Composition containing styrene resin, and molded article

A technology for styrene resin and composition, which is applied in the field of compositions and molded bodies containing styrene resin, can solve the problems of undisclosed mixed content, undocumented mixed content, etc., and achieves excellent mixability and antistatic properties. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

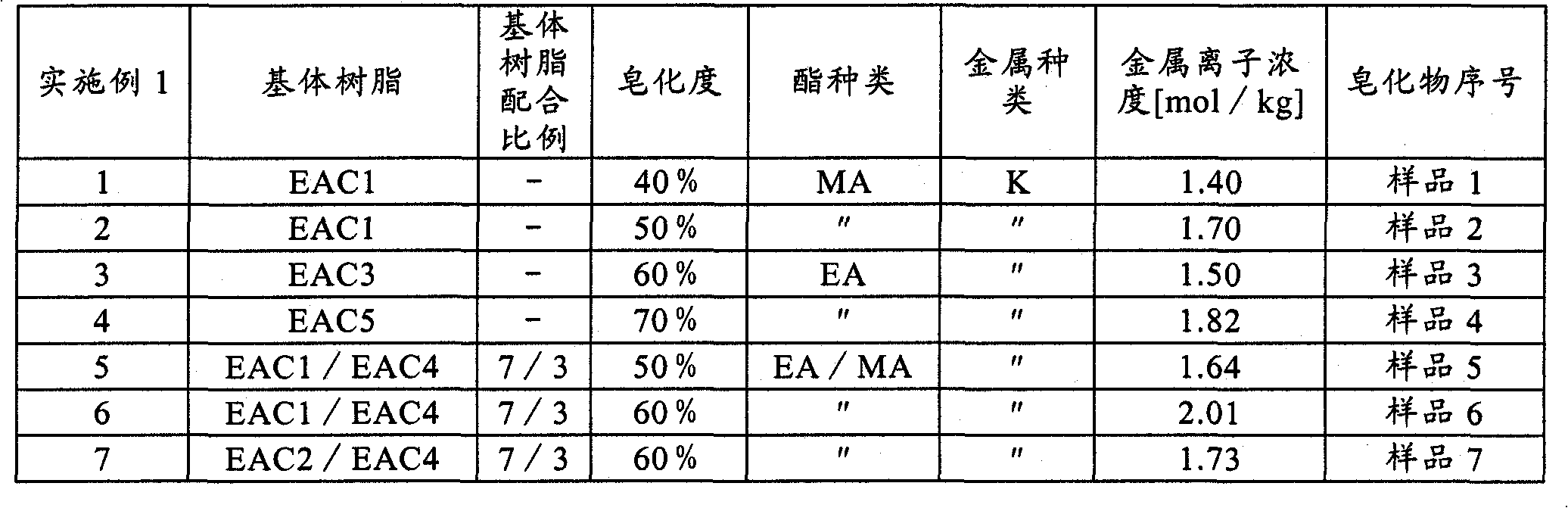

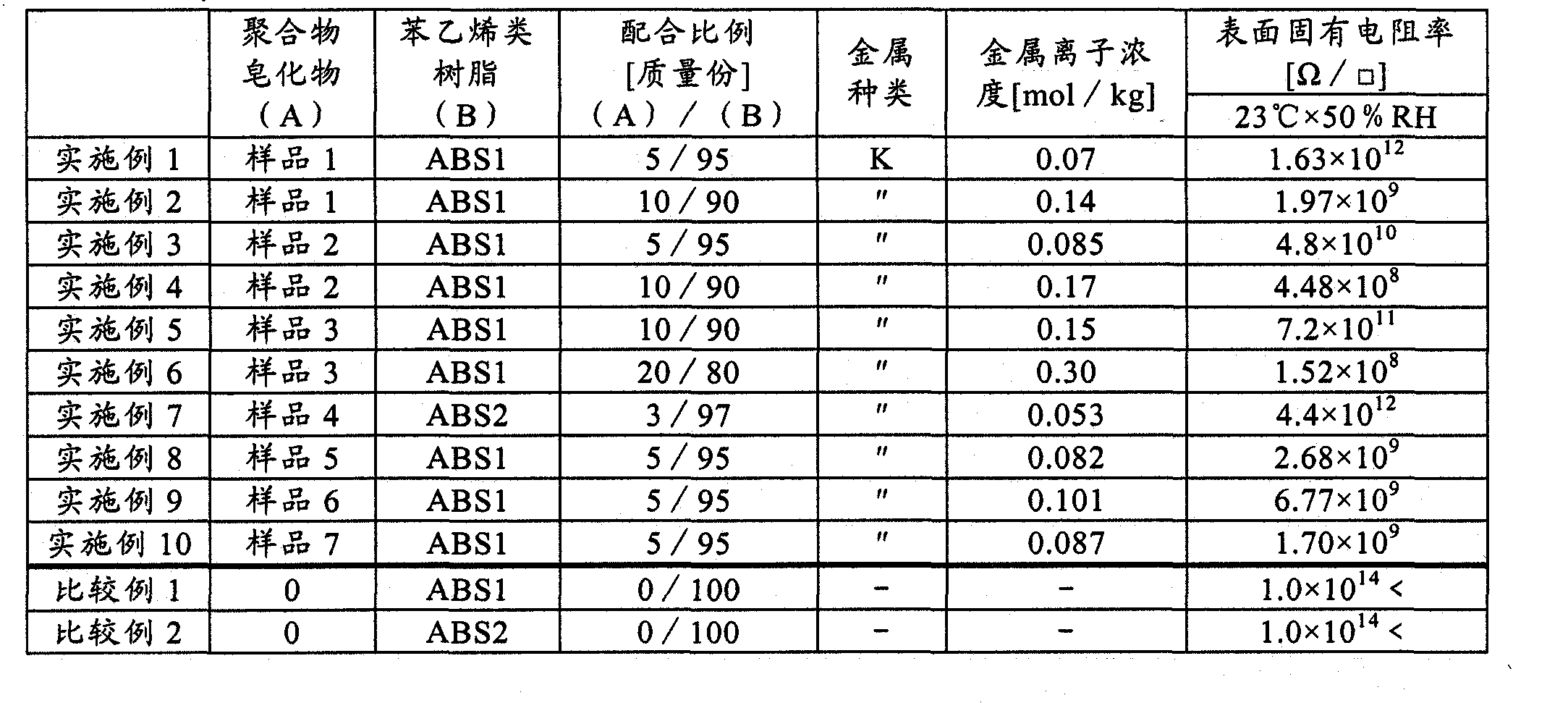

Embodiment 1

[0092] Using an extruder, 5 parts by weight of Sample 1 synthesized in Example 1 and 95 parts by weight of ABS were melt-kneaded to obtain a polymer composition. The concentration of K ions present in the form of acrylate in the polymer composition was 0.07 mol / kg.

[0093] This composition was formed into a sheet by injection molding, and the surface intrinsic resistivity of the obtained sheet was measured. The results are shown in Table 2 below.

