Patents

Literature

36results about How to "Increased Vicat softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

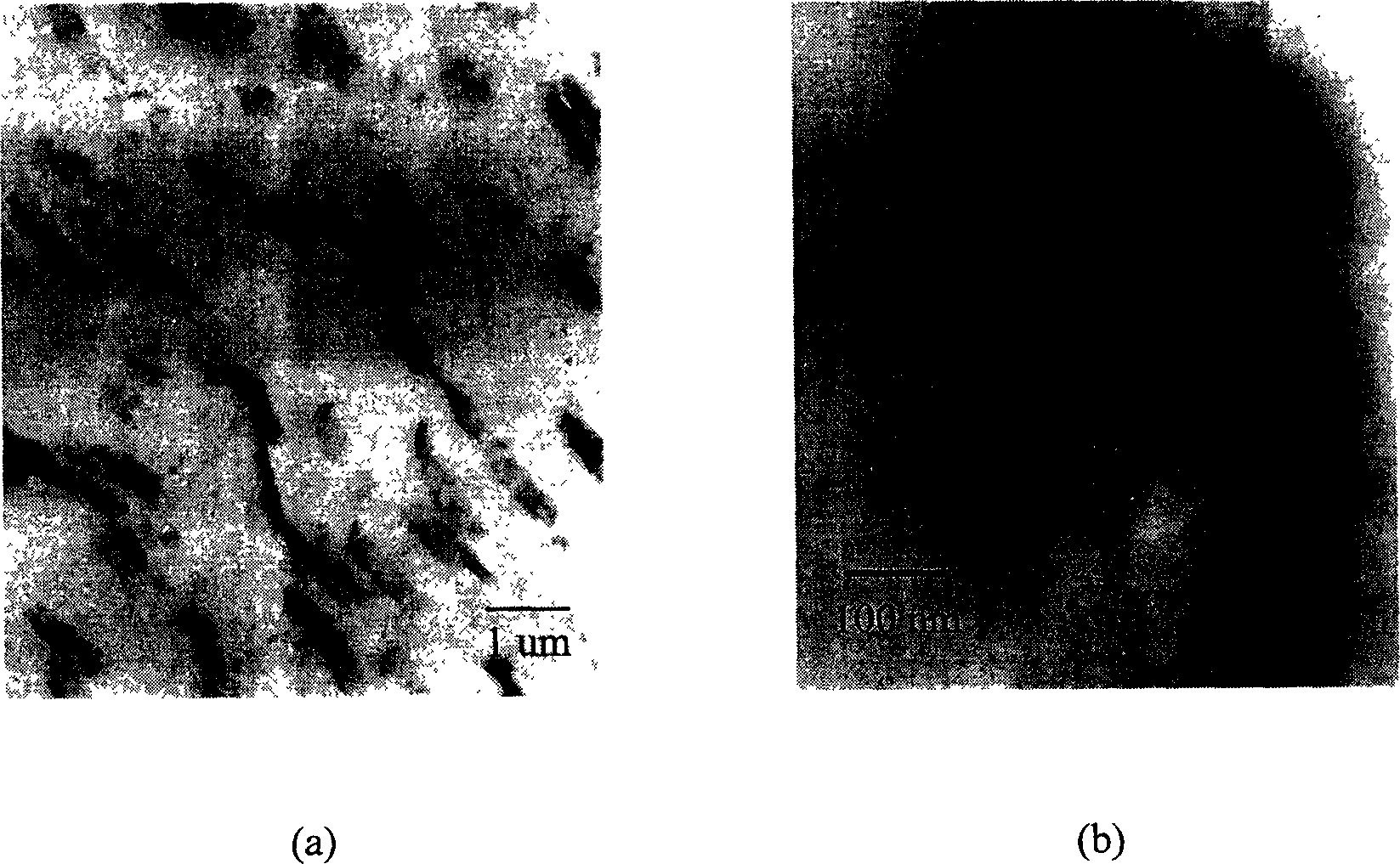

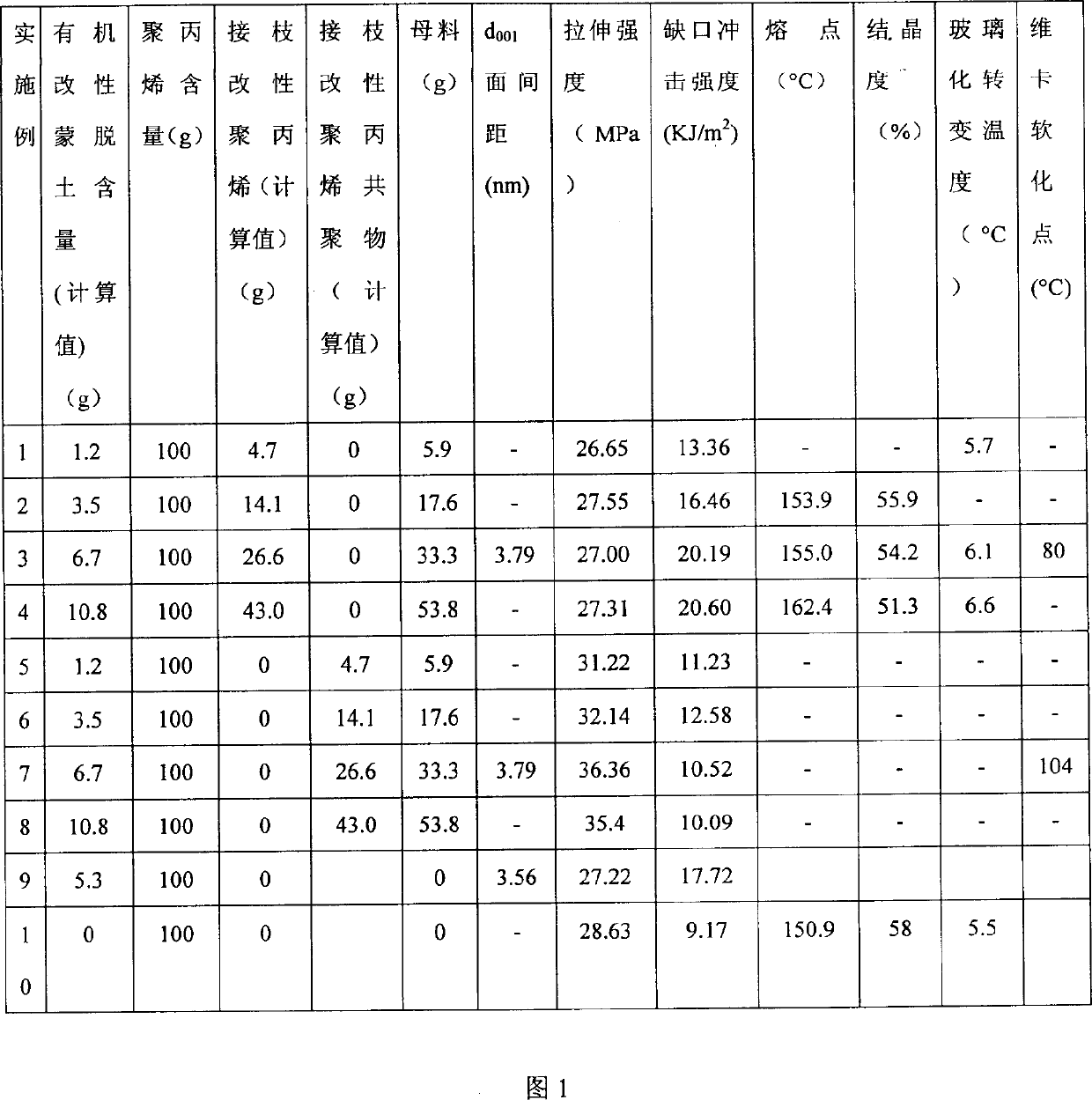

Method for preparing Nano-composite material of poly lactic acid/montmorillonite

A nano-class polylactic acid-montmorillonie composition is prepared from polylactic acid, organically modified montmorillonite with different interlayer gaps, compatibilizer and antioxidizing agent through fusing and mixing polylactic acid with said montmorillonite to obtain mother material, and fusing and mixing the mother material with polylactic acid. Its advantages are high mechanical performance, resistance to high temp and biodegradability.

Owner:TONGJI UNIV

Method for preparing Inserted layers type nano composite material of polypropylene/montmorillonite

An intercalation-type nano-class composite polypropene / montmorillonite material is prepared from isotactic polypropylene, modified organic montmorillonite with different layer gaps, graft modified polypropylene and graft modified polypropylene copolymer through fusing and intercalating. It has the obviously improved mechanical performance and machinability.

Owner:TONGJI UNIV

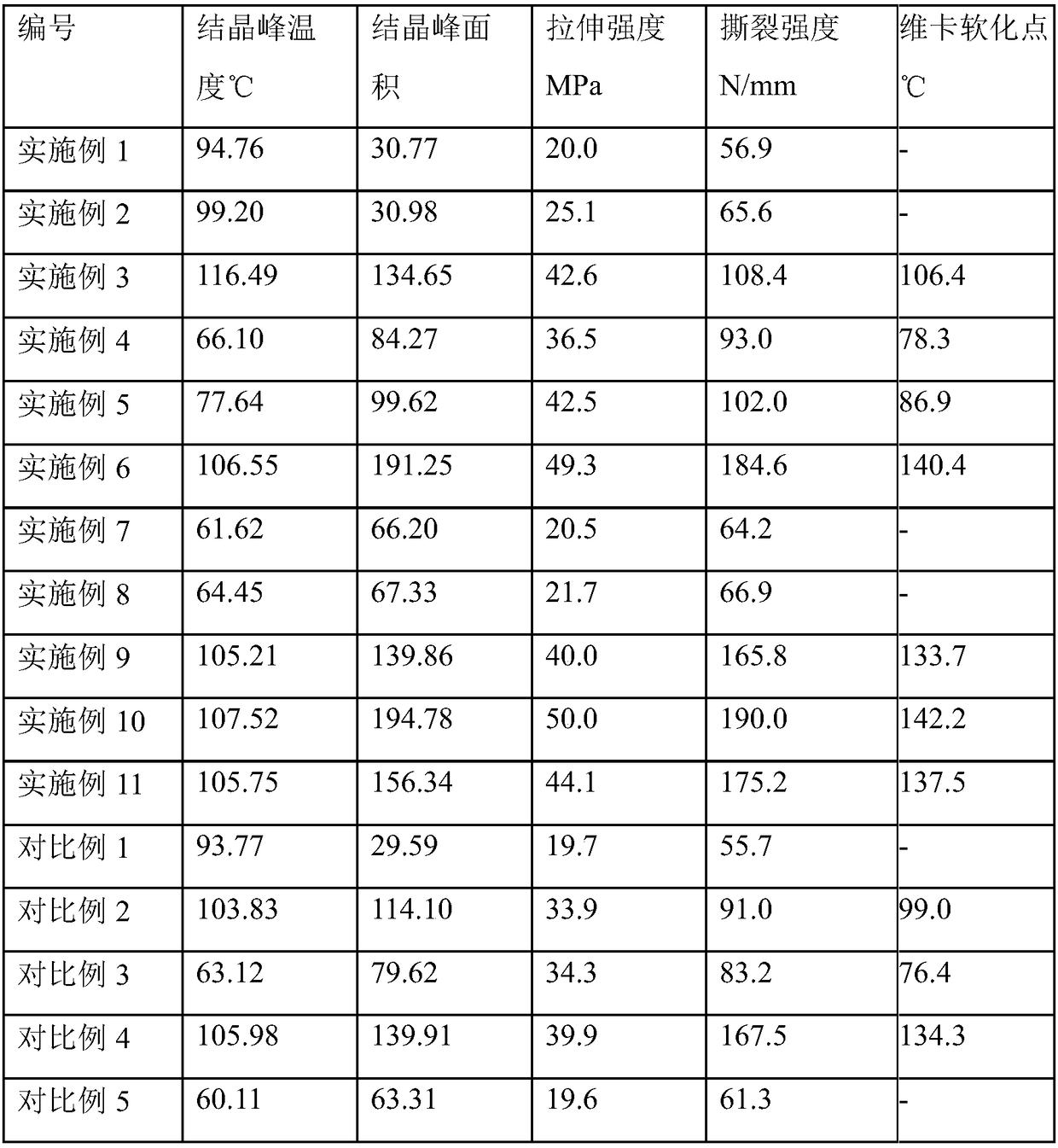

TPU (thermoplastic polyurethane) elastomer composition with high crystallization capacity and preparation method of TPU elastomer composition

InactiveCN108102340ASimple preparation processEasy to operateInorganic compoundThermoplastic polyurethane

The invention relates to TPU (thermoplastic polyurethane) elastomer composition with high crystallization capacity. The composition is characterized by being prepared from 100 parts by weight of TPU elastomers and 0.1-20 parts by weight of layered inorganic compounds, wherein preferably, the layered inorganic compounds are modified layered inorganic compounds treated with an organic ion intercalation modifier, and the dosage of the organic ion intercalation modifier is 10wt%-60wt%, preferably, 30wt%-50wt%, of the modified layered inorganic compounds. The crystallization peak temperature of theTPU composition with high crystallization capacity can be increased by 10 DEG C or more, and degree of crystallinity is increased by 10% or higher.

