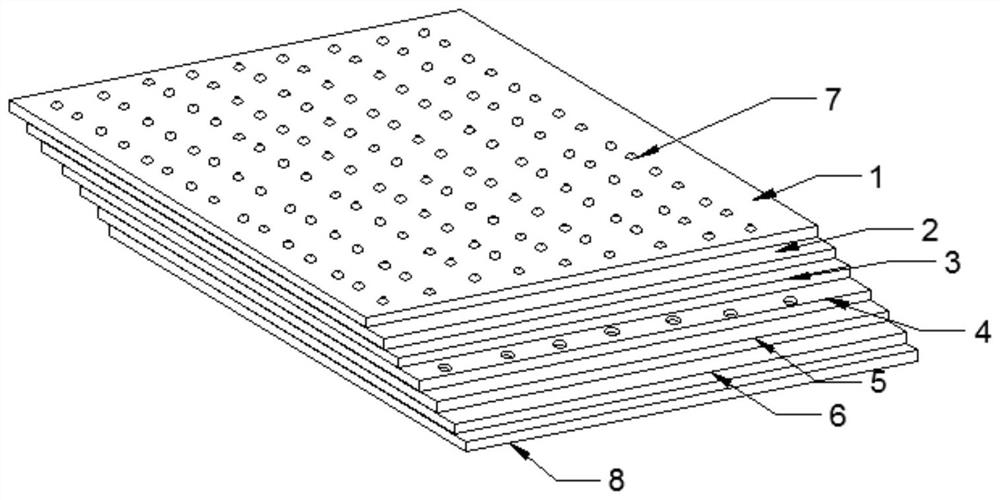

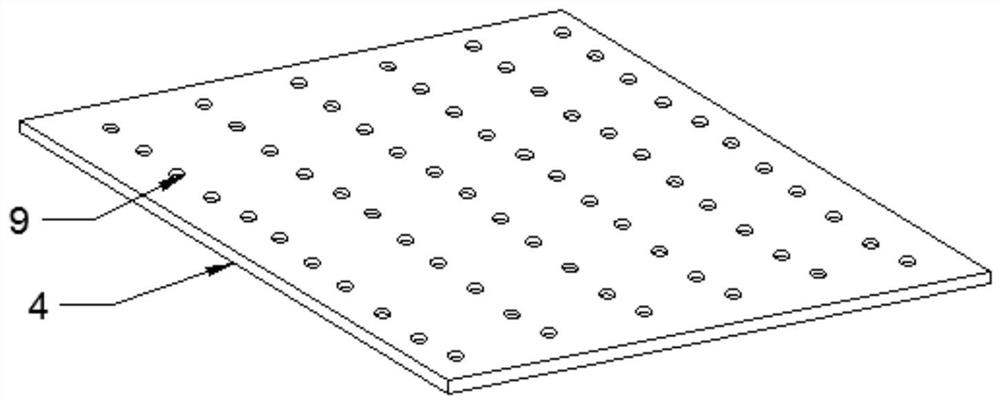

[0032] like Figure 1-Figure 2 As shown, the antistatic multi-color multi-film release film provided in this embodiment includes a silicone oil surface layer 1, and the top of the silicone oil surface layer 1 is integrally formed with hollow convex grain layers 7 at equal intervals, and the hollow convex grain layer The inside of 7 is stuffed with reflective color particles, and the bottom of the silicone oil surface layer 1 is laid with an antistatic layer 2, the antistatic layer 2 is in close contact with the bottom of the hollow convex bead layer 7, and the bottom of the antistatic layer 2 is laid with the first rubber Buffer layer 3 and the second rubber buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com