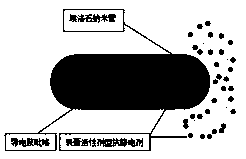

Halloysite nanotube-loaded surfactant/conductive polypyrrole composite antistatic agent, and preparation method and application thereof

A technology of halloysite nanotubes and surfactants, applied in the field of polymer materials, can solve the problems of being easily affected by environmental humidity, reducing surface resistivity, easily affecting physical properties, etc. Set and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

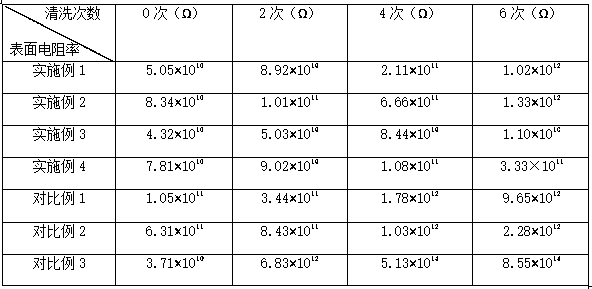

Embodiment 1

[0039] The preparation method of a halloysite nanotube-loaded surfactant / conductive polypyrrole composite antistatic agent involved in the present embodiment is as follows:

[0040] (1) Drying treatment of halloysite nanotubes

[0041] Put 35mg of halloysite nanotubes into a vacuum drying oven, and dry at a constant temperature of 60°C for 24 hours;

[0042] (2) Preparation of surfactant solution

[0043] Take 150 mg of betaine-type surfactant and add it to a three-necked flask filled with 100 ml of methanol, and stir magnetically at a temperature of 500 r / min at a temperature of 40 ° C for 10 h until it is completely dissolved to obtain an organic solution of a surfactant with a concentration of 1.5 mg / ml;

[0044] (3) Preparation of halloysite nanotube-loaded surfactant

[0045]Add the dried halloysite nanotubes to the surfactant organic solution prepared in step (2), first ultrasonically disperse for 60 minutes, then raise the temperature to 50°C, and then stir with a wor...

Embodiment 2

[0049] The preparation method of a halloysite nanotube-loaded surfactant / conductive polypyrrole composite antistatic agent involved in the present embodiment is as follows:

[0050] (1) Drying treatment of halloysite nanotubes

[0051] Put 40 mg of halloysite nanotubes into a vacuum drying oven, and dry at a constant temperature of 70 ° C for 28 hours;

[0052] (2) Preparation of surfactant solution

[0053] Take 200 mg of amine oxide-type surfactant and add it to a three-necked flask filled with 100 ml of ethanol, stir magnetically at a temperature of 50 °C at a rate of 400 r / min for 7 h until completely dissolved, and obtain a surfactant organic solution with a concentration of 2.0 mg / ml;

[0054] (3) Preparation of halloysite nanotube-loaded surfactant

[0055] Add the dried halloysite nanotubes into the surfactant organic solution prepared in step (2), first ultrasonically disperse for 45 minutes, then heat up to 60°C, and then stir with a working frequency of 50KHZ and ...

Embodiment 3

[0059] The preparation method of a halloysite nanotube-loaded surfactant / conductive polypyrrole composite antistatic agent involved in the present embodiment is as follows:

[0060] (1) Drying treatment of halloysite nanotubes

[0061] Put 40 mg of halloysite nanotubes into a vacuum drying oven, and dry at a constant temperature of 75 ° C for 36 hours;

[0062] (2) Preparation of surfactant solution

[0063] Take 250 mg of a betaine-type surfactant and add it to a three-neck flask filled with 100 ml of acetone, and stir magnetically at a speed of 800 r / min at a temperature of 55 ° C for 8 hours until completely dissolved to obtain an organic solution of a surfactant with a concentration of 2.5 mg / ml;

[0064] (3) Preparation of halloysite nanotube-loaded surfactant

[0065] Add the dried halloysite nanotubes into the surfactant organic solution prepared in step (2), first ultrasonically disperse for 50 minutes, then heat up to 55°C, and then use a working frequency of 75KHZ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com