Owner:WANHUA CHEM GRP CO LTD

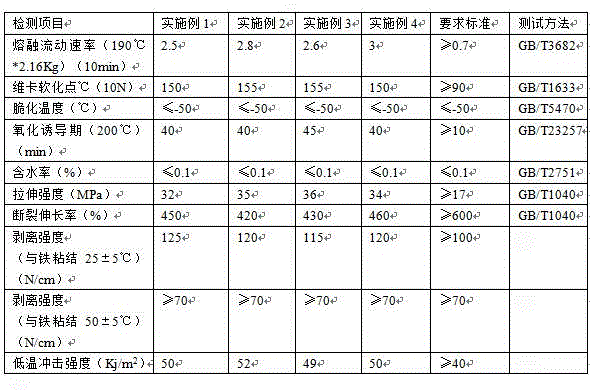

Adhesive for anticorrosive paint for deep-sea oil-gas delivery steel tube outer walls and preparation method thereof

InactiveCN104087211AHigh temperature limitImprove adhesionNon-macromolecular adhesive additivesPolymer sciencePolyolefin

The invention provides an adhesive for an anticorrosive paint for deep-sea oil-gas delivery steel tube outer walls and a preparation method thereof. The adhesive is prepared from the following raw materials in percentage by mass: 55-70% of polypropylene, 20-30% of functional polyolefin, 2-6% of reactive monomer, 1-3% of graphene, 2-5% of nano CaCO3, 0.1-0.6% of initiator, 0.4-0.8% of nucleating agent and 0.1-1.5% of antioxidant. The preparation method comprises the following steps: mixing the raw materials, stirring uniformly, putting in a double screw extruder, carrying out compounding and plastifying, drawing, cooling with water, airing, granulating, extruding for granulation, and packaging to obtain the adhesive. The adhesive has excellent mechanical properties, higher low-temperature impact resistance and wide application range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

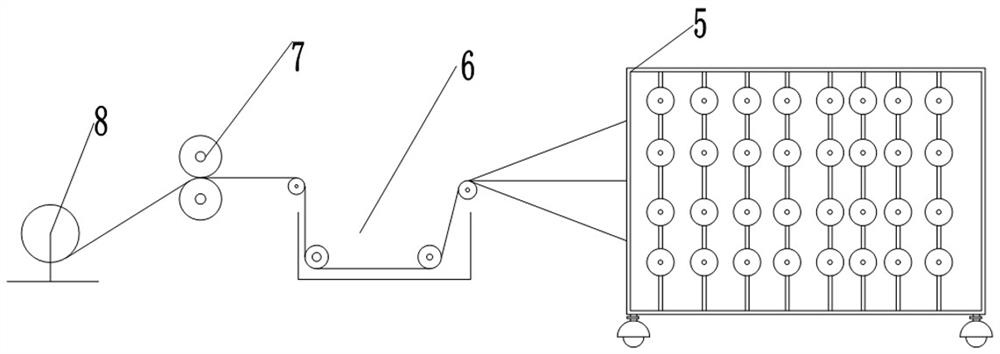

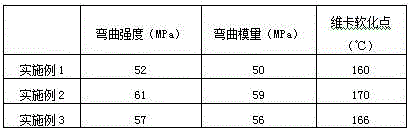

Insulating flame-retardant MPP power cable tube and preparation method thereof

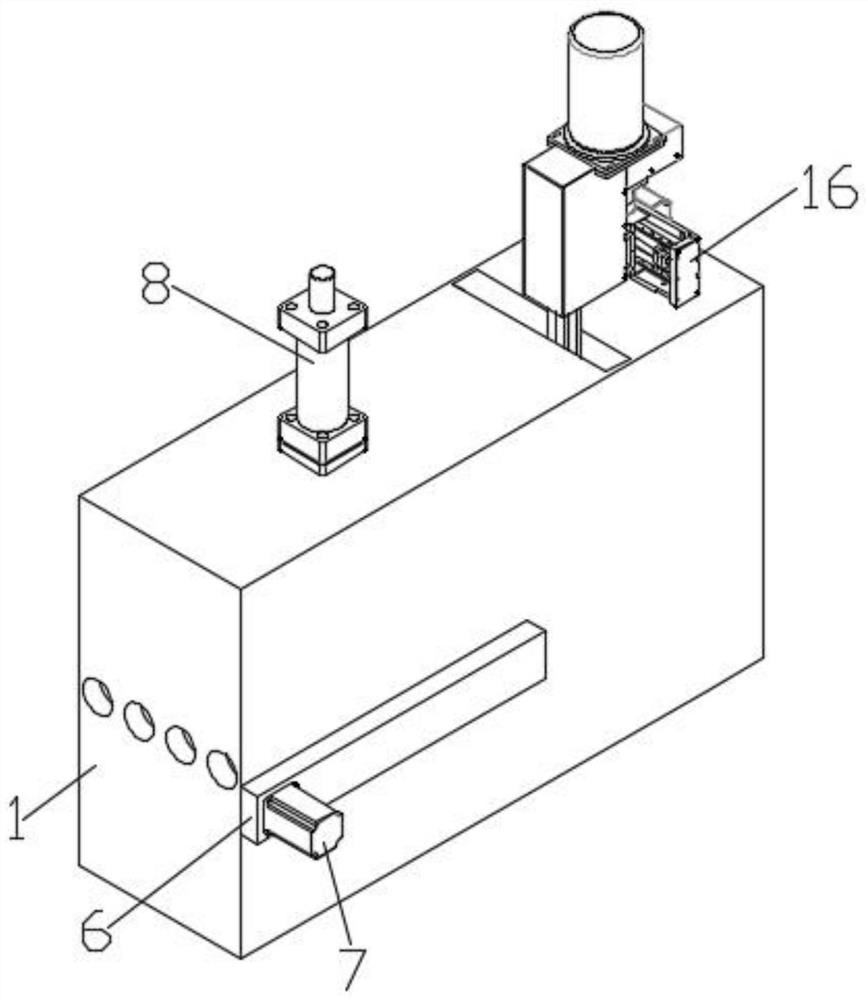

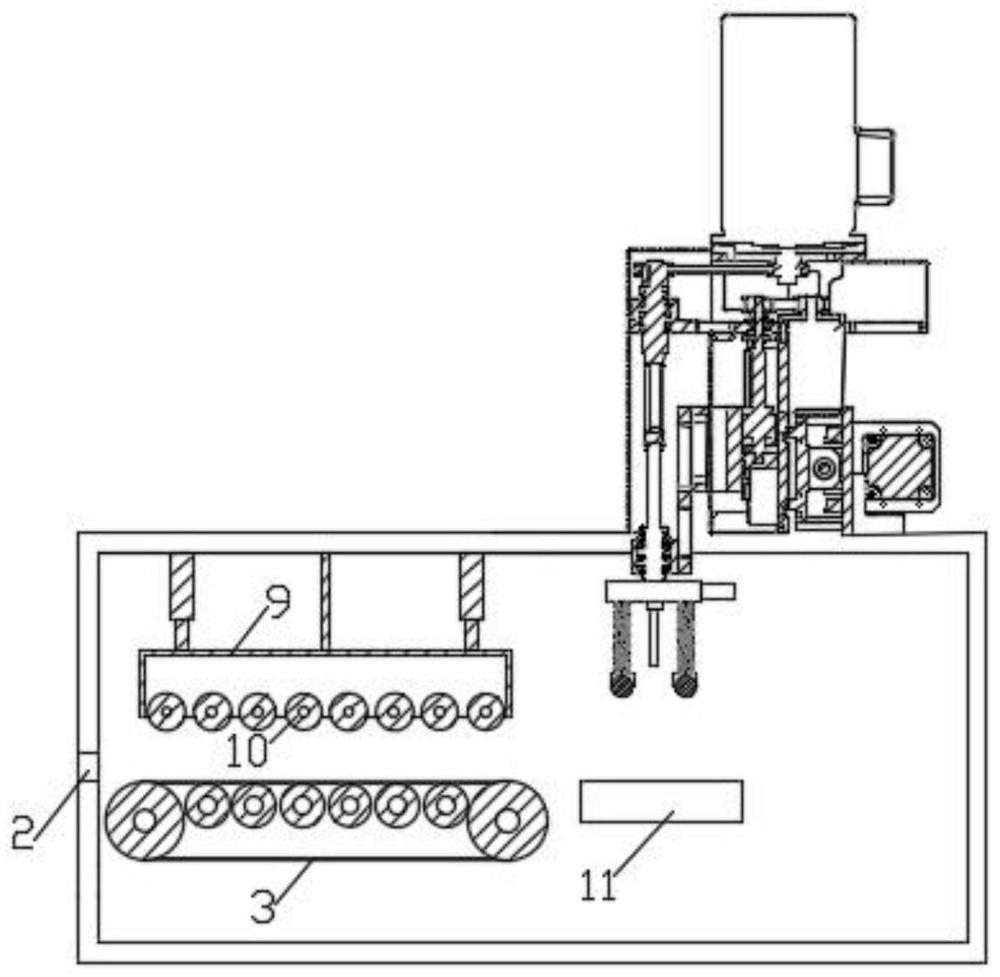

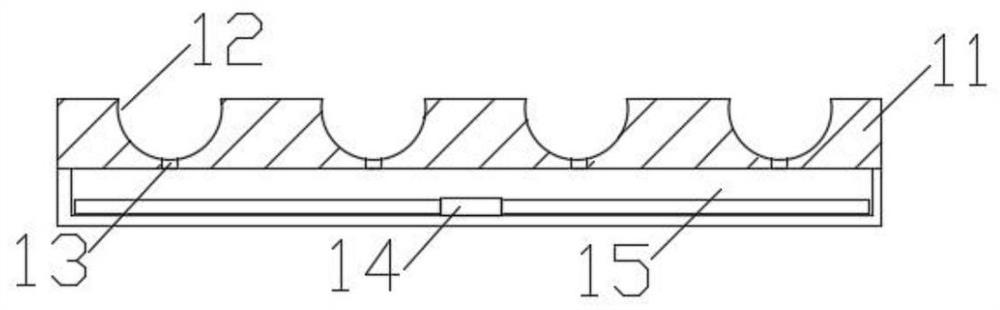

InactiveCN112810098AHigh crystallinityIncreased Vicat softening pointElectrical apparatusMetal working apparatusPower cableEngineering

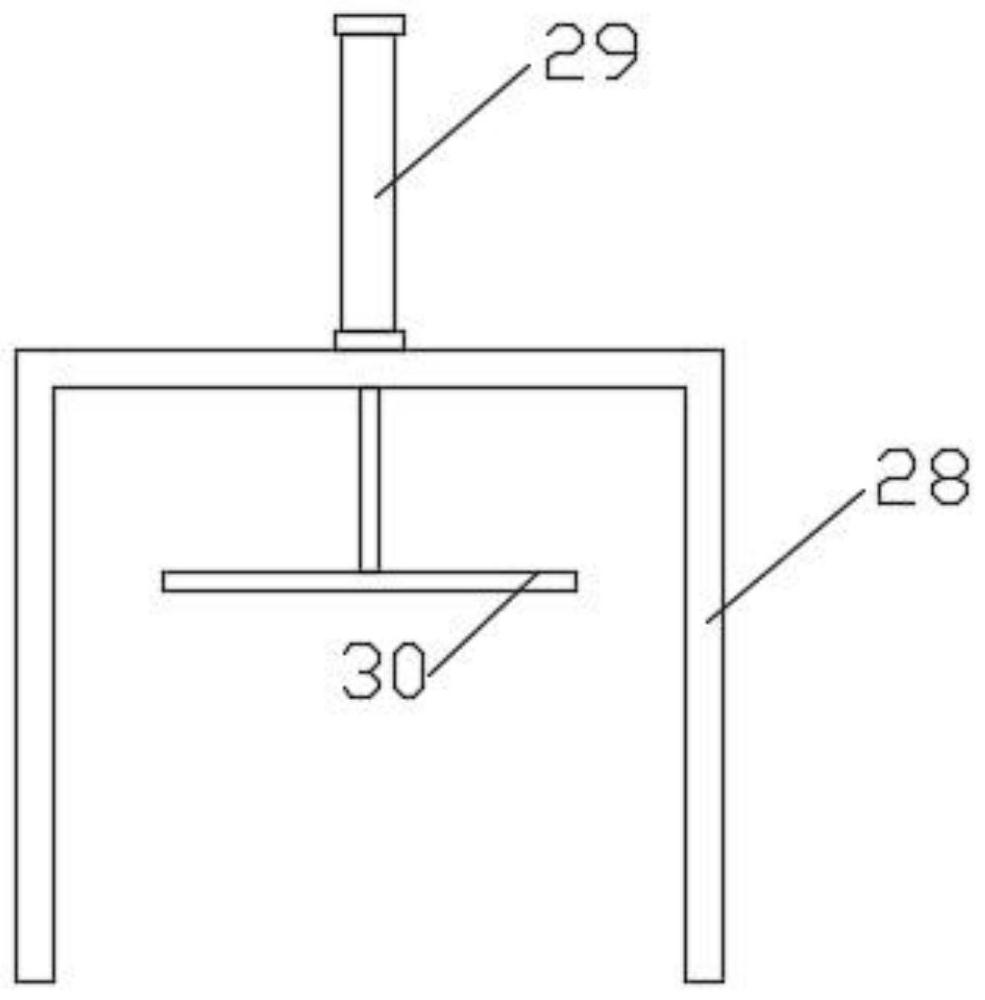

The invention discloses an insulating flame-retardant MPP power cable tube and a preparation method thereof. According to the insulating flame-retardant MPP power cable tube and the preparation method thereof, isotactic polypropylene is high in crystallinity, and the prepared insulating flame-retardant MPP power cable tube has the characteristics of high vicat softening point, high modulus and low-temperature brittleness by adding the isotactic polypropylene; by adding ultra-high molecular weight polyethylene, the wear resistance of the prepared insulating flame-retardant MPP cable tube is good, and according to GB / T 8802-2001 measurement, the Vicat softening point of the prepared insulating flame-retardant MPP cable tube is 160-168 DEG C; meanwhile, the invention discloses cutting equipment, the cutting equipment can convey multiple strands of cable tubes at the same time; meanwhile, limiting rollers are matched with conveying, then conveying of the cable tubes with different diameters can be met; and meanwhile, the situation that multiple strands of cable tubes are mutually wound during conveying is avoided.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

