An anti-blocking, antistatic heat-sealing coating and cover tape

A heat-sealing coating and anti-static technology, applied in coatings, conductive coatings, etc., can solve the problems of uneven dispersion of heat-sealing coating liquid, adhesion of cover tape and electronic components, and hazards of electronic components storage and transportation. Enhance anti-blocking effect, good anti-static effect, maintain anti-static effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

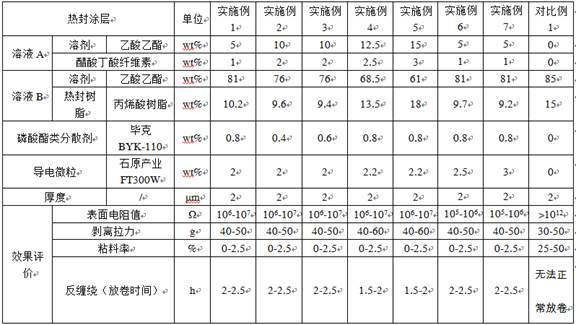

Embodiment 1

[0028] An anti-blocking, antistatic heat-sealing coating is formed by coating a coating liquid, and the coating liquid includes the following components: cellulose acetate butyrate 1wt%, acrylic resin 10.2wt%, ethyl acetate 86wt%, Titanium dioxide conductive particles 2wt%, phosphate ester dispersant 0.8wt%; Among them, the titanium dioxide conductive particles adopt the FT300W product of Ishihara Industry, which is needle-shaped titanium dioxide conductive particles with a diameter of 0.2-0.3μm and a length of 5-6μm; The quasi-dispersant uses BYK-110 product.

Embodiment 2

[0030] An anti-blocking, antistatic heat-sealing coating is formed by coating a coating liquid, and the raw materials of the coating liquid are the same as those in Example 1, with differences in content, and specifically include the following components: cellulose acetate butyrate 2wt%, Acrylic resin 9.6wt%, ethyl acetate 86wt%, titanium dioxide conductive particles 2wt%, phosphate ester dispersant 0.4wt%.

Embodiment 3

[0032] An anti-blocking, antistatic heat-sealing coating is formed by coating a coating liquid, and the raw materials of the coating liquid are the same as those in Example 1, with differences in content, and specifically include the following components: cellulose acetate butyrate 2wt%, Acrylic resin 9.4wt%, ethyl acetate 86wt%, titanium dioxide conductive particles 2wt%, phosphate ester dispersant 0.6wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com