Method for preparing Nano-composite material of poly lactic acid/montmorillonite

A nano-composite material and montmorillonite technology are applied in the field of preparation of polylactic acid/montmorillonite nano-composite materials to achieve the effects of improving flexural modulus, improving flexural strength, and a simple and effective preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

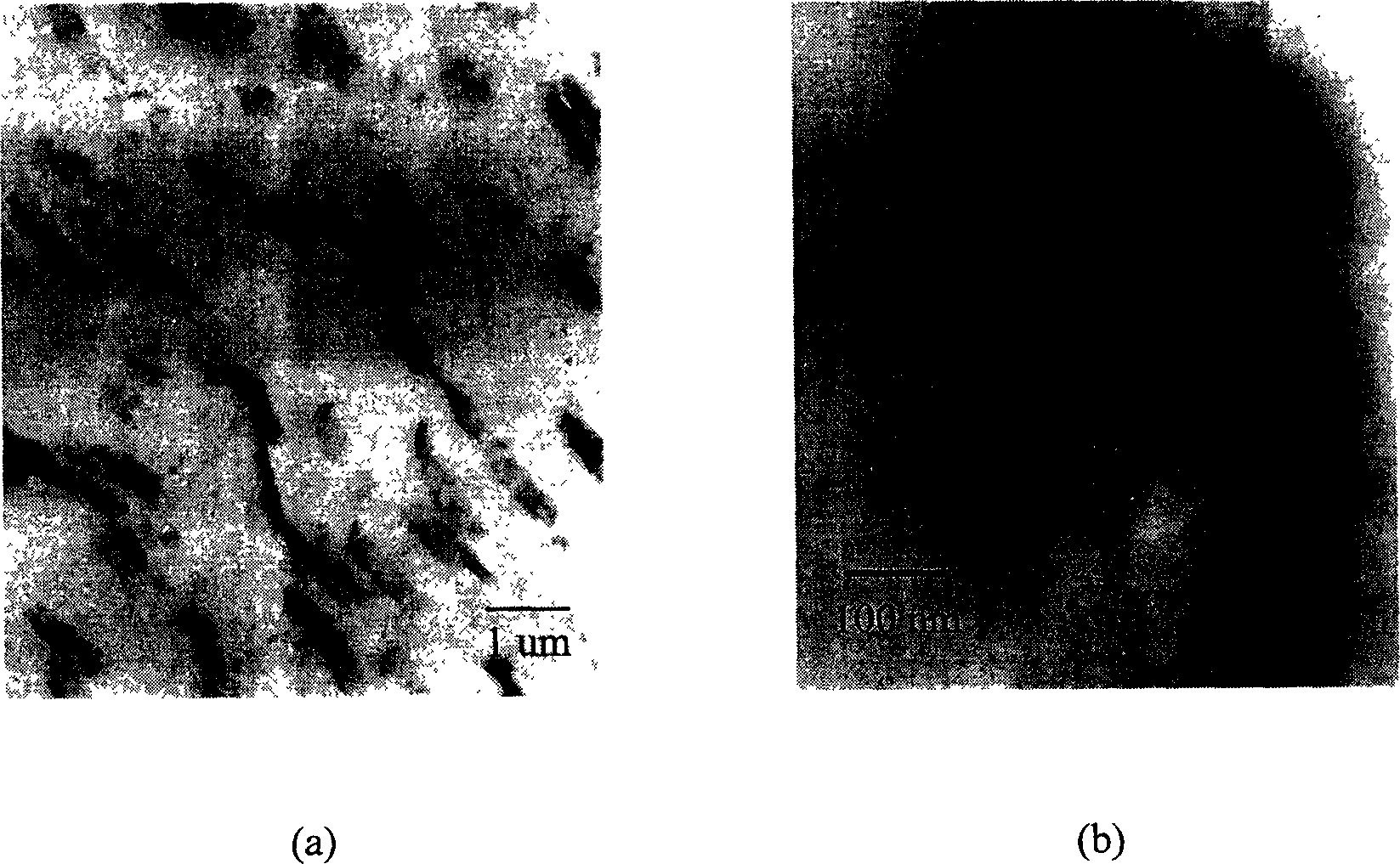

Image

Examples

Embodiment 1

[0028] 100g polylactic acid, 25g organically modified montmorillonite, 0.9g antioxidant phosphite tris (2,4-di-tert-butylphenyl) ester were mixed uniformly, extruded and granulated with twin-screw extruder, extruded The output temperature is 155-200°C, the screw speed is 50-150rpm, and the masterbatch is obtained; then 100g polylactic acid, 5.1g masterbatch, 0.8g antioxidant phenylene diisodecyl phosphite are mixed evenly, and extruded by twin-screw Machine extrusion granulation, the extrusion temperature is 155-200°C, the screw speed is 50-150rpm, and the residence time of the material is 4-8 minutes to obtain the product. Its performance is shown in Table 1.

Embodiment 2

[0030] 100g polylactic acid, 20g organically modified montmorillonite, 0.95g antioxidant phosphite tris (2,4-di-tert-butylphenyl) ester were mixed uniformly, extruded and granulated with twin-screw extruder, extruded The outlet temperature is 155-200°C, and the screw speed is 50-150rpm to obtain the masterbatch; then mix 100g polylactic acid with 12.3g masterbatch, 0.8g antioxidant tris(2,4-di-tert-butylphenyl) The ester is mixed evenly, extruded and granulated by a twin-screw extruder, the extrusion temperature is 155-200°C, the screw speed is 50-150rpm, and the residence time of the material is 4-8 minutes to obtain the product. Its performance is shown in Table 1.

Embodiment 3

[0032] Mix 100g polylactic acid, 30g organically modified montmorillonite, and 1.0g antioxidant tris(2,4-di-tert-butylphenyl) phosphite evenly, extrude and granulate with a twin-screw extruder, and extrude The temperature is 155-200°C, the screw speed is 50-150rpm to obtain the masterbatch; then mix 100g polylactic acid with 18.06g masterbatch, 0.8g antioxidant tris(2,4-di-tert-butylphenyl) Mix evenly, extrude and granulate with a twin-screw extruder, the extrusion temperature is 155-200°C, the screw speed is 50-150rpm, and the residence time of the material is 4-8 minutes to obtain the product. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com