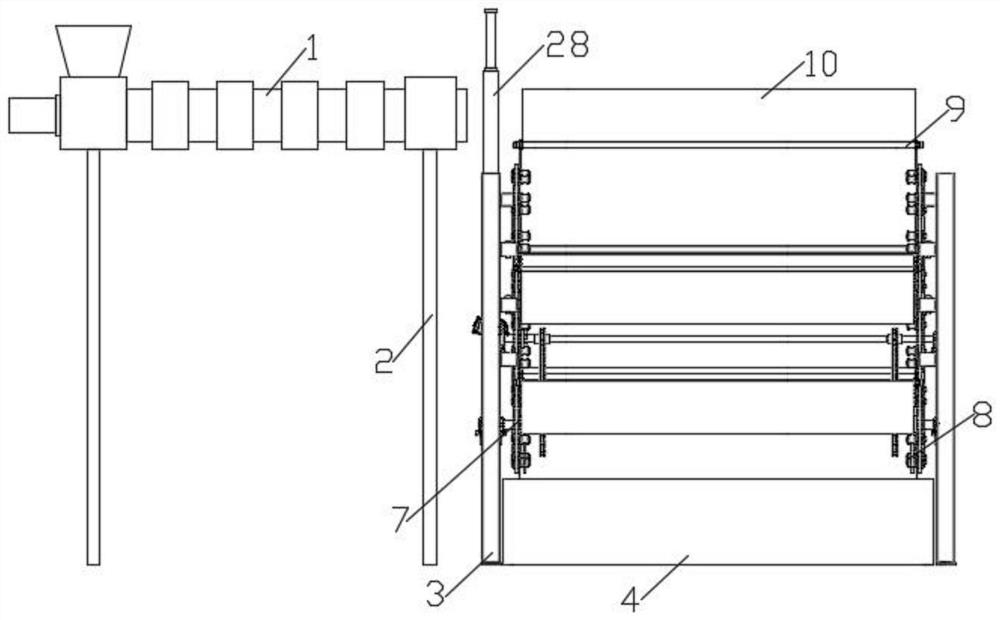

Heat-resistant insulating MPP cable tube and preparation method thereof

ActiveCN112625355AIncreased Vicat softening pointHigh modulusTubular articlesPolypropyleneElectric cables

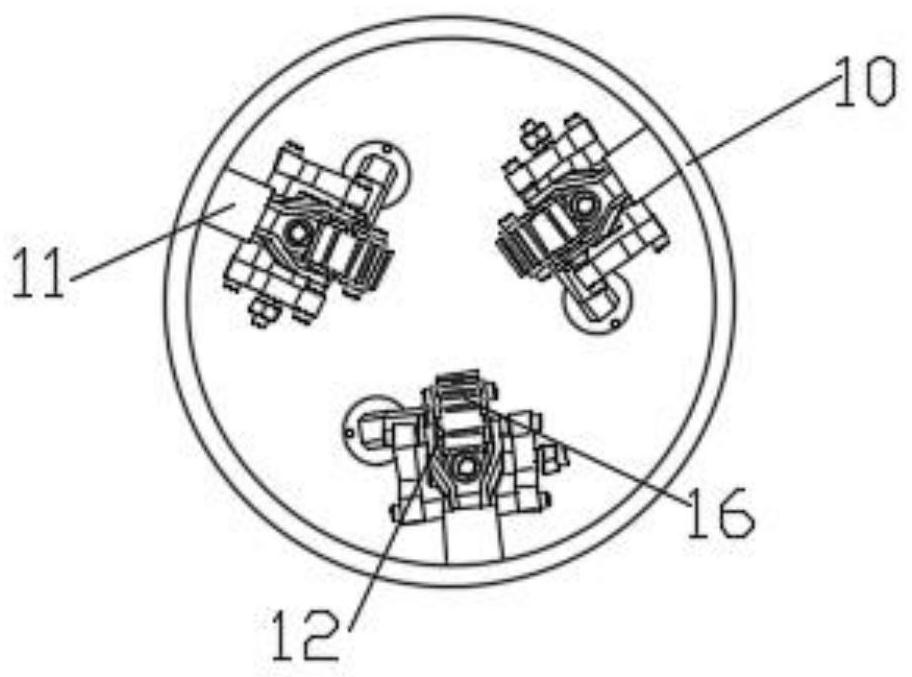

The invention discloses a heat-resistant insulating MPP cable tube and a preparation method thereof, the prepared heat-resistant insulating MPP cable tube has the characteristics of high Vicat softening point, high modulus and low-temperature brittleness by adding isotactic polypropylene, and the prepared heat-resistant insulating MPP cable tube has good wear resistance by adding ultra-high molecular weight polyethylene. According to measurement of GB / T 8802-2001, the Vicat softening point of the prepared heat-resistant insulating MPP cable tube is 154-163 DEG C. Meanwhile, the invention discloses extrusion cooling equipment which is provided with a plurality of circulating channels, so that circulating cooling of a plurality of cable tubes can be met at the same time, the cooling efficiency of the cable tubes is high, the extrusion cooling equipment can complete cooling of the bottom cable tube while cutting, conveying and cutting the top cable tube, and the production efficiency of the cable tube is greatly improved.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Makrolon/modified polyester blending rolling base material and preparation method thereof

The invention provides a markrolon / modified polyester blending rolling base material and a preparation method thereof. The markrolon / modified polyester blending rolling base material comprises the following components by weight percent: 55-65% of makrolon, 15-20% of modified polyester, 4-8% of modified copolyesters additive, 3-5% of compatilizer 4051, 4-7% of titanium white, 2-6% of calcium carbonate and 0.01-0.1% of pigment. The vicat softening point of the invention can be 115 DEG C+ / -2 (50-5kg of vicat A), the tensile strength is larger than 45Mpa, the tensile yield strength is larger than 750KJ / m<2>; and the invention meets the rolling technology requirement by improving the formula lubrication systems, can meet the requirement of the processes such as material application, card making technology of smart card base materials and the like.

Owner:上海达凯塑胶有限公司

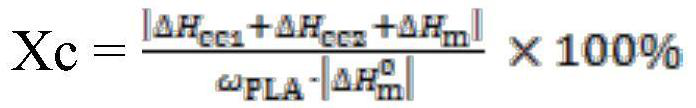

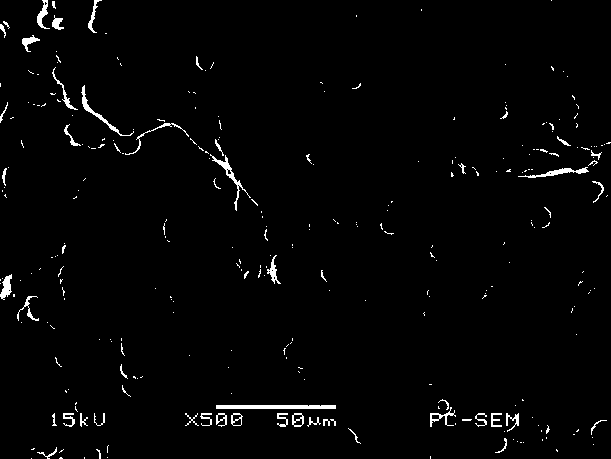

Method for preparing heat-resisting polylactic acid nanocomposite through irradiation modification

The invention belongs to a method for preparing a heat-resisting polylactic acid nanocomposite through irradiation modification. The heat-resisting polylactic acid nanocomposite comprises polylactic acid, modified montmorillonite, PE (Poly Ethylene) wax, antioxidant, and polyfunctional monomer. Extruding granulation is carried out through a double-screw, then forming is realized through mould pressing or other methods, and finally a formed workpiece is placed in nitrogen atmosphere and is irradiated by electron beams at room temperature. The obtained product has excellent heat resistance.

Owner:BEIJING UNIV OF CHEM TECH

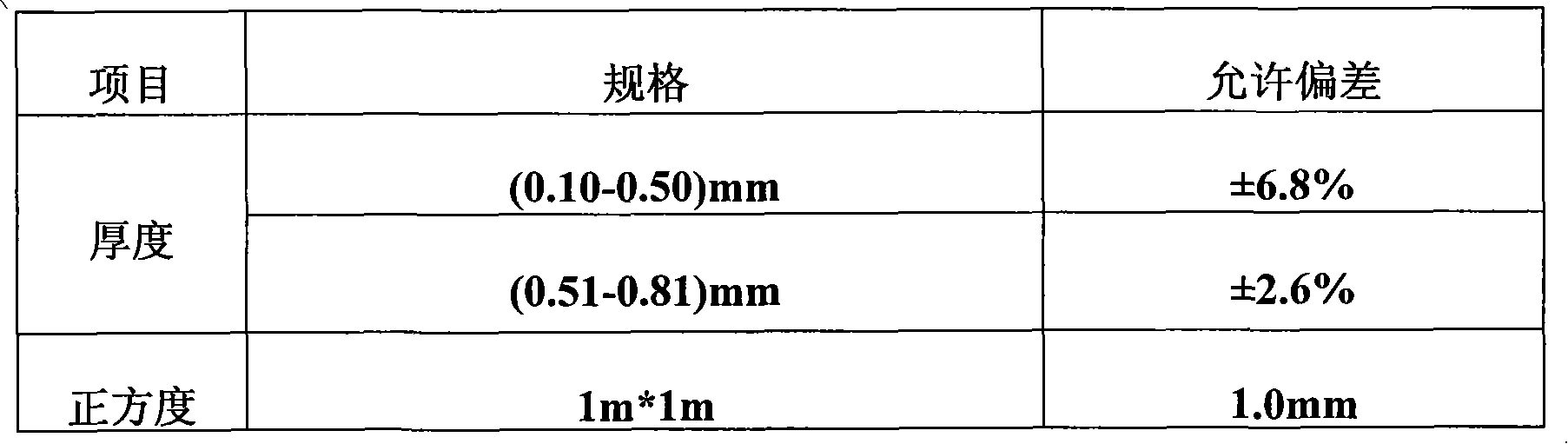

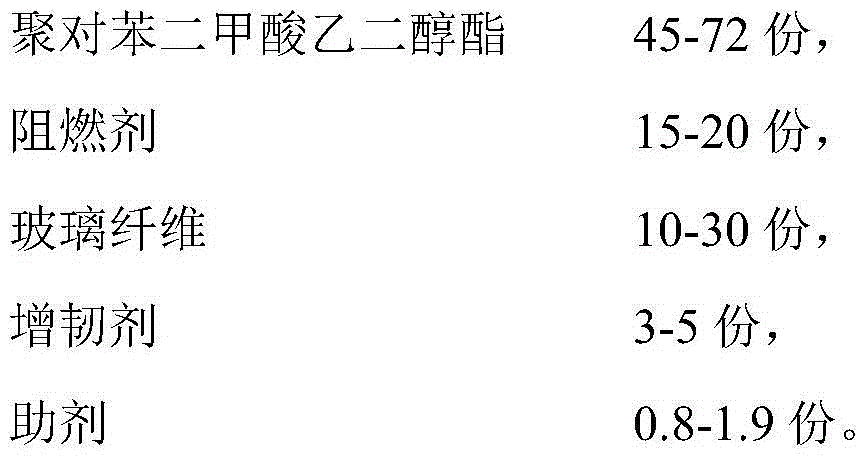

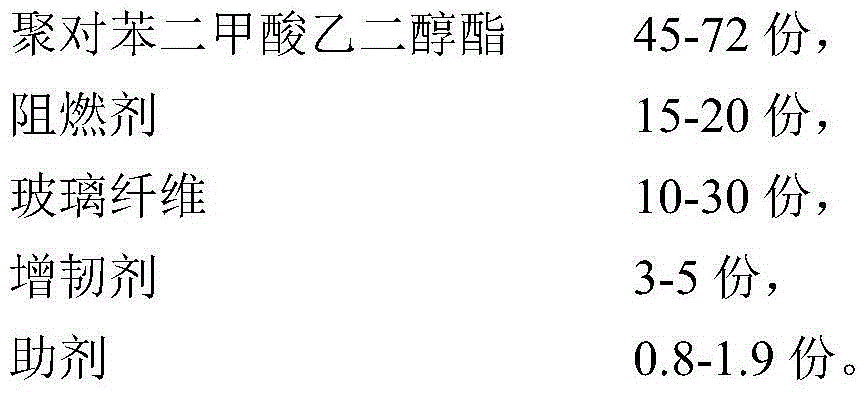

Flame retardant enhanced PET material having high glowing filament temperature and preparation method of material

The invention belongs to the technical field of high polymer materials and relates to a flame retardant enhanced PET material having a high glowing filament temperature and a preparation method of the material. The material is prepared from the following components in parts by weight: 45-72 parts of PET, 10-30 parts of glass fibers, 0.3-0.6 part of lubricant, 0.3-0.6 part of antioxidant, 0.2-0.7 part of nucleating agent, 15-20 parts of flame retardant and 3-5 parts of flexibilizer. The material has the characteristics of high strength, good flame retardancy, high glowing filament temperature, high temperature resistance, easy molding and the like, and has a wide application prospect in the household appliance industry.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

