Preparation method and application of antistatic flame retardant polyester resin

A flame-retardant polyester and anti-static technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, conductive/antistatic filaments, and single-component polyester rayon. It can solve the problems of poor electrical conductivity and improve the The effect of antistatic and flame retardant ability, good fiber spinnability and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A kind of preparation method of antistatic flame retardant polyester resin

[0033] This embodiment includes the following processes:

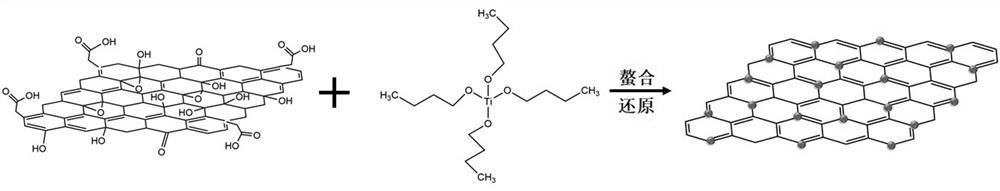

[0034] First, disperse 1kg of graphene oxide with a sheet size of 700 nm and a carboxyl content of 20% in 100kg of water, then add 1kg of n-butyl titanate, react at 40°C for 4 hours, and drop at a rate of 5 drops / second Add ultrapure water for 2 minutes, heat up to 60°C and react for 4 hours. The principle of the above reaction process is as follows: figure 1 shown;

[0035] The product of the above reaction, after centrifugation, was washed with deionized water for 2 to 3 times, and placed in a muffle furnace with a nitrogen atmosphere at 300°C for 8 hours to obtain a graphene oxide-supported titanium dioxide hybrid material, in which the particle size of titanium dioxide was about 50nm, mass fraction is 20%;

[0036] The heat-treated graphene oxide-supported titanium dioxide hybrid material and aluminum diethylphosphin...

Embodiment 2

[0038] Embodiment 2 A kind of preparation method of antistatic flame retardant polyester fiber

[0039] This example is an application of the antistatic and flame retardant polyester resin obtained in Example 1. specifically:

[0040] In this example, the antistatic and flame retardant polyester resin particles prepared in Example 1 were melt-spun at 285° C. at a spinning speed of 4500 m / min to prepare antistatic and flame retardant polyester fibers.

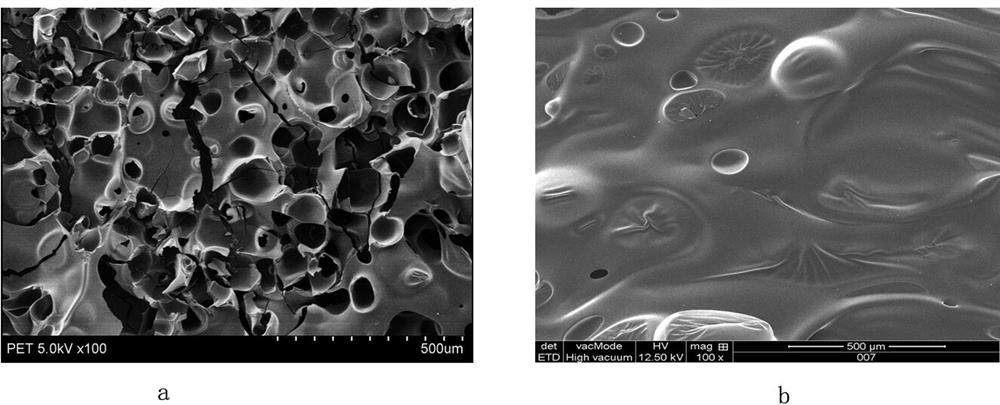

[0041] The antistatic and flame retardant polyester fiber prepared in this example has a limiting oxygen index of 34, a flame retardant grade of UL94 reaching V0, and a fiber resistivity of 4.6*10 after testing. 6 Ω∙cm. like figure 2 Shown in a, is the SEM photo of the charcoal residue after the burning of the polyester of the prior art in the embodiment of the present invention 2; figure 2 b is the SEM photo of the residual charcoal after the antistatic flame retardant fiber prepared in Example 2 of the present invention ...

Embodiment 3

[0042] Embodiment 3 A kind of preparation method of antistatic flame retardant polyester resin

[0043] This embodiment includes the following processes:

[0044] First, disperse 2kg of graphene oxide with a sheet size of 800 nm and a carboxyl content of 15% in 100kg of water, then add 1kg of germanium chloride and react at 60°C for 6h;

[0045] The product of the above reaction, after centrifugation, was washed with deionized water for 2 to 3 times, and placed in a muffle furnace with a nitrogen atmosphere at 800 ° C for 2 hours to obtain a graphene oxide-supported germanium oxide hybrid material, wherein the germanium oxide particle size About 50nm, mass fraction is 15%;

[0046] The heat-treated graphene oxide-supported germanium oxide hybrid material and zinc diethylphosphinate were ultrasonically dispersed in ethylene glycol and reacted with PTA at 250°C and 400Kpa for 2h, and then reacted at 290°C for 3.5h under vacuum conditions. An antistatic flame retardant polyeste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com