Bamboo-plastic composite board material for container bottom board

A container floor and composite board technology, applied in the field of composite materials, can solve the problems of being easily eroded and rotted by water vapor, poor impact resistance, easy to be damaged, etc., to improve the interface morphology, tight internal structure, and Vicat softening point. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

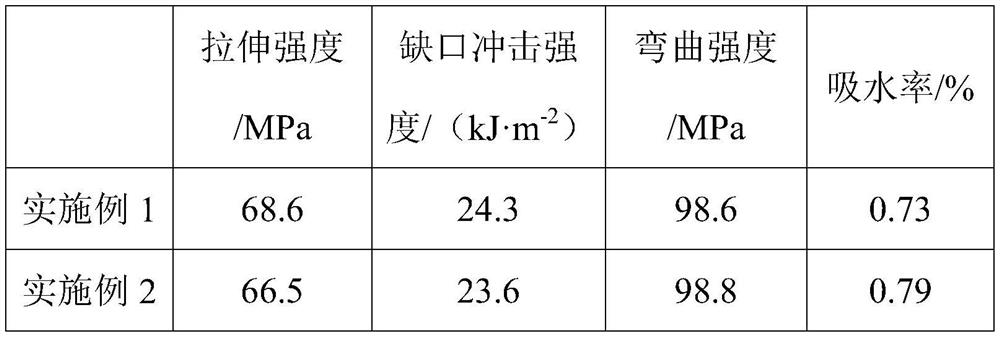

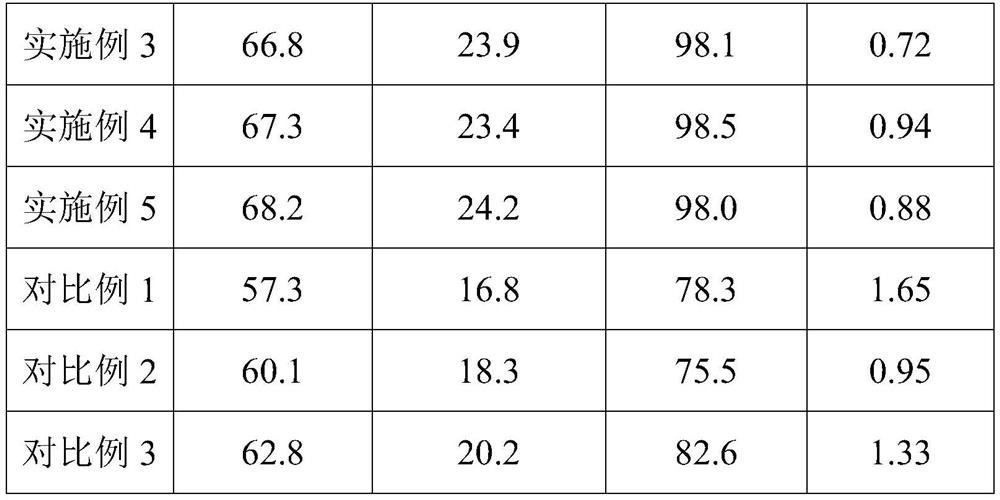

Examples

Embodiment 1

[0027] A bamboo-plastic composite board material for a container floor, comprising the following components in parts by weight:

[0028] 60 parts of MMA grafted modified bamboo pulp fiber, 25 parts of HDPE, 25 parts of LLDPE, 0.5 part of sarin resin, 2 parts of maleic anhydride grafted polypropylene, 0.5 part of polyethylene wax, and 8 parts of thermotropic liquid crystal polymer.

[0029] Wherein, the preparation method of MMA graft modified bamboo pulp fiber is as follows:

[0030] Add 5g of DMAP and 15mL of triethylamine into 500mL of THF, stir for 20min, blow nitrogen, then add 10g of bamboo pulp fiber, continue stirring for 20min, cool the reaction solution to 0°C, add 10mL of 2-bromoisobutyryl bromide, After returning to room temperature and reacting for 20 minutes, the temperature was raised to 65°C for 20 hours and then filtered. The resulting solid was extracted with absolute ethanol for 10 hours and then dried to obtain 12 g of intermediates. Copper bromide and penta...

Embodiment 2

[0036] Substantially the same as Example 1, the difference is that the prepared bamboo-plastic composite board material for the container floor includes the following components in parts by weight:

[0037] 60 parts of MMA grafted modified bamboo pulp fiber, 30 parts of HDPE, 30 parts of LLDPE, 0.5 part of sarin resin, 4 parts of maleic anhydride grafted polypropylene, 1 part of polyethylene wax, and 10 parts of thermotropic liquid crystal polymer.

Embodiment 3

[0039] Substantially the same as Example 1, the difference is that the prepared bamboo-plastic composite board material for the container floor includes the following components in parts by weight:

[0040] 40 parts of MMA grafted modified bamboo pulp fiber, 25 parts of HDPE, 25 parts of LLDPE, 0.5 part of sarin resin, 2 parts of maleic anhydride grafted polypropylene, 0.1 part of polyethylene wax, and 5 parts of thermotropic liquid crystal polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com