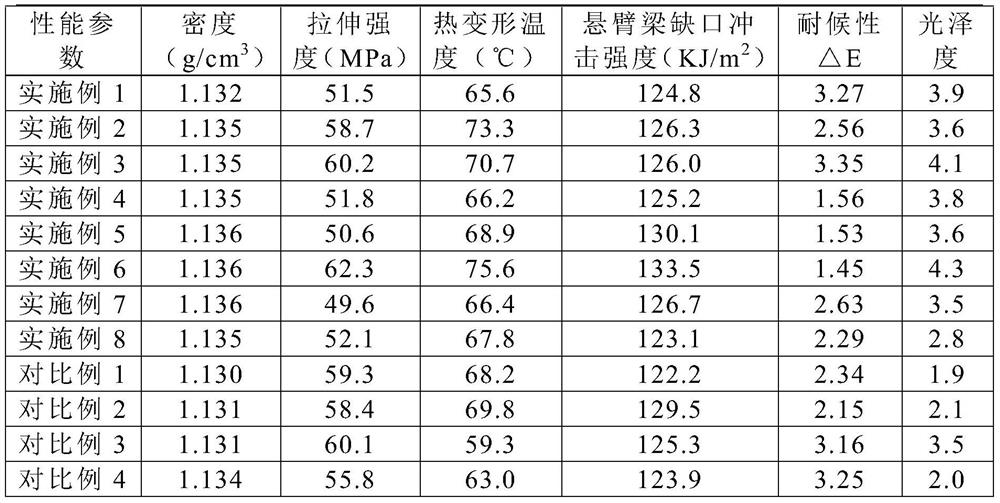

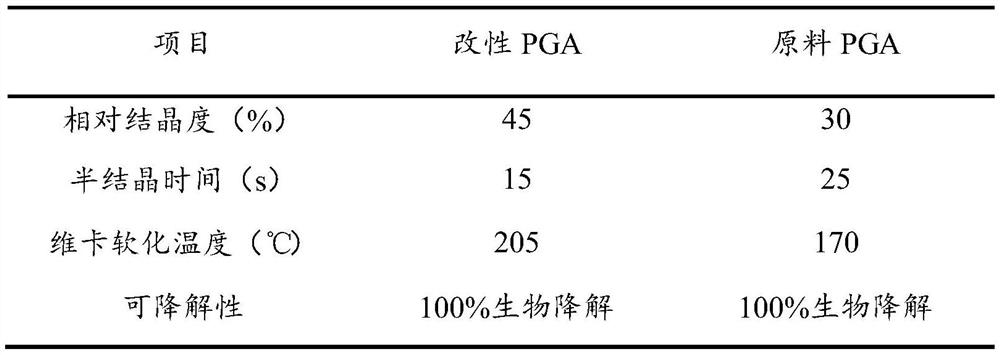

High-heat-resistance modified PGA material and preparation method thereof

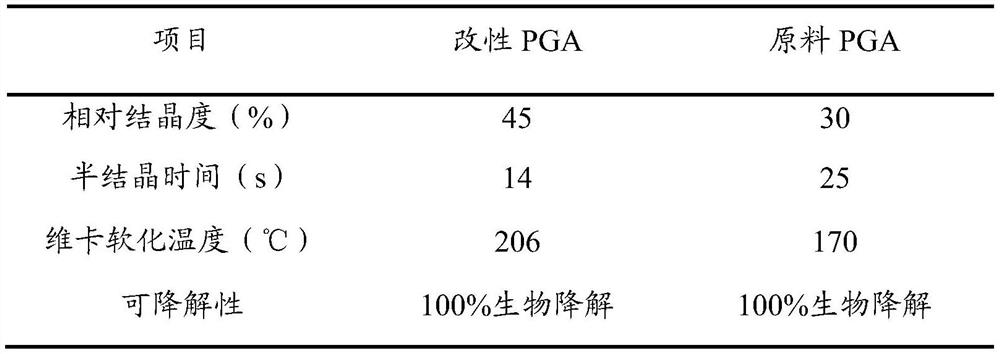

The invention provides a high-heat-resistance modified PGA material and a preparation method thereof. The modified PGA material is prepared from the following raw materials in parts by weight: 70-80 parts of polyglycolic acid resin, 5-15 parts of filler, 10-30 parts of castor oil mixture and 0.5-1 part of nucleating agent; wherein the castor oil mixture is a mixture of castor oil with purity of 90% and methanol, and the mass ratio of castor oil to methanol is 7.5-8.5:2. The nucleating agent is selected from one or more of talcum powder, inositol and sebacic acid dimethylbenzene hydrazide; the filler is selected from one or more of nano montmorillonite, nano calcium carbonate and edible starch. The castor oil mixture, the nucleating agent and the filler are used for modifying the polyglycolic acid resin, so that the modified PGA material has high crystallization performance and can be used for preparing high-heat-resistance products.

Owner:海南赛高新材料有限公司

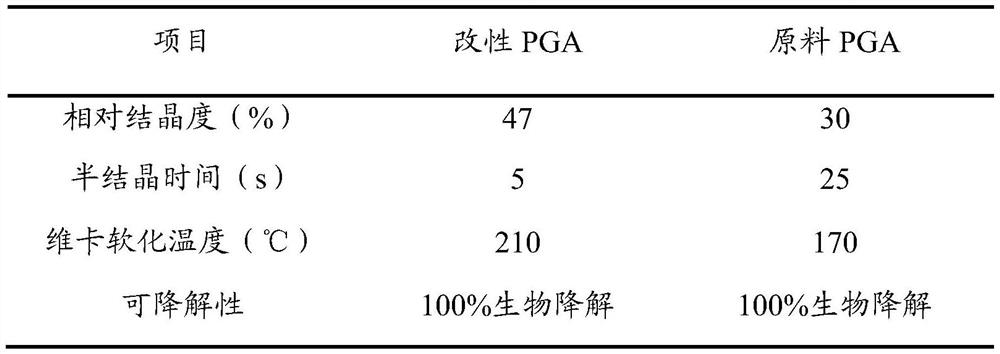

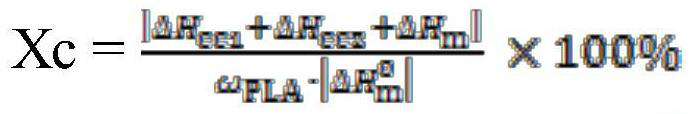

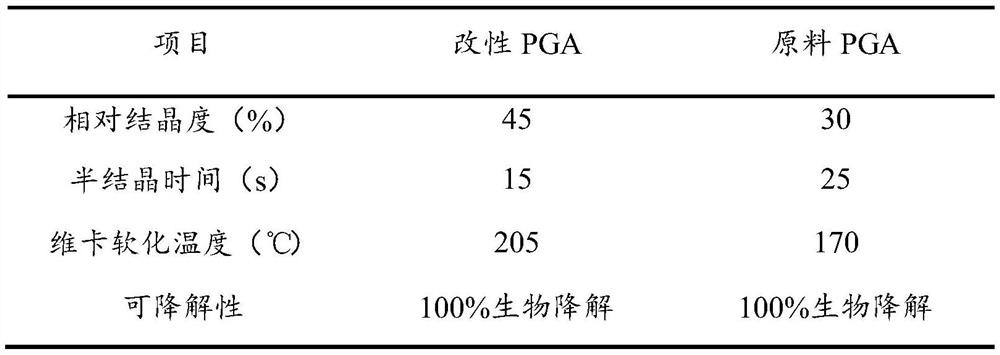

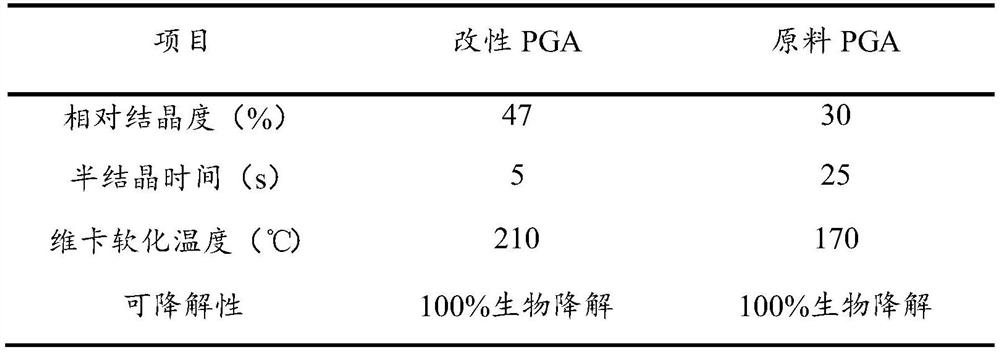

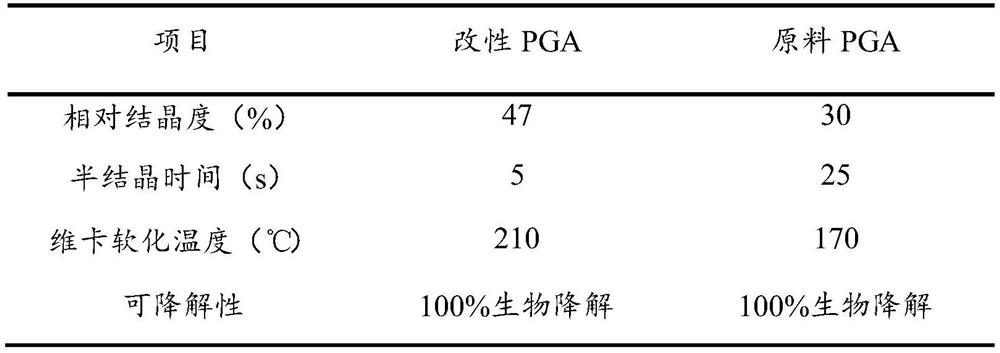

High-crystallinity modified PGA material and preparation method thereof

The invention provides a high-crystallinity modified PGA material and a preparation method thereof. The modified PGA material is prepared from the following raw materials in parts by weight: 70-80 parts of polyglycolic acid resin, 5-15 parts of filler, 4-25 parts of plasticizer and 0.5-1 part of nucleating agent. The plasticizer is a mixture of polyvinyl alcohol and glycerol in a mass ratio of 1:(1.8-2.3), the molecular weight of polyvinyl alcohol is 300-500g / mol, and the alcoholysis degree is greater than or equal to 98%; the nucleating agent is selected from one or more of talcum powder, inositol and sebacic acid dimethylphenyl hydrazide; and the filler is selected from one or more of nano montmorillonite, nano calcium carbonate and edible starch. The polyglycolic acid resin is modified by adopting the plasticizer, the nucleating agent and the filler, so that the modified PGA material has relatively high crystallization property and can be used for preparing a high-heat-resistance product. The Vicat softening temperature is 205 to 210 DEG C; the semi-crystallization time is 5-15 seconds; and the relative crystallinity is 45-47%.

Owner:HAINAN SHINER IND

Calendering base material for bank double-interface intelligent card and preparation method thereof

