Insulating flame-retardant MPP power cable tube and preparation method thereof

A cable tube and power technology, which is applied in the field of insulation and flame retardant MPP power cable tube and its preparation, can solve the problems of poor insulation and heat resistance, inconvenient cutting of multi-strand cables, and intertwining of multi-strand cable tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

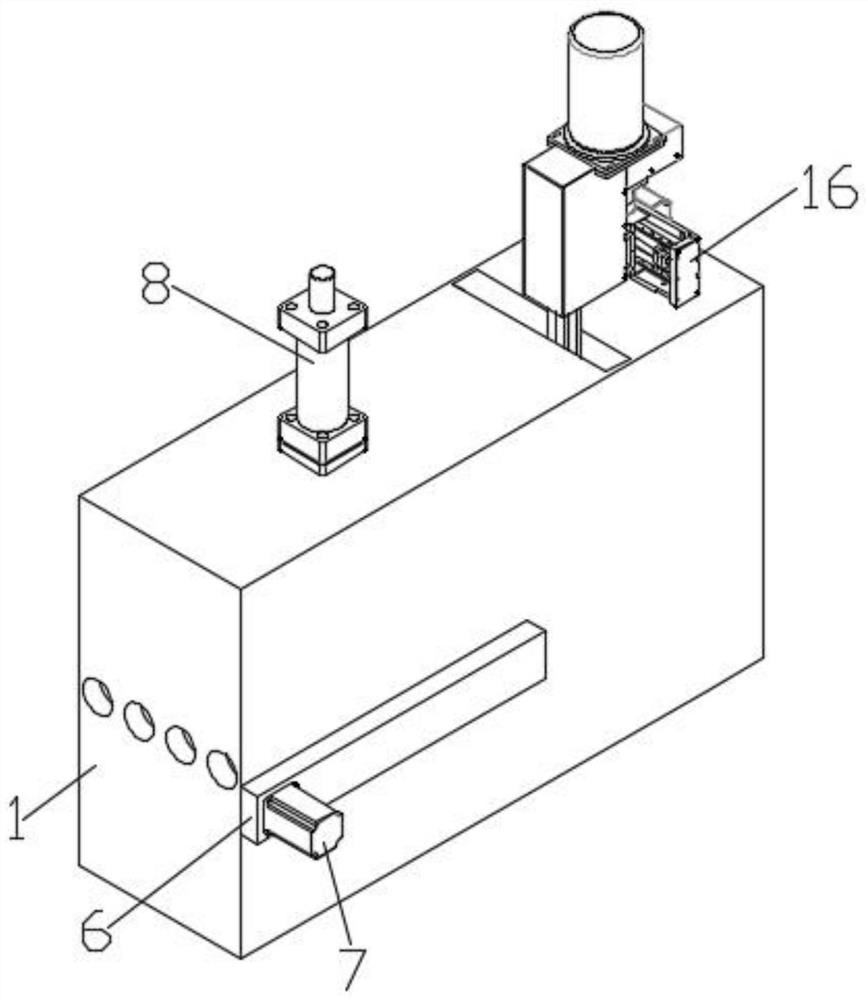

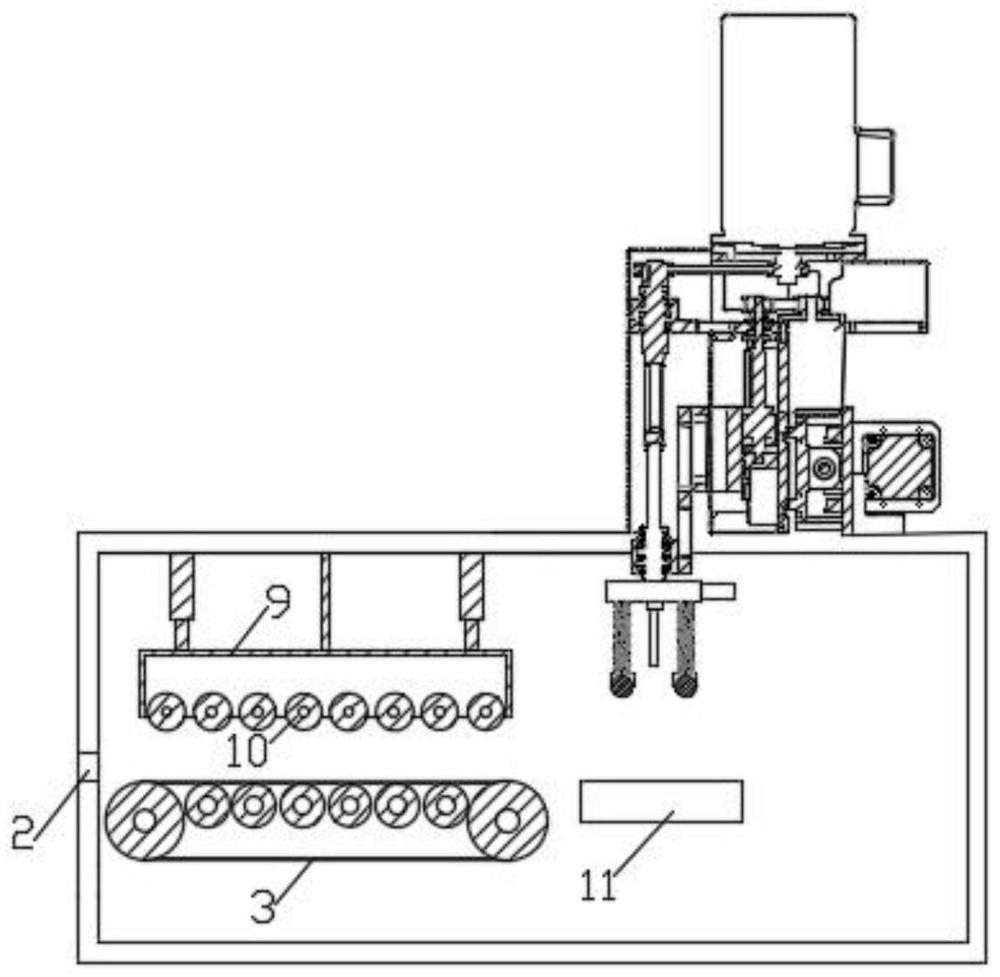

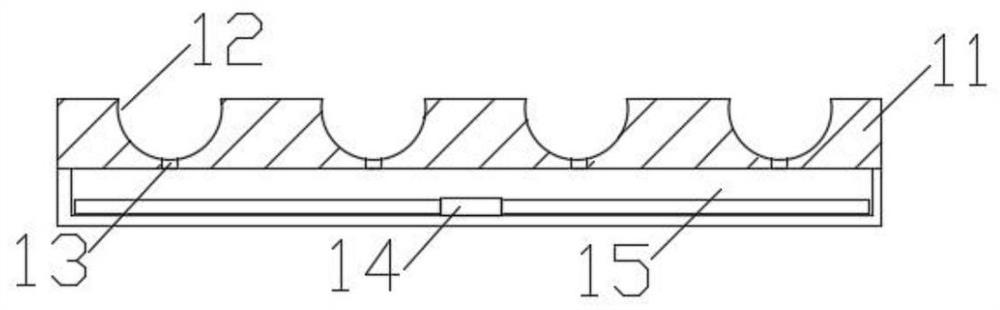

Image

Examples

Embodiment 1

[0035] The Vicat softening point of the insulating flame-retardant MPP power cable tube of Example 1 is 160°C.

Embodiment 2

[0037] An insulating and flame-retardant MPP power cable tube, prepared from the following raw materials in parts by weight: 95 parts of isotactic polypropylene resin, 12 parts of block copolymerized polypropylene, 8 parts of olefin block copolymerized elastomer OBC, insulating and flame-retardant functional matrix 4 parts of grains, 28 parts of ultra-high molecular weight polyethylene resin;

[0038] All the other steps are the same as in Example 1.

[0039] Specifically, the insulating and flame-retardant functional masterbatch is prepared through the following steps: surface-treat the nano-red powder with a surface synergist and a hyperdispersant in an atomized spraying manner, and obtain a pre-treated nano-red powder after drying , standby, by weight, take 55 parts of block copolymer polypropylene resin, 3 parts of pretreated nano red powder, 3 parts of nano yellow powder, 5 parts of lubricant, 6 parts of processing aid, 2 parts of antioxidant 4 parts, 4 parts of light st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com