Method for preparing plastic granules for antistatic flame-retardant shoes

A plastic particle, antistatic technology, applied in the field of plastic processing, can solve the problems of affecting product quality, poor grounding wire contact, product performance degradation, etc., to achieve the effect of small relative humidity dependence, long-lasting antistatic effect, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

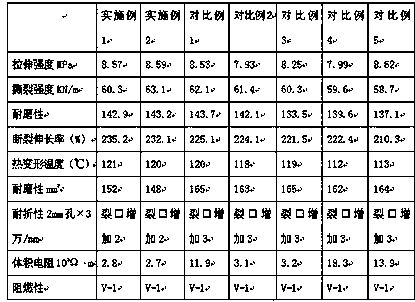

Examples

Embodiment 1

[0019] A method for preparing plastic particles for antistatic and flame-resistant shoes, specifically comprising the following steps

[0020] (1) After adding 3.1 parts of SEBS and 5.1 parts of maleic anhydride in the reaction kettle, add 16 parts of xylene. After it is completely dissolved, control the temperature with a water bath, protect it under a nitrogen atmosphere, and add dropwise a mass fraction of 0.9% 1.2 parts of toluene solution of BPO, the reaction time is 1~2h, the reaction solution is poured into acetone for precipitation, suction filtration, air drying, and vacuum drying to obtain maleic anhydride grafted SEBS, SEBS is YH-503;

[0021] (2) Add 14 parts of SEBS and 3.9 parts of maleic anhydride grafted SEBS to another reaction kettle, and add 17 parts of solvent xylene. When SEBS and maleic anhydride grafted SEBS are completely dissolved, add a mass fraction of 16 parts of 6.1% acrylamide aqueous solution, stir to form an emulsion, control the temperature wit...

Embodiment 2

[0028] A method for preparing plastic particles for antistatic and flame-resistant shoes, specifically comprising the following steps

[0029] (1) After adding 2.4 parts of SEBS and 3.4 parts of maleic anhydride in the reaction kettle, add 14 parts of xylene, after it is completely dissolved, control the temperature with a water bath, protect it under a nitrogen atmosphere, and add dropwise a mass fraction of 0.5% 1.1 parts of toluene solution of BPO, the reaction time is 1h, the reaction solution is poured into acetone to precipitate, suction filtered, dried in the air, and vacuum-dried to obtain maleic anhydride grafted SEBS, SEBS is YH-502;

[0030](2) Add 14 parts of SEBS and 3.9 parts of maleic anhydride grafted SEBS to another reaction kettle, add 15~17 parts of solvent xylene, when SEBS and maleic anhydride grafted SEBS are completely dissolved, add mass The fraction is 15-16 parts of acrylamide aqueous solution with a fraction of 4.5%, stir to form an emulsion, control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com