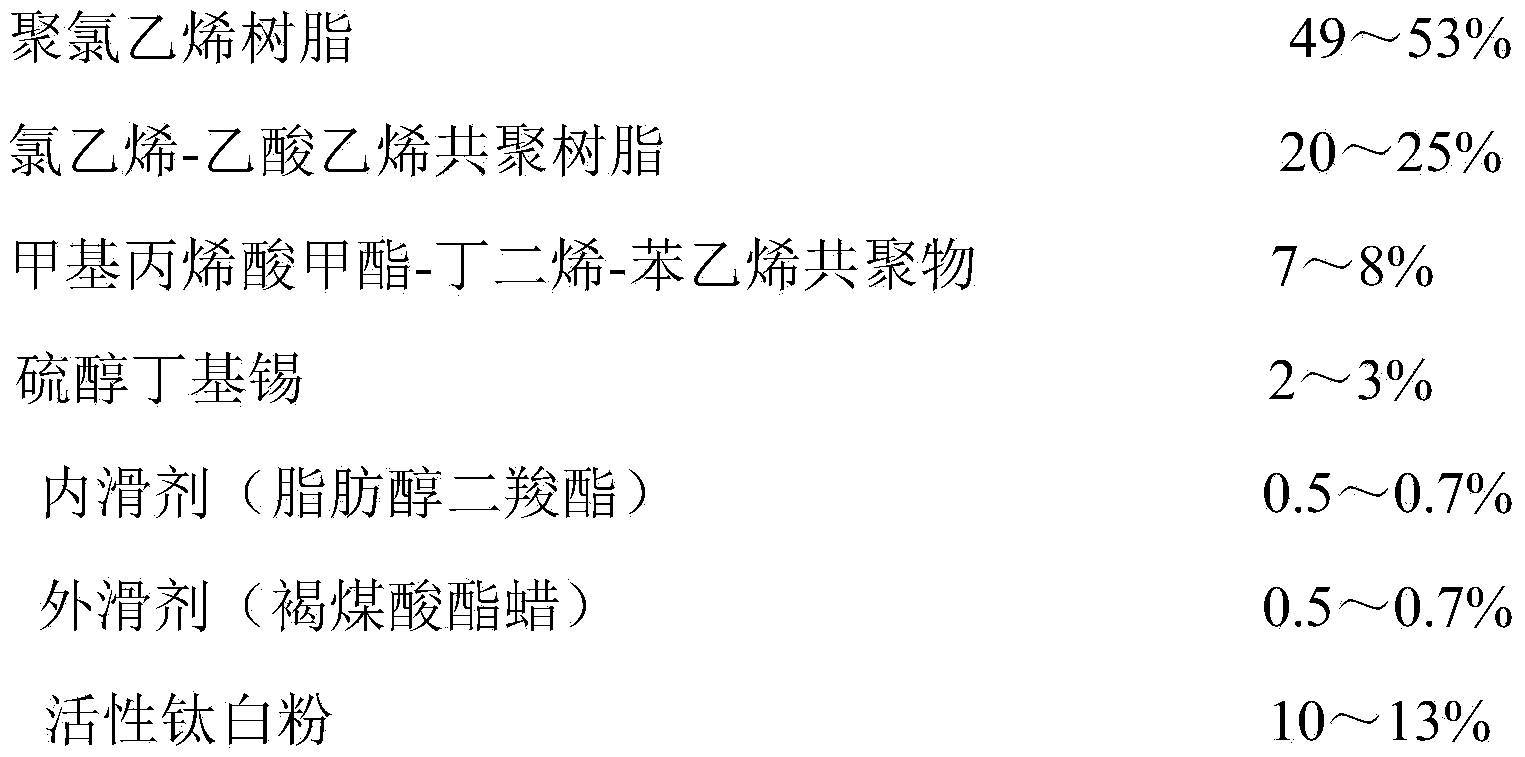

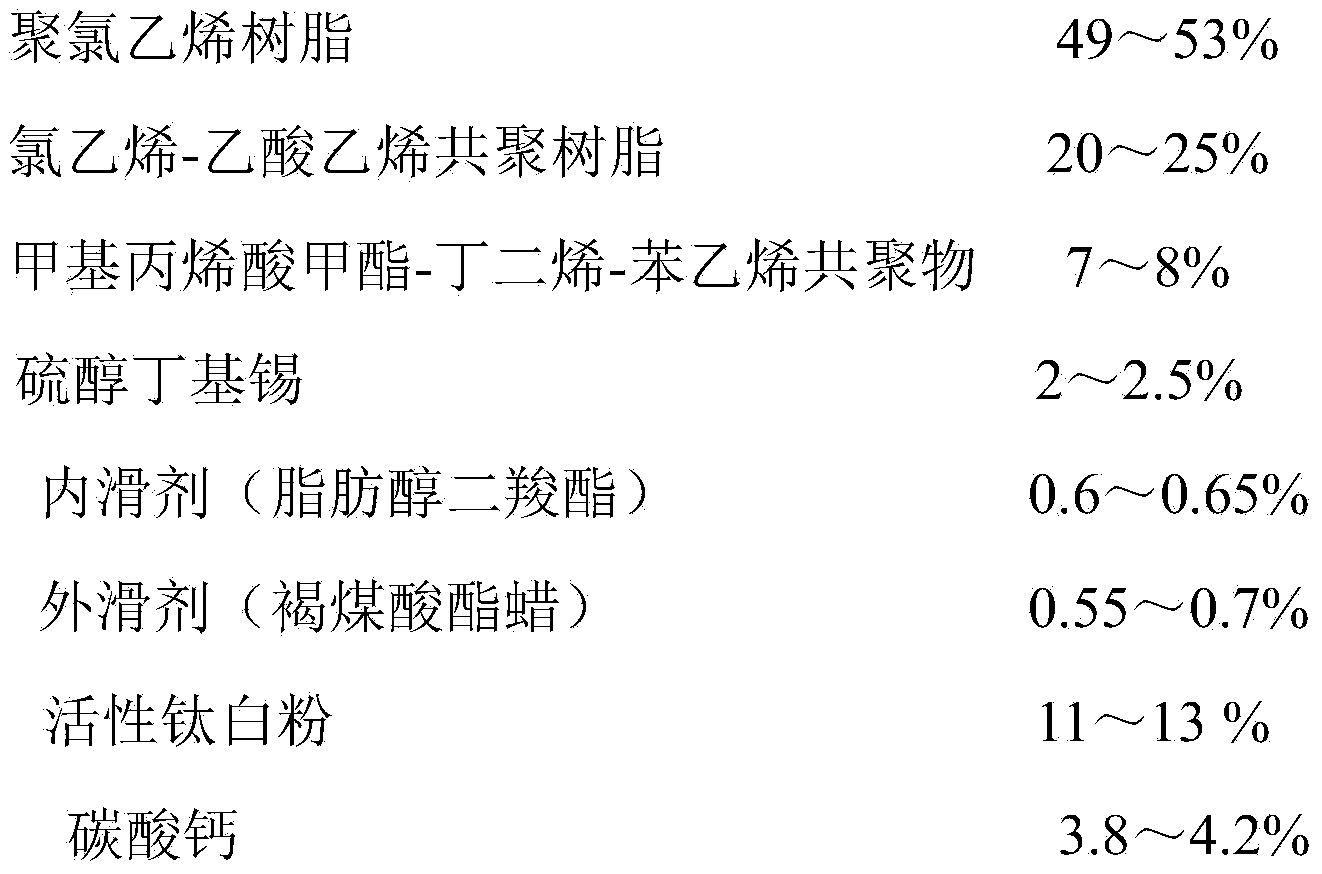

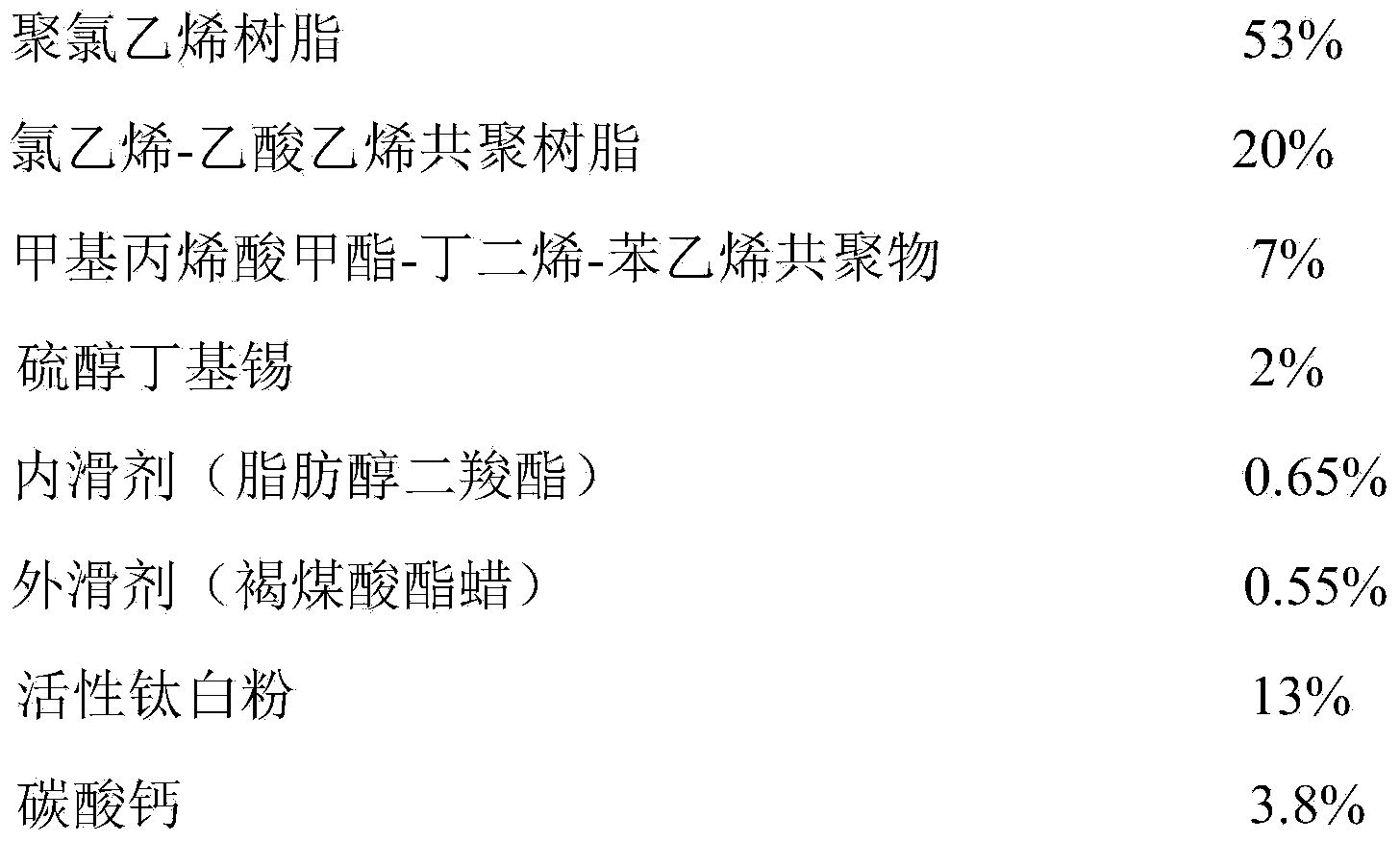

InactiveCN103554755AIncrease coverageMeet the calendering process requirementsPolyvinyl chlorideSmart card

The invention discloses a calendering base material for a bank double-interface intelligent card and a preparation method of the calendering base material for a bank double-interface intelligent card. The calendering base material for a bank double-interface intelligent card is prepared from the following components in weight percentage: 49-53% of polyvinyl chloride resin, 20-25% of vinyl chloride-vinyl acetate copolymer resin, 7-8% of methyl methacrylate-butadiene-styrene copolymer, 2-3% of butyltin mercaptide, 0.5-0.7% of internal lubricant, 0.5-0.7% of external lubricant and 10-13% of active titanium dioxide. The double-interface intelligent card calendering base material considers the high-temperature laminating adhesion force of an internal chip and a rear coil card matrix, high-temperature resistance of the chip and the coil and the rigid-flexible characteristic of an external chip card matrix, and an equipment condition for producing the calendaring base material for a bank double-interface intelligent card (contact type and non-contact type) is realized.

Owner:上海达凯塑胶有限公司

ABS (Acrylonitrile Butadiene Styrene) calendered substrate and preparation method thereof

The invention discloses an ABS (Acrylonitrile Butadiene Styrene) calendered substrate and a preparation method thereof. The ABS calendered substrate contains acrylonitrile-styrene copolymer and acrylonitrile-butadiene-styrene copolymer, wherein the acrylonitrile-styrene copolymer accounts for 69% by weight and the acrylonitrile-butadiene-styrene copolymer accounts for 29% by weight. The blend in the invention has the characteristics of environmental protection, good rigidity, impact resistance of ABS, high vicat softening point, easy processing, high surface quality, less bubble and excellent printing performance, and is suitable for making environmental-friendly and high heat-resistant cards of mobile phone SIM cards, television charging cards, oiling charging cards, and the like.

Owner:上海达凯塑胶有限公司

Novel modified polyvinyl chloride pipe fitting and preparation method thereof

InactiveCN106566121AHigh physical and mechanical strengthIncreased Vicat softening pointWeather resistancePipe fitting

The invention relates to a novel modified polyvinyl chloride pipe fitting and a preparation method thereof. The polyvinyl chloride pipe fitting is composed of the following raw materials in parts by weight: 100 parts of PVC resin, 10-30 parts of silicate-like modifier, 5-10 parts of heat-resistant modifier and 1-5 parts of processing aids, wherein the silicate-like modifier is a superfine fibre-shaped wollastonite powder subjected to surface treatment; and the heat-resistant modifier is one or more of alpha-methyl styryl polymer and alpha-styryl polymers. The polyvinyl chloride pipe fitting provided by the invention is high in physical and mechanical property, has a high Vicat softening point, and is high in weather resistance, dimensional stability and smooth finish.