Embodiment 2~10

[0095] In Example 1, the saponified polymer (A) was changed to the substance indicated by the saponified product serial number shown in the following Table 2, and the compounding amount was changed to the ratio shown in the following Table 2 at the same time as in Example 1 conduct. The results are shown in Table 2 below.

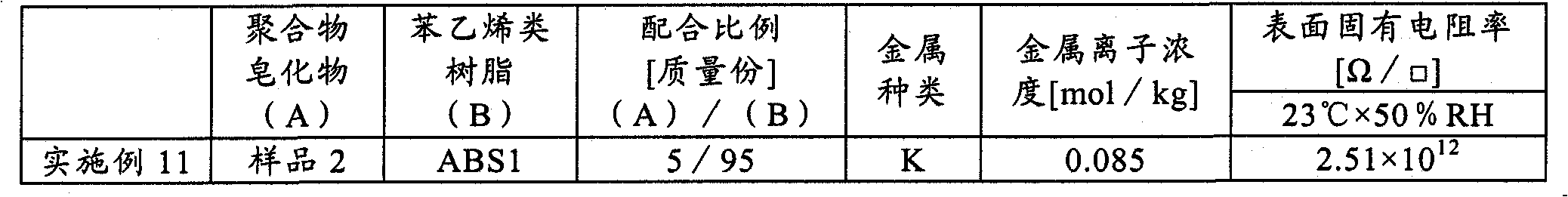

Embodiment 11

[0099] In Example 1, the saponified polymer (A) was replaced with the substance indicated by the saponified product serial number shown in Table 3 below, and the compounding amount was changed to the ratio shown in Table 3 below, and the polymer was obtained by dry mixing For the composition, an injection-molded sheet was produced in the same manner as in Example 1, and the surface specific resistivity of the obtained sheet was measured. The results are shown in Table 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com