Deactivator for polypropylene production

A technology of polypropylene and polypropylene powder, applied in the field of olefin polymerization, which can solve the problems of unsafe environmental protection and poor anti-caking ability, and achieve excellent antistatic, excellent anti-caking performance, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

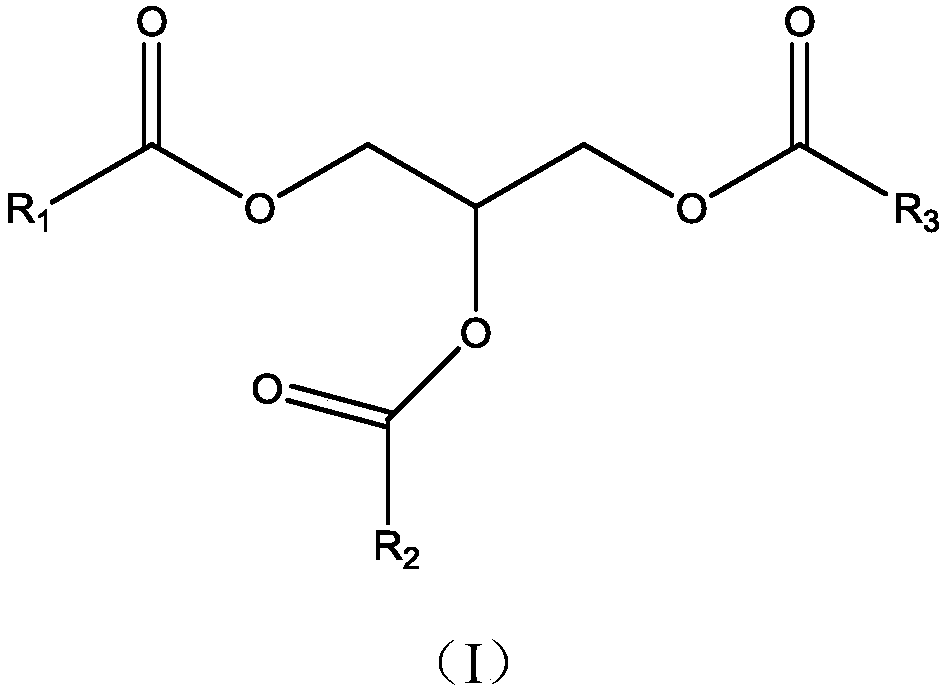

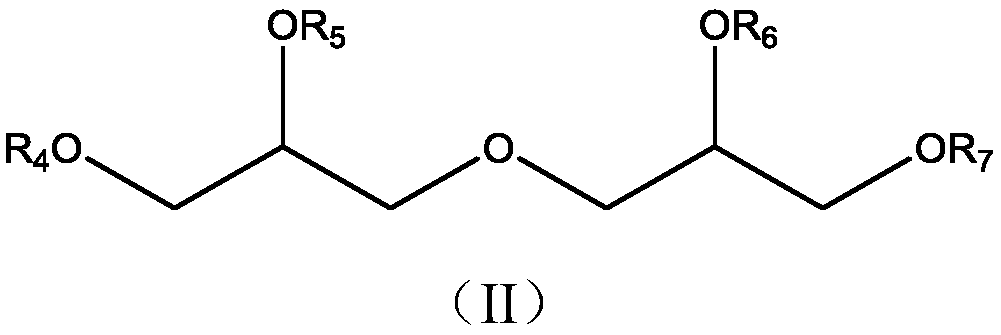

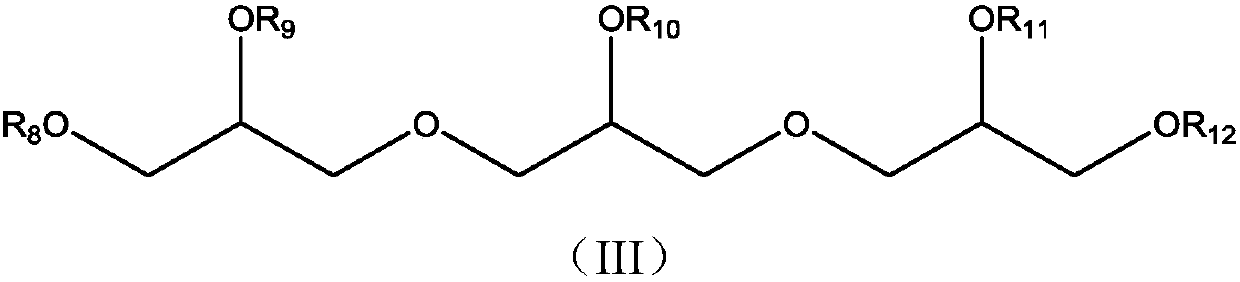

Method used

Image

Examples

Example Embodiment

[0034] Example 1

[0035] The biocide used in the production of polypropylene in this embodiment includes hydrogenated castor oil ethylhexanoic acid monoglyceride and dipolyglycerol stearate, and the molar ratio is 0.35:0.02.

Example Embodiment

[0036] Example 2

[0037] The biocide used in the production of polypropylene in this embodiment includes hydrogenated castor oil diglyceride butyrate, hydrogenated castor oil diglyceride formate, and triglyceride myristate, with a molar ratio of 0.4:0.15:0.1.

Example Embodiment

[0038] Example 3

[0039] The biocide used in the production of polypropylene in this embodiment includes hydrogenated castor oil n-capric acid diglyceride, dipolyglycerol ditetradecanoate and triglycerol distearate, and the molar ratio is 0.72:0.2 : 0.06.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com