Owner:GUANGDONG LIANSU TECH INDAL

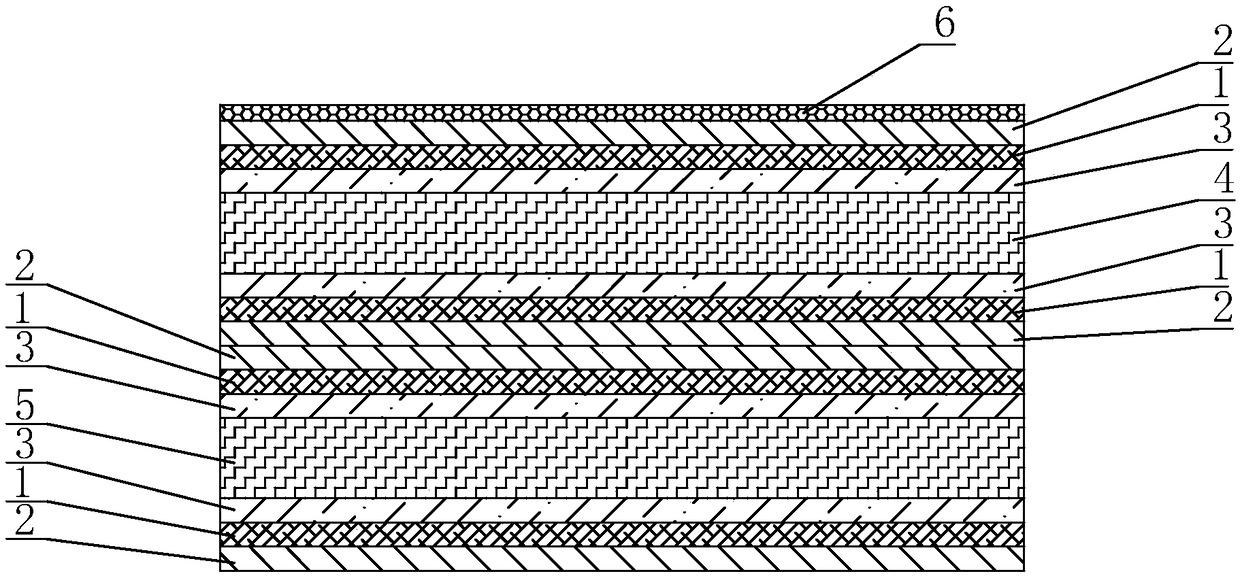

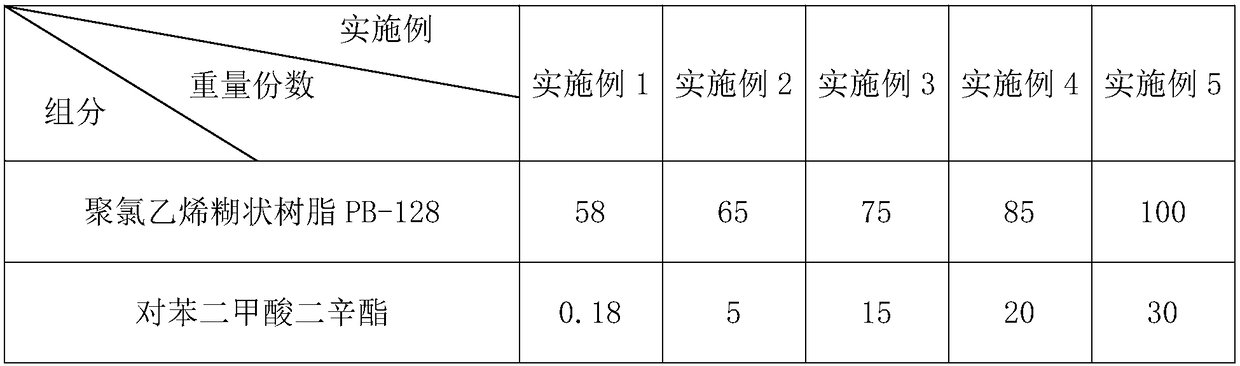

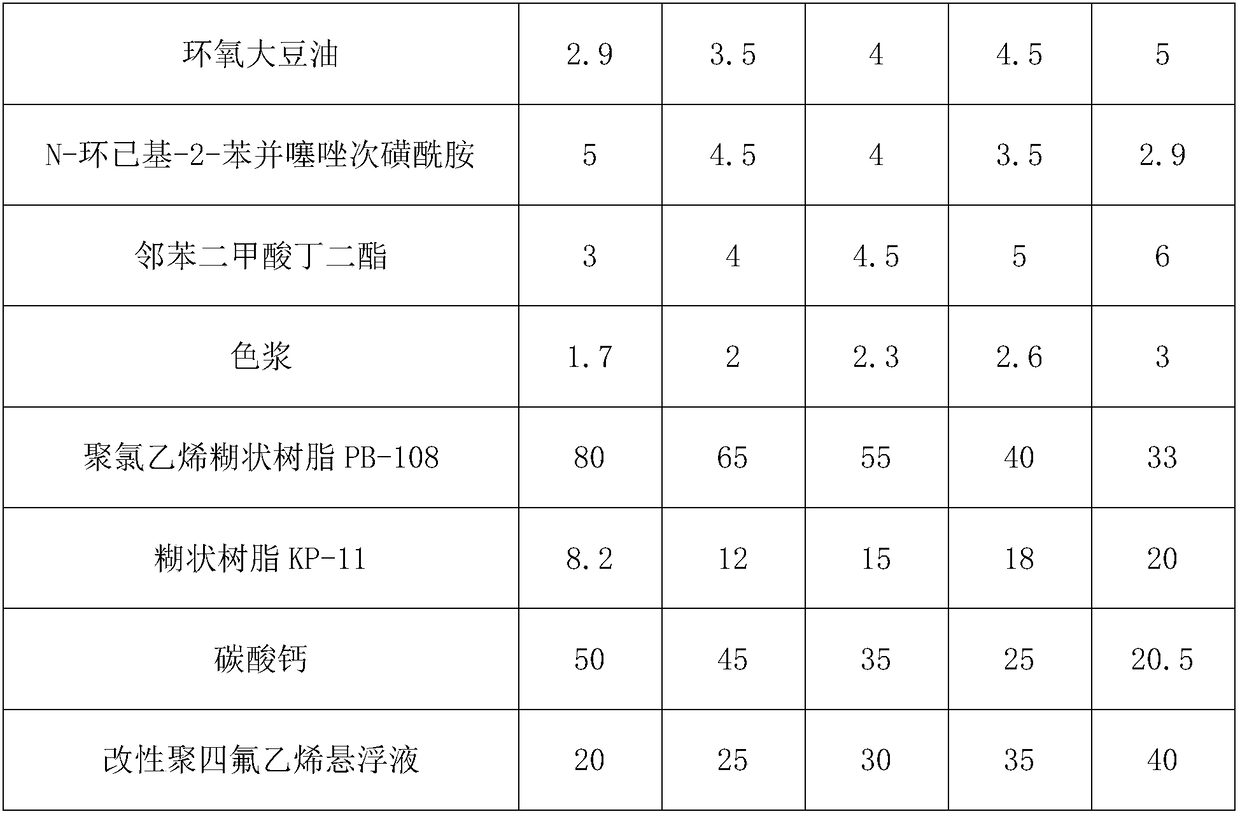

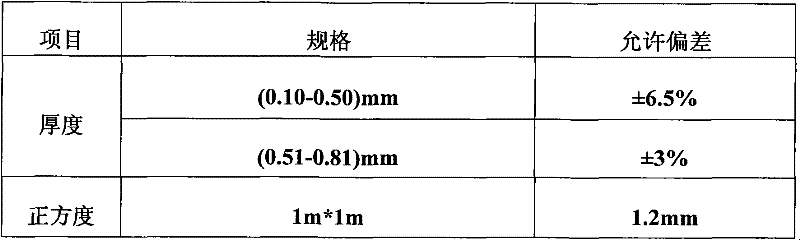

High-temperature-resistant in-adhesion PCV conveyer belt and preparing method thereof

ActiveCN108545402AHigh surface energyImprove temperature resistanceFireproof paintsConveyorsDioctyl terephthalateEngineering

The invention discloses a high-temperature-resistant in-adhesion PCV conveyer belt and a preparing method thereof, and relates to the technical field of conveyer belt machining. The problem that in the prior art, the conveyer belt cannot achieve high temperature resistance is solved. The high-temperature-resistant in-adhesion PCV conveyer belt comprises a product framework and face glue, and the face glue comprises the following components including, by weight, 58-100 parts of polyvinyl chloride paste resin PB-128, 0.18-30 parts of dioctyl terephthalate, 2.9-5 parts of epoxidized soybean oil,2.9-5 parts of N-hydroxycyclohexyl phenyl ketone-benzothiazole sulfonamide, 3-6 parts of dibutyl phthalate, 1.7-3 parts of color paste, 33-80 parts of polyvinyl chloride paste resin PB-108, 8.2-20 parts of paste resin KP-11, 20.5-50 parts of calcium carbonate and 20-40 parts of modified teflon suspension. The conveyer belt has the high temperature resistance, material adhesion can be avoided evenwhen the conveyer belt is used for conveying foods at the high temperature ranging from 200 DEG C-250 DEG C, and bubbling, peeling or falling can be avoided.

Owner:上海米莜凯自动化装备有限公司

Makrolon/modified polyester blending rolling base material and preparation method thereof

InactiveCN101864161BImprove physical performanceMeet the requirements of card making process, etc.CopolyesterTitanium

The invention provides a markrolon / modified polyester blending rolling base material and a preparation method thereof. The markrolon / modified polyester blending rolling base material comprises the following components by weight percent: 55-65% of makrolon, 15-20% of modified polyester, 4-8% of modified copolyesters additive, 3-5% of compatilizer 4051, 4-7% of titanium white, 2-6% of calcium carbonate and 0.01-0.1% of pigment. The vicat softening point of the invention can be 115 DEG C+ / -2 (50-5kg of vicat A), the tensile strength is larger than 45Mpa, the tensile yield strength is larger than750KJ / m<2>; and the invention meets the rolling technology requirement by improving the formula lubrication systems, can meet the requirement of the processes such as material application, card making technology of smart card base materials and the like.

Owner:上海达凯塑胶有限公司

A heat-resistant and impact-resistant polyvinyl chloride-poly-1-butene compound and its preparation method

The invention relates to a heat-resistant and impact-resistant polyvinyl chloride and poly-1-butene compound and a preparation method thereof. The heat-resistant and impact-resistant polyvinyl chloride and poly-1-butene compound comprises the following components in parts by weight: 70-90 parts of polyvinyl chloride, 10-30 parts of poly-1-butene, 1-5 parts of a compatibilizer, 5-10 parts of rigid nanometer particles, 1-3 parts of a rare earth-epoxy compound stabilizer, 1-10 parts of an inner lubricant and 0.5-2 parts of an outer lubricant. The materials are sequentially and gradually added into a high-speed mixer and fully and uniformly mixed, and then melted and extruded. The heat resistance and the impact resistance of the compound are effectively improved, and the poly-1-butene is adopted to improve the tenacity and the heat resistance of the polyvinyl chloride. The synergy of the poly-1-butene, the compatibilizer and the rigid nanometer particle is adopted to improve the tenacity and the heat resistance of the polyvinyl chloride. The impact resistance of the compound is higher than that of the existing product on the market. The heat resistance is great, the vicat softening point is effectively improved by about 10 DEG C, moreover, the comprehensive performance is improved. All of the raw materials are nontoxic and environment-friendly.

Owner:SHAANXI COAL & CHEM TECH INST

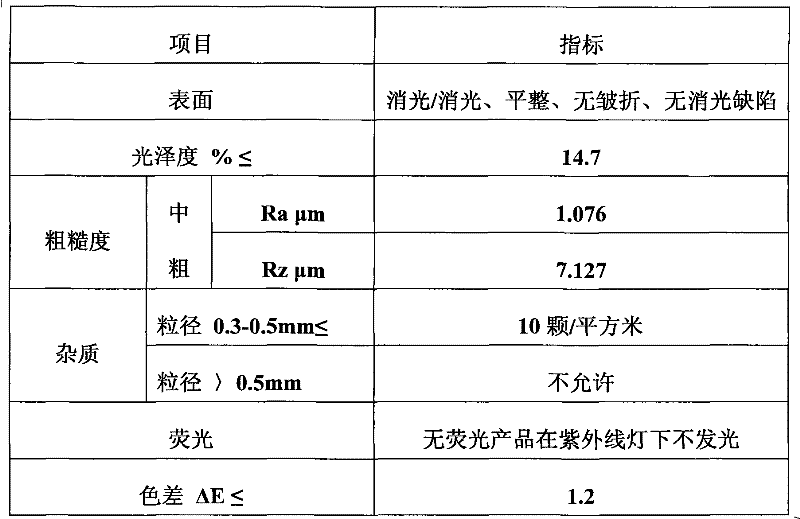

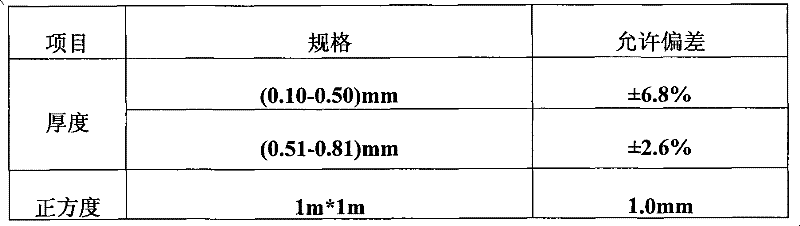

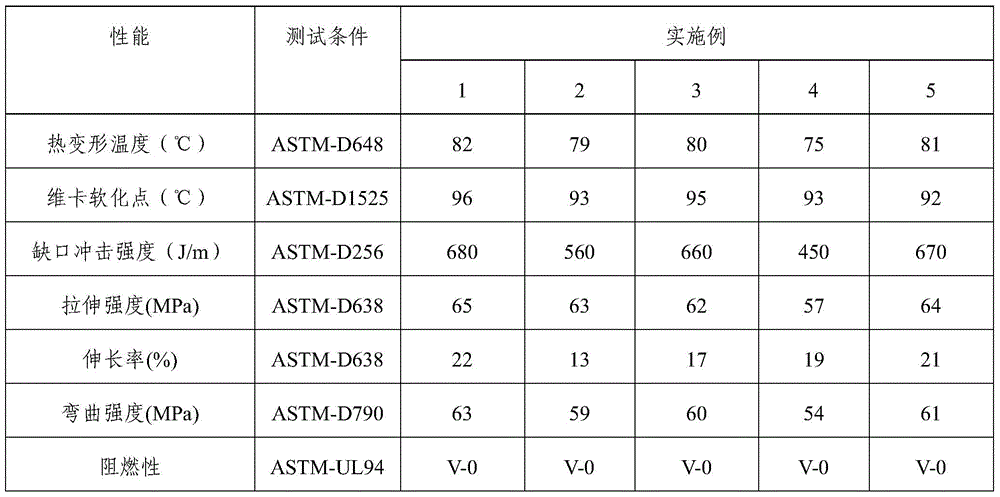

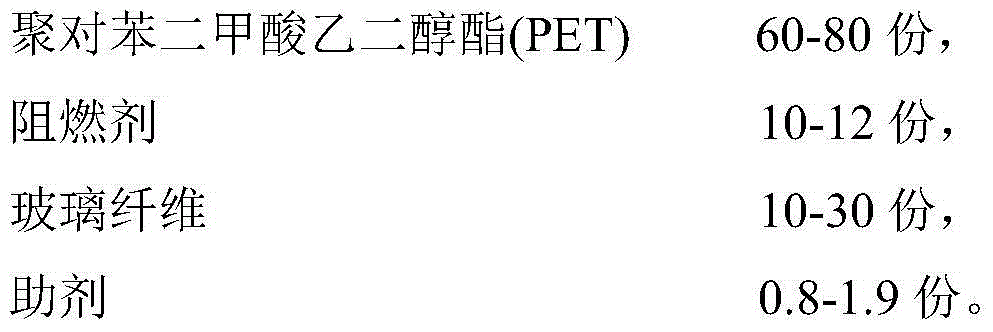

PET material for energy-saving lamp holder and preparation method of PET material

The invention belongs to the technical field of high molecular materials, and relates to a PET material for energy-saving lamp holder and a preparation method of the PET material. The material comprises the following components in parts by weight: 60-80 parts of PET, 10-30 parts of glass fiber, 0.3-0.6 parts of a lubricating agent, 0.3-0.6 part of an antioxidant, 0.2-0.7 part of a nucleating agent and 10-12 parts of a fire retardant. The material disclosed by the invention has the characteristics of high strength, good flame retardant property, high temperature resistance, easy forming and the like, is suitable for manufacturing of energy-saving lamp holder, and is widely applicable in the market due to the lower cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

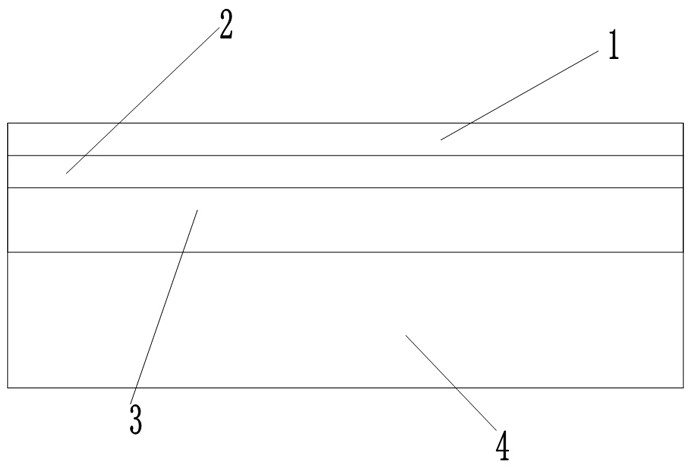

Stone crystal composite floor and preparation method thereof

PendingCN114083850AInhibit swellingGood dimensional stabilitySynthetic resin layered productsConstructions elementsGlass fiberPolymer science

A stone crystal composite floor comprises a wear-resistant layer, a color film layer, a PVC impregnated glass fiber layer and a base material layer which are sequentially arranged from top to bottom; the base material layer is prepared from, by weight, 150-200 parts of a filler, 25-50 parts of PVC resin, 0.5-2 parts of an internal lubricant, 0.5-1.5 parts of an external lubricant and 5-10 parts of a stabilizer, the length-diameter ratio of the filler is n, the length of the filler is m, n is more than or equal to 4 and less than or equal to 20, and m is more than or equal to 5 microns and less than or equal to 25 microns; and due to the adoption of the filler with the length-diameter ratio, the floor has excellent dimensional stability when coping with a complex temperature environment.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

Degradable poly-methyl ethylene carbonate base composite material and preparation method thereof

The invention discloses a degradable poly-methyl ethylene carbonate base composite material and a preparation method thereof. The degradable poly-methyl ethylene carbonate base composite material comprises poly-methyl ethylene carbonate and polyvinyl formal, wherein the percentage by weight of the polyvinyl formal is 10 to 60 percent. The degradable poly-methyl ethylene carbonate base composite material can also comprise a compatibilizer, a lubricant, a foaming agent, a pigment or one or more of other fillers. The composite material is prepared by melting and co-blending the poly-methyl ethylene carbonate and the polyvinyl formal. The composite material has the advantages of high mechanical property, high vicat softening point, low cost and the like.

