High-use-temperature accident-condition-resistant radiation-resistant material and preparation method thereof

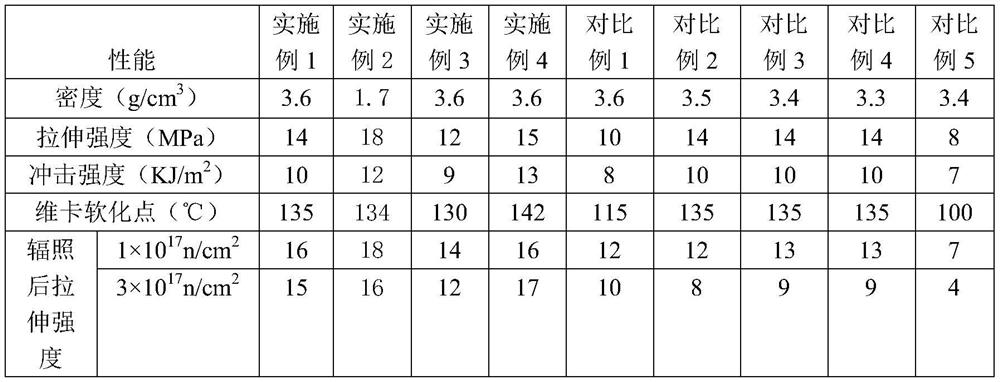

An accident working condition and anti-irradiation technology, applied in the field of nuclear radiation protection, can solve problems such as plasticizing collapse, unsafety, and inability to maintain shielding functions, and achieve improved mechanical properties, improved heat resistance and radiation resistance, The effect of Vicat softening point improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a radiation-resistant material with high service temperature and accident-resistant working conditions, comprising the following steps:

[0039] Step 1, preparation of radiation-resistant compound additive

[0040] Weigh the nanometer yttrium oxide and polyolefin anti-aging composite system according to the mass ratio of 3:100 and put it into a ball mill tank, add 8% ethanol of the aforementioned material, and then add zirconia balls for ball milling, the nanometer oxide The mass of the yttrium and polyolefin anti-aging composite system and the mass ratio of the ball to the ball are 1:10, the ball milling speed is 800 rpm, the ball milling time is 12 hours, and the radiation-resistant compound additive is obtained by sieving and discharging;

[0041] The polyolefin anti-aging composite system is a mixture of phenolic anti-aging agent and phosphite anti-aging agent according to the mass ratio of 1:5;

[0042] Step 2. Mix lead powder and boron carb...

Embodiment 2

[0056] The difference between this example and Example 1 is that the lead powder content is 40wt%, the boron carbide powder content is 10wt%, the ultra-high molecular weight polyethylene content is 47.5wt%, and the radiation-resistant additive is 2.5wt%.

Embodiment 3

[0058] The difference between this example and Example 1 is that the molecular weight of the ultra-high molecular weight polyethylene is 3 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com