Owner:SUN YAT SEN UNIV

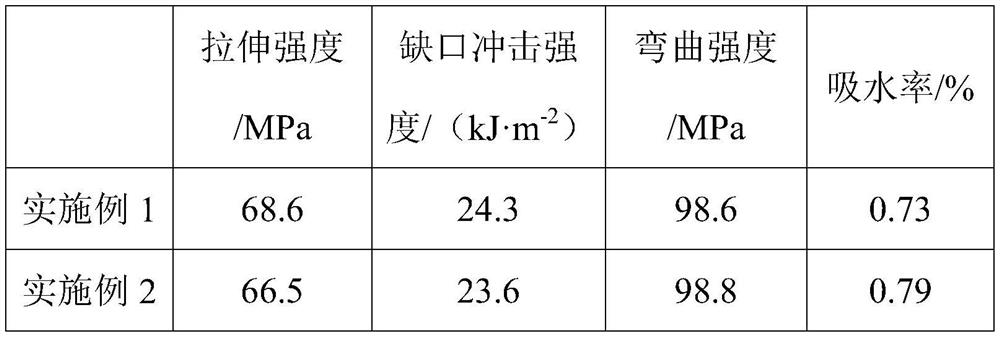

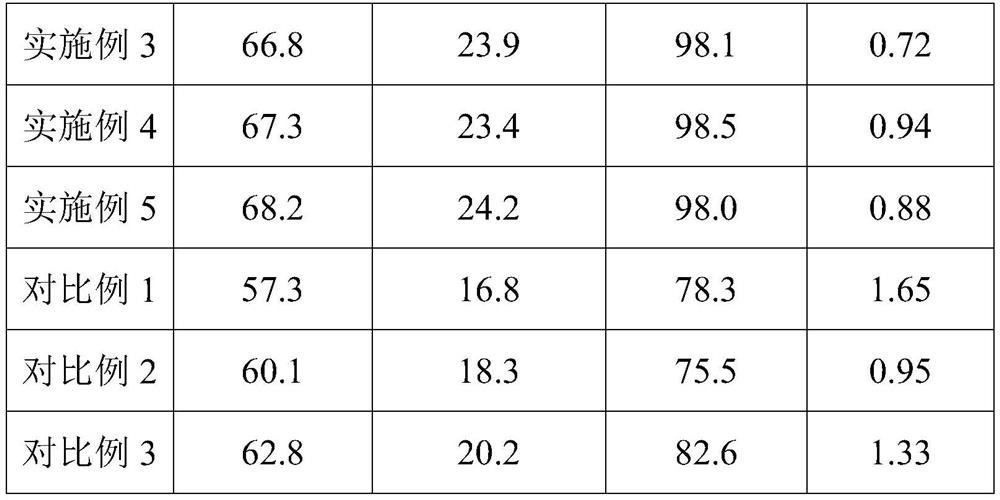

Bamboo-plastic composite board material for container bottom board

The invention relates to the field of composite materials, in particular to a bamboo-plastic composite board material for a container bottom board. The material comprises the following components: modified bamboo pulp fiber, HDPE (high-density polyethylene), LLDPE (linear low-density polyethylene), sarin resin, maleic anhydride grafted polypropylene, polyethylene wax and thermotropic liquid crystal polymer, and tests show that the bamboo-plastic composite board material prepared by the invention has excellent mechanical properties, the tensile strength is greater than or equal to 66.5 MPa, the notch impact strength is greater than or equal to 23.4 kJ.m <-2 >, the bending strength is greater than or equal to 98.0 MPa, the water absorption rate is low, and the waterproof performance is excellent.

Owner:益阳桃花江竹业发展有限公司

Novel heat-resistant PVC profile and preparation method thereof

PendingCN112094466AIncreased Vicat softening pointImprove heat resistanceCalcium carbonateDioxide titanium

The invention discloses a novel heat-resistant PVC profile and a preparation method thereof.The novel heat-resistant PVC profile is composed of PVC resin powder and auxiliaries, the auxiliaries are composed of a heat-resistant modifier, a stabilizer, calcium carbonate, a flexibilizer, a processing modifier, titanium dioxide and a lubricant, and the heat-resistant agent is a styrene-butenoic acid-acrylonitrile copolymer; the PVC profile has the advantages that the Vicat softening point can be obviously improved by adding the heat-resistant agent styrene butenoic acid-acrylonitrile copolymer, and on the basis of obviously improving the heat resistance of the PVC profile, the impact strength and the tensile strength can be kept slightly changed, and the overall performance is excellent.

Owner:亿利生态科技有限责任公司

Salt drainage concealed conduit containing chitosan oligosaccharide and preparation method of salt drainage concealed conduit

InactiveCN106117751AGood antistaticIncreased Vicat softening pointSoil lifting machinesHeat deflection temperatureTime range

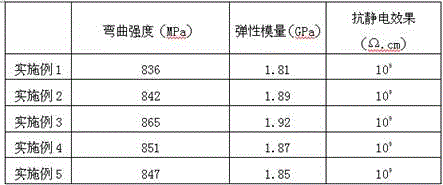

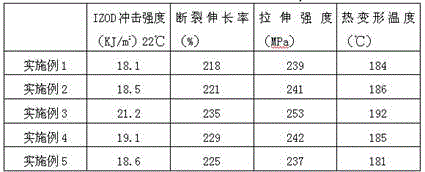

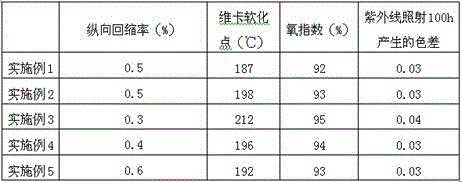

The invention relates to a salt drainage concealed conduit containing chitosan oligosaccharide. The salt drainage concealed conduit is characterized by being prepared from chitosan oligosaccharide. The invention further provides a preparation method of the salt drainage concealed conduit containing chitosan oligosaccharide. The preparation method is characterized by including a mixing step; according to the mixing step, the mixing temperature ranges from 220 DEG C to 223 DEG C, the mixing rotating speed ranges from 650 r / min to 670 r / min, and the mixing time ranges from 30 min to 40 min. The IZOD impact strength of the prepared salt drainage concealed conduit ranges from 18.1% to 21.2%; the elongation at break of the prepared salt drainage concealed conduit ranges from 218% to 235%; the tensile strength of the prepared salt drainage concealed conduit ranges from 237% to 253%; the heat deflection temperature of the prepared salt drainage concealed conduit ranges from 181 DEG C to 192 DEGC.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

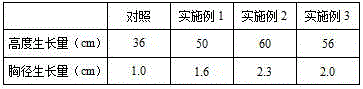

Salt-removing pipe containing high-strength water-permeable layer and application of salt-removing pipe in salt removing of saline-alkaline land

InactiveCN106233840AImprove bending strengthIncreased flexural modulusSoil lifting machinesFlexural modulusHigh intensity

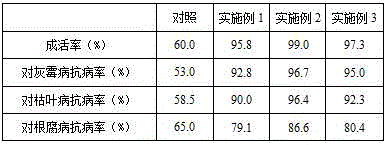

The invention provides a salt-removing pipe containing a high-strength water-permeable layer. The salt-removing pipe comprises a concealed pipe and the water-permeable layer, wherein the external surface of the concealed pipe is wound with a nylon mesh. The invention further provides an application of the salt-removing pipe containing the high-strength water-permeable layer in salt removing of saline-alkaline land. According to the salt-removing pipe and the application thereof, the concealed pipe is high in flexural strength, large in flexural modulus and high in Vicat softening point, wherein the flexural strength is 52MPa to 61MPa, the flexural modulus is 50MPa to 59MPa, and the Vicat softening point is 160 DEG C to 170 DEG C; the growth speed of plants planted in the saline-alkaline land which is subjected to salt-removing amendment by using the salt-removing pipe provided by the invention is increased greatly; the plants planted in the saline-alkaline land which is subjected to salt-removing amendment by using the salt-removing pipe provided by the invention are high in survival rate and high in disease resistance; and taking cedar for example, the survival rate of transplanted cedars can reach 95.8% to 99.0%, and the disease resistance to common diseases of the cedars is high.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

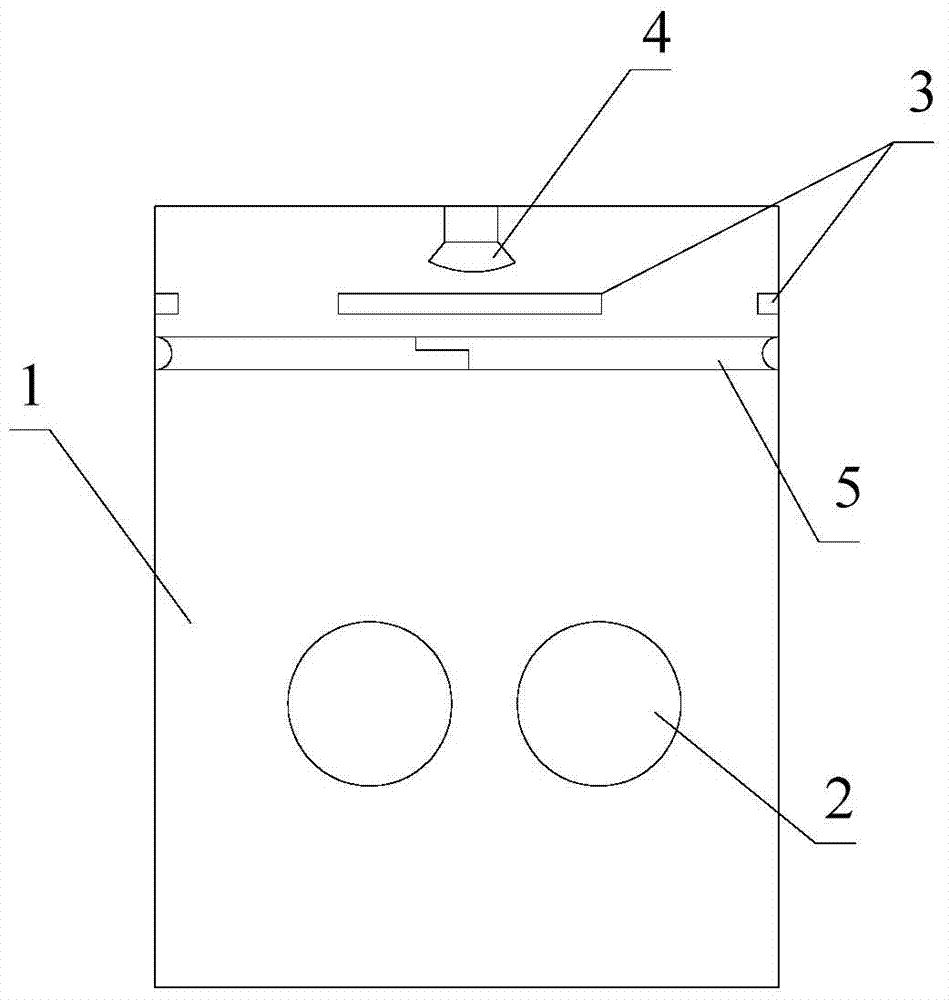

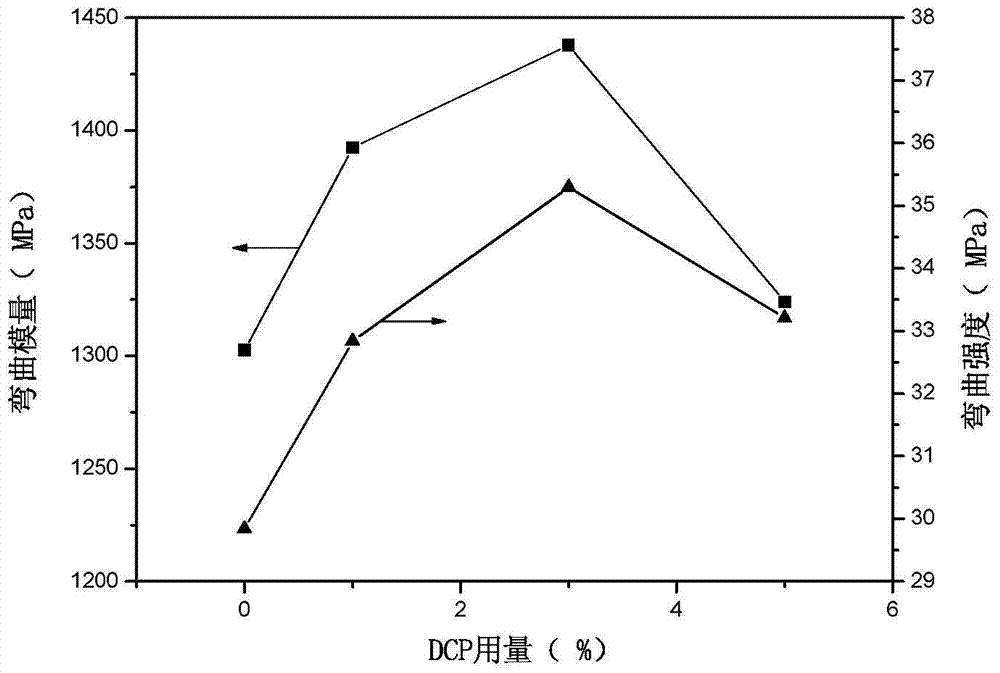

Modified polypropylene composite material and preparation method thereof

InactiveCN105061889BHigh tensile strengthHigh impact strengthPolypropylene compositesPolymer science

The invention discloses a modified polypropylene composite material and a preparation method thereof. The modified polypropylene composite material is prepared from polypropylene, a butylbenzene thermoplastic elastomer, powdered steatile and dicumyl peroxide according to a mass ratio of 9: 1: 1: 0.3-0.4. The preparation method comprises adding polypropylene, a butylbenzene thermoplastic elastomer and powdered steatile into an internal mixer, carrying out primary internal mixing at a temperature of 165-170 DEG C at a rotation rate of 50-60rpm for 3-5min, adding 3-4 parts by weight of dicumyl peroxide into the mixture, carrying out secondary internal mixing at a temperature of 150-155 DEG C at a rotation rate of 40-45rpm for 3-5min, taking out the mixture in the internal mixer and carrying out granulation on the mixture. The modified polypropylene composite material has high shock resistance, good stretching performances, high bending strength and a high Vicat softening point.

Owner:GUANGXI TEACHERS EDUCATION UNIV

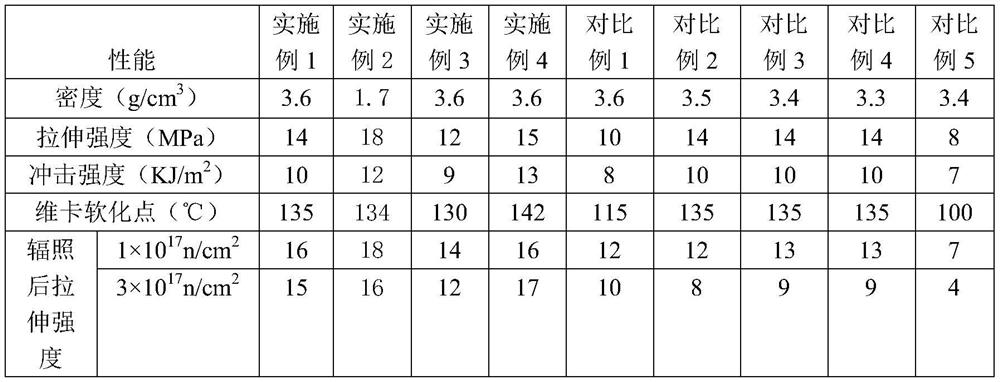

High-use-temperature accident-condition-resistant radiation-resistant material and preparation method thereof

ActiveCN113214558AImprove heat resistanceImprove radiation resistancePlasticultureIrradiated materials

The invention discloses a high-use-temperature accident-condition-resistant radiation-resistant material and a preparation method thereof, and solves the technical problems that an existing shielding material taking a polyethylene material as a matrix can be plasticized and collapsed in a very short time at an accident condition environment temperature, cannot keep a shielding function, flows and aggravates insecurity in a reactor. The high-use-temperature accident-condition-resistant radiation-resistant material comprises ultra-high molecular weight polyethylene, a shielding substance and an irradiation-resistant composite additive, wherein the irradiation-resistant composite additive is formed by compounding a nano rare earth oxide and an organic irradiation-resistant composite system. The material has the advantages of good mechanical properties and anti-radiation performance and the like.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

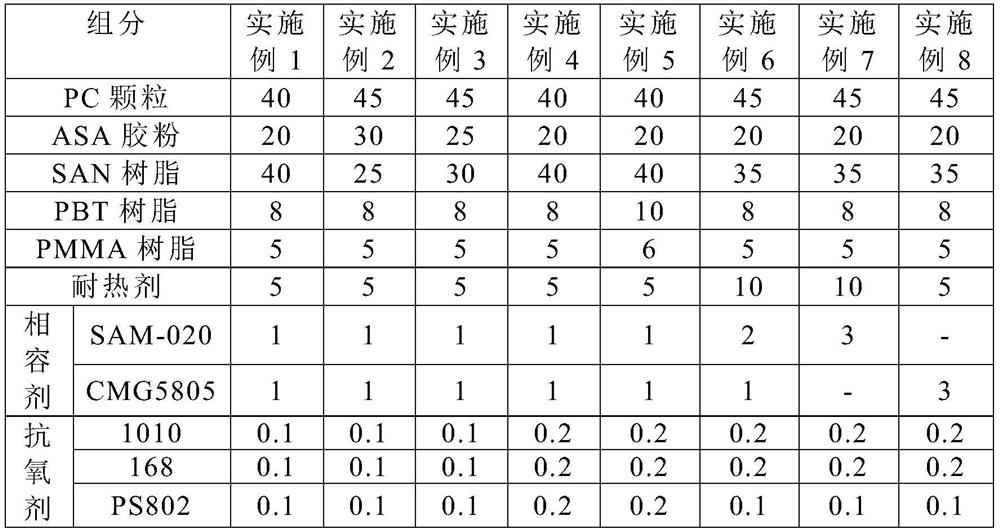

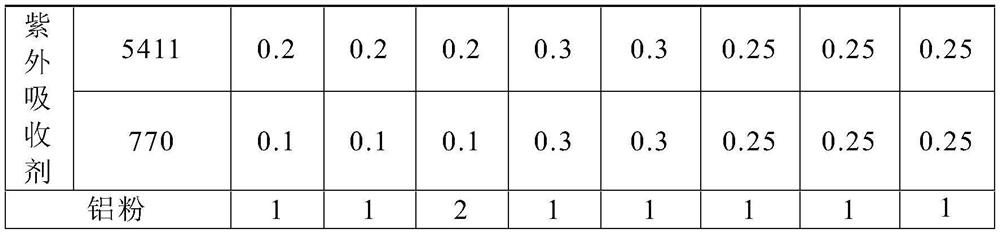

High-heat-resistance electroplating-free PC/ASA alloy material for vehicle heat dissipation grid

ActiveCN111675892AMaintain tensile strengthIncreased interfacial adhesionComposite materialWeather resistance

The invention belongs to the technical field of high polymer materials, and particularly relates to a high-heat-resistance electroplating-free PC / ASA alloy material for a vehicle heat dissipation grid. The material comprises following components in parts by weight: 30 to 60 parts of PC resin, 5 to 20 parts of ASA rubber powder, 30 to 60 parts of SAN resin, 5 to 10 parts of PBT resin, 1 to 6 partsof PMMA resin, 0.3 to 1 part of an antioxidant, 0.3 to 1 part of an ultraviolet absorbent, 5 to 15 parts of a heat-resistant agent, 1 to 5 parts of a compatilizer and 1 to 3 parts of metal powder. Based on a common PC / ASA formula, PBT resin and PMMA resin are added, the influence of water absorption of the material on the material appearance is reduced; meanwhile, a heat-resistant agent and a compound compatilizer are added to jointly improve the heat resistance and weather resistance of the modified material, and metal powder with a proper particle size is added, so that the surface of the product has special metallic luster, spraying or electroplating is not needed, and the material is environmentally friendly, safe, capable of meeting the high appearance requirement of a vehicle heat dissipation grid and wide in application range.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Polrvinyl chloride heat-resistance modifier and preparation method thereof

The invention discloses a polrvinyl chloride heat-resistance modifier and a preparation method thereof. The heat-resistance modifier is a methyl methacrylate-alpha-methyl styrene-N-phenylmaleimide terpolymer. Methyl methacrylate and alpha-methyl styrene account for 60 to 80 percent of the total mass of the modifier, N-phenylmaleimide terpolymer accounts for 20 to 40 percent of the total mass of the modifier, and the mass ratio of methyl methacrylate to alpha-methyl styrene is 1:1; and in a polymerization process, the mass ratio of monomer to water is (30-40):(60-70), the polymerization temperature is 60 to 80 DEG C, a peroxide initiator, an alkyl sulfate or alkane sulfonate emulsifier and a thiol molecular weight regulator are added at the same time, the reaction time is 6 to 9 hours, anda pressure type spray dryer is used for spray drying in a post-treatment process. Compared with the conventional heat-resistance modifier, the performance is high, the form of product particles is desirable, the yield is high, fewer raw material varieties are adopted, the cost is low, the spray drying post-treatment process is simple, and the Vicat softening point of the prepared heat-resistance modified resin is obviously improved, and the processability is high.

Owner:SHANDONG SHUNTIANLI PLASTIC

A kind of highly crystalline modified PGA material and preparation method thereof

The invention provides a highly crystalline modified PGA material and a preparation method thereof. The modified PGA material is prepared from the following raw materials in parts by weight: 70-80 parts of polyglycolic acid resin, 5-15 parts of filler, 4-25 parts 1 part of plasticizer and 0.5 to 1 part of nucleating agent; the plasticizer is a mixture of polyvinyl alcohol and glycerin with a mass ratio of 1:1.8 to 2.3, the molecular weight of polyvinyl alcohol is 300 to 500 g / mol, and the degree of alcoholysis ≥ 98 %; the nucleating agent is selected from one or more of talcum powder, inositol and sebacic acid xylene hydrazide; the filler is selected from one or more of nano-montmorillonite, nano-calcium carbonate and food-grade starch. The polyglycolic acid resin is modified by using the above-mentioned plasticizers, nucleating agents and fillers, so that the modified PGA material has high crystallization performance and can be used for the preparation of high heat-resistant products. The Vicat softening temperature is 205-210°C; the half-crystallization time is 5-15s; the relative crystallinity is 45-47%.

Owner:HAINAN SHINER IND

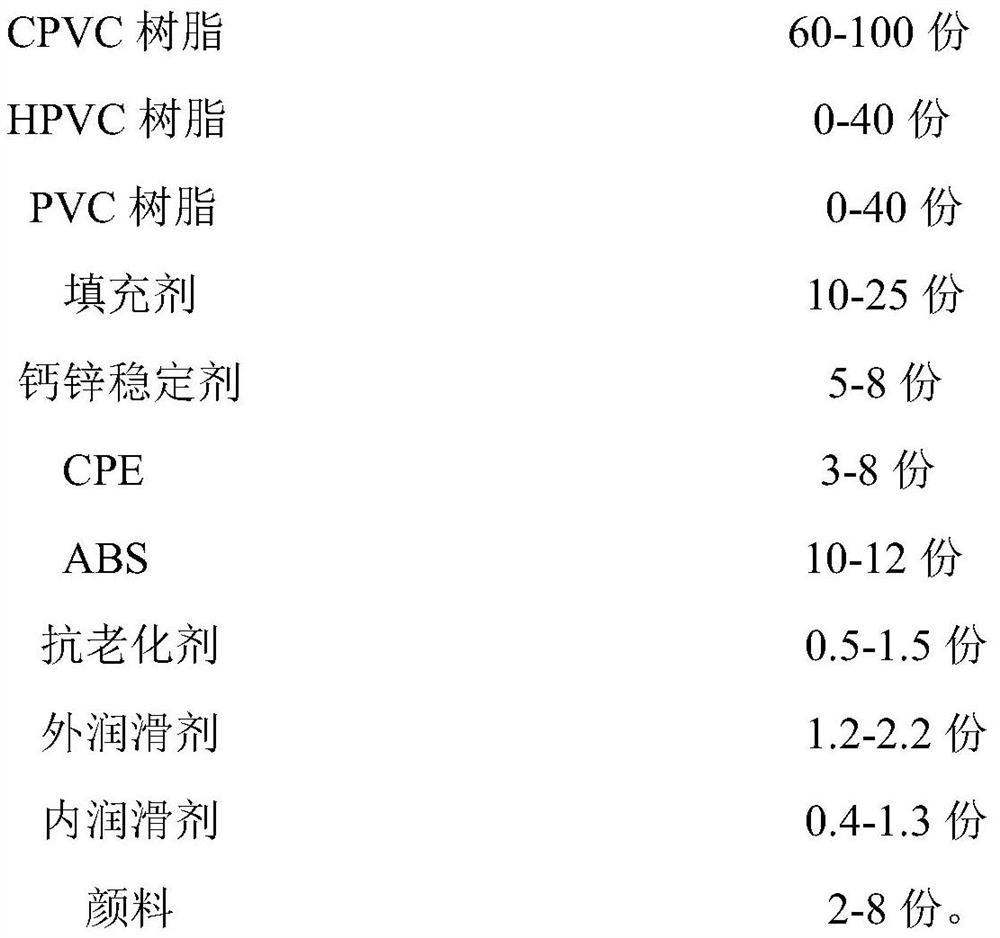

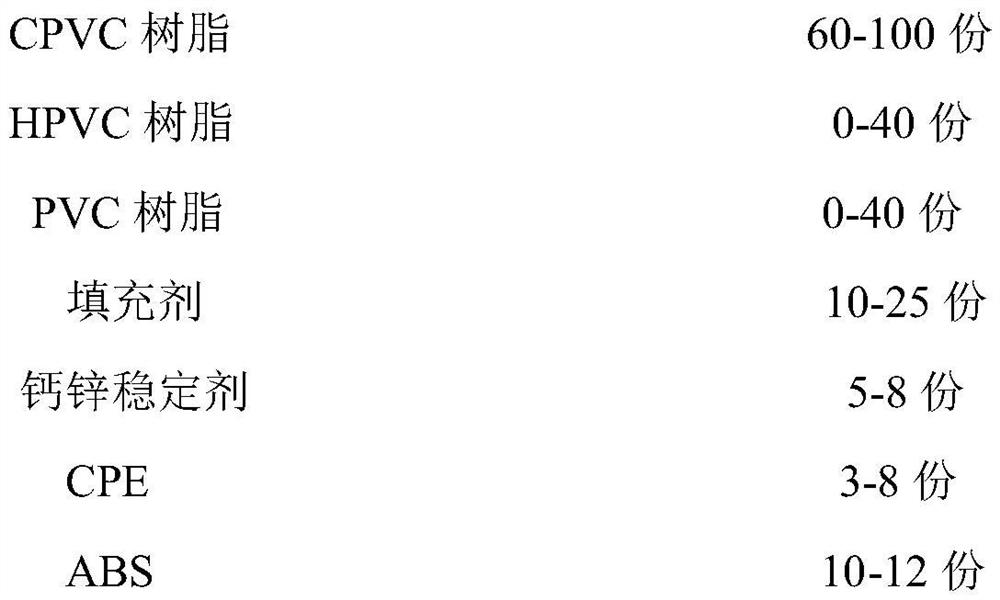

Environment-friendly high-vicat high-impact-resistance low-temperature-resistant vulcanization-pollution-resistant electric conduit and preparation method thereof

The invention discloses an environment-friendly vicat high-impact low-temperature-resistant vulcanization-pollution-resistant electric conduit and a preparation method thereof. The electric conduit is prepared from CPVC resin, HPVC resin, PVC resin, a filler, a calcium-zinc stabilizer, CPE, ABS, an anti-aging agent, an external lubricant, an internal lubricant and a pigment according to a certain proportion. The preparation method comprises the following steps: uniformly mixing the raw materials, adding the uniformly mixed raw materials into a double-screw extruder, setting the temperature of a machine barrel to be 160-200 DEG C, the temperature of a confluence core to be 150-155 DEG C, the temperature of a template to be 160-190 DEG C and the temperature of a mouth mold to be 160-190 DEG C, adding the pigment red through a stepping machine of the double-screw extruder, carrying out extrusion molding, and then carrying out cooling and shaping to obtain the environment-friendly high-vicat high-impact-resistance low-temperature-resistance vulcanization-pollution-resistance electric conduit. The electric conduit is high in vicat softening point, low in pipe ring stiffness at high temperature and good in impact resistance at low temperature. The preparation method of the electric conduit is simple, convenient to operate and low in preparation cost.

Owner:HUBEI KINGBULL